Hydraulic fracturing testing machine for concrete members under reciprocating load and high water pressure

A technology of hydraulic splitting and concrete specimens, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, measuring devices, instruments, etc., which can solve the problems of inability to observe crack expansion in real time, limited strength of spring or magnet, and incomplete crack closure process. Sufficient and other issues, to achieve the effect of various testing functions, convenient operation, safe and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

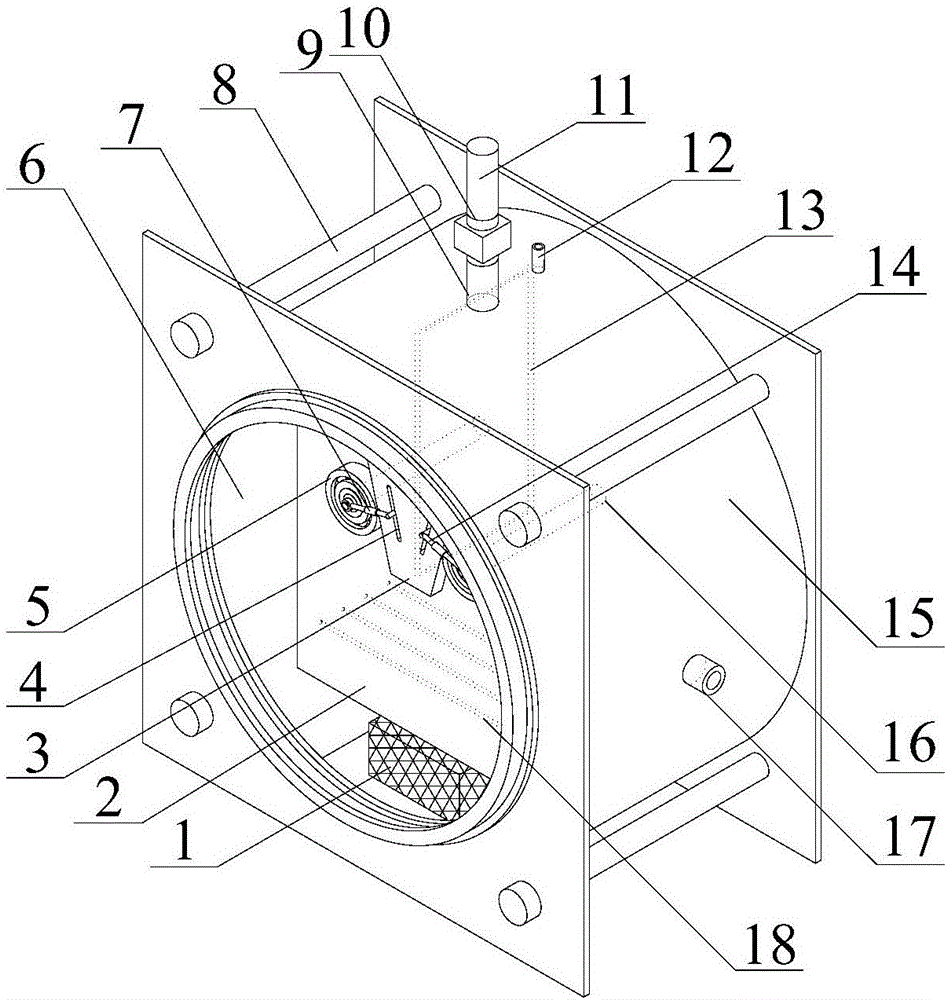

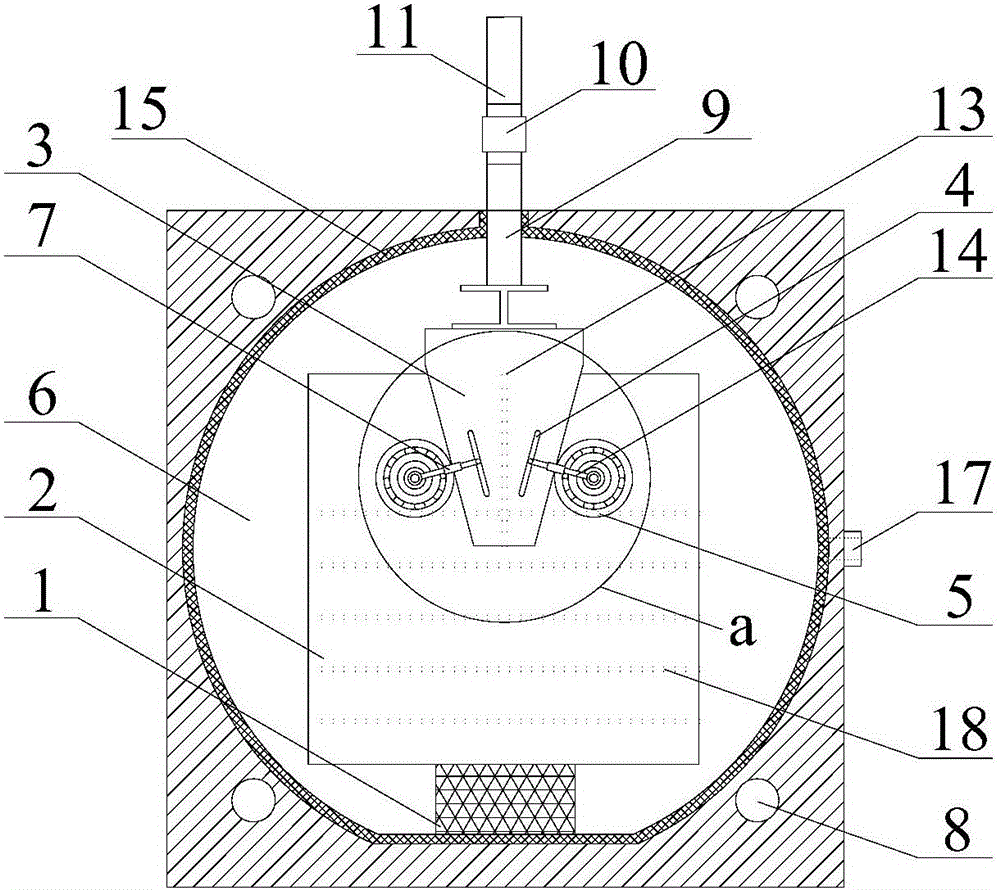

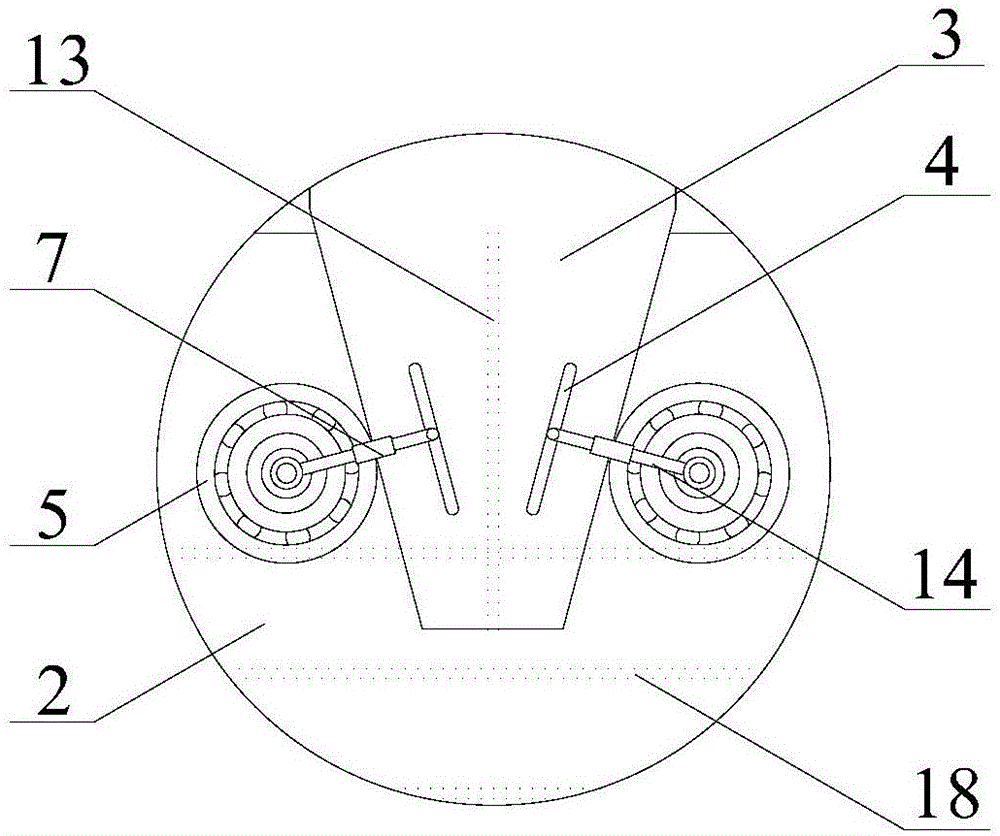

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0030] Such as figure 1 As shown, a schematic diagram of the implementation of the hydraulic splitting test machine for concrete members under a kind of reciprocating load and high water pressure provided by the present invention, including MTS testing machine operating head (11), axial force sensor (10), Actuating connecting rod (9), wedge-shaped loading frame (3), bearing (5), force transmission steel shaft (16), small axial force sensor (7), small actuating connecting rod (14), linear guide rail (4) , high-pressure sealed cylinder (15), sealed cylinder connecting rod (8), non-contact optical measurement window (6), exhaust hole (12) and water injection pipe (17); MTS testing machine actuating head (11), shaft The force sensor (10), the actuating connecting rod (9), and the wedge-shaped loading frame (3) form the reciprocating load loading part on the conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com