Patents

Literature

170results about How to "Safe and reliable sealing" patented technology

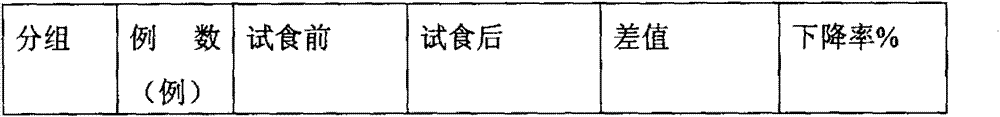

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

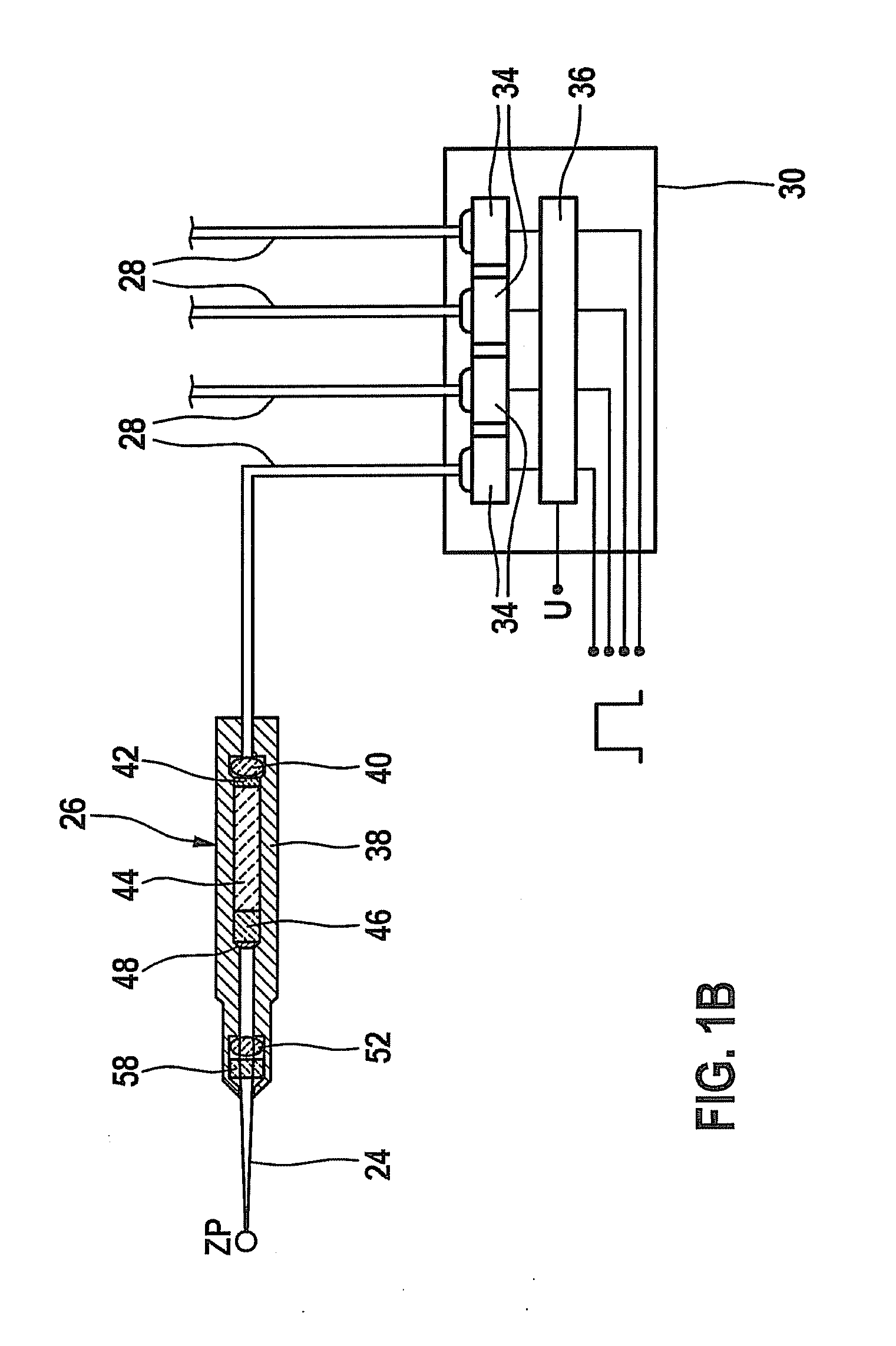

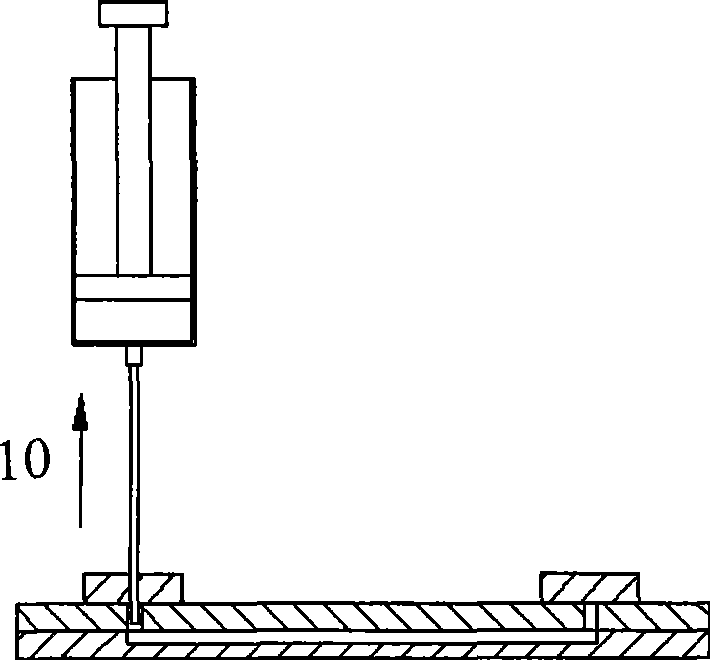

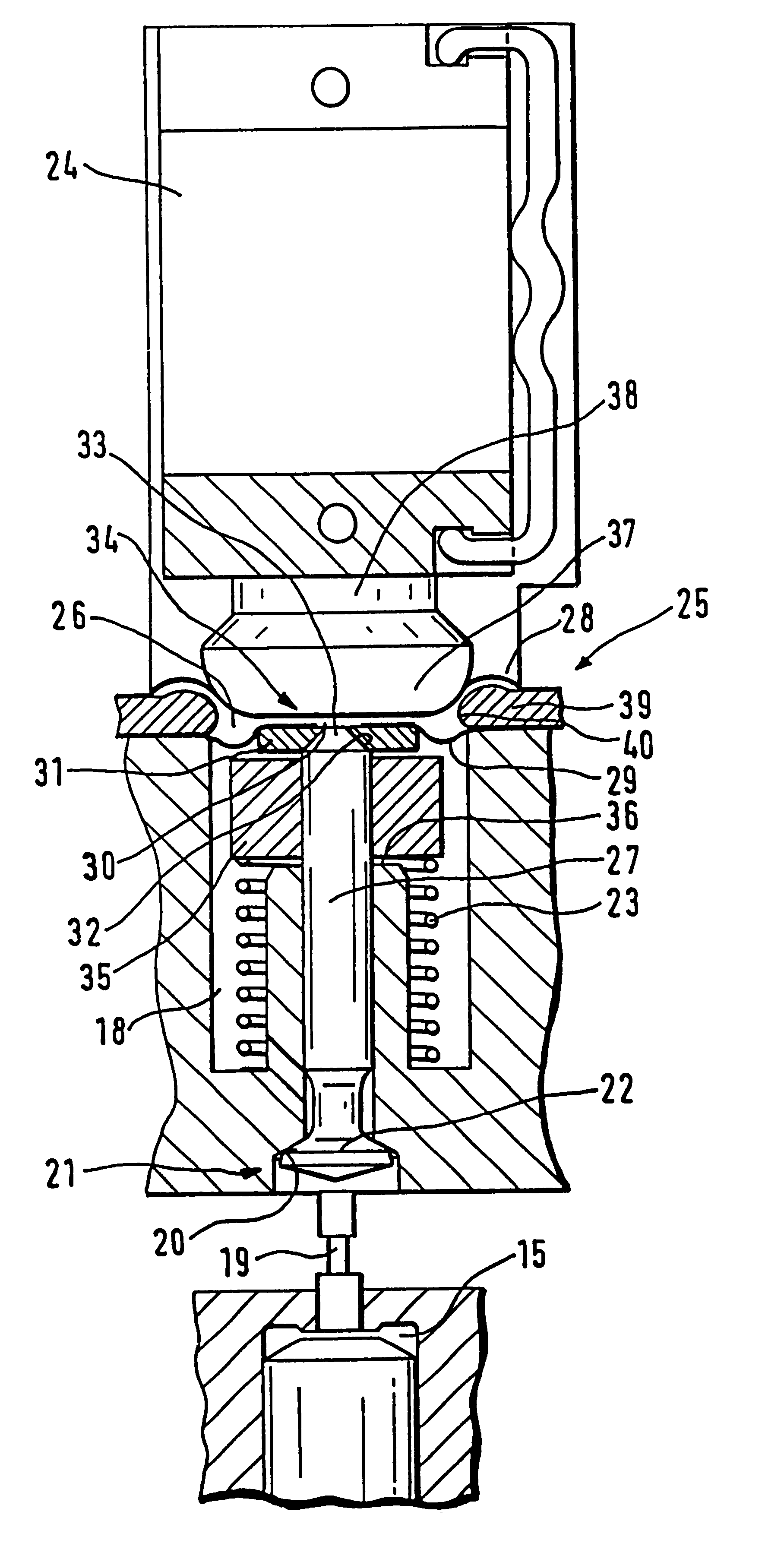

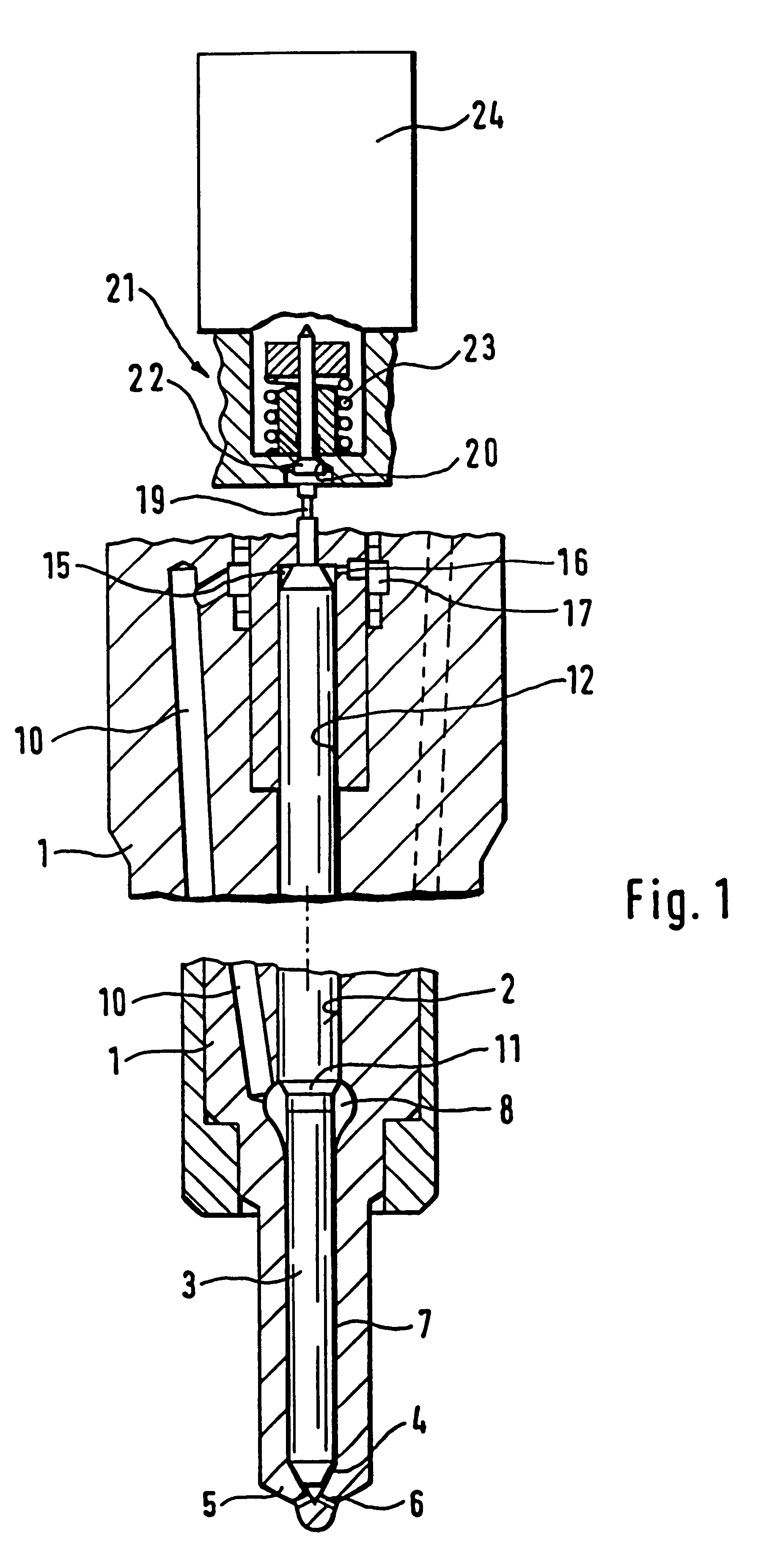

Piezoelectrically actuated fuel injection valve

InactiveUS6168133B1Simple designReliable functionOperating means/releasing devices for valvesFluid pressure injection controlCombustionWork cycle

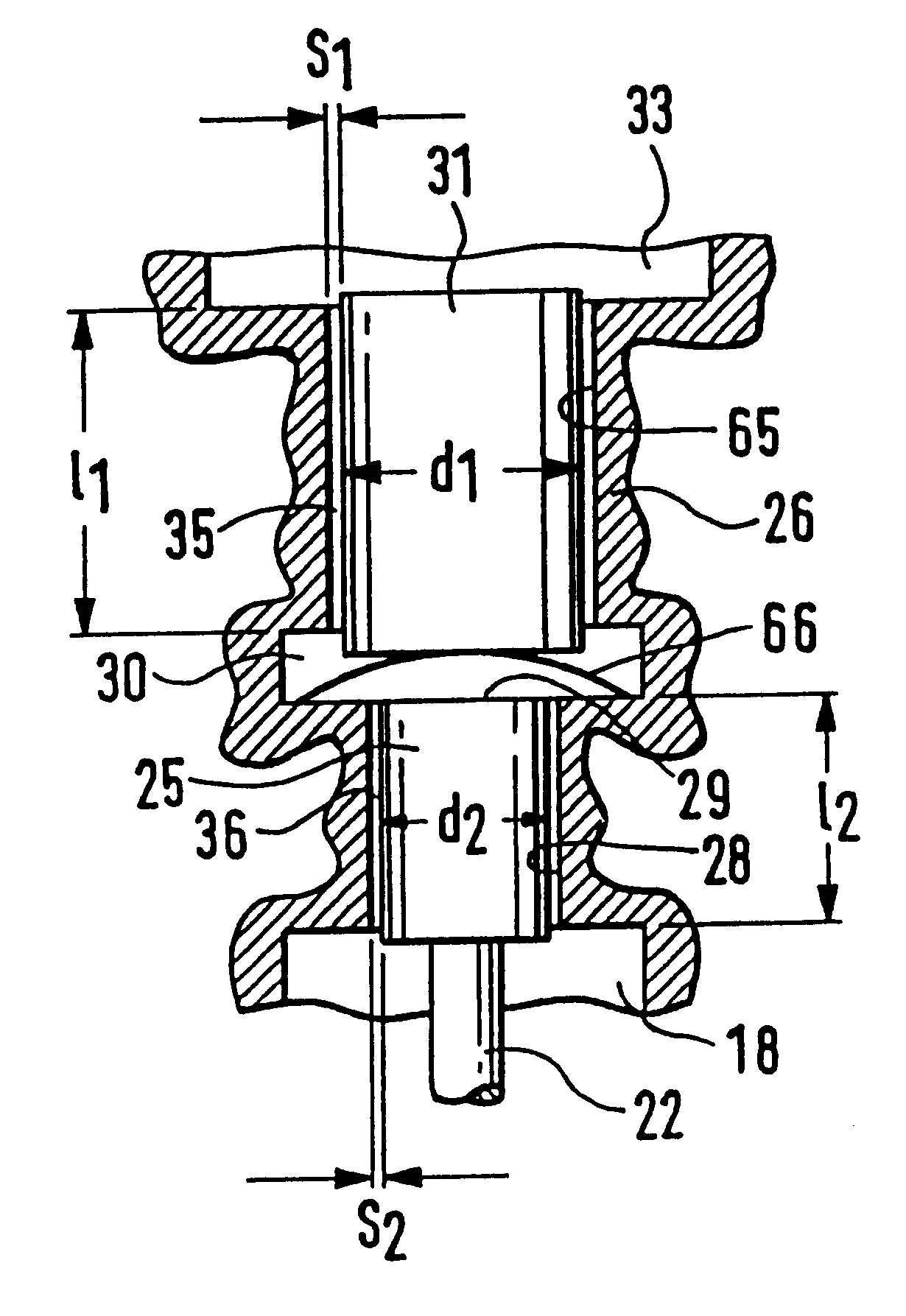

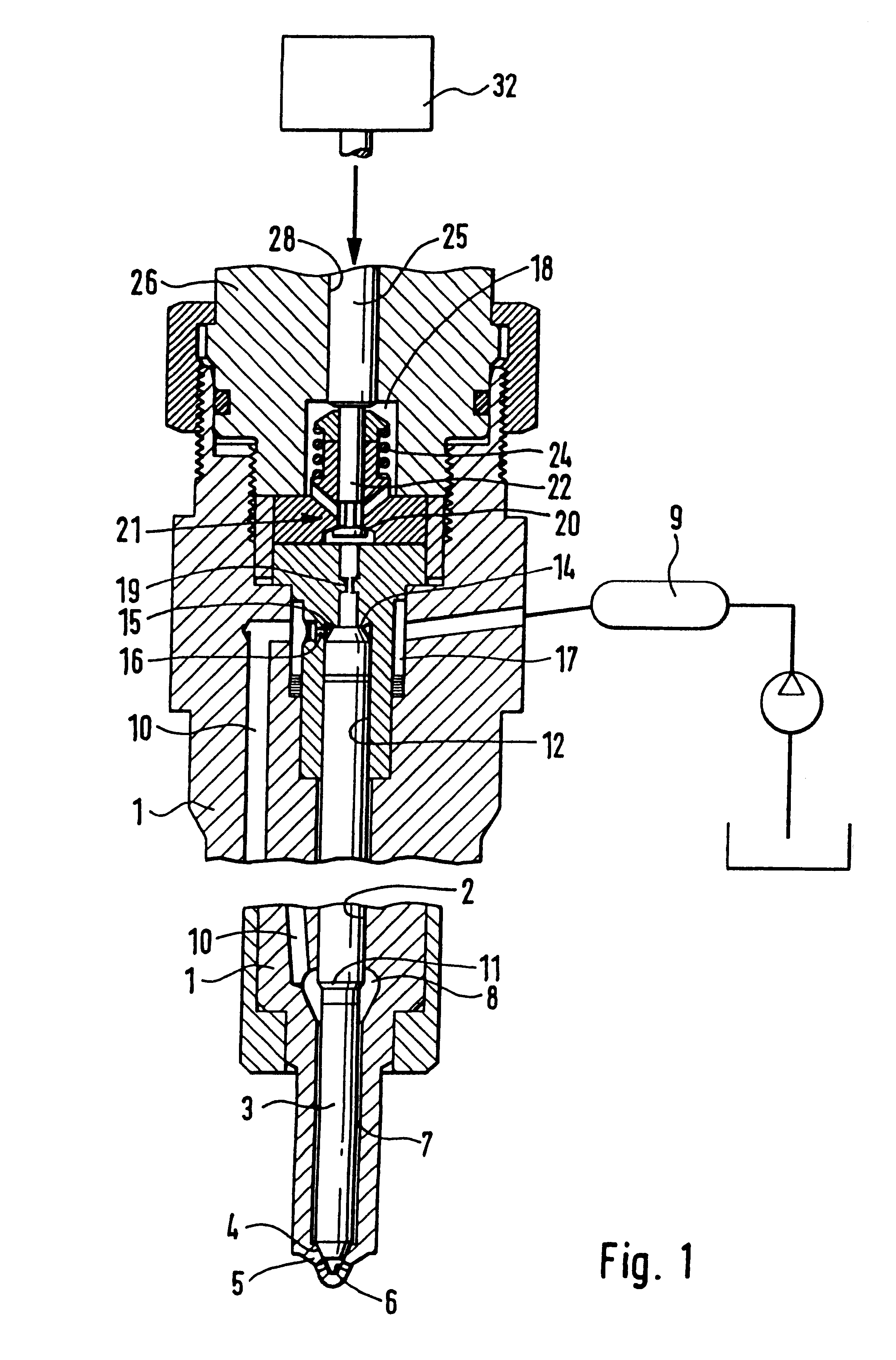

A valve for controlling liquids which for its actuation is provided with a liquid-filled coupling chamber, which is disposed between an actuator piston of a piezoelectric actuator and a piston that actuates a valve member. To compensate for liquid losses suffered by the coupling chamber, which is briefly at high in each work cycle, the pressure difference that exists during the return stroke of the actuator piston between the coupling chamber and the opposite sides of the actuator piston and of the that actuates the valve member that are remote from the coupling chamber is utilized to achieve refilling in valveless fashion along gaps. The valve is used for use in fuel injection systems for internal combustion engines of motor vehicles.

Owner:ROBERT BOSCH GMBH

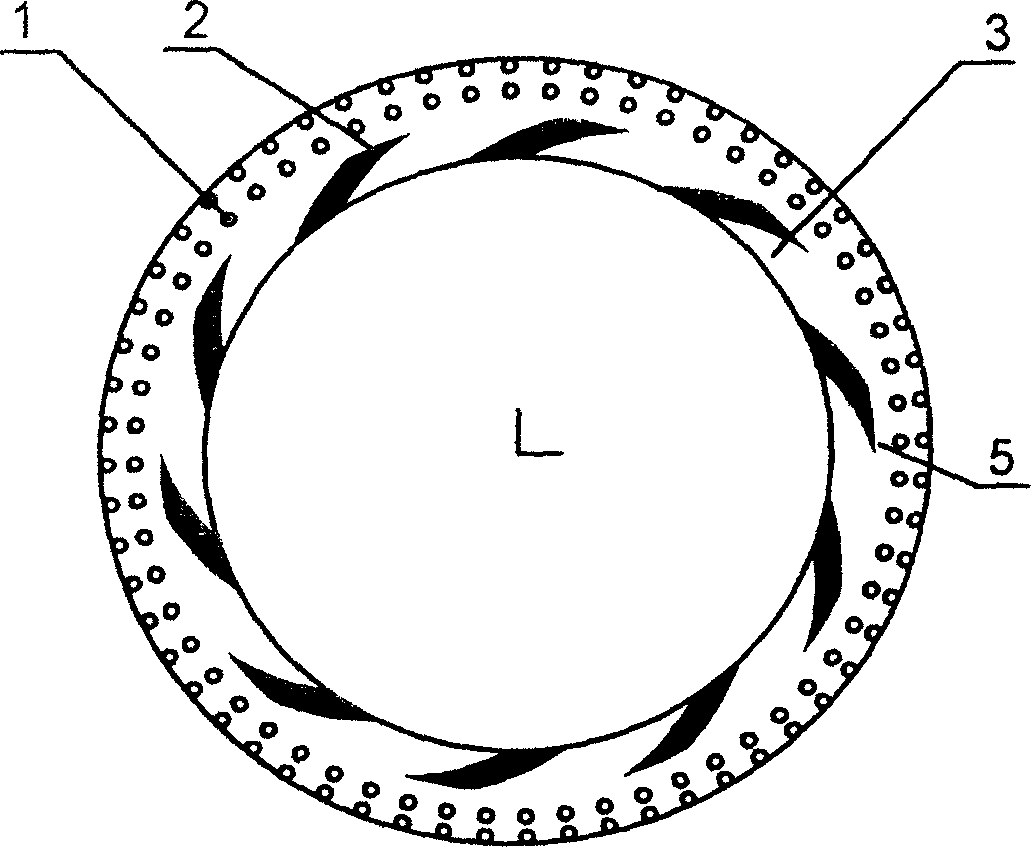

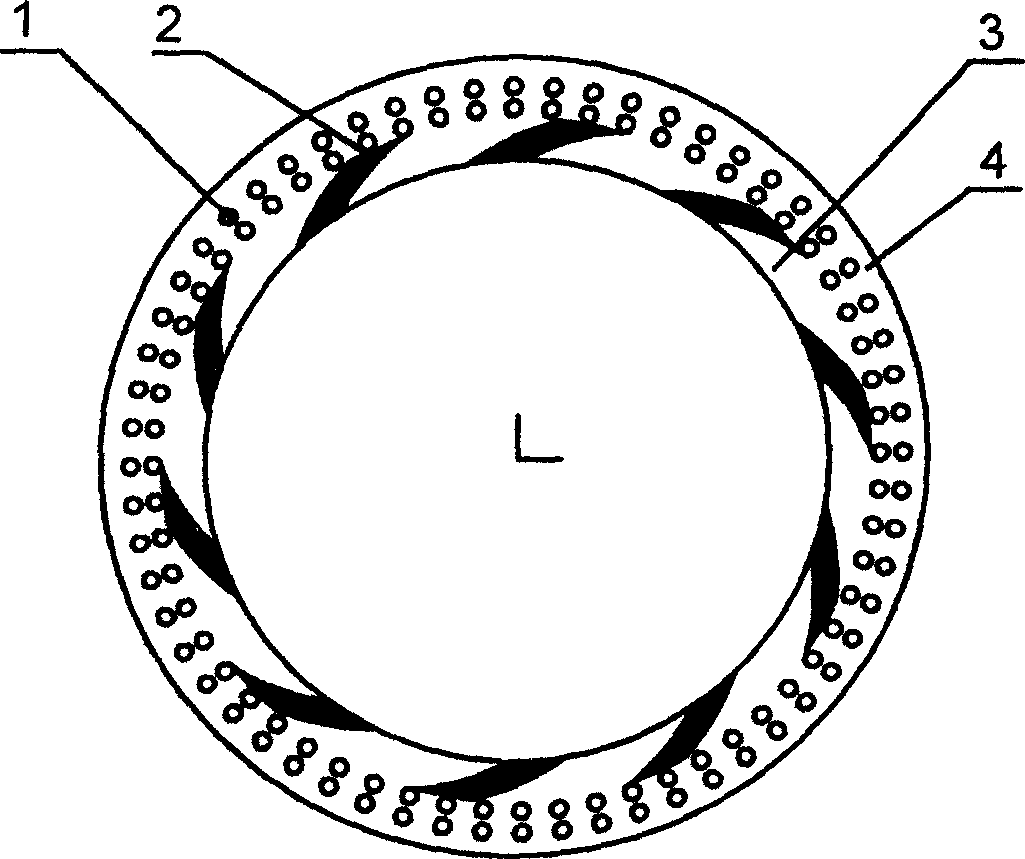

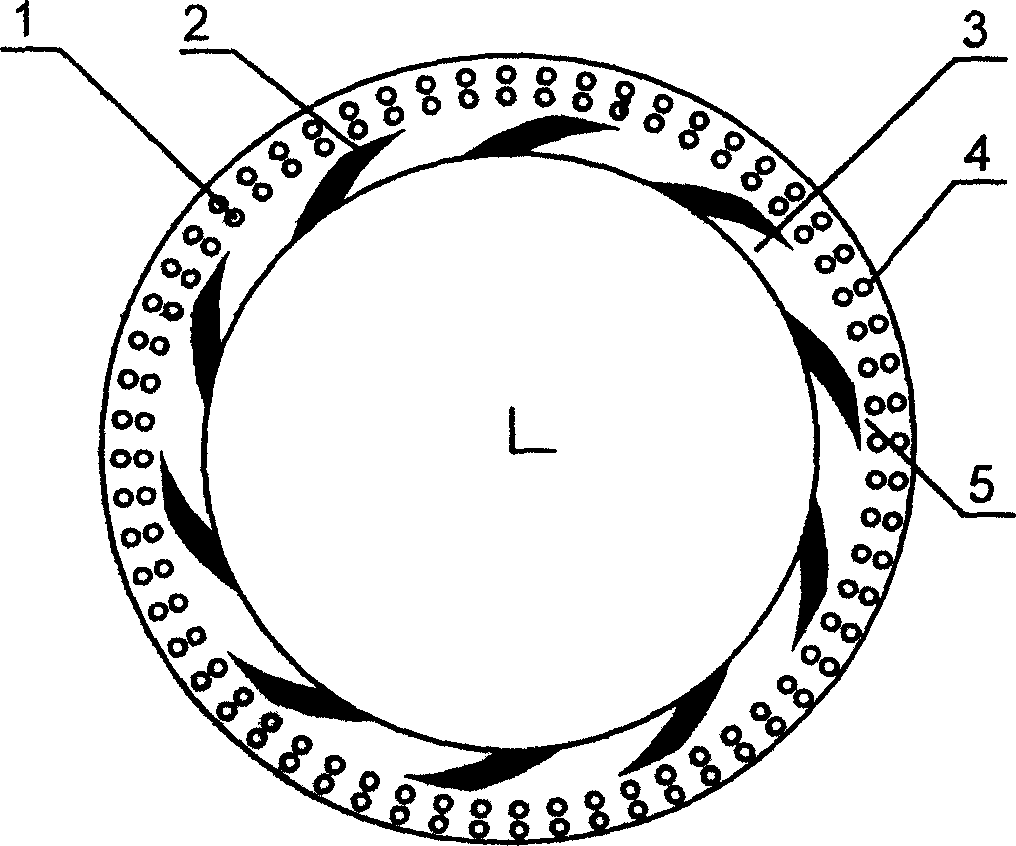

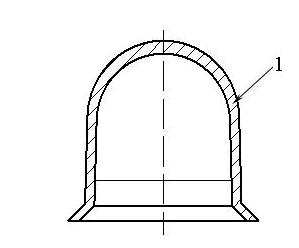

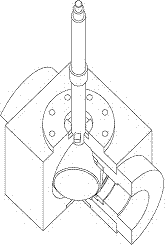

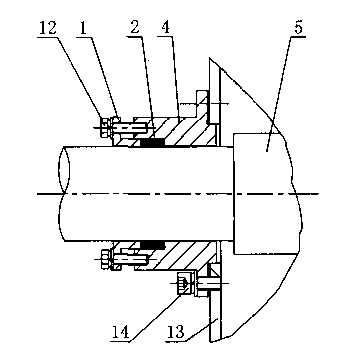

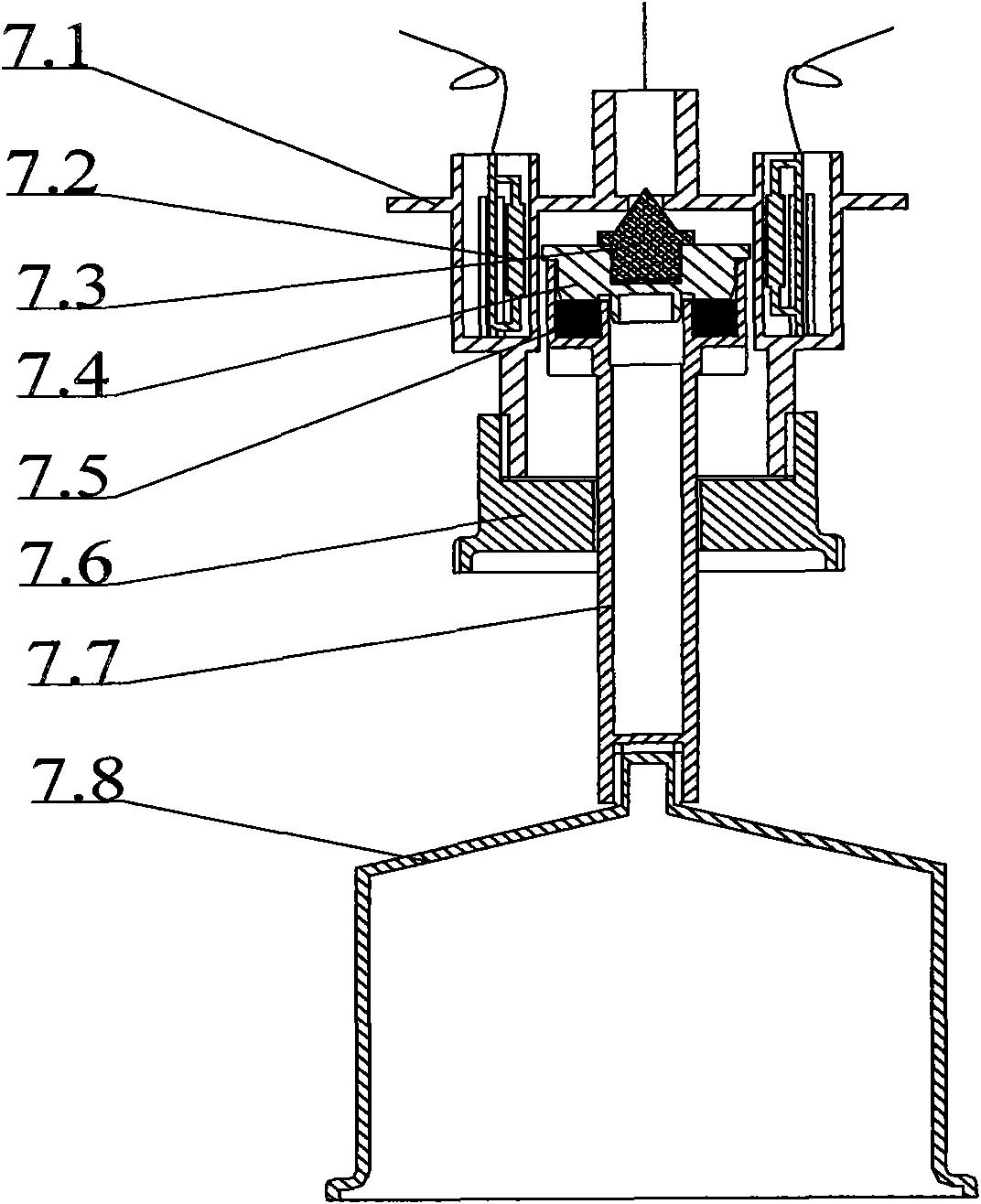

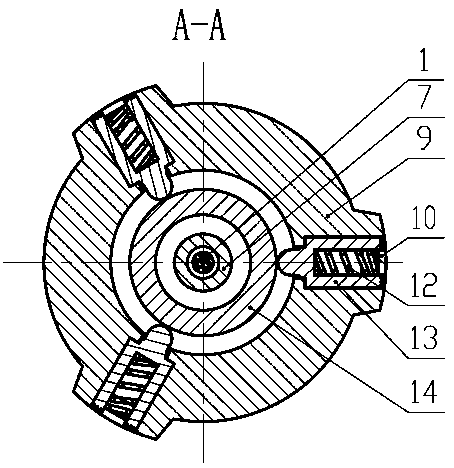

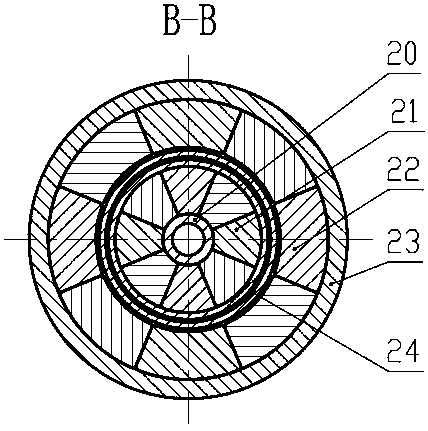

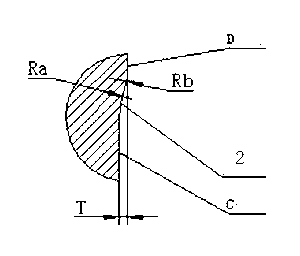

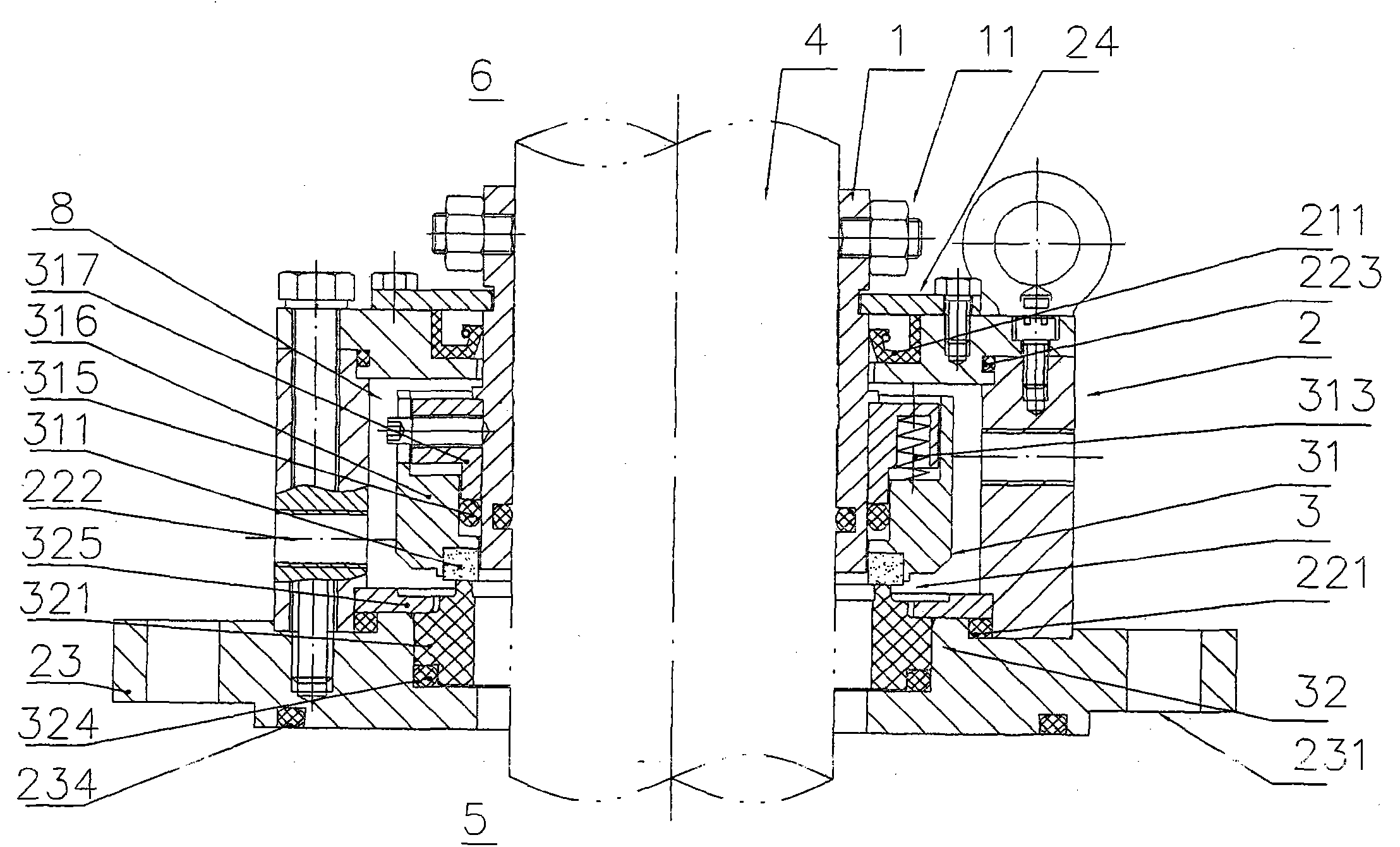

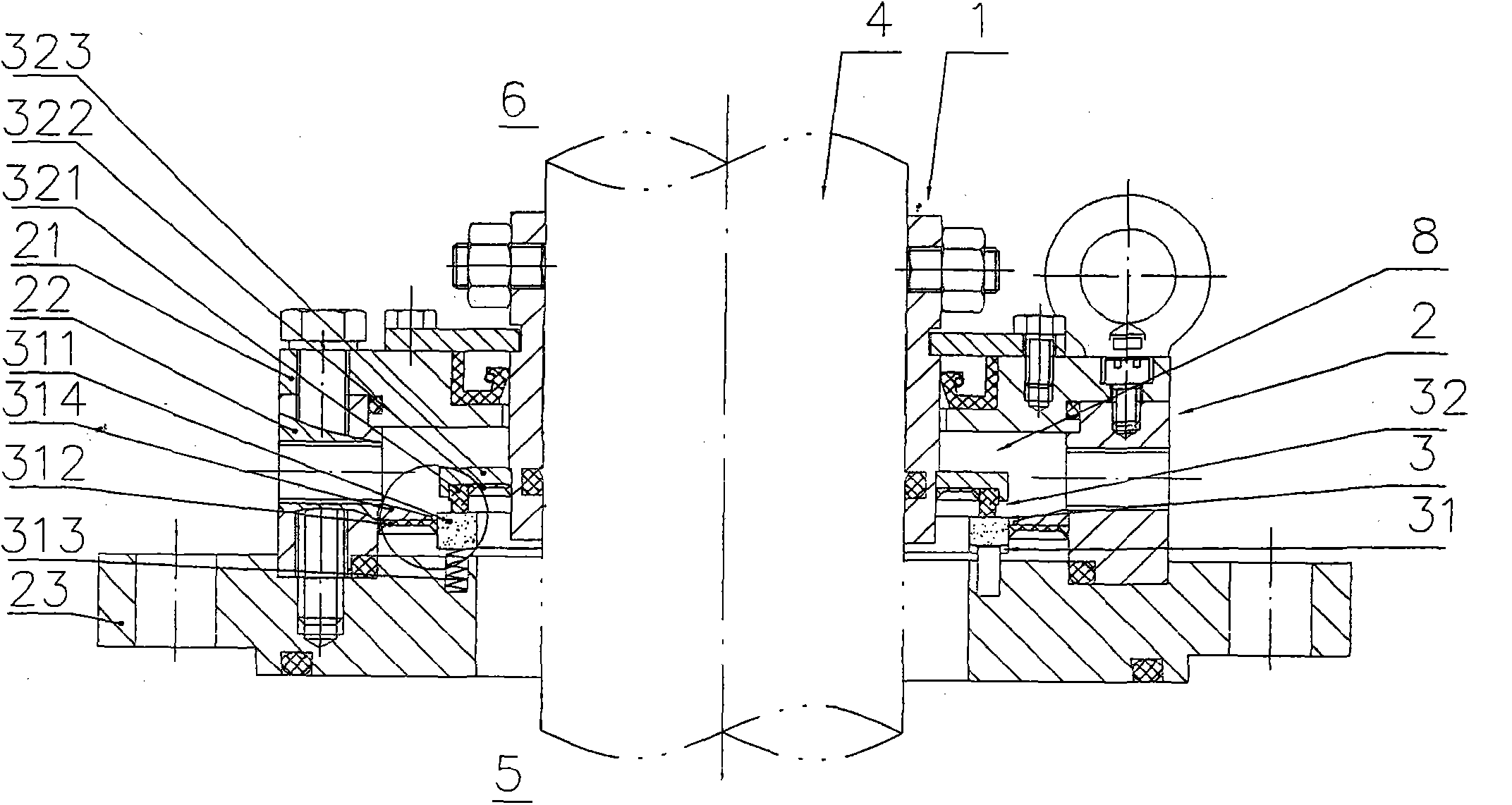

Non-contact mechanical end face sealing structure

InactiveCN1828098AImprove sealing abilityExtended service lifeEngine sealsCentre of rotationEngineering

The invention relates to a non-contact mechanical end surface sealing structure, which comprises mechanical sealed movable ring and stable ring. While the end surface of stable or movable ring has micro groove and porous zone that symmetry according to the rotational center. Wherein, said zone is at the ascending part of end surface and the micro groove is at the descending part, which has a circular sealing dam beside it. The invention can be used in variable mediums to increase the ability of solid particle, the static pressure property, fluid dynamic pressure property and the pump adsorption property, to attain better sealing effect, with long service life.

Owner:ZHEJIANG UNIV OF TECH

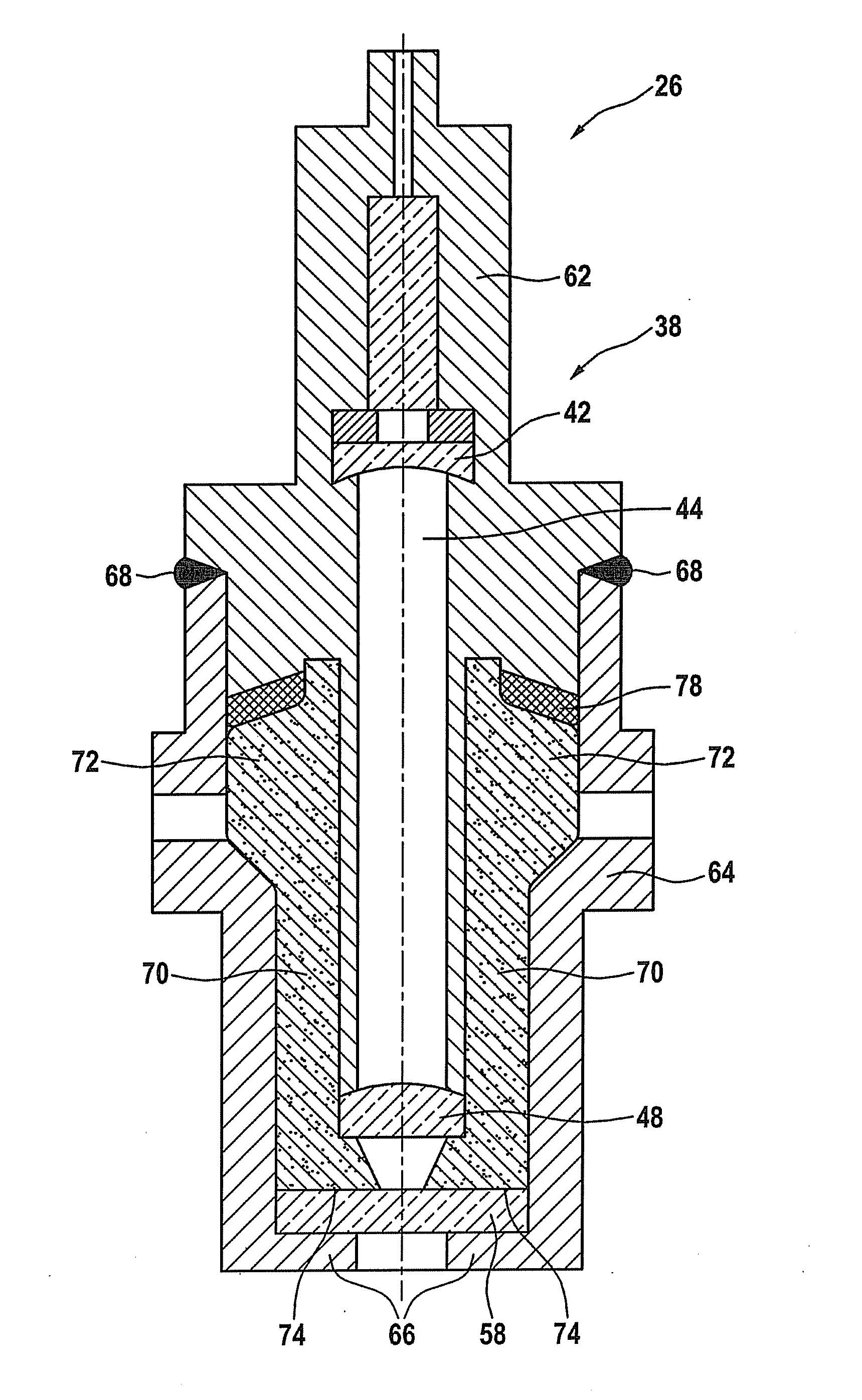

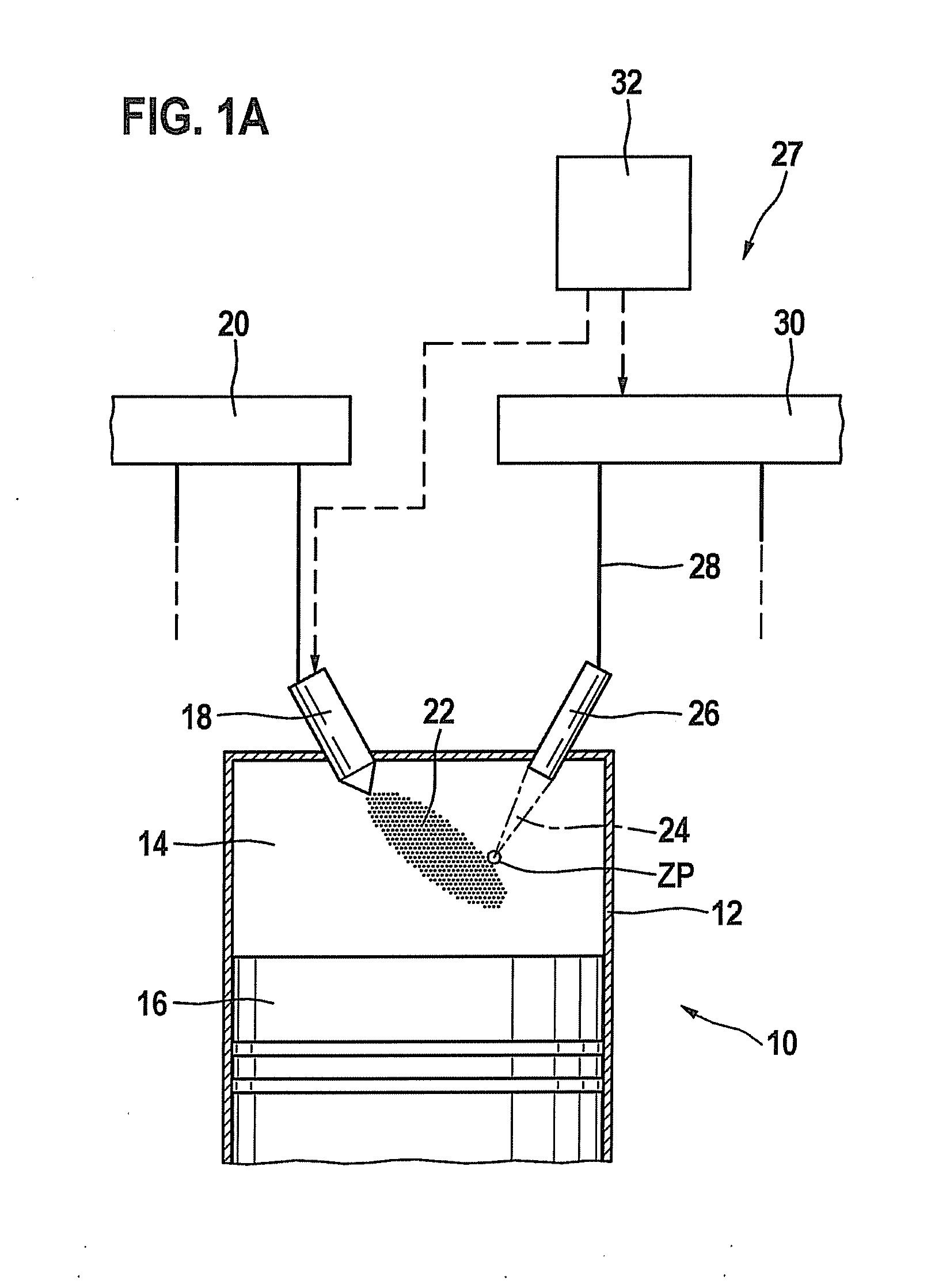

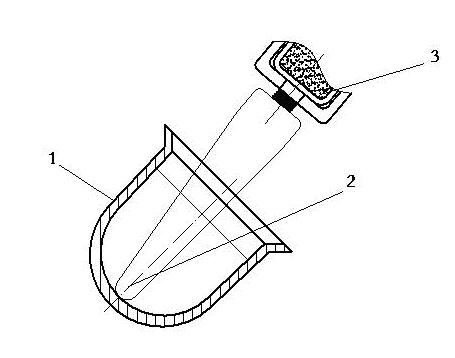

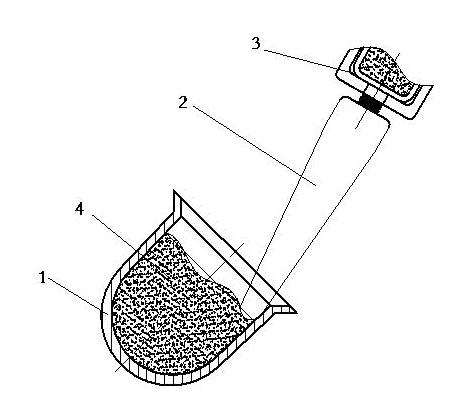

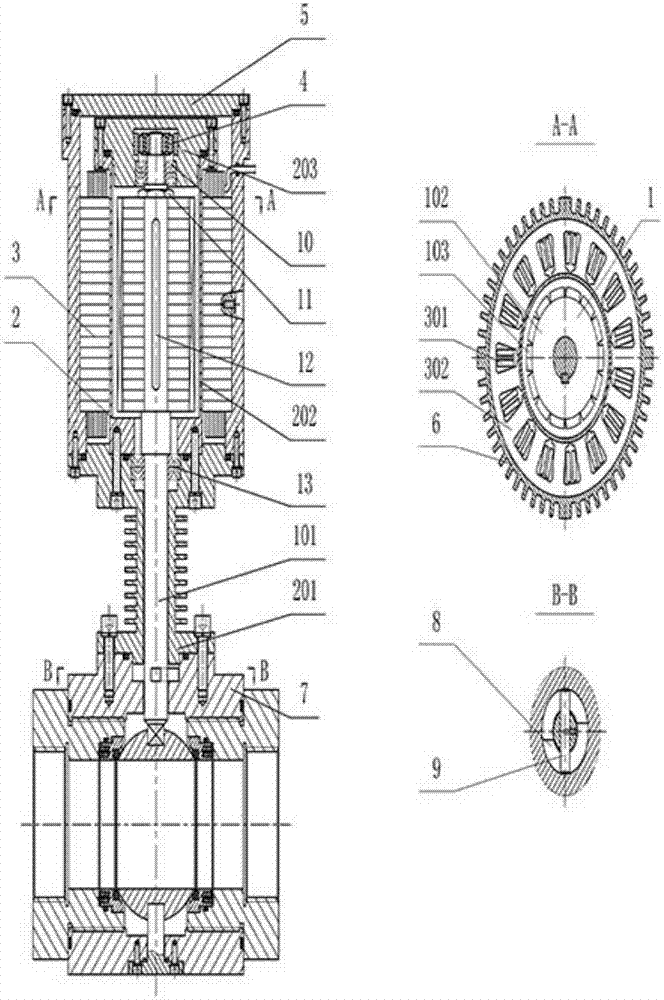

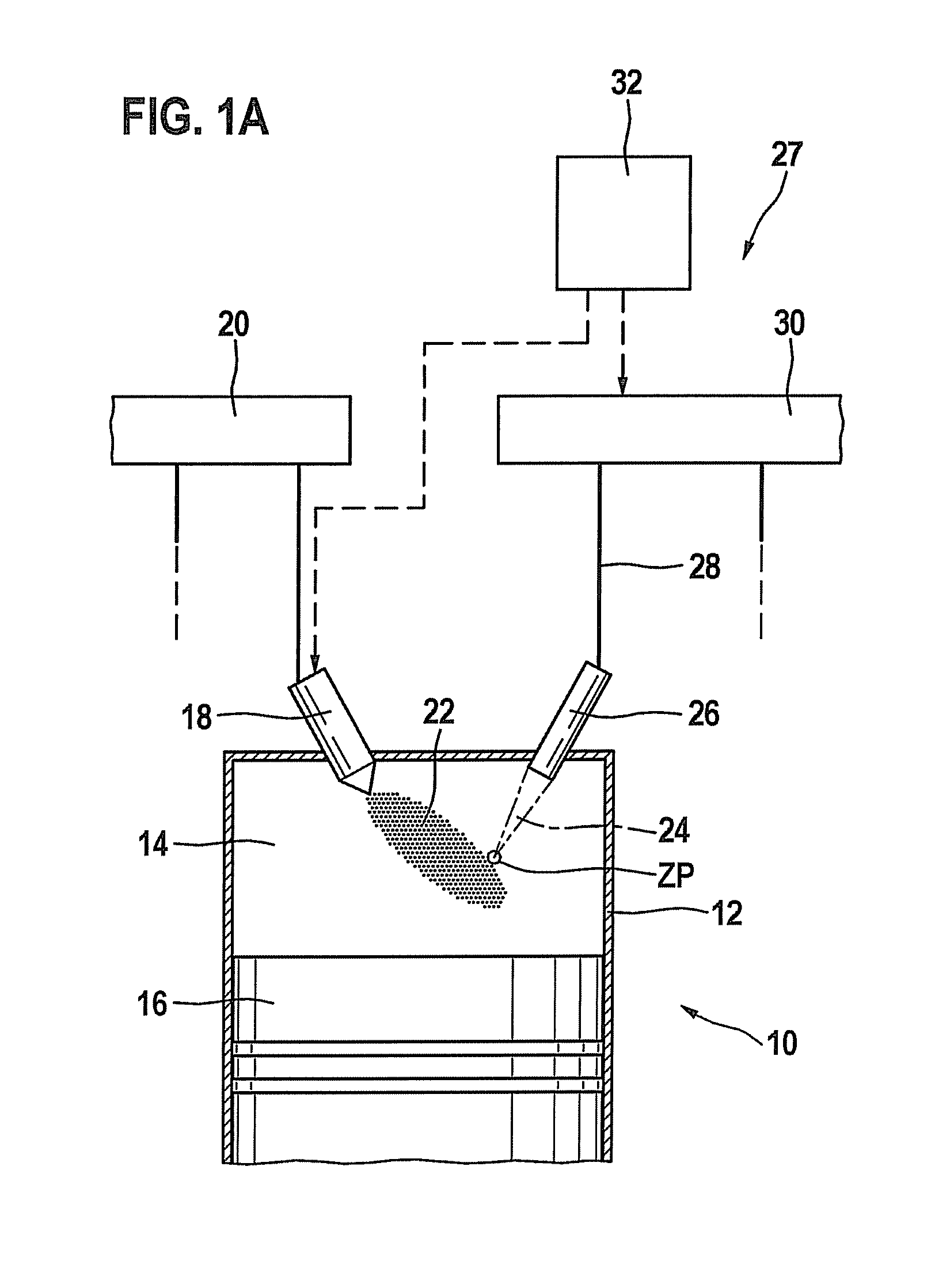

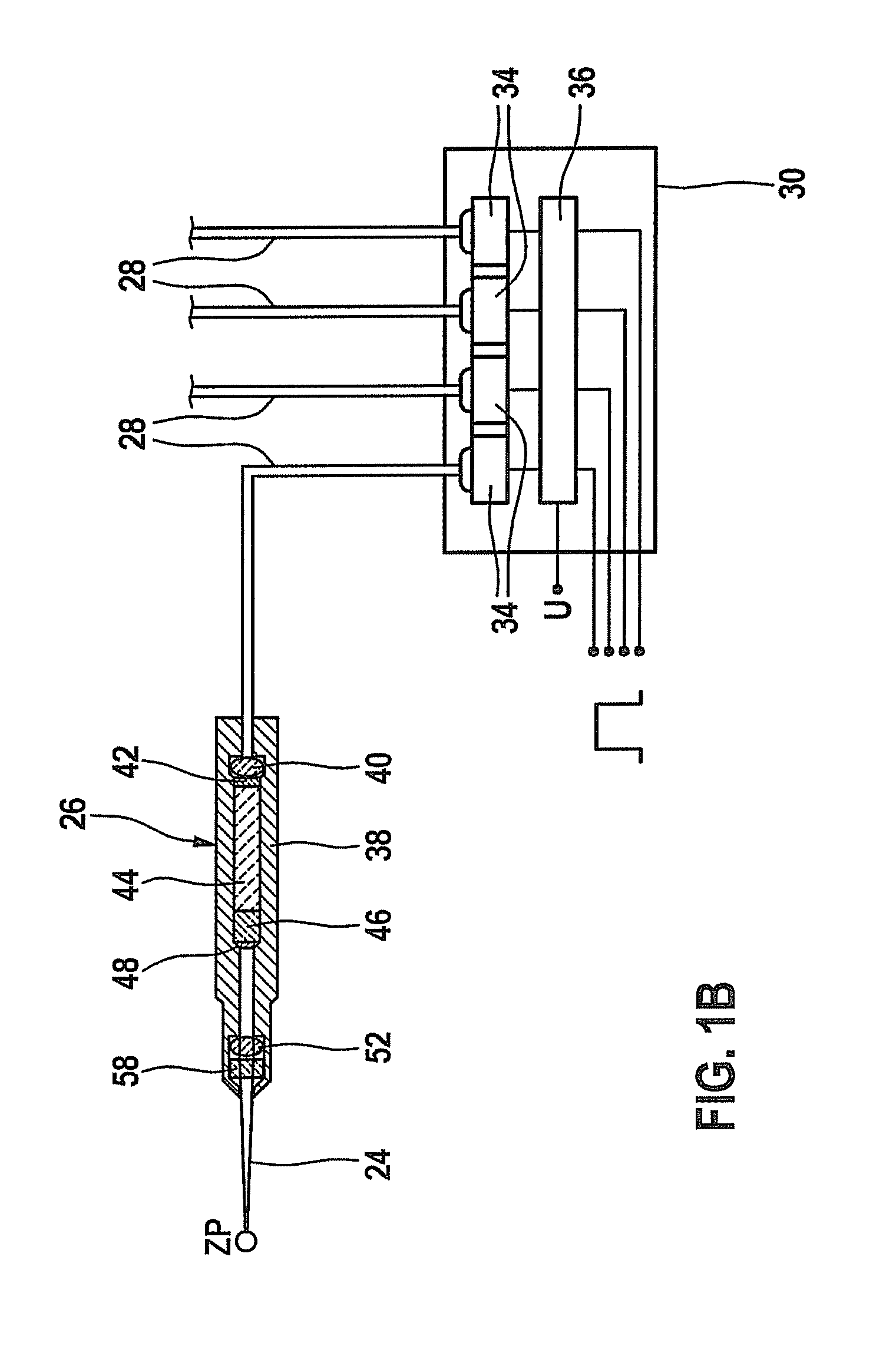

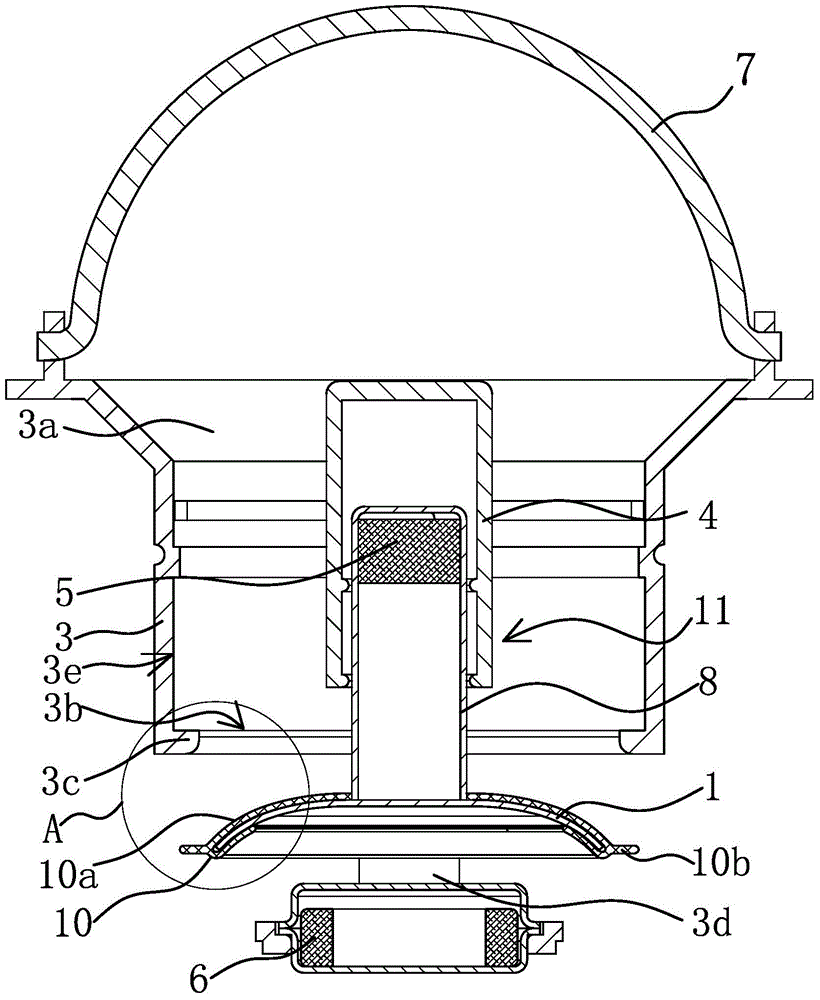

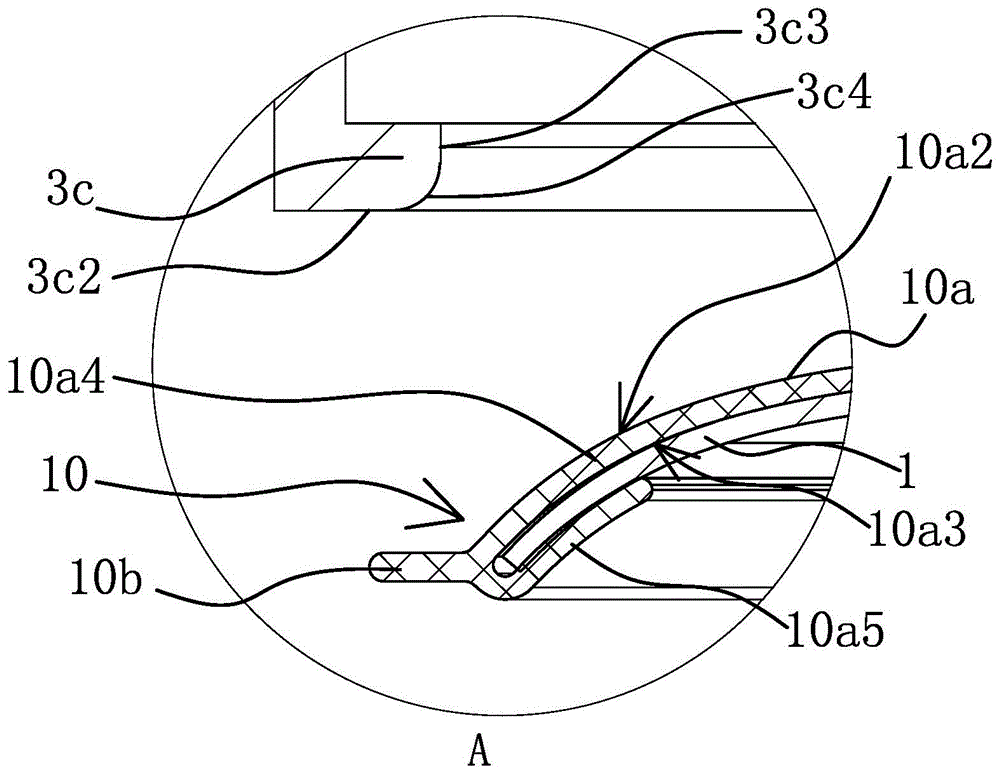

Ignition laser

InactiveUS20120024250A1Safe and reliable sealingLong lastingCombustion enginesGas turbine plantsCombustion chamberEngineering

An ignition laser, includes a laser-active solid-state body, a housing and a combustion chamber window, the housing having an inner sleeve and an outer sleeve. An insert is provided between the inner sleeve and the outer sleeve, the insert and the combustion chamber window being joined sealingly and integrally.

Owner:ROBERT BOSCH GMBH

Sealing method of fastener

InactiveCN102678927ASafe and reliable sealingAppearance quality is beautifulEngine sealsSealantFastener

The invention relates to a sealing method of a fastener. The sealing method comprises the following steps of: selecting a sealing cap with the size matched with the fastener; injecting sealant with the 2 / 3 of volume into the sealing cap by using a sealant injector; and buckling the sealing cap on the fastener head perpendicularly and pressing tightly with a hand so that the bottom edge of the sealing cap is tightly attached to the surface of the structure.

Owner:XIAN AIRCRAFT IND GROUP

Expansion hanger

ActiveCN102979472AConvenient seat sealSafe Suspension Cementing OperationSealing/packingRubber ringWell cementing

The invention relates to the technical field of hanging and expanding devices for cementing of wells in oil drilling, in particular to an expansion hanger. The expansion hanger comprises an expansion pipe, a switching barrel, a single-current valve seat, a guide shoe, an expansion device, a salvageable setting device and a single-current control device, wherein the expansion device is arranged in the expansion pipe; the expansion pipe comprises a diameter expansion pipe, a frustum-shaped oblique pipe neck and a body of which the outer diameters increase in sequence from top to bottom; a vulcanized rubber ring is fixed on the upper outer wall of the diameter expansion pipe, or at least two circles of vulcanized rubber rings are fixed on the upper outer wall of the diameter expansion pipe from top to bottom; the lower end of the body is fixedly arranged together with the upper end of the switching barrel; the inner diameter of the switching barrel is the same as the inner diameter of the body; and the salvageable setting device is arranged in an inner cavity between the lower part of the body and the switching barrel. Under the condition that the drift diameter loss of a shaft of an oil-gas well, hanging and sealing are realized through expansion and cold drawing deformation of tubular products, high reliability is achieved, sealing does not fail easily, and hanging and well cementing operation of a tail pipe is completed safely and rapidly.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

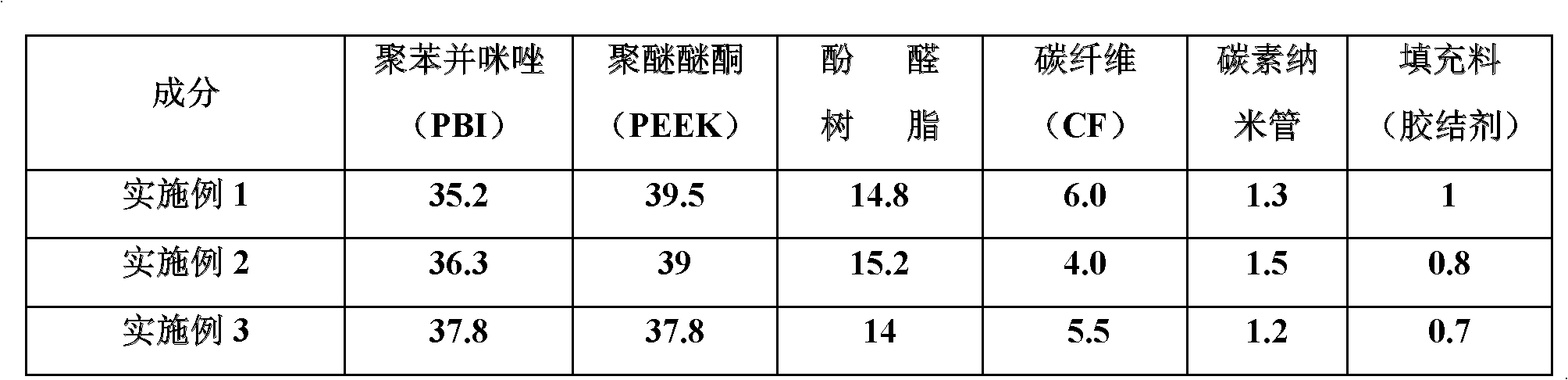

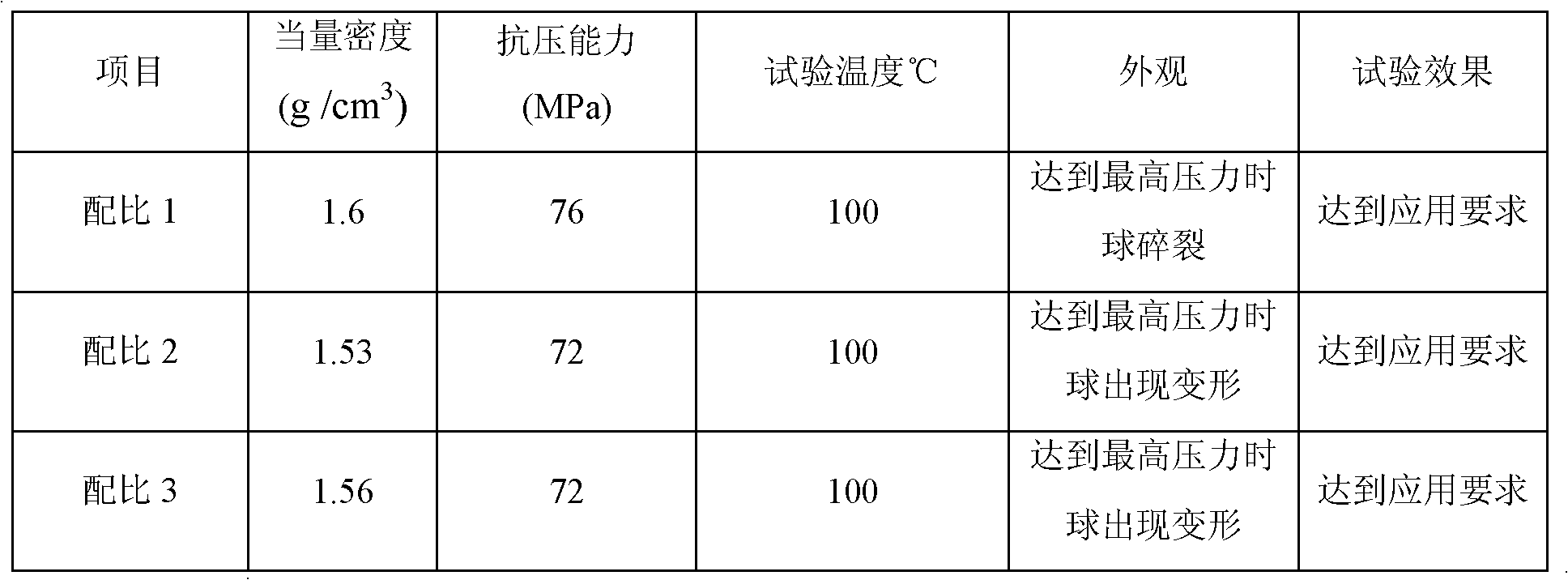

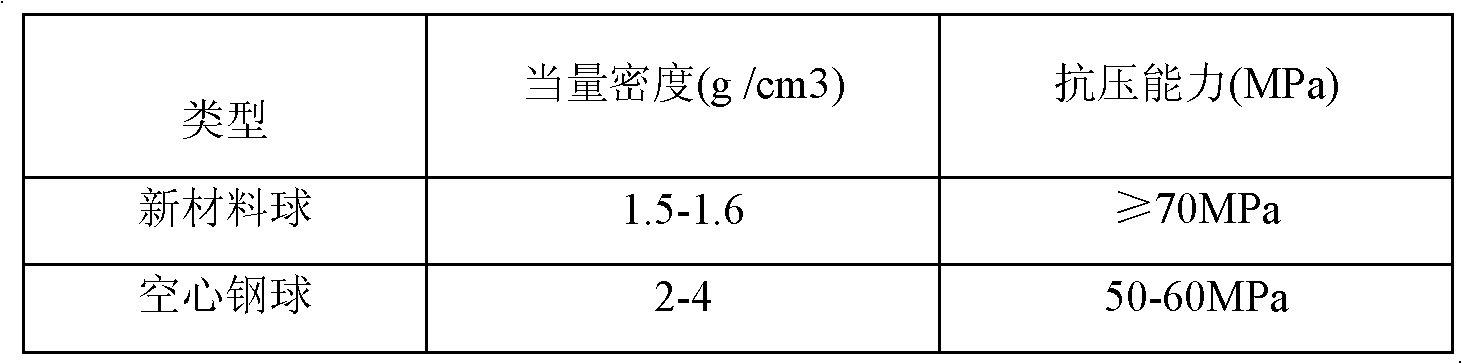

Novel material pressure-out ball used in staged fracturing pitching slide sleeve opening

The invention provides a novel material pressure-out ball for a multi-stage slide sleeve staged fracturing pitching opening-type slide sleeve. The novel material pressure-out ball employs main materials such as polybenzimidazole and polyetheretherketone. The main function of the pressure-out ball is that with the pressure-out ball, pressure-out sealing can be rapidly and reliably realized, pitching slide sleeve can be opened, and fracturing can be realized. The pressure-out ball has substantial characteristics that: (1) the density is low, wherein the density is 1.5-1.6g / cm<3>, such that the capacity of pressure-out ball for rapidly moving forward in a horizontal state can be improved, and backflow is easy; (2) a composite material with main components of polybenzimidazole and polyetheretherketone is adopted, such that a high impact strength is provided, and the abrasion of the pressure-out ball in a forward moving process is small, such that reliable sealing can be realized; (3) a pressure resistance is high, wherein as a result of experiments, no damage is caused under a high pressure of 70MPa; and (4) time is saved, and construction risk is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

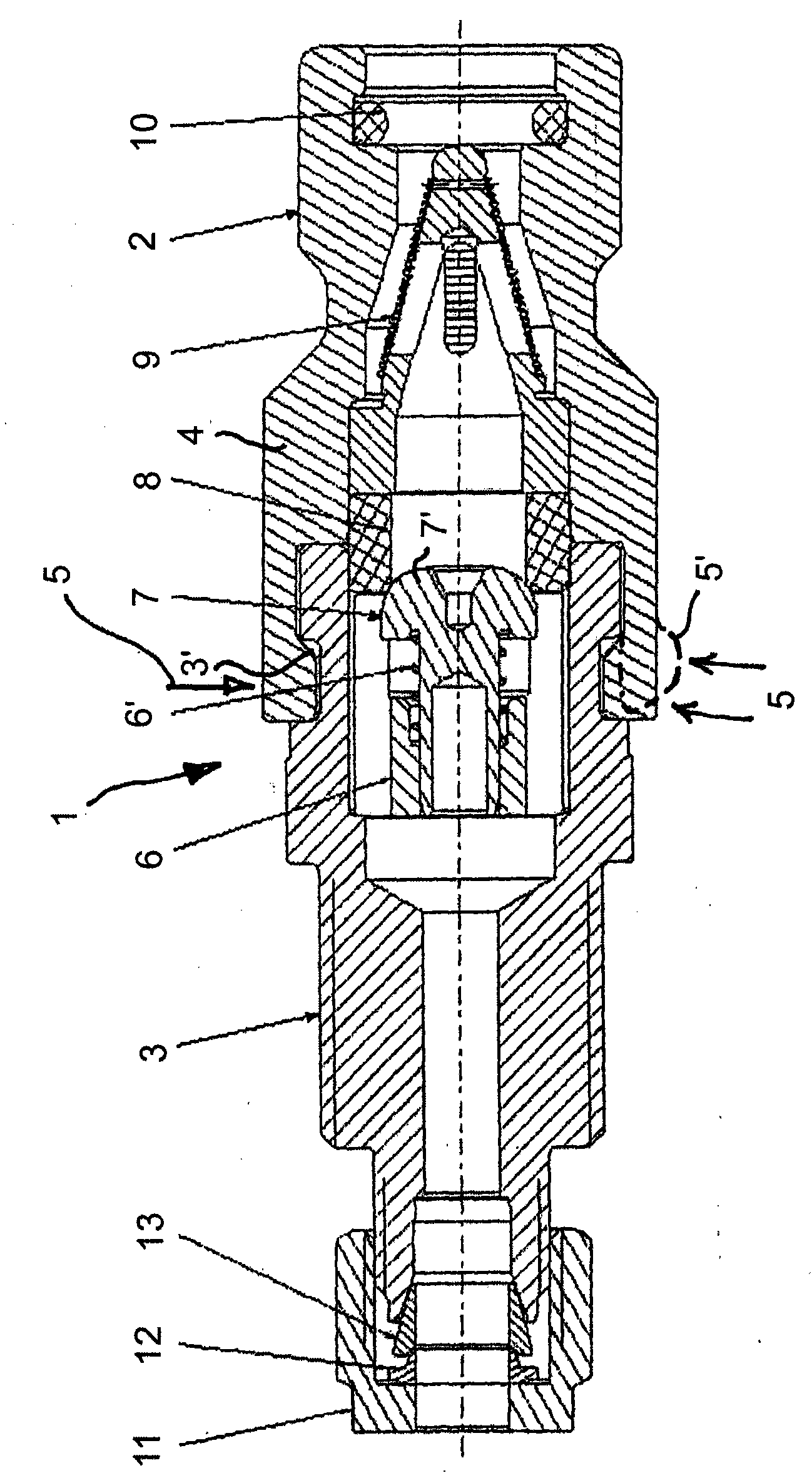

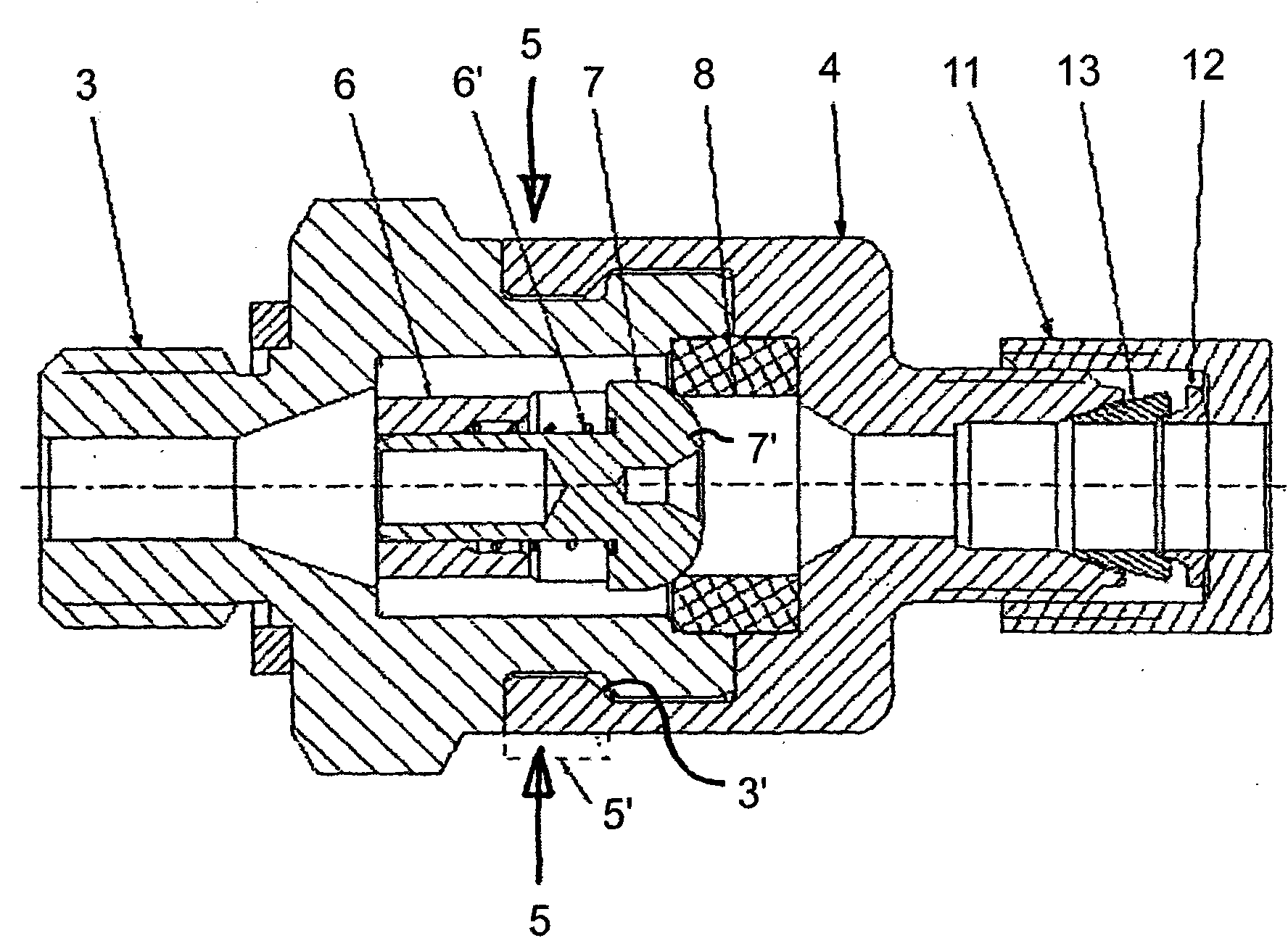

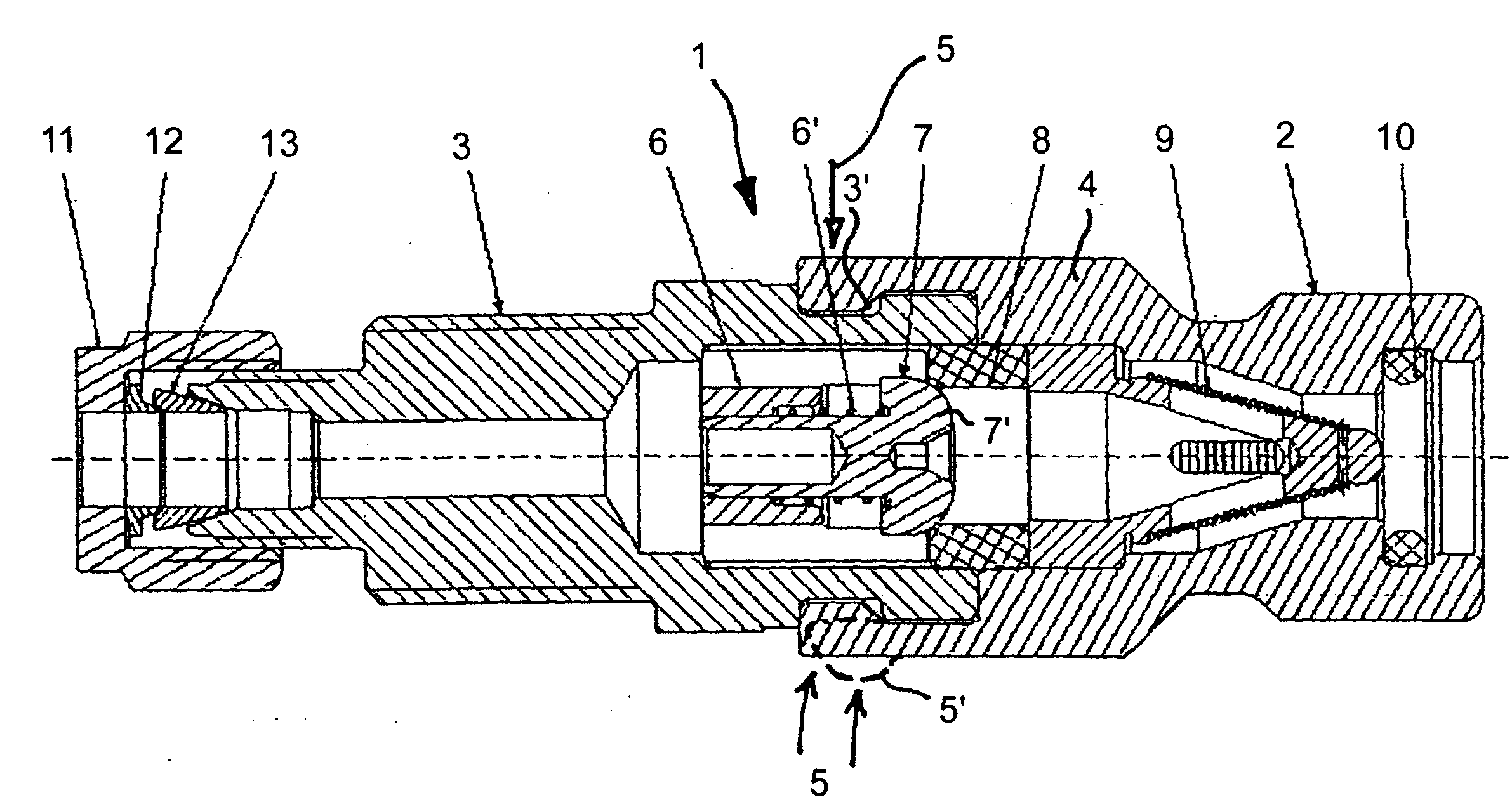

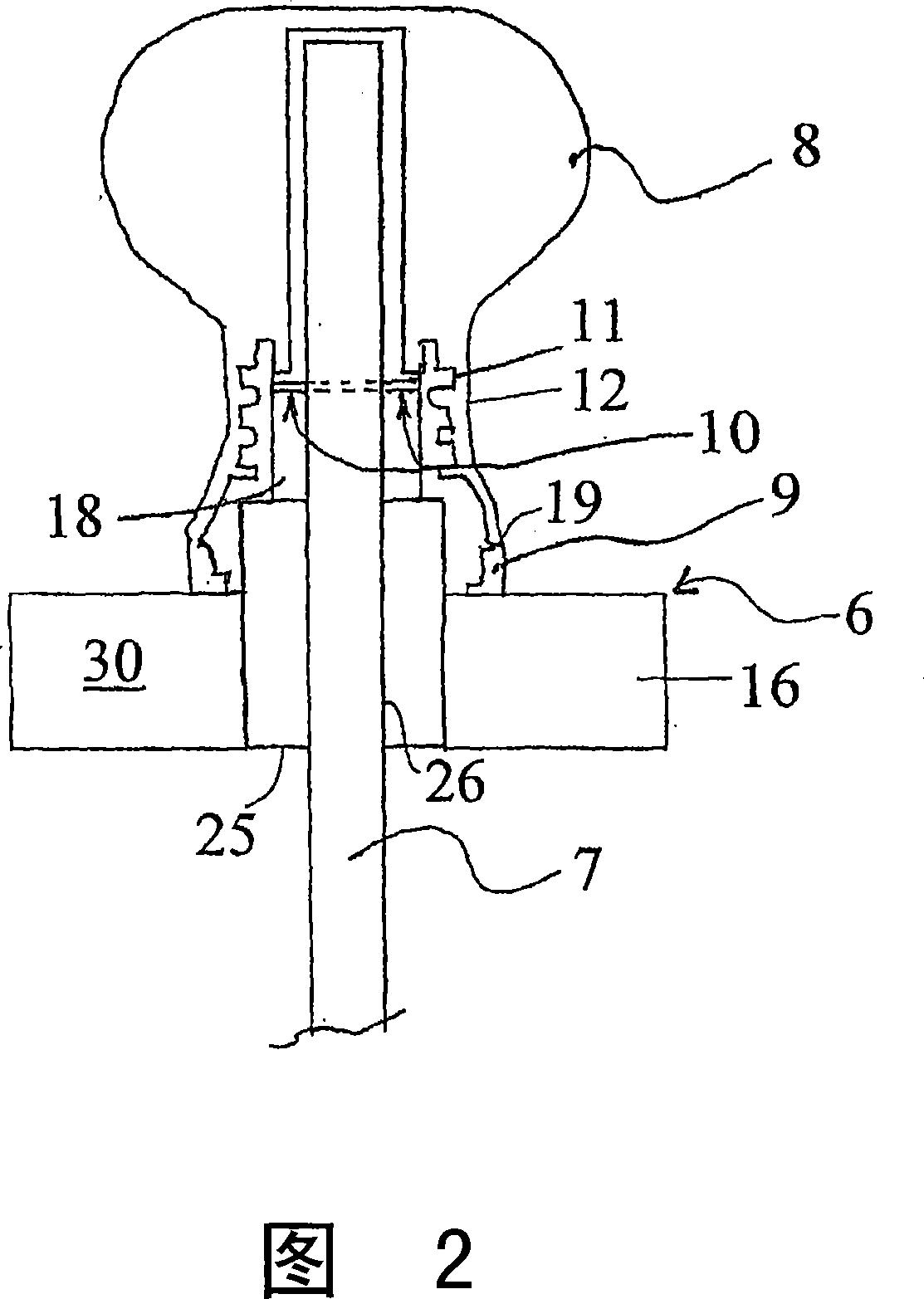

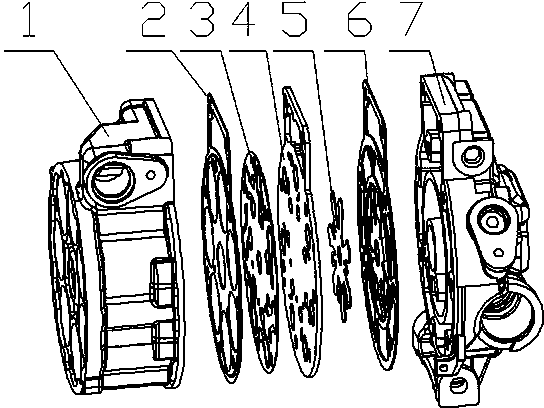

Valve component

InactiveCN101796336ASafe and reliable sealingLow costVessel mounting detailsCheck valvesCouplingEngineering

For the simple and cost-effective production of a valve component (1) in the form of a non-return valve or a connecting nipple, in particular for the refuelling of natural gas vehicles, or for the pressure-tight connection to a fluid line or a plug-in coupling, wherein the valve component (1) has two housing parts (3, 4) which are connected pressure-tightly to each other and accommodate a valve (7) there within, it is proposed that the housing parts (3, 4) are pressed together at an annular groove (3').

Owner:欧文韦 +1

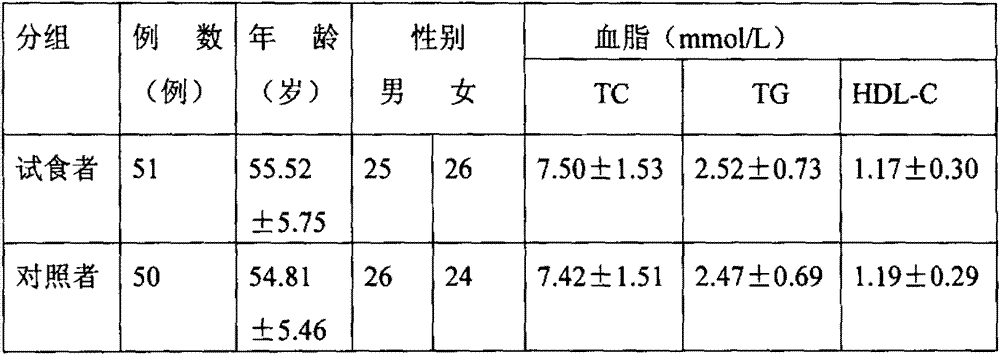

Soybean phospholipids soft capsule and preparation method thereof

InactiveCN103191176ASignificant decreaseImprove securityOrganic active ingredientsMetabolism disorderAdditive ingredientBioavailability

The invention relates to a soybean phospholipids soft capsule and a preparation method thereof. The soybean phospholipids soft capsule comprises a content and a capsule shell, wherein the content comprises ingredients in parts by weight: 25-90 parts of soybean phospholipids, 5-15 parts of soybean oil, and 0.1-0.5 part of vitamin E. Compared with the prior art, the soybean phospholipids soft capsule has the advantages of being good in bioavailability, excellent in drug stability, capable of covering unpleasant odor, accurate in dosage, sealed, safe, convenient to carry and use, and the like.

Owner:SHANGHAI SPRING TANG BIO PROD

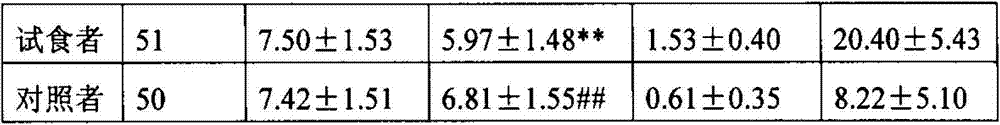

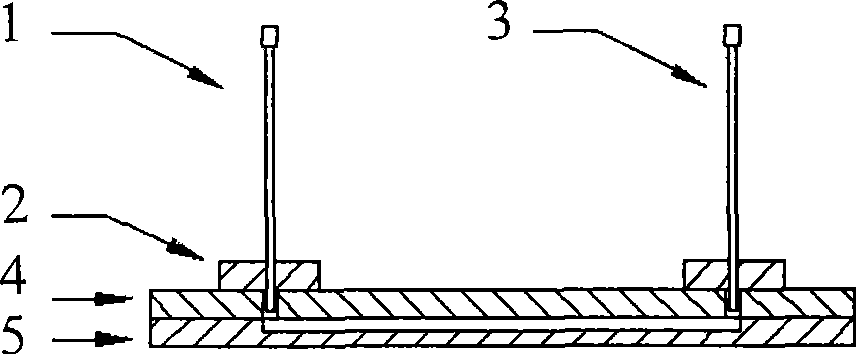

Volume segmentation type liquid pouring and sealing method based on silicone base subfebrile temperature pipe

InactiveCN101509739APrecise volume controlSimple control methodIndirect heat exchangersEngineeringHeating temperature

The invention discloses a cubage segmentation-typed liquid-injection and a sealing method for a silicon-based micro-heat pipe. By twice precise cubage segmentation to an enclosed space consisting of the silicon-based micro-heat pipe and an injector, little working liquid is taken out of the working liquid and the air in the sealing space; furthermore, two fine metal pipes used for connecting the liquid injection holes are sealed so as to retain the liquid in the micro-heat pipe, thus precisely controlling the charge liquid proportion of the micro-heat pipe. As the whole process is carried out in an enclosed small space, the liquid is isolated from the environmental air during the whole operation process, thus ensuring the working efficiency of the micro-heat pipe. The method avoids the step of vacuuming, and only requires two injectors and a heating device for the operation; the usage amount of the silicone sealant and the working liquid is small; the control method is simple, requiring only the heating temperature and the calibration of the injector to be adjusted; and the sealing is safe.

Owner:ZHEJIANG UNIV

Full-shielding valve with electromagnetic driving mechanism arranged inside

PendingCN107061840ASimple structureFix the leakPlug valvesOperating means/releasing devices for valvesStator coilElectromagnetic torque

The invention relates to a sealing execution mechanism and a full-shielding valve with an electromagnetic driving mechanism arranged inside and including the sealing execution mechanism, and belongs to the technical field of fluid machines. The full-shielding valve comprises a full-shielding assembly, a stator and a rotor. The full-shielding assembly comprises a shielding sleeve, a shielding sleeve end cover and a heat insulation support. The full-shielding assembly can bear fluid pressure in a valve body, and a formed pressure bearing cavity isolates a valve rod and the interior of the valve body from the outside. A dynamic sealing point of the valve rod is eliminated, and full-shielding sealing is achieved. A rotary electromagnetic field generated when a stator coil is powered on and a magnetic field generated by a rotor permanent magnet interact, generated electromagnetic torque penetrates the full-shielding assembly to be transferred to the rotor in a non-contact manner, and the rotor directly drives the valve rod to rotate through a transmission key. Effective driving of the valve under the full-shielding sealing condition is achieved.

Owner:BEIJING UNIV OF CHEM TECH

Ignition laser

InactiveUS8833323B2Long lastingSafe and reliable sealingCombustion enginesGas turbine plantsCombustion chamberEngineering

An ignition laser, includes a laser-active solid-state body, a housing and a combustion chamber window, the housing having an inner sleeve and an outer sleeve. An insert is provided between the inner sleeve and the outer sleeve, the insert and the combustion chamber window being joined sealingly and integrally.

Owner:ROBERT BOSCH GMBH

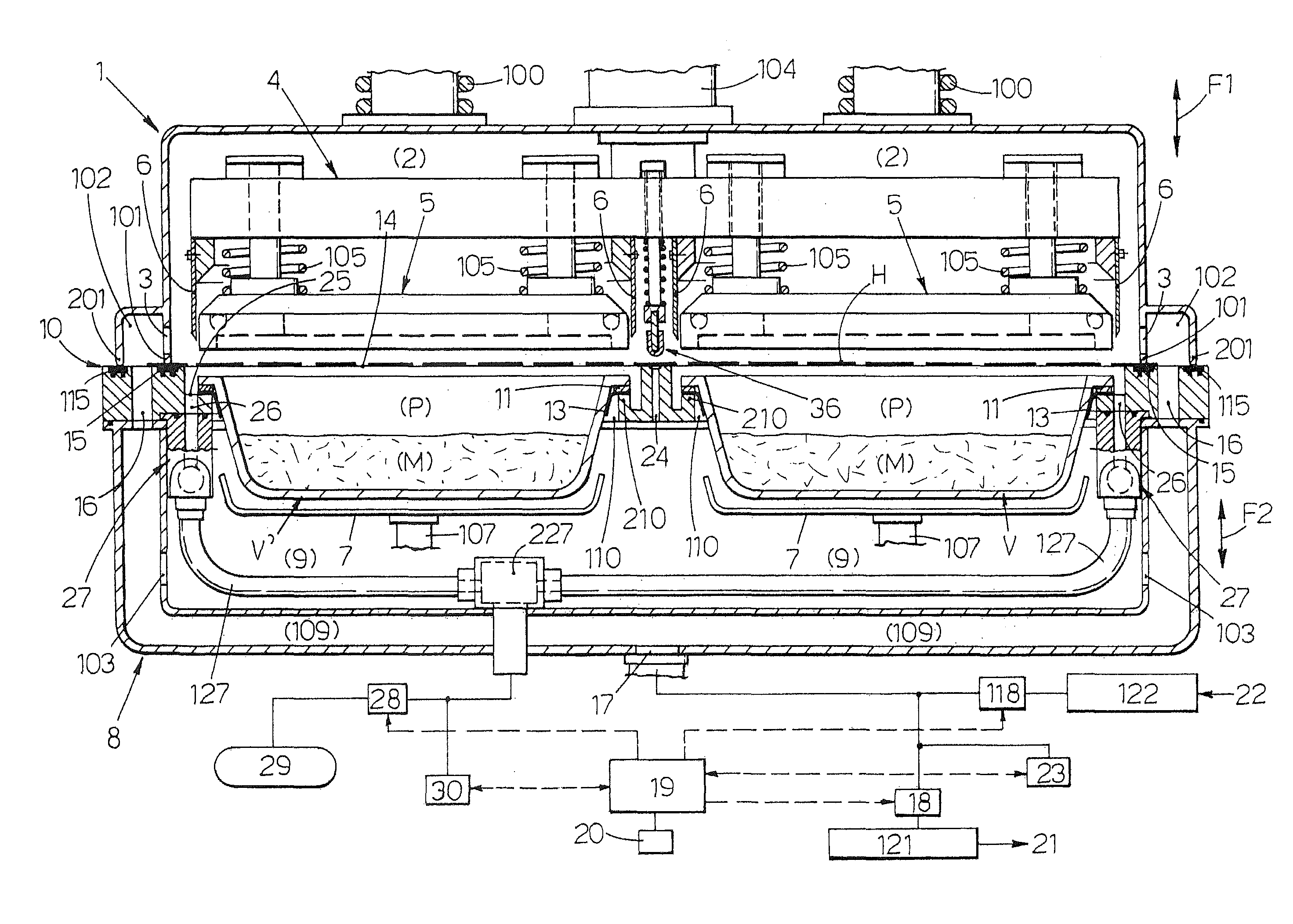

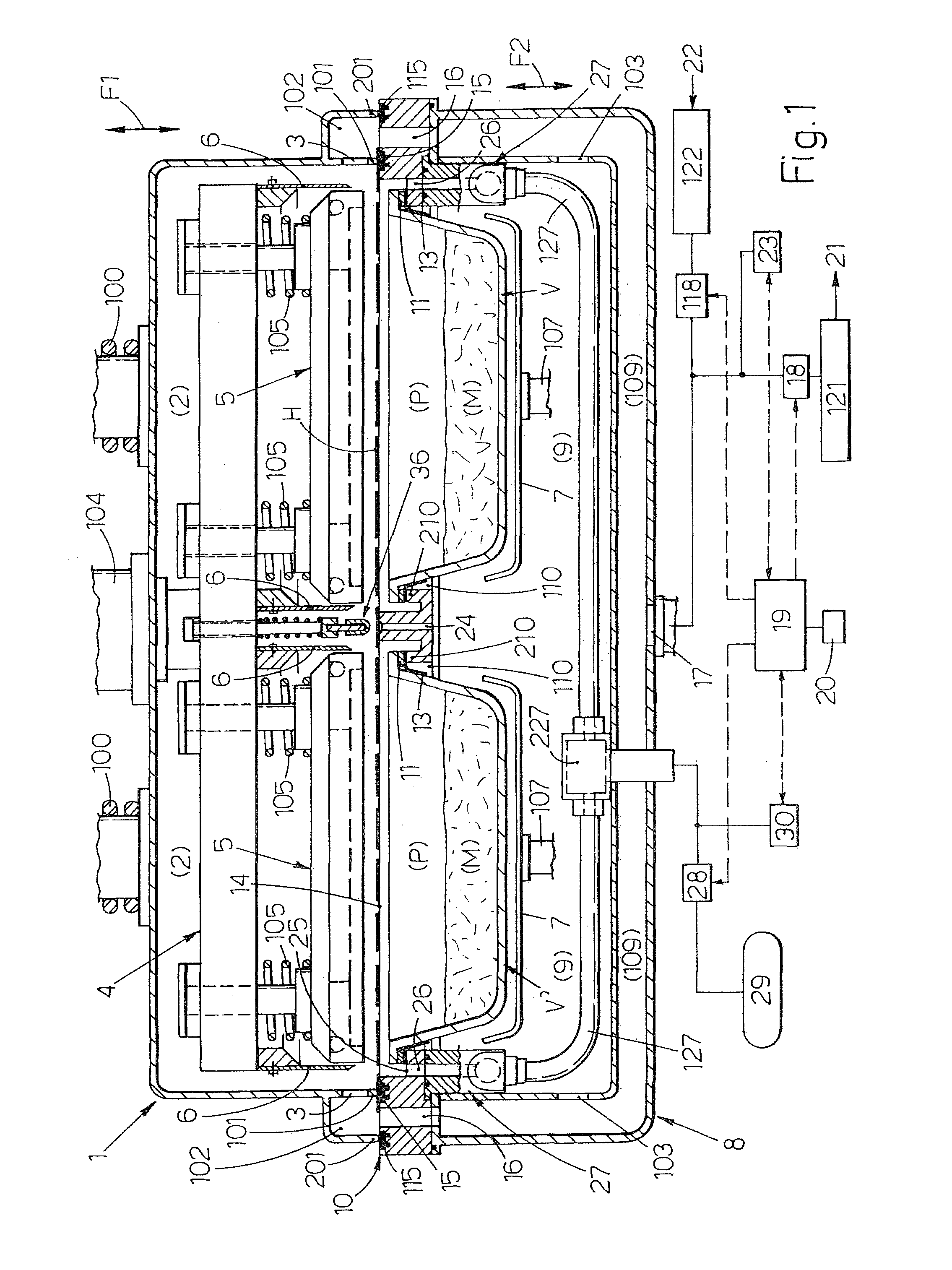

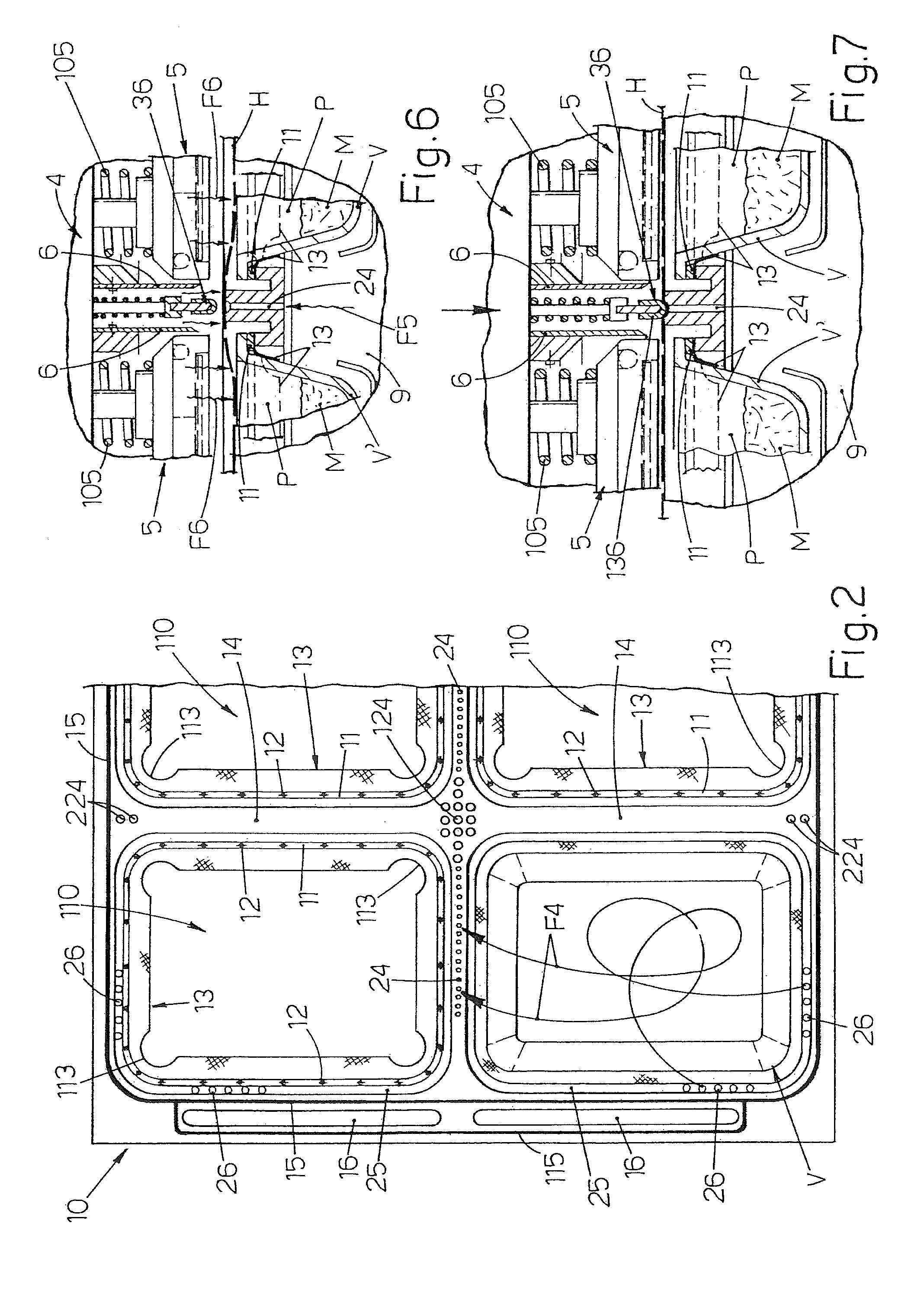

Apparatus with facing bell members, for modified atmosphere packaging of products placed in trays

ActiveUS20150210413A1Safe and reliable sealingPromote resultsPackaging under vacuum/special atmosphereShock-sensitive articlesEngineeringModified atmosphere

Apparatus with facing bell members, for modified-atmosphere packaging of products placed in trays, which comprises means for the cyclic positioning of an extended portion of bather film between the said two open bell members and over trays housed with gasket means in the seats of the bottom bell member, which comprises means for moving the said bell members towards each other so as to close between them the said film and to close under and at a suitable distance from this latter the edge of the tray, apparatus of the type that when the bell members are closed, they form therein two volumes not directly communicating, one of which is formed by the internal chambers of the same bell members that communicate with each other via circuits, for example peripheral, while the other volume is formed by the main chambers of the trays with the product, wherein the said chambers are connected with a portion of their perimeter to holes and to a dedicated circuit for the controlled introduction of process gases and are connected with another portion of their same perimeter to discharge holes for implementation of the air extraction and washing steps, comprising internal valve means to enable the said discharge holes of the main chambers of the trays to communicate, or not, with the said internal chambers to balance the differences in pressures between the said two volumes during the exchange cycle of the gases required to produce packaging of the type known as MAP.

Owner:GRUPPO FABBRI VIGNOLA

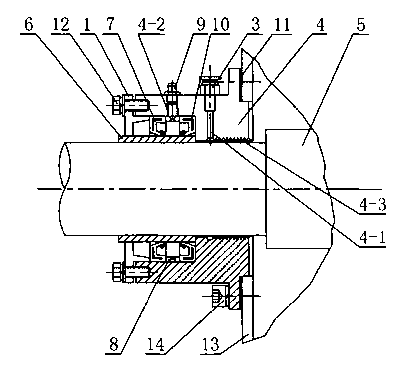

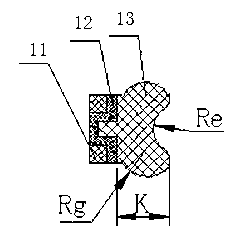

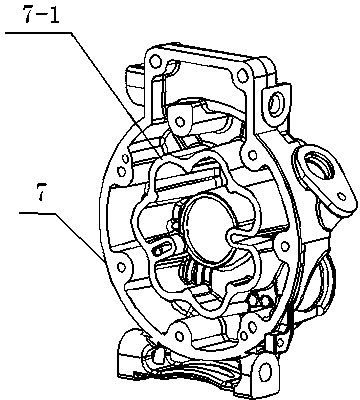

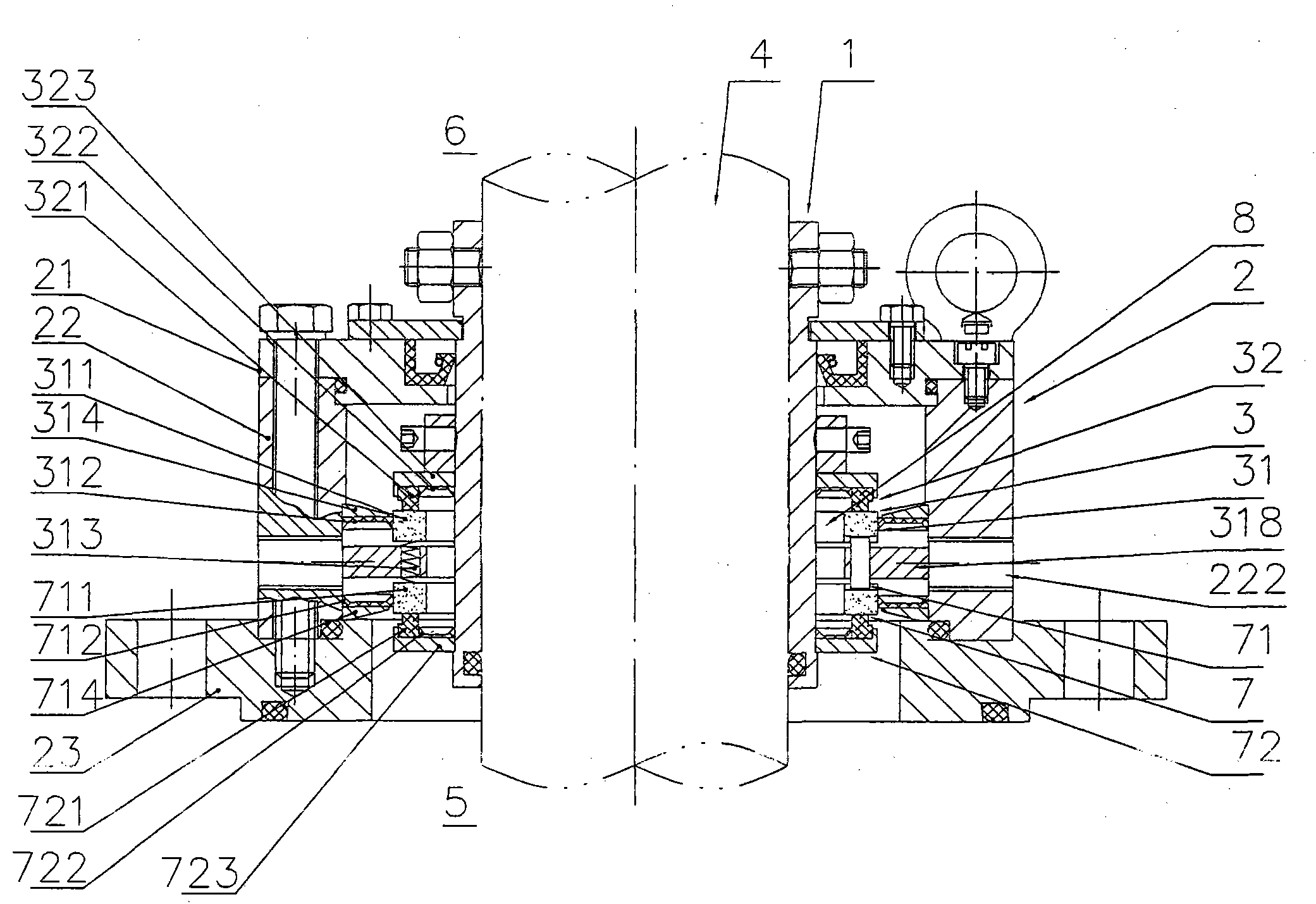

Novel sealing mechanism for shaft end of mixing machine

InactiveCN103122999AIncrease the airtight structureImprove sealingEngine sealsEngineeringMechanical engineering

The invention relates to a mixing machine, in particular to a novel sealing mechanism for a shaft end of the mixing machine. The novel sealing mechanism for the shaft end of the mixing machine comprises a sealing seat (4) and a sealing cover (1), wherein the sealing seat (4) and the sealing cover (1) are installed on a main shaft (5) in a sleeved mode. The novel sealing mechanism further comprises an abrasion-resistant sleeve (6), a first oil seal (7), a space ring (8) and a second oil seal (10). The sealing cover (1) is connected on the end face of one side of the sealing seat (4). A through hole (4-1) is formed in the sealing seat (4), an air inlet connector (3) is arranged at the position of the through hole (4-1), the sealing cover (1), the first oil seal (7) and the second oil seal (10) are installed on the outer diameter of the abrasion-resistant sleeve (6) in a sleeved mode, the outer diameters of the first oil seal (7) and the second oil seal (10) are installed in a hollow cavity on the front portion of the sealing seat (4) in a clamping mode, and the space ring (8) is installed between the first oil seal (7) and the second oil seal (10). The novel sealing mechanism is provided with multiple and various seals, the phenomenon of material leakage or powder injection does not occur, a sealing effect is good, and sealing is safe and reliable.

Owner:LIYANG HONGYUE MASCH MFG CO LTD

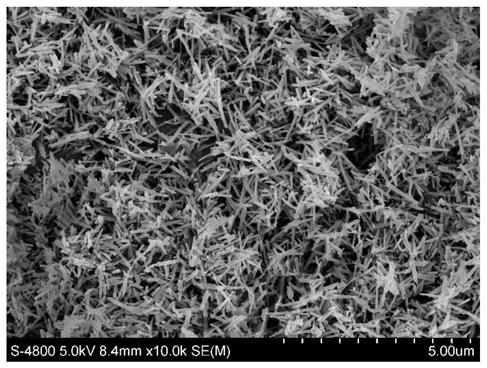

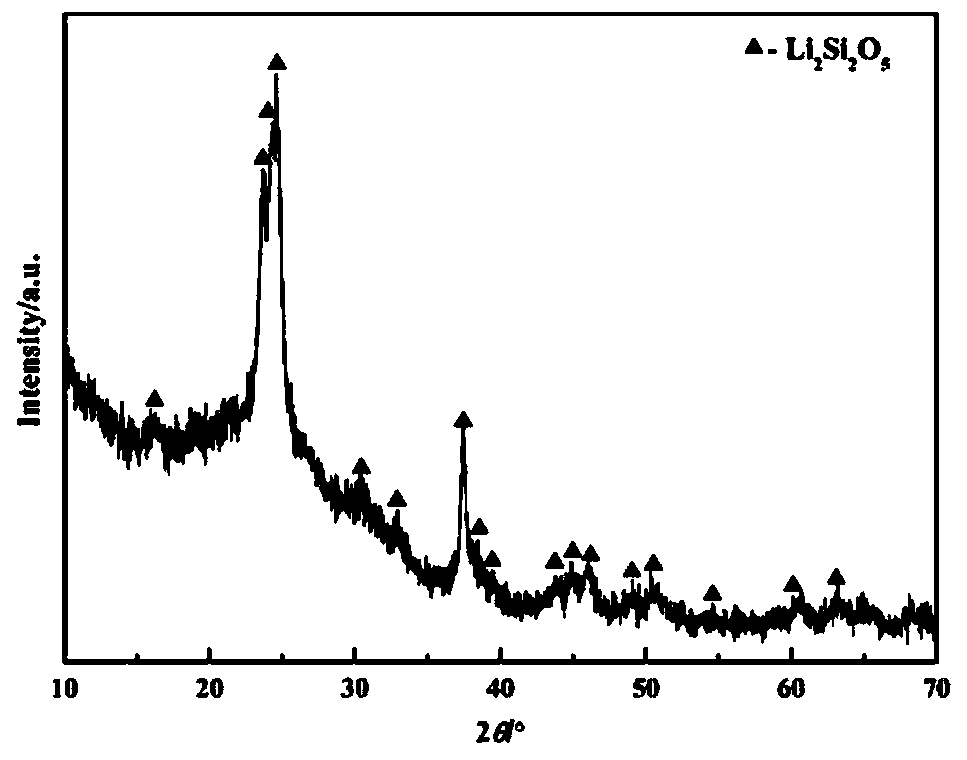

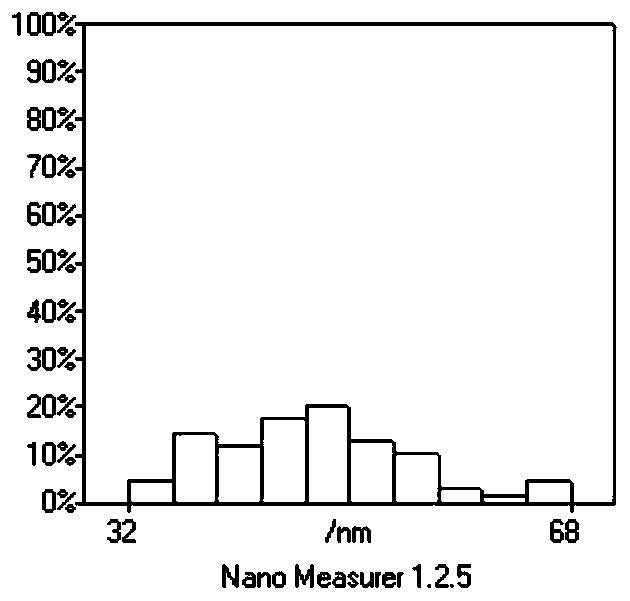

Preparation method of pure-phase Li2Si2O5 rodlike crystal

InactiveCN110079857AImprove structural strengthNo pollution in the processPolycrystalline material growthFrom normal temperature solutionsDistilled waterWhite powder

The invention discloses a preparation method of a pure-phase Li2Si2O5 rodlike crystal. After LiOH.H2O is dissolved in distilled water, tetraethyl orthosilicate is dropwise added, the mixture is uniformly mixed, a mixed solution is obtained, the mixed solution is placed in a hydrothermal reaction liner to react to obtain a white precipitate, the white precipitate is subjected to suction filtration,a filter cake is obtained, the filter cake is dried again, white powder is obtained and ground, and the pure-phase Li2Si2O5 rodlike crystal is obtained after heat treatment. The method is simple to operate, low in equipment requirement, wider in parameter range, easy to control and high in yield, the price of raw materials is low, the size of the obtained rodlike crystal is adjustable, the structural strength is high, and the method is suitable for mass commercial promotion.

Owner:XI AN JIAOTONG UNIV

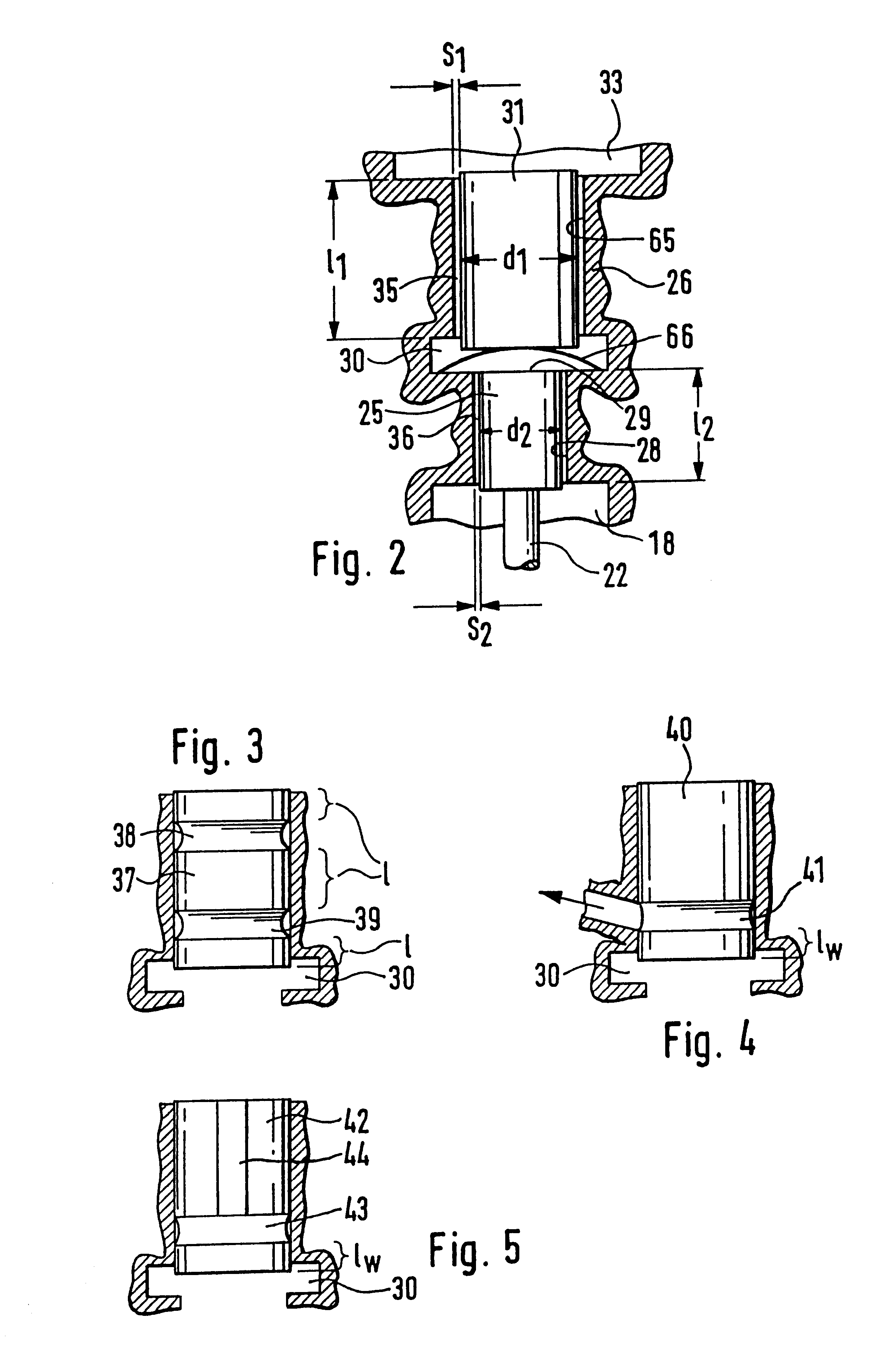

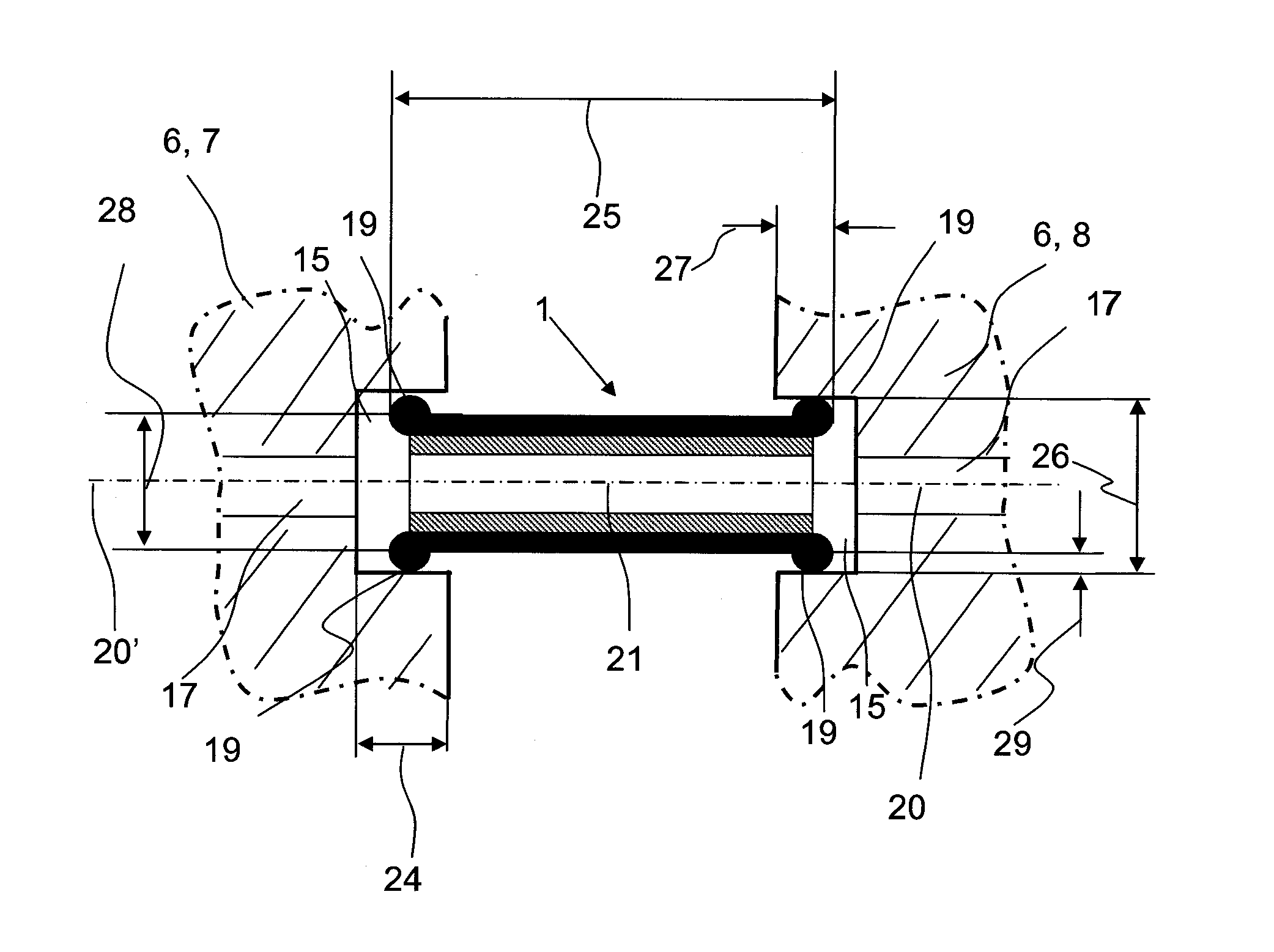

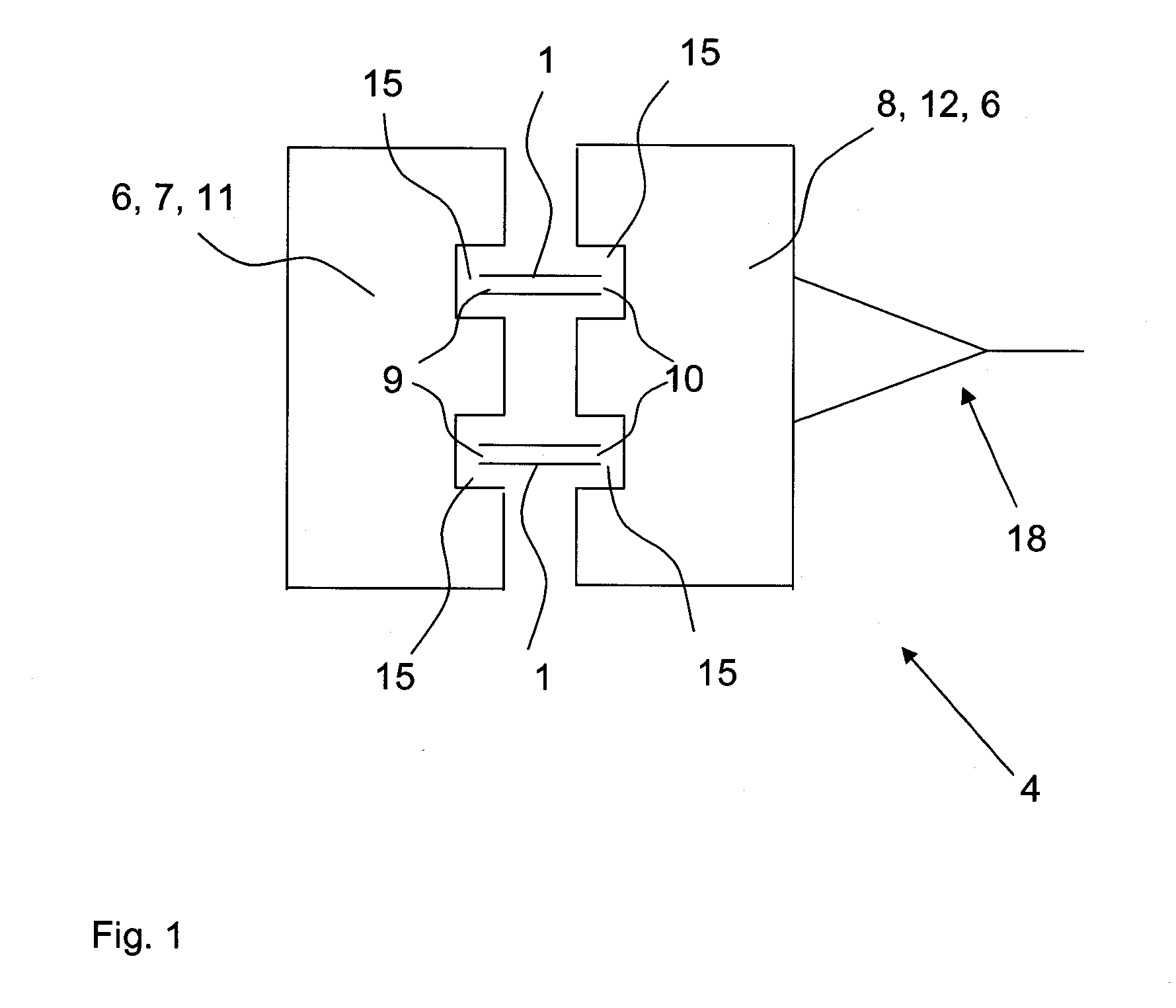

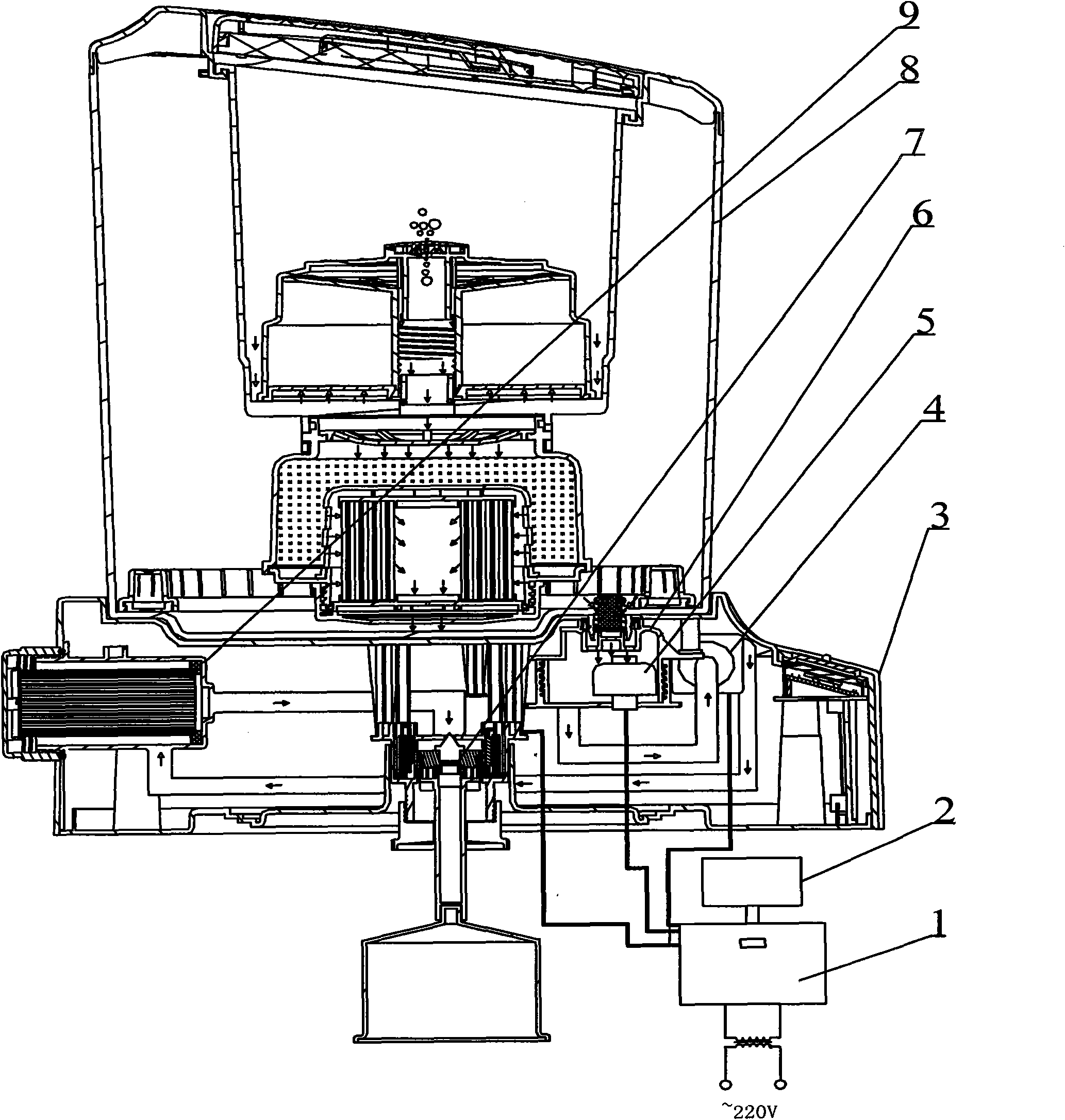

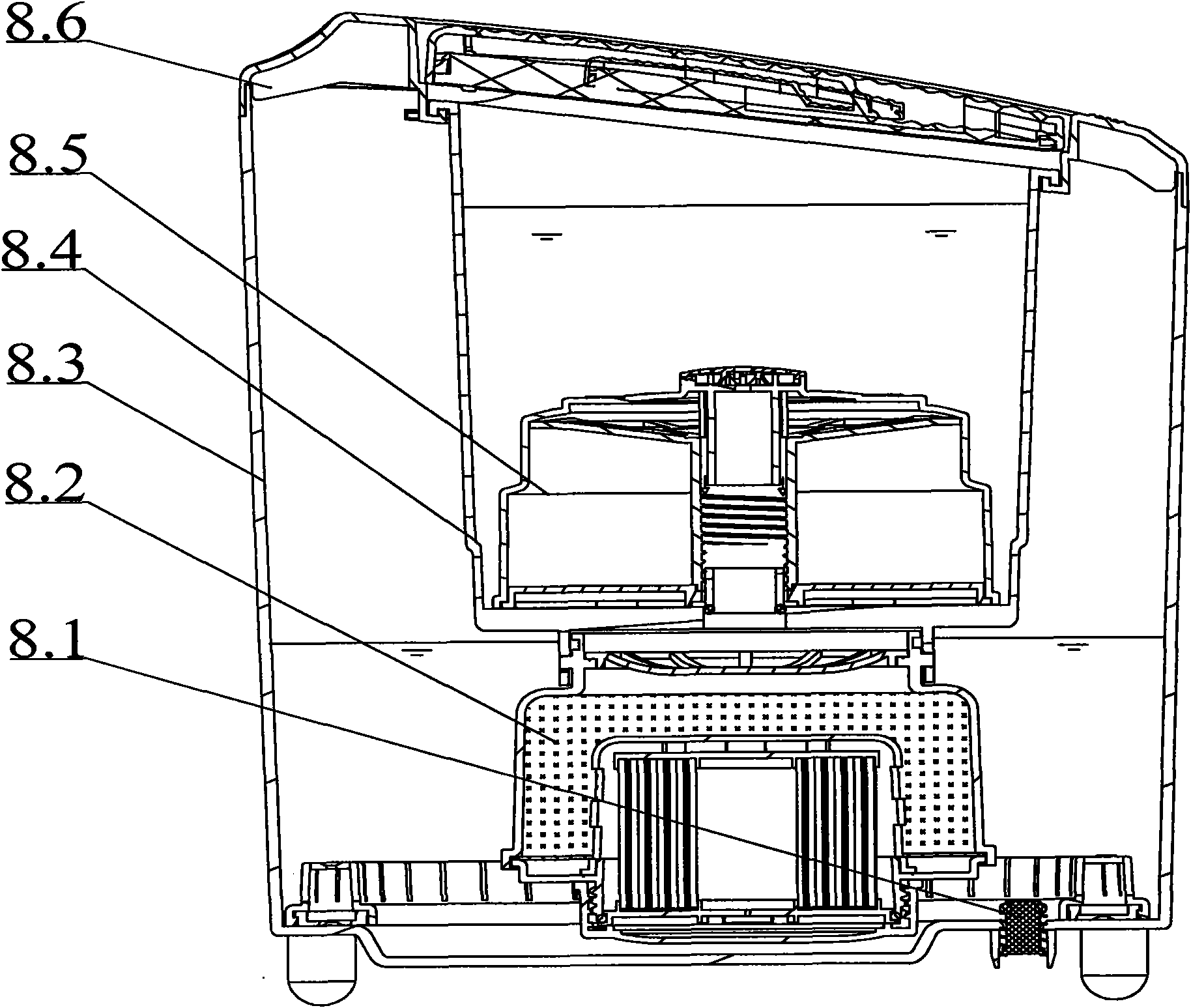

Respirator or anesthesia apparatus

InactiveUS20110168176A1The method is simple and reliableSmall space requirementRespiratorsInhalatorsRespiratorBreathing system

A pneumatic connection for connecting two modules (6) with one another into a simple and reliable pneumatic connection of modules (6) of the respirator or anesthesia apparatus (5). A small installation space needed is provided in a respirator or anesthesia apparatus (5), including at least two modules (6), e.g., a blower, a breathing system, a mixer and / or an anesthetic evaporator (11, 12, 13, 14). The at least one pneumatic connection includes a connection tube (1), which is surrounded with a first end (9) by a first module (7) and with a second end (10) by a second module (8), so that there is a pneumatic connection through the connection tube (1) between the first module (7) and second module (8). The reliable pneumatic connection is also established when the modules (6) have an offset in their alignment in relation to one another.

Owner:DRAGERWERK AG

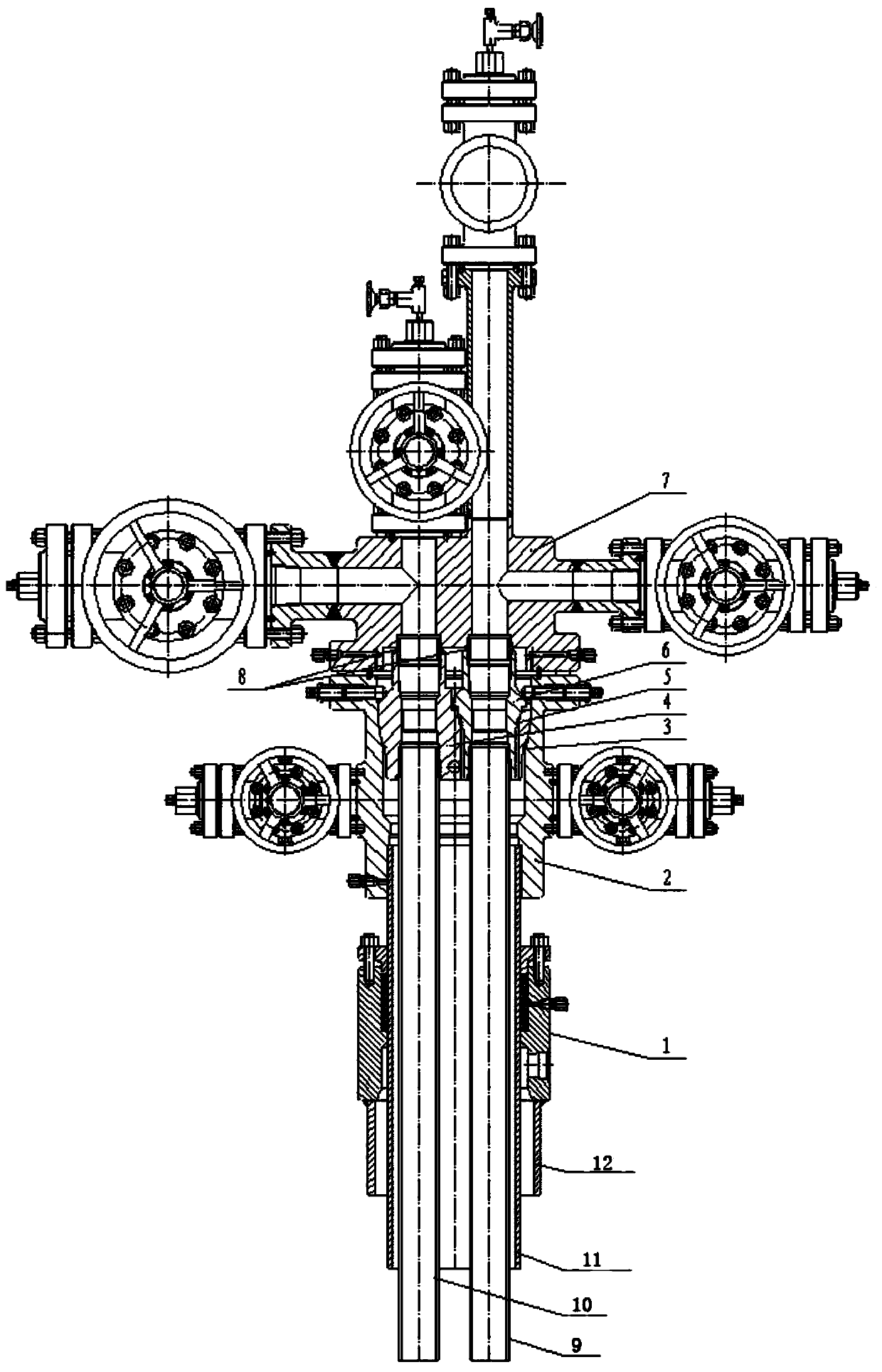

Full-metal seal dual-pipe steam injection well head device used for inclined shaft

InactiveCN110656908AThe sealing structure is safe and reliableCounteracts the effects of radial forcesFluid removalSealing/packingThermodynamicsEngineering

The invention discloses a full-metal seal dual-pipe steam injection well head device used for an inclined shaft, and relates to the technical field of oil exploitation. A production casing pipe is sleeved with a surface layer casing pipe, the top of the surface layer casing pipe is welded with a simple casing pipe head assembly, the top of the production casing pipe is welded with an oil pipe headfour-way assembly, a four-way inner cavity of the oil pipe head four-way assembly is provided with a main hanger, and a main hanging metal seal assembly, a main hanger inner cavity is provided with asub hanger and a sub hanger metal seal assembly, a first oil pipe and the main hanger are connected to the four-way inner cavity of the oil pipe head four-way assembly, the second oil pipe and the sub hanger are connected into the main hanger inner cavity, a steam injection tree assembly is arranged above the oil pipe head four-way assembly, metal seal rings are arranged in a top groove of the main hanger and a top groove of the sub hanger, the metal seal rings are connected with the bottom of a vertical channel of the steam injection tree assembly, and the main hanger and the sub hanger areprovided with automatic guide-right centering positioning structures, the dual-pipe steam injection function is achieved, and the seal effect under the inclining state is ensured.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Novel water purifier for split instant filtering water dispenser

InactiveCN102115268AFresh drinking waterDrinking water healthMultistage water/sewage treatmentEnvironmental engineeringPurchase cost

The invention discloses a water purifying device, which comprises a water purifying component, a water pump, a rear filter element and an electronic floating ball switch for controlling water discharge, which are connected in series in turn by a water circuit, and is characterized in that the water purifying component, the water pump, the rear filter element and the electronic floating ball switch are arranged respectively and independently on a base. The water purifier for the split instant filtering water dispenser has the characteristics of convenience for detachment, cleaning and adding water, small volume, low purchase cost, simple structure and the like.

Owner:QINYUAN GRP CO LTD

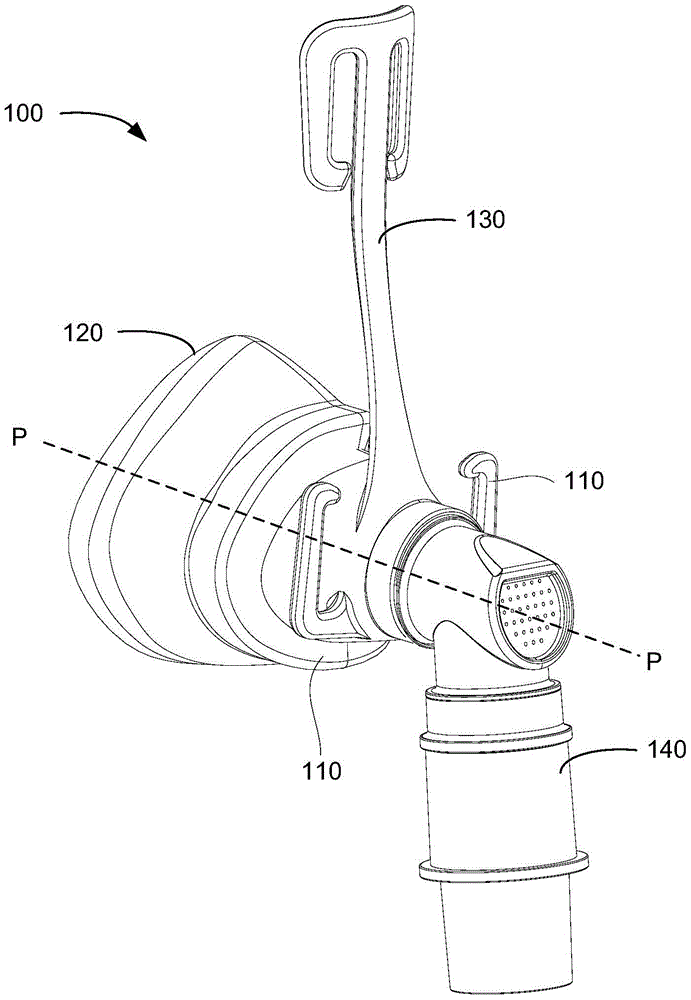

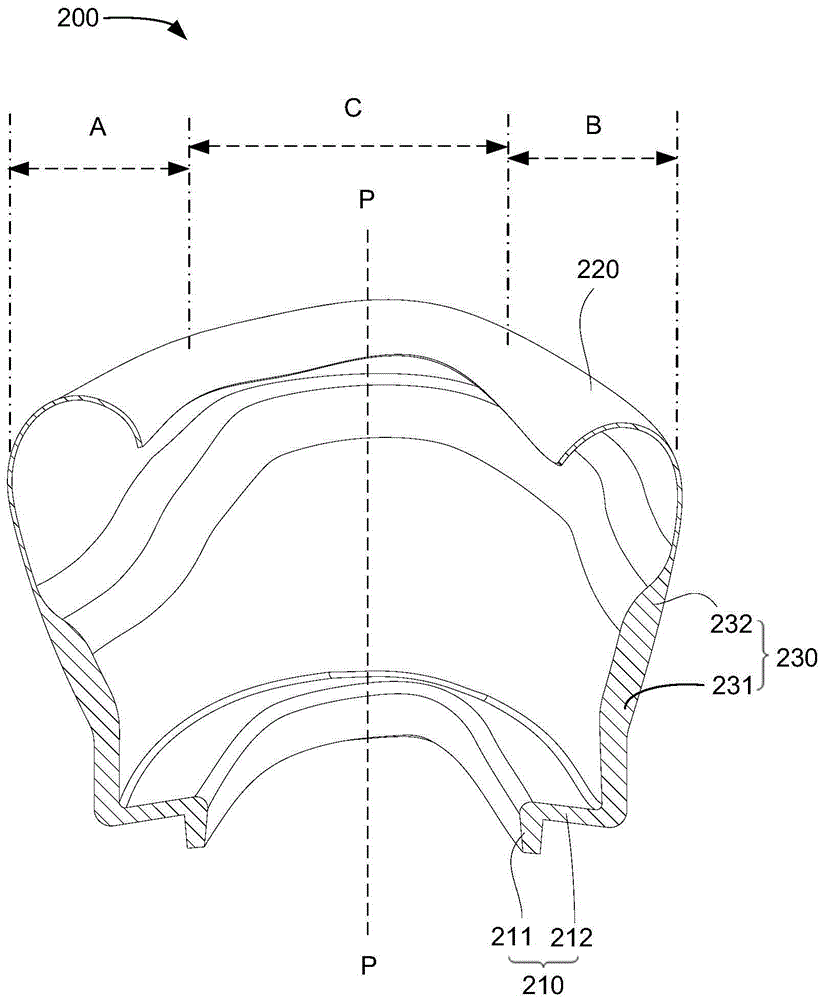

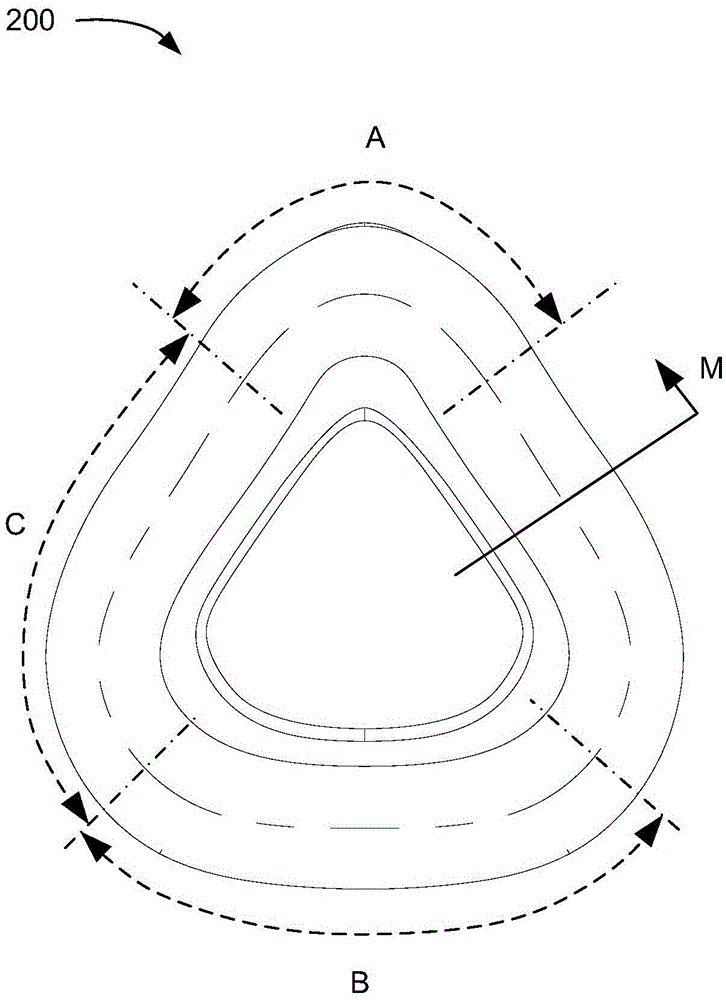

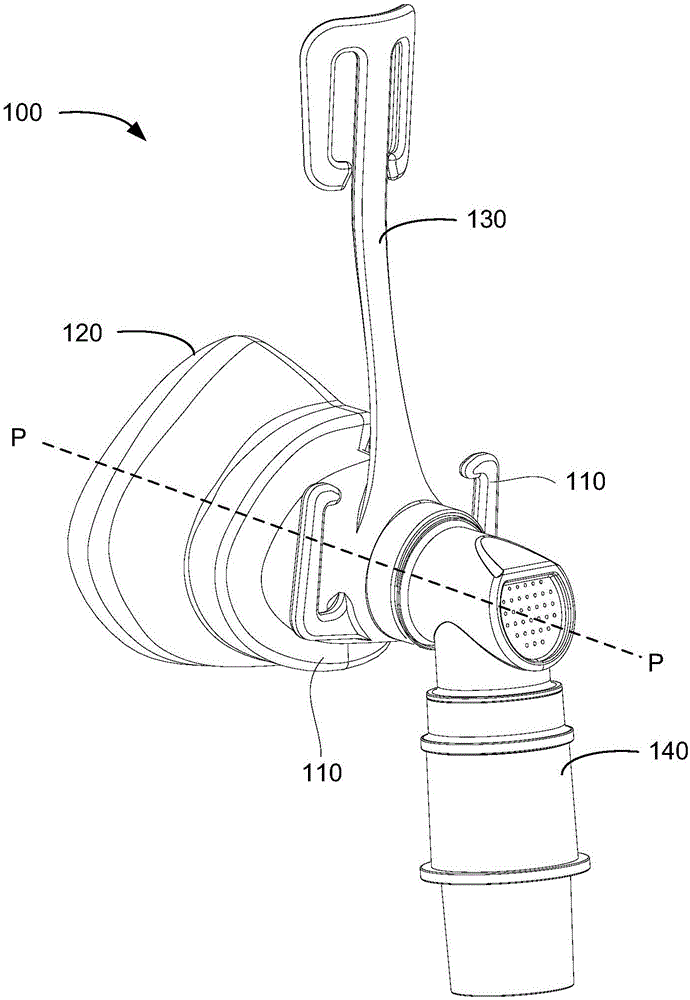

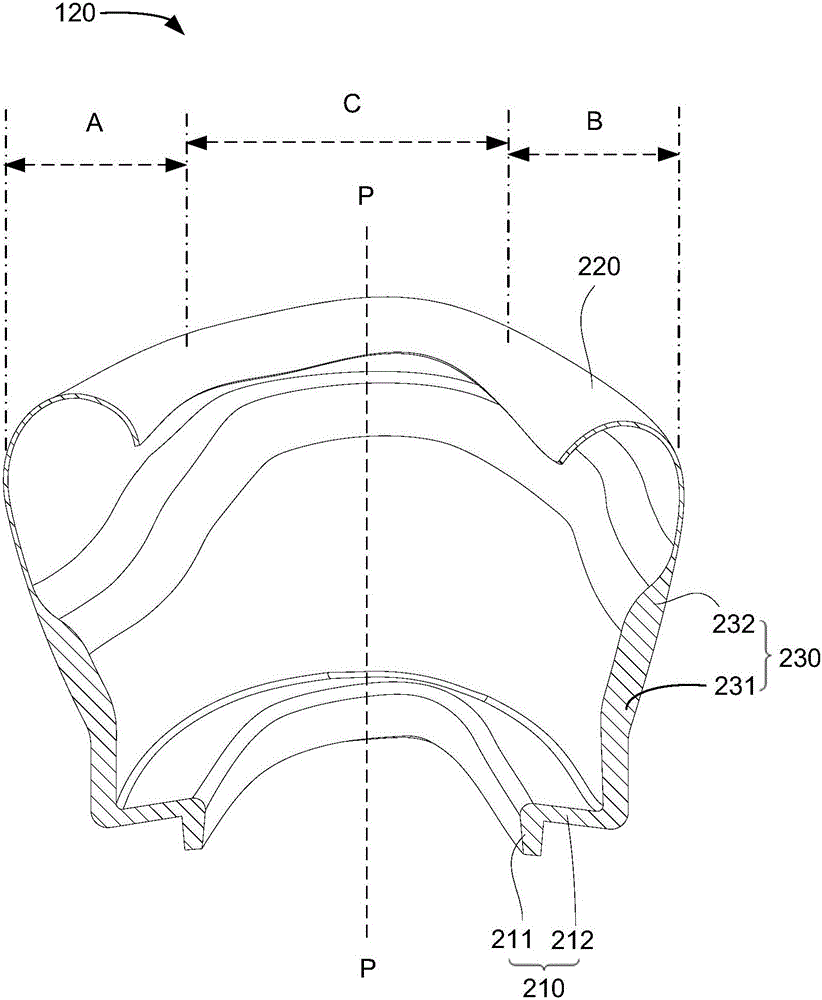

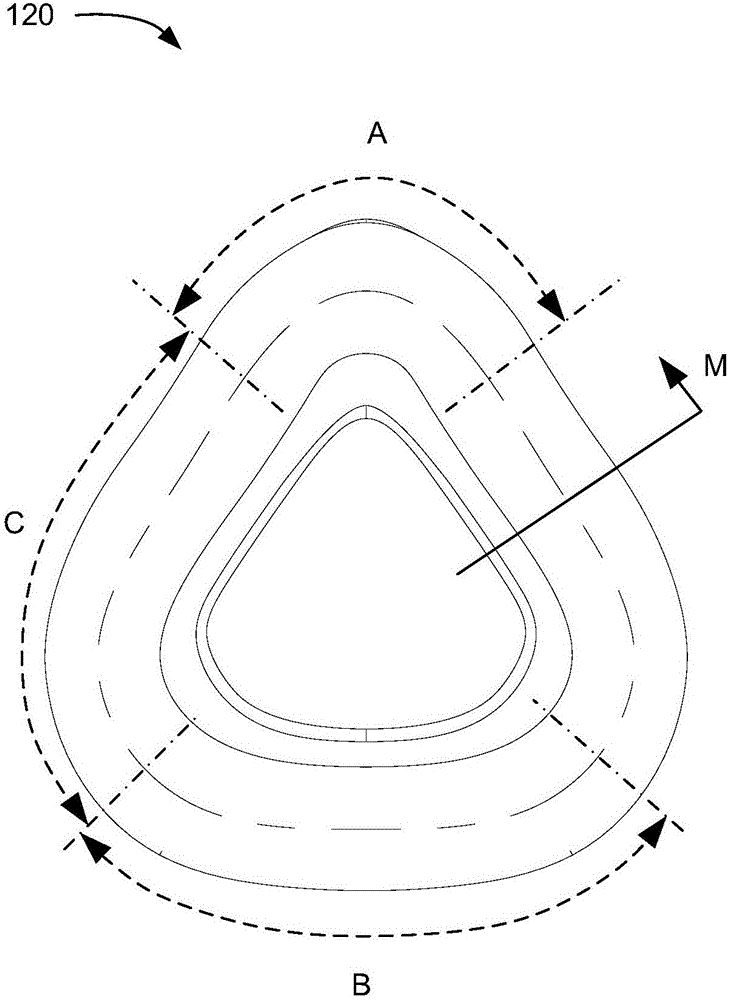

Liner for breathing mask and breathing mask

InactiveCN105413035AEasy to manufactureEasy to cleanRespiratory masksMedical devicesWide areaEngineering

Owner:BMC MEDICAL

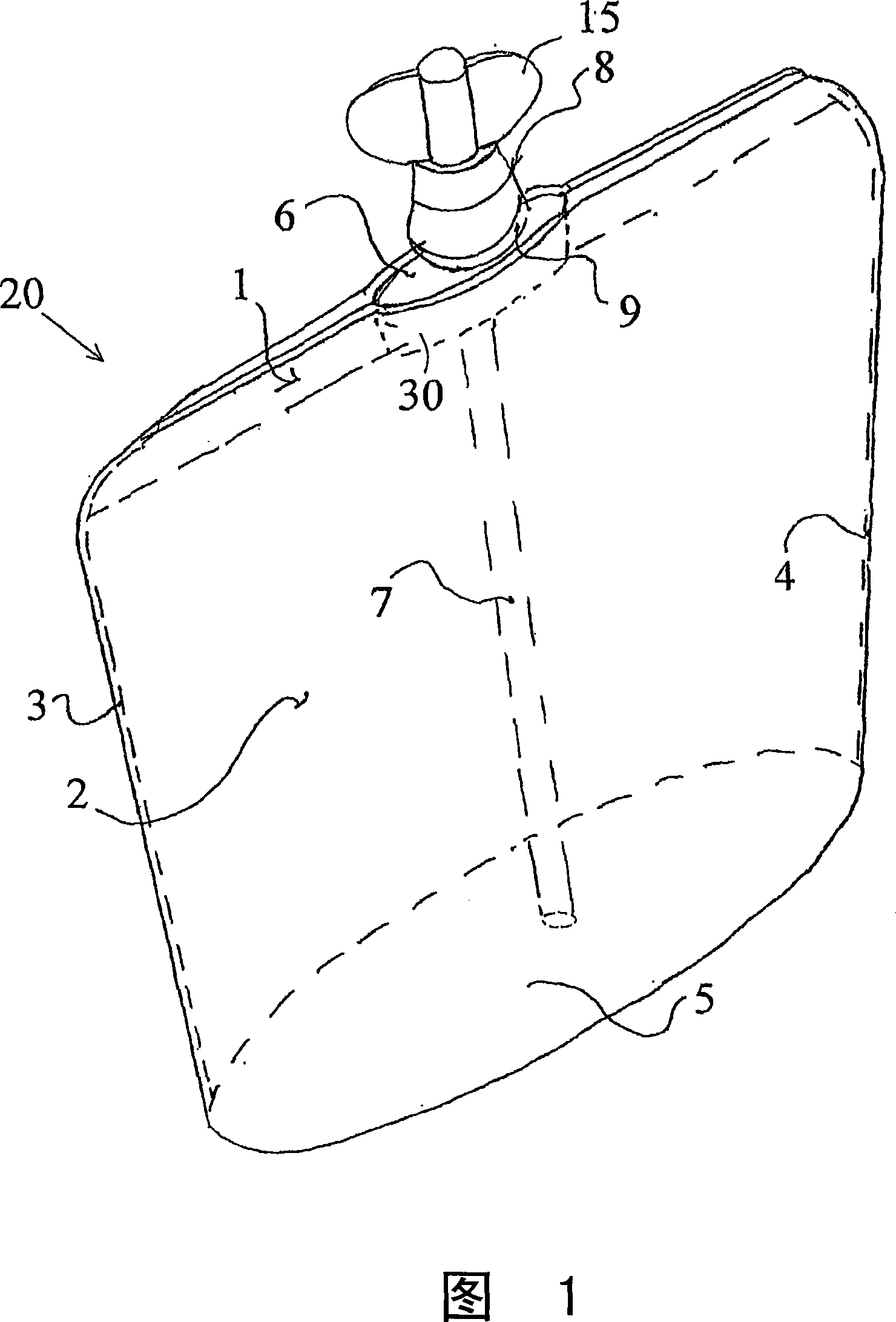

Flexible stand-up pouch with integral fitment and internal straw

InactiveCN101203440ASafe and reliable sealingEasy to openCapsDispensing apparatusDrinking strawUrology

A fitment for a liquid containing pouch wherein the fitment is attached to the top portion of the pouch by sealing the top portion of the pouch together and to the sealing portion of the fitment. The fitment having a straw therein and a removeable cap for sealing the liquid in the pouch. The cap can be removed to allow access to the straw and the liquid in the pouch. The cap ban be replaced on the fitment to reseal the pouch. Since the straw is already in the fitment it is easier to use than liquid containing pouches where the straw has to be inserted into the pouch by breaking a seal. Further the straw in the fitment helps prevent spills and injuries associated with straws having to break the seal of the pouch.

Owner:WFCP LLC

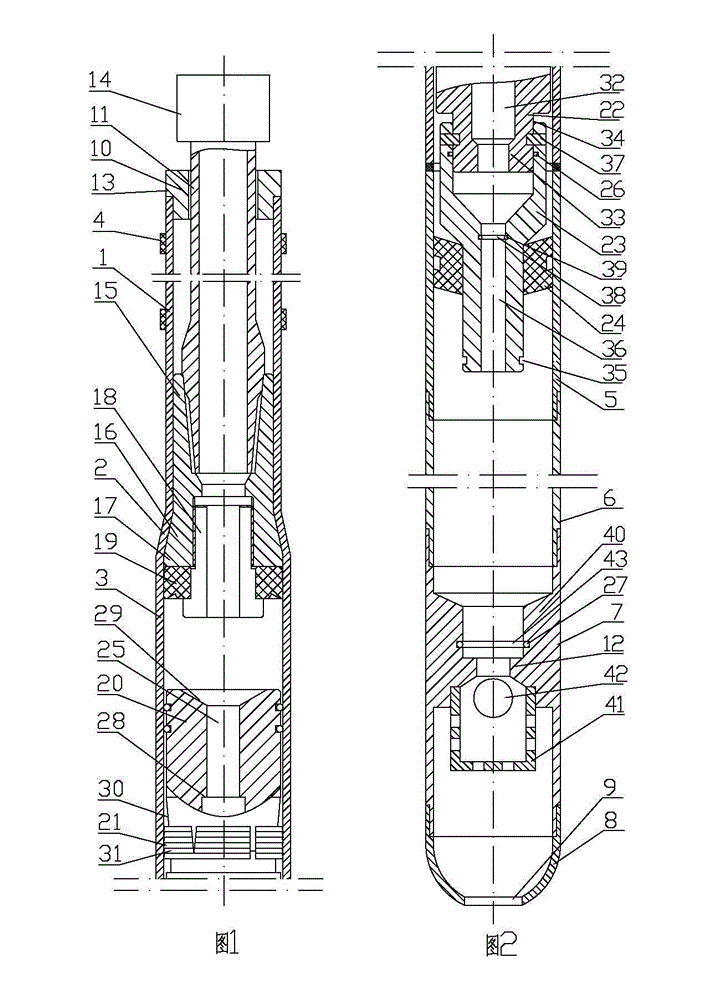

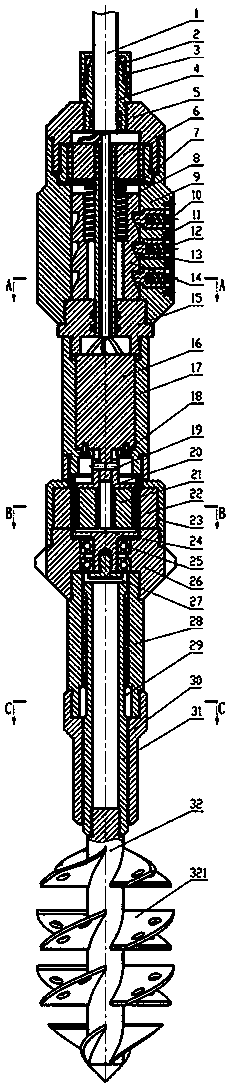

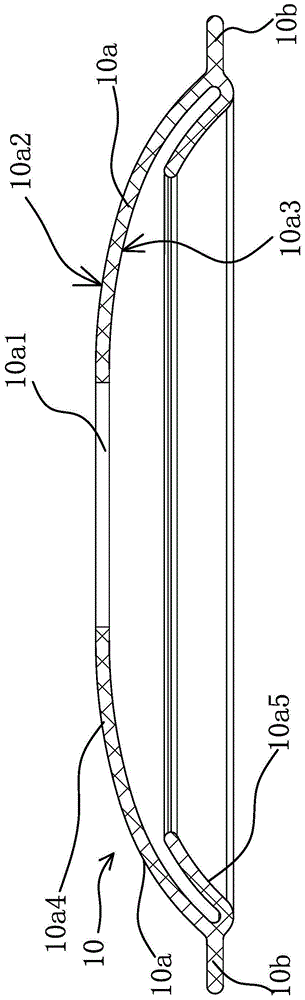

Well drilling fluid mixing and drifting tool

ActiveCN108533201AReal-time feedback on load conditionsRealize the well effectBorehole/well accessoriesAutomatic control for drillingDrive shaftWell drilling

The invention relates to a well drilling fluid mixing and drifting tool, and belongs to the field of well drilling and logging in petroleum and natural gas industries. According to the well drilling fluid mixing and drifting tool, a logging instrument is effectively trapped into the downhole, and drifting operation is effectively completed. According to the technical scheme of the well drilling fluid mixing and drifting tool, a cable core at one end of a cable is connected with an electromagnet and a motor in a conducting mode, and a cable core at the other end of the cable is connected with aground electronic control platform in a conducting mode; the middle of the outer circle of a locking connector is in screw thread connection with the lower portion of an inner cavity of a locking nut, and the lower portion of the outer circle of the locking connector is in screw thread connection with the upper portion of an inner hole of a connecting head; the electromagnet is mounted on the upper portion of an inner cavity of an electromagnet sealing seat; an anchor jaw and an anchoring spring are overall arranged in a radial through hole in a centering wing of an anchor body; the upper endof an input magnetic tile seat and an output shaft of the motor are fixed through a transmission pin, the lower end of an inner cavity of an output magnetic tile seat is in screw thread connection with the upper end of the outer circle of a centering cylinder, and the upper end of a mixing head is in screw thread connection with the lower end of a transmission shaft. According to the well drilling fluid mixing and drifting tool, viscous well drilling fluid is electrically mixed, and thus the drifting effect is effectively achieved; and a magnetic driving technology is adopted, the motor and the electromagnet are sealed in a static sealing mode, and thus sealing is safe and reliable.

Owner:XIHUA UNIV

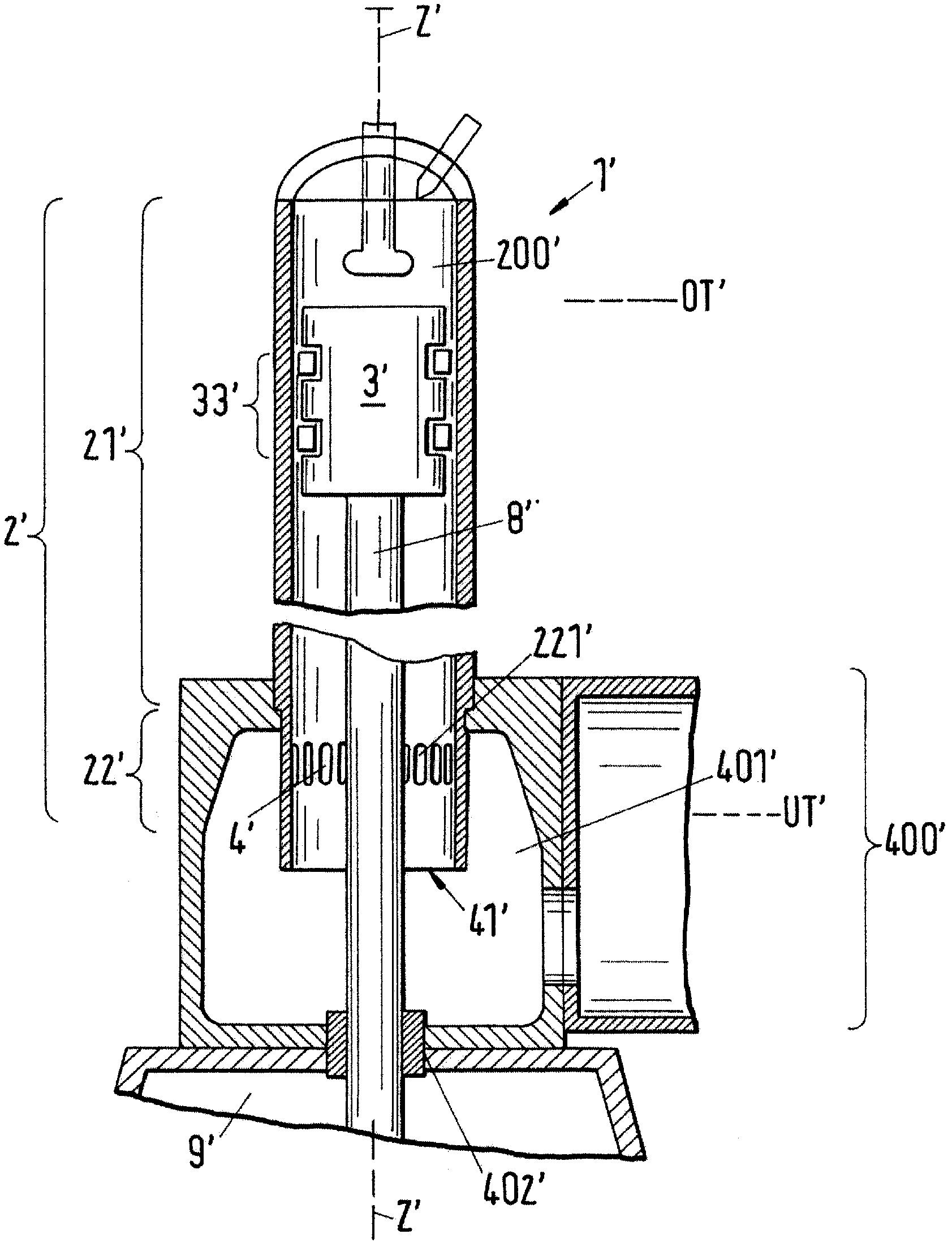

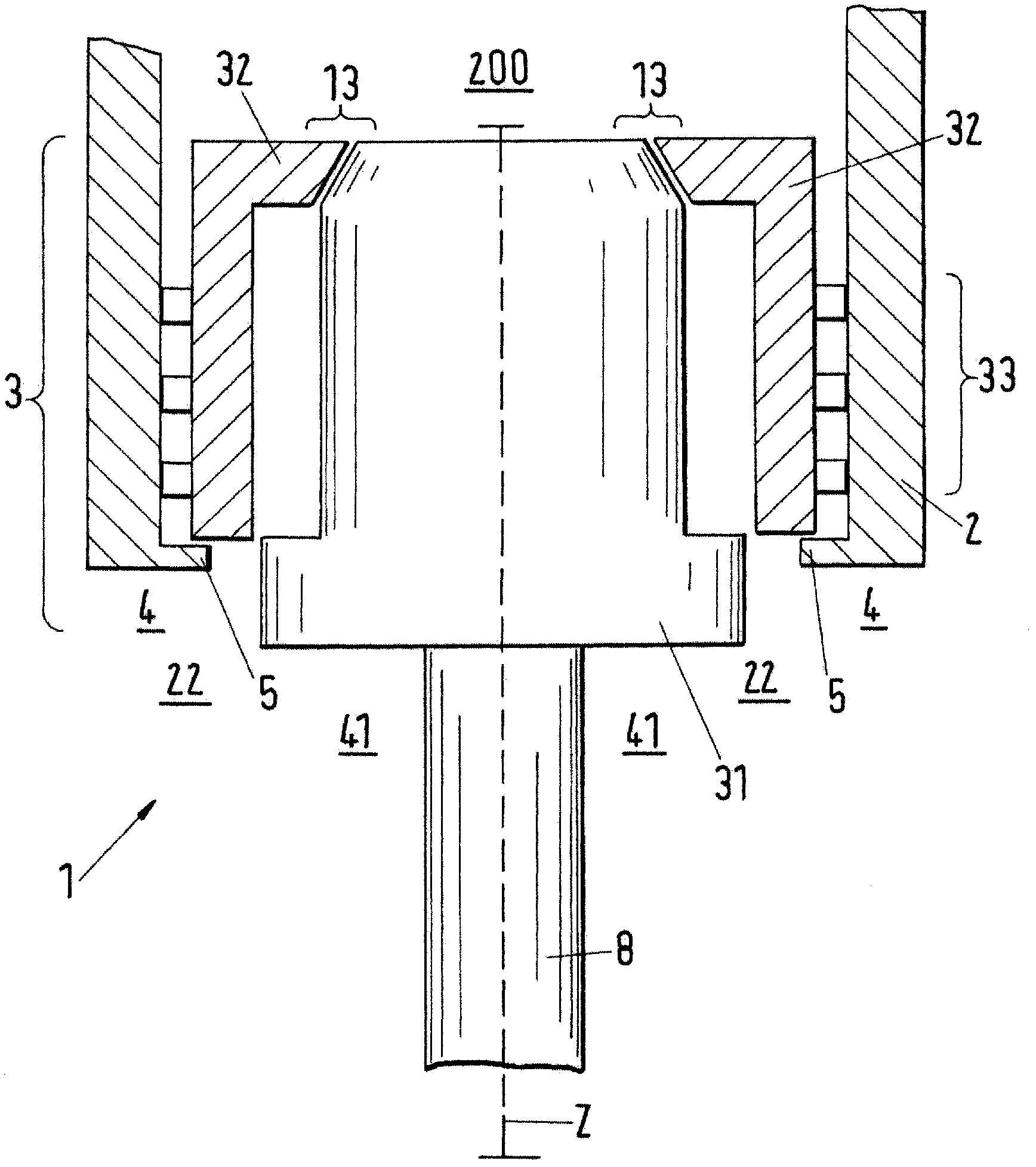

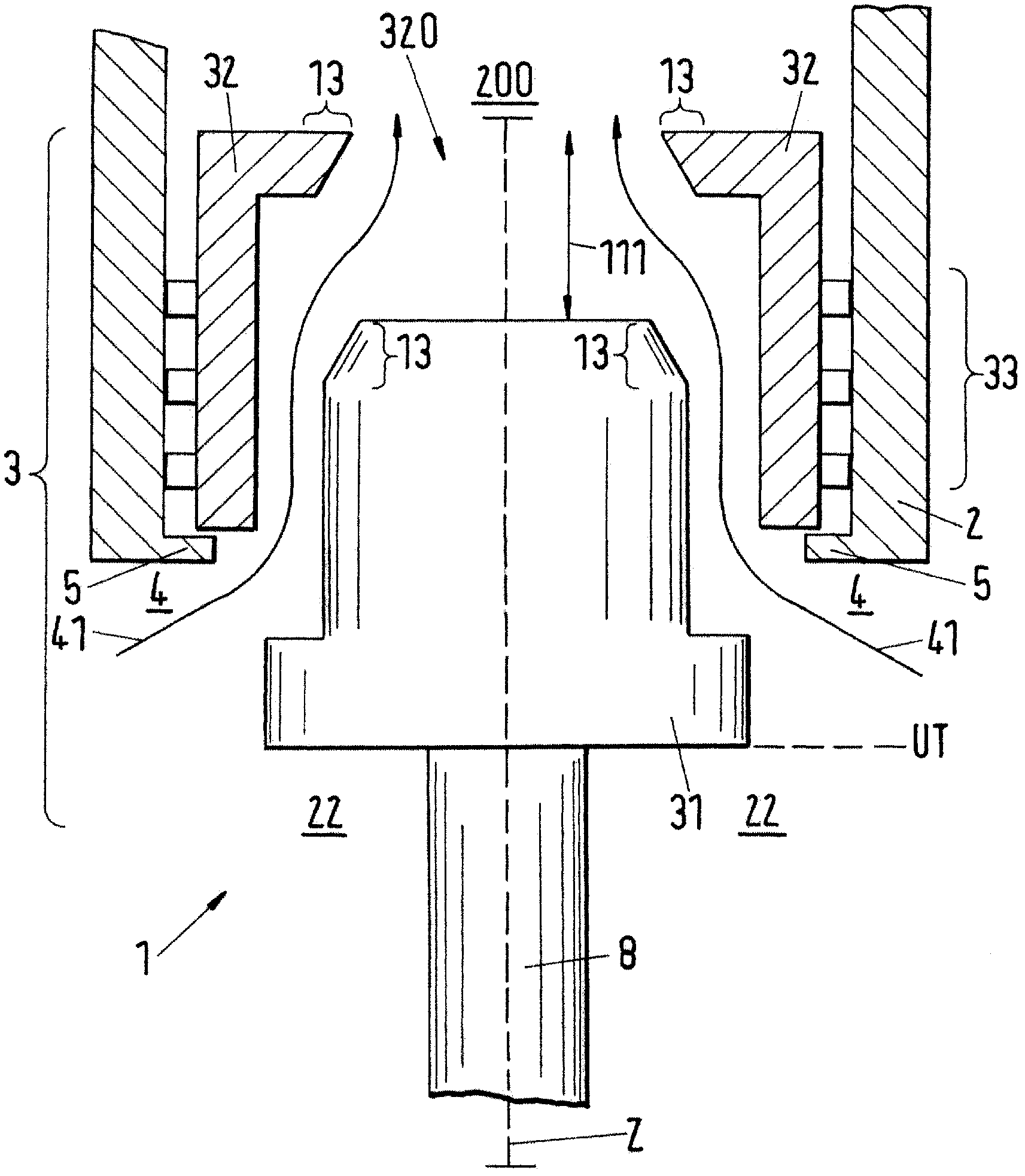

Cylinder assembly and piston for a longitudinally flushed stroke piston combustion engine

InactiveCN102691565AAvoid damageDamage no longer occursValve arrangementsCylinder headsCombustion chamberPiston ring

The invention relates to a cylinder assembly 1 for a longitudinally flushed stroke piston combustion engine and especially to a large-size two-stroke diesel generator moving slowing and flushing longitudinally. The cylinder assembly 1 includes an air cylinder provided with a combustion room 200 and an entrance area 22. A piston 3 moving back and forward long a cylinder axis Z is installed between an upper dead point and a lower dead point in the cylinder 2. And a flushing air entrance 4 is arranged in the cylinder 2 to facilitate to lead the flushing air 4 into the combustion room 200. The cylinder arrangement comprises a piston (3) which is provided as two piece piston. A mantle piston (32) is provided with a piston ring (33), where a main piston (31) is positioned in the mantle piston. A retaining device is provided at a cylinder for the mantle piston. The rinsing air (41) is introduced from an inlet area (22) to a combustion chamber (200) by the rinsing air opening (320) of the mantle piston.

Owner:WAERTSILAE SCHWEIZ AG

Deodorizing floor drain

Owner:TAIZHOU HAITIAN BRASS MFR

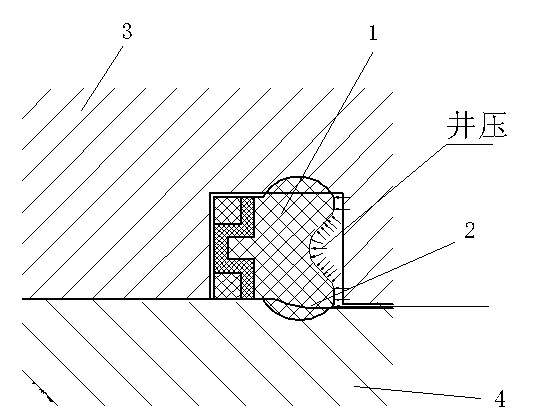

Sealing structure for side door of blowout preventer

ActiveCN102996795AEasy to assemble and disassembleReduced finish requirementsEngine sealsSealing/packingHigh pressureBlowout preventer

The invention discloses a sealing structure for a side door of a blowout preventer. The sealing structure is used for sealing a side door and a casing and comprises a sealing ring and a casing sealing surface. The sealing ring is arranged on the side door and comprises a side door sealing framework, an extruding proof steel wire gauze and sealing rubber which are vulcanized into a whole; and the casing sealing surface is opened on the casing and matched with the sealing ring. The sealing rubber is provided with a convex arc sealing surface and a concave arc sealing auxiliary surface respectively. The sealing structure can bear high pressure, the sealing is safe and reliable, the mounting and dismounting is convenient, and finish requirements for side door planes can be appropriately reduced.

Owner:SHANGHAI GASOLINEEUM & CHEM EQUIP +1

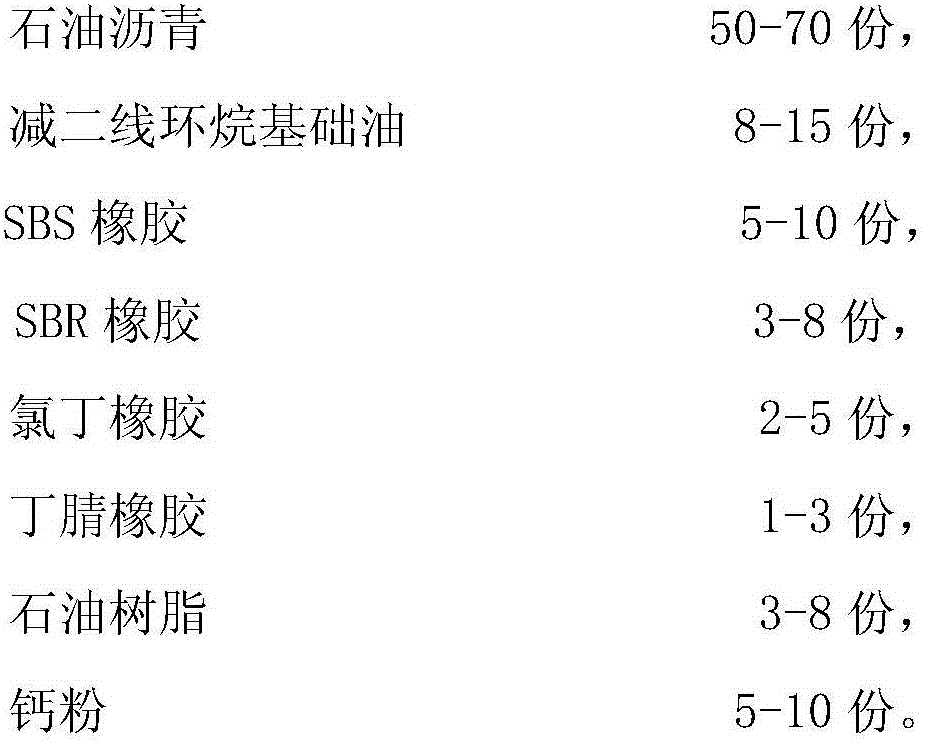

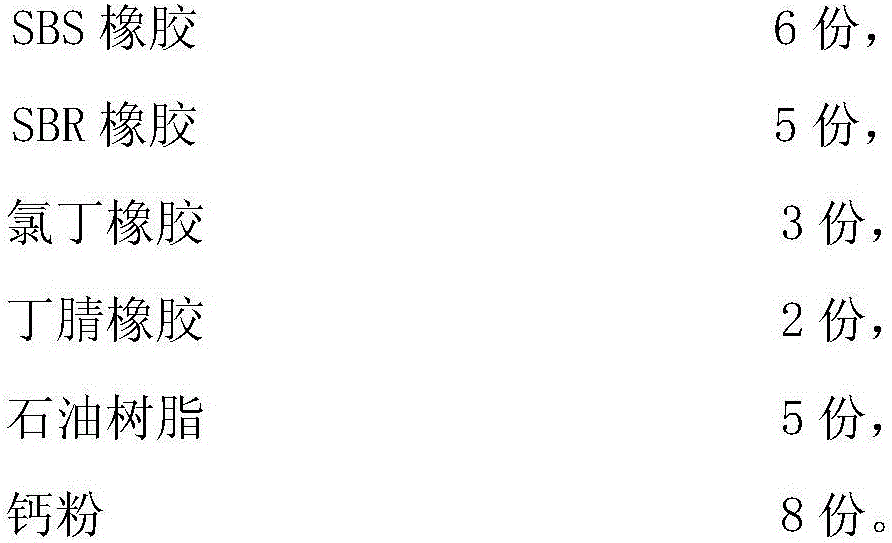

Molecular adhesive used for TPZ waterproof rolls and preparation method of molecular adhesive

ActiveCN105860925AGood adhesionGood compatibilityNon-macromolecular adhesive additivesBituminous material adhesivesMineralogyAdhesive

The invention discloses molecular adhesive used for TPZ waterproof rolls and a preparation method of the molecular adhesive. The molecular adhesive comprises, by weight, 50-70 parts of asphalt, 8-15 parts of second-vacuum naphthenic oil, 5-10 parts of SBS rubber, 3-8 parts of SBR rubber, 2-5 parts of chloroprene rubber, 1-3 parts of nitrile rubber, 3-8 parts of oil resin, and 5-10 parts of calcium powder. The adhesive layer formed by the adhesive can be fused and adhered at low temperature, and the molecular adhesive is good in adhesive sealing performance and is used for TPZ waterproof rolls, and performance of the TPZ waterproof rolls is improved.

Owner:重庆大禹防水科技发展有限公司

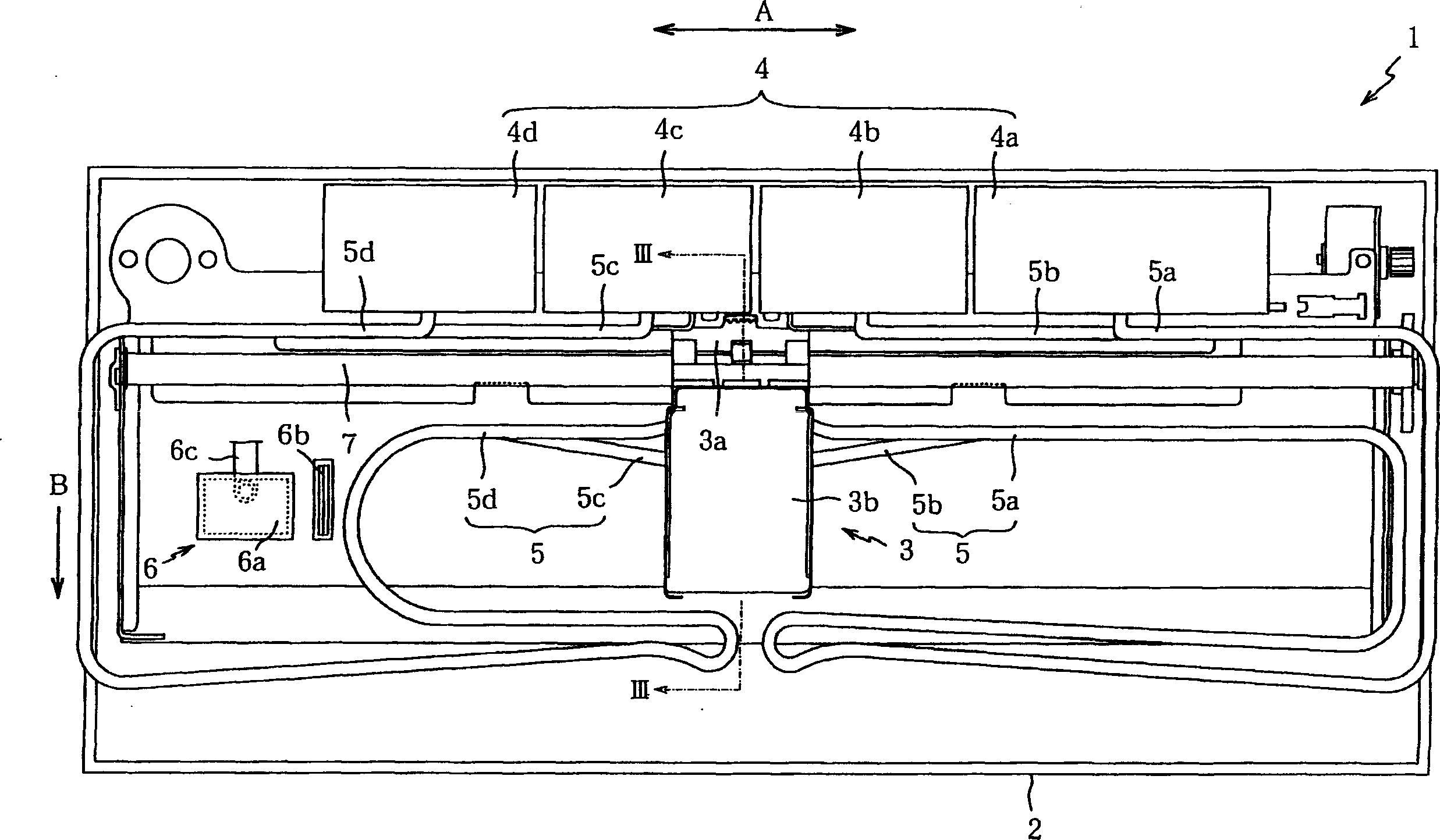

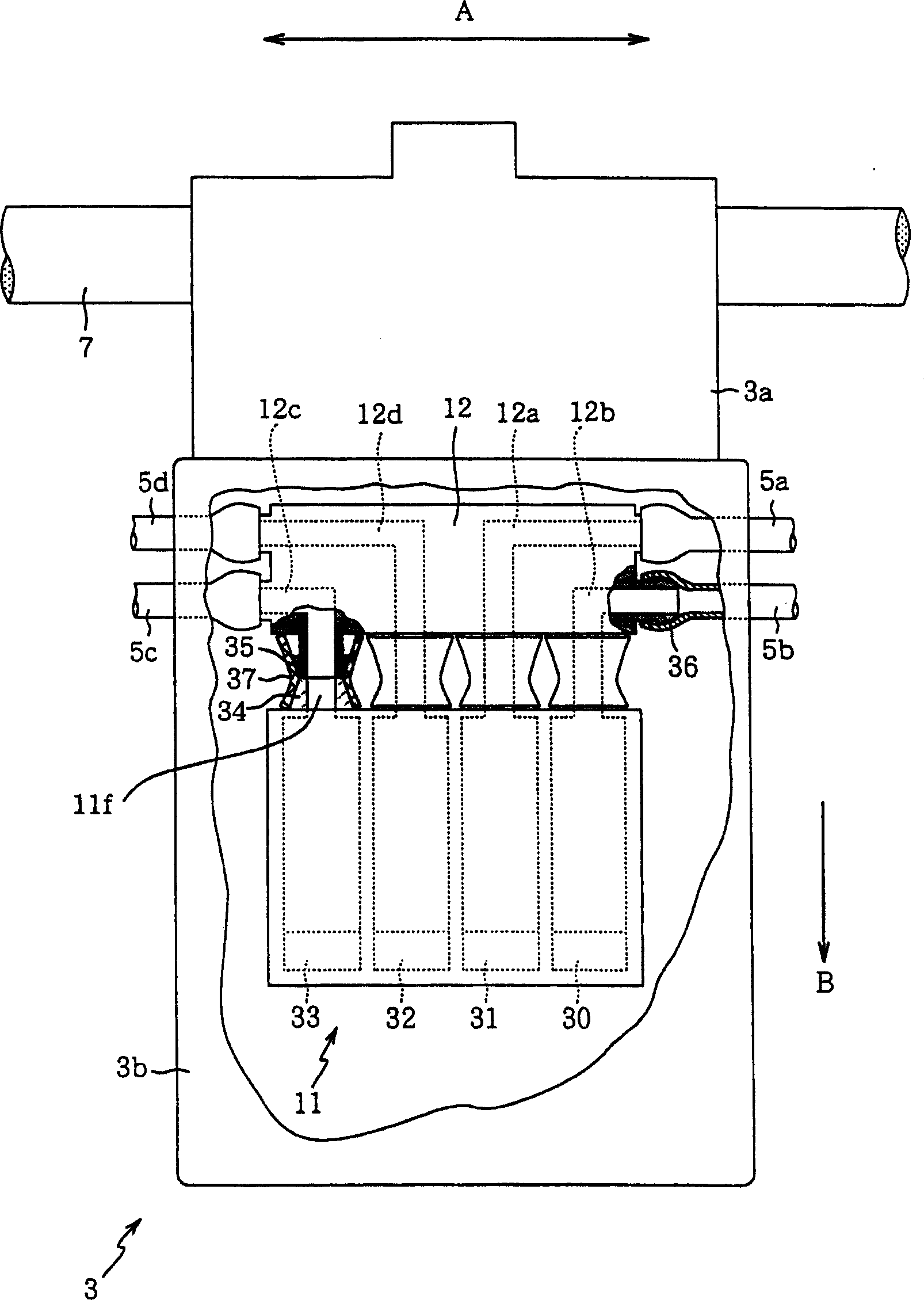

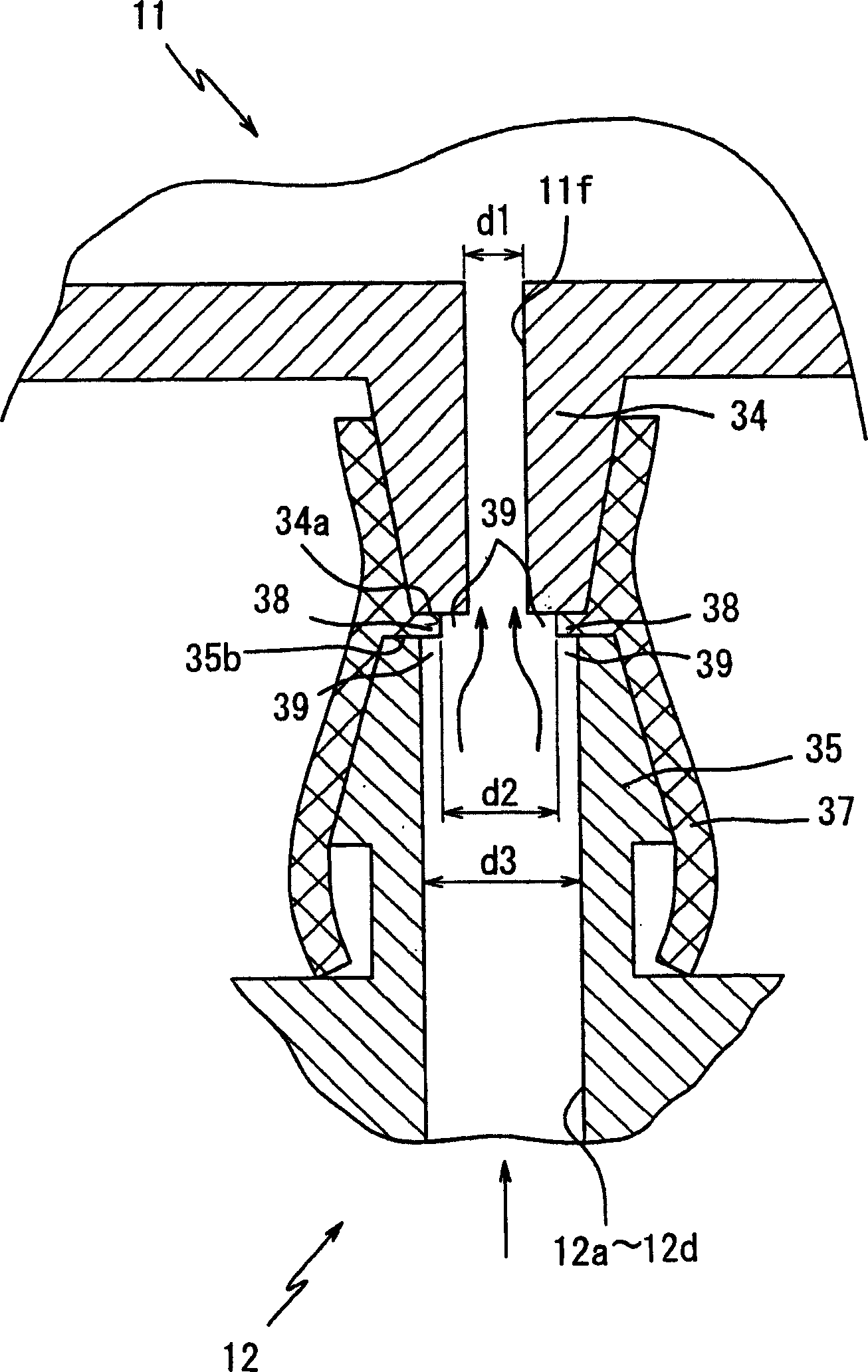

Ink jet printer with ink-path and method for forming ink path

An ink path through which ink is delivered from an ink source to a printhead unit includes an ink tube and a joint. The ink tube has a first layer formed of a material with low vapor and gas permeability and a second layer radially thicker than the first layer and formed of a flexible material. The joint has a maximum-diameter portion whose outer diameter is larger than an inner diameter of the ink tube. The joint is inserted into the ink tube. Further, a locking member is fitted over the ink tube. The locking member has an inner-diameter portion whose inner diameter is smaller than an outer diameter of a connection between the maximum-diameter portion of the joint and the ink tube.

Owner:BROTHER KOGYO KK

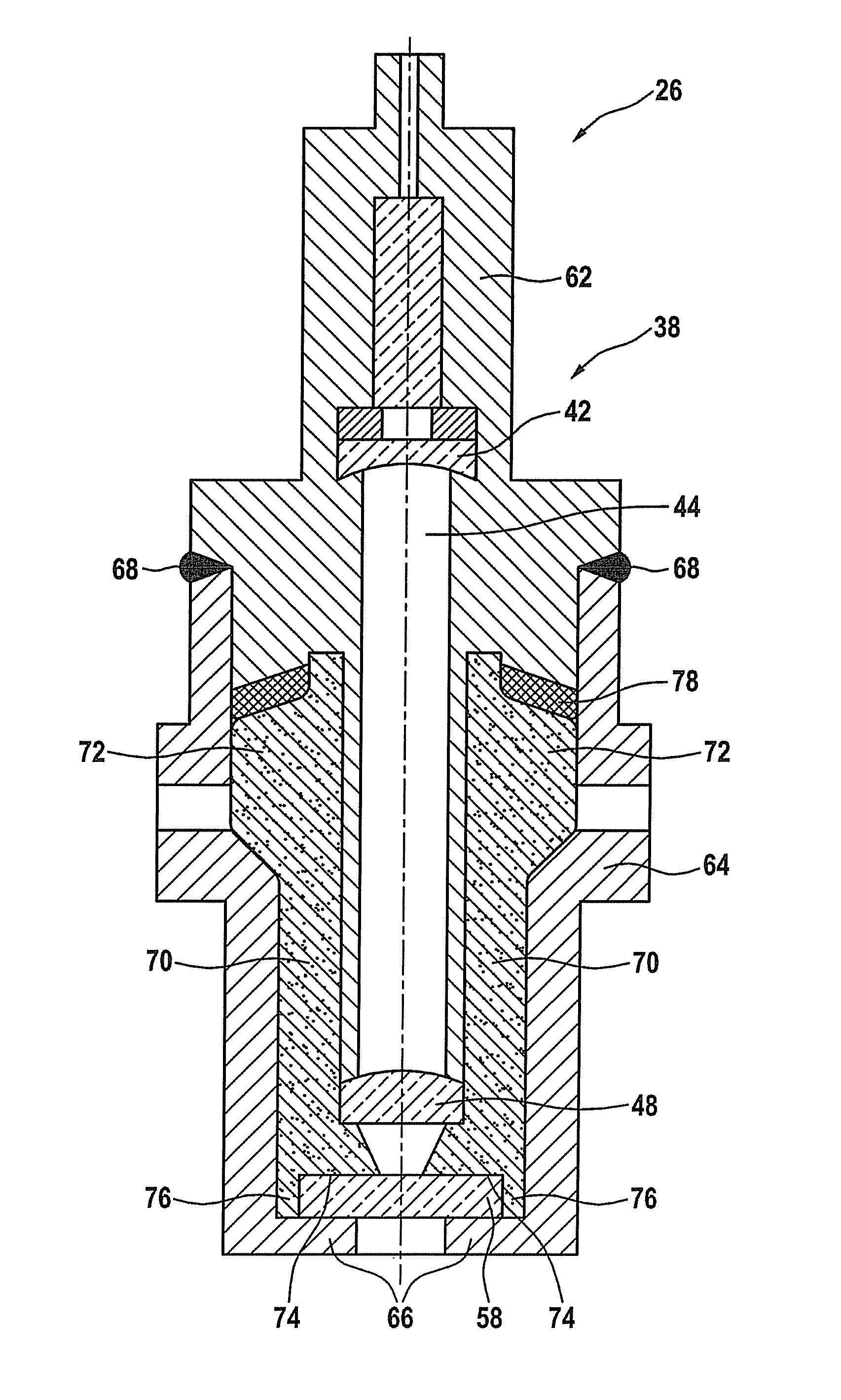

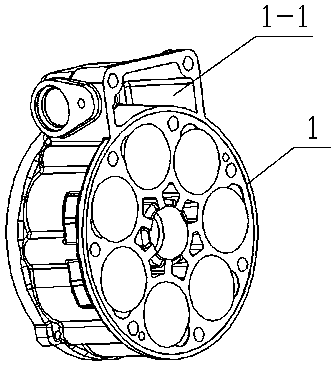

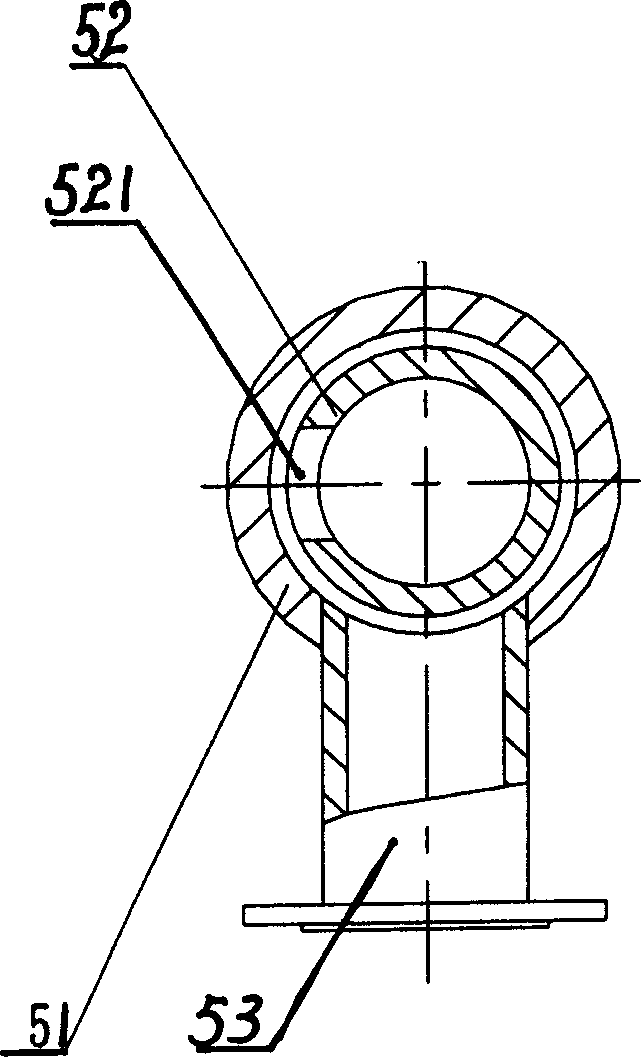

Variable-displacement rotary swash plate compressor

ActiveCN104179656ASafe and reliable sealingReduce resistancePositive displacement pump componentsMulti-stage pumpsEngineeringHigh pressure

The invention provides a variable-displacement rotary swash plate compressor. The variable-displacement rotary swash plate compressor is characterized in that a cylinder block is connected with a rear cover through a valve plate assembly, the middle of the rear cover is provided with a suction cavity and an exhaust cavity, a circular partition rib is arranged between the suction cavity and the exhaust cavity, a silencing cavity is arranged in the middle of the exhaust cavity, and a check valve is arranged between the circular partition rib and the silencing cavity; the bottom end face of a suction port of the cylinder block is an inclined drag reduction face. Due to the fact that the silencing cavity and the check valve are arranged in the exhaust cavity of the rear cover, high-pressure air flows passing through the inner side and the outer side of the rear cover can flow more stably, back flowing is avoided, and air flow noise is weakened; owing to the inclined drag reduction face arranged at the bottom end of the suction port of the cylinder block, air flows in different directions tend to be uniform after air enters the suction port and flows through the drag reduction face, the air flows are orientated, resistances of the air flows are reduced, and accordingly power consumption is reduced, and energy efficiency of the compressor is improved.

Owner:ANHUI DYNE AUTO AIR CONDITIONER LTD

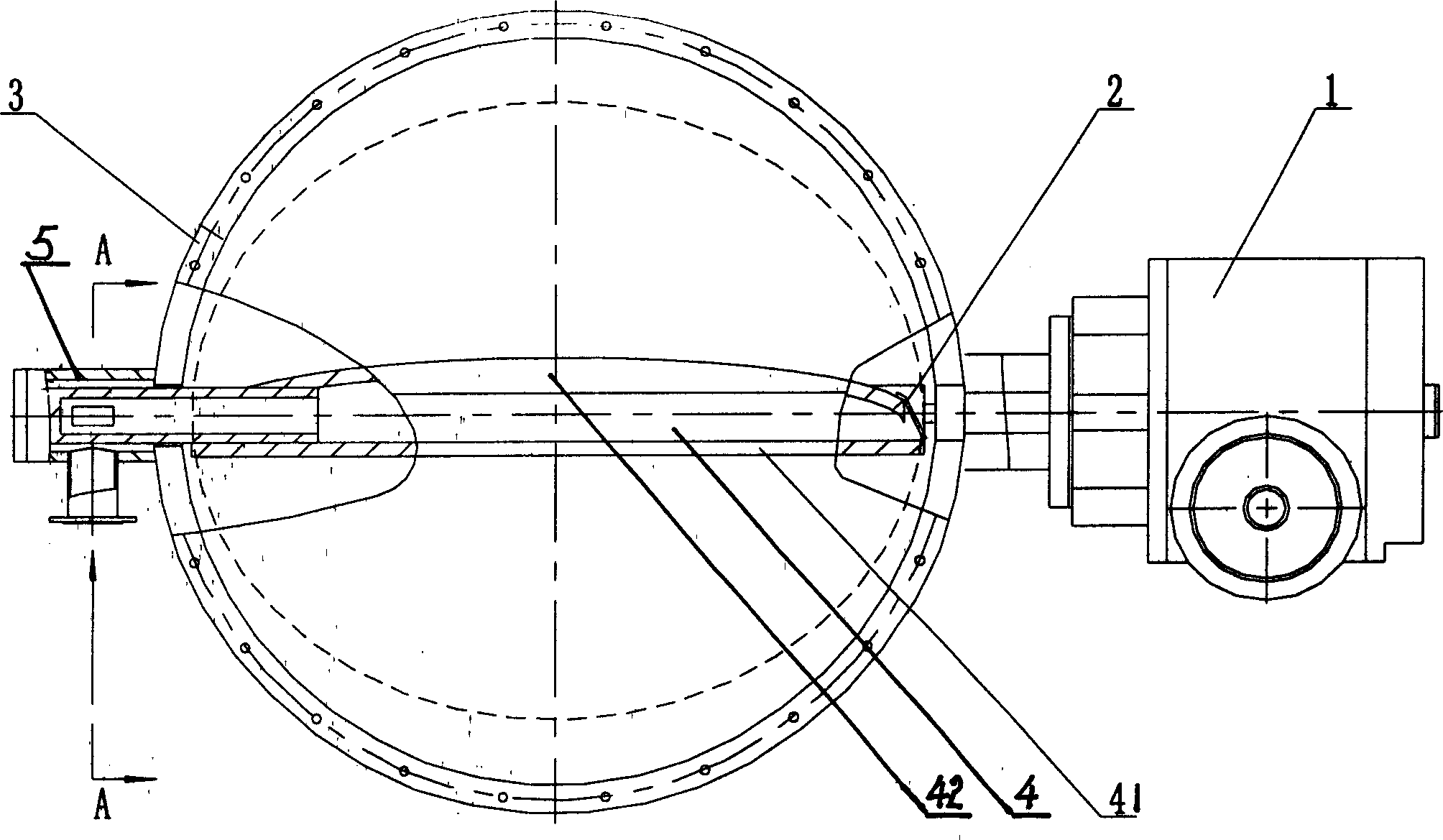

Damper throttle for insulating smoke

InactiveCN1560497AAvoid enteringAirtight, safe and reliableValve arrangementsMedia controlsEngineering

The invention is a smoke insulating damper-throttle relating to a insulating block used for smoke switch and insulation in smoke desulphurizing system, it can realize insulation to smoke with simple and reliable structure, the throttle includes a valve of a closed structure valve board with a sealed cavity, a middle media control switching valve, a electric executing mechanism; the electric executing mechanism, the middle media control switching valve are at two sides of the valve, the self-closed structure valve board with sealed cavity is in the valve, one end is connected to the outer electric executing mechanism, another end is connected to the outer middle media control switching valve, the middle media control switching valve and the hollow part of the self-closed structure valve board are connected; the valve board can be driven by the electric executing mechanism to rotate 90 degrees, at the same time, it drives the middle media control switch valve to rotate 90 degrees. It integrates the middle media control switch system and the valve board control, it guarantees the safety and reliability of the seal.

Owner:孙克勤 +3

Liner for breathing mask and breathing mask

ActiveCN106512174AThe sealing state is stableTreatment comfortRespiratory masksMedical devicesEngineeringMechanical engineering

Disclosed are a liner for a breathing mask and the breathing mask. The liner comprises a connection portion used for connecting the liner onto a frame or an elbow component of the breathing mask, a face contact portion used for contacting the face of a patient and formed by thin films and a support portion connected between the connection portion and the face contact portion, wherein at least a part of the face contact portion is provided with an outward extension portion extending from the support portion to the exterior of the liner and an inward extension portion extending from the periphery of the outward extension portion to the interior of the liner. Two seal areas are formed on the liner through the face contact portion so as to generate reliable sealing, and therefore ideal sealing effects can be achieved by applying low support force, and then wearing comfort is improved.

Owner:BMC MEDICAL

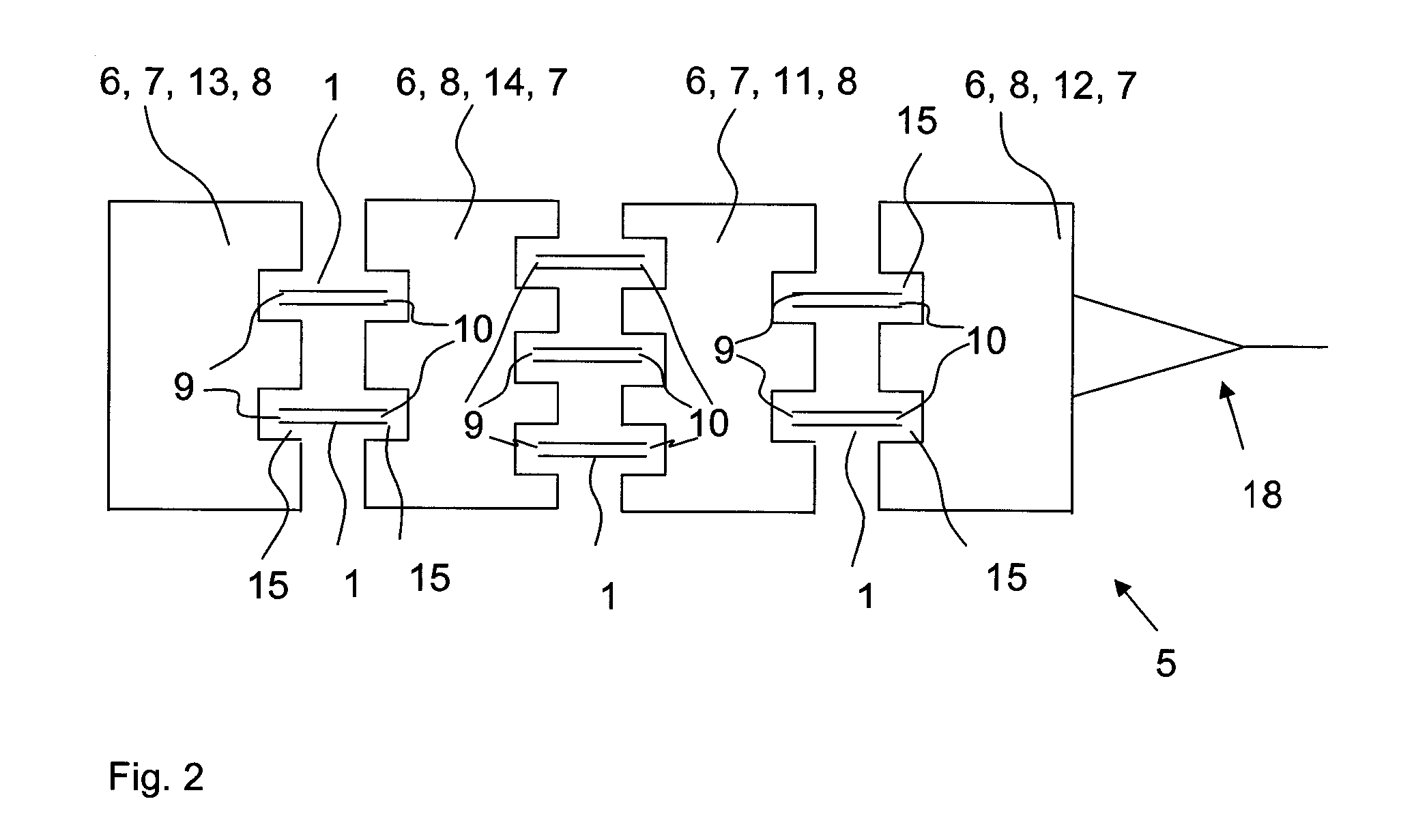

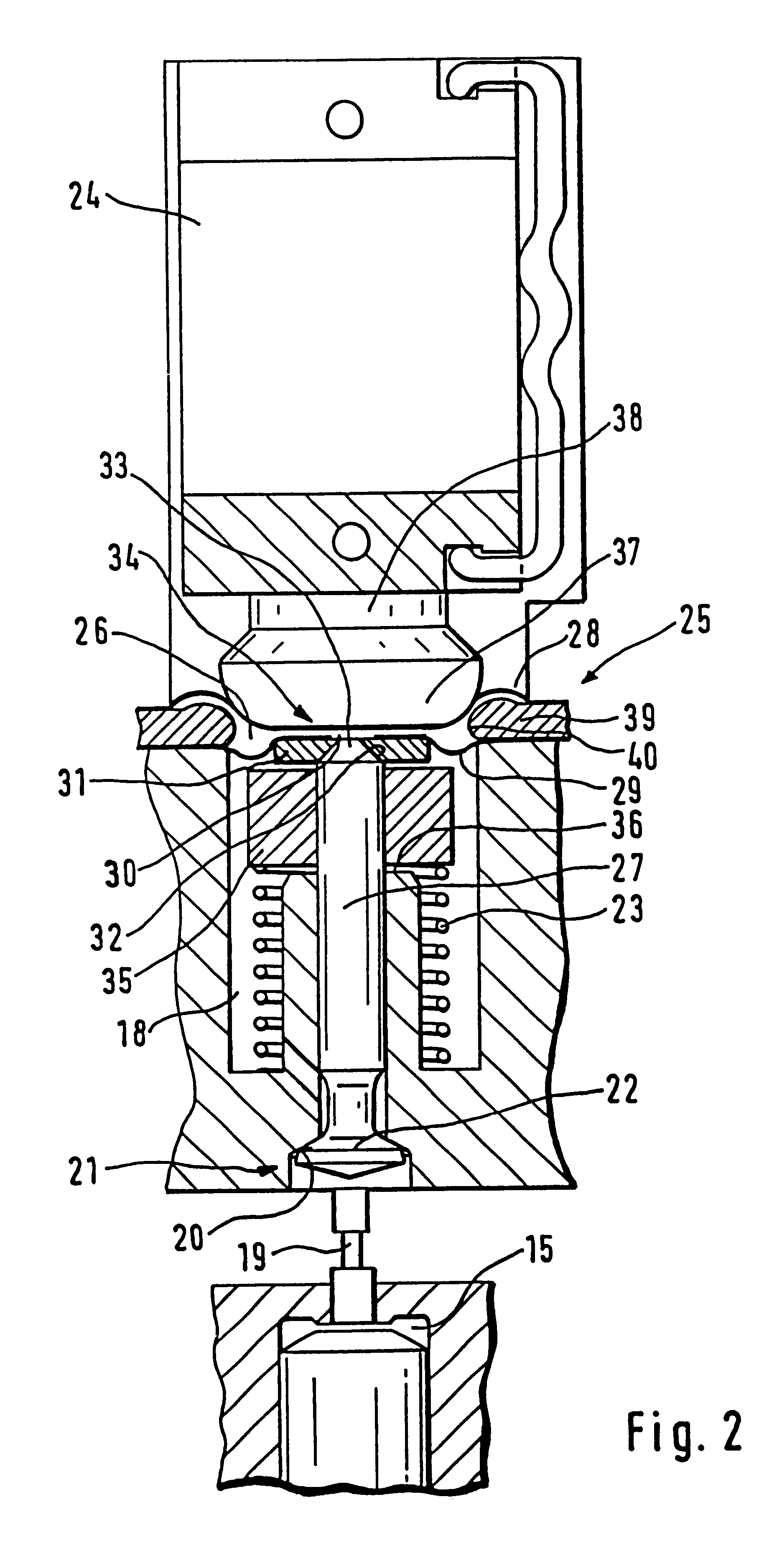

Piezoelectric actuated valve with membrane chamber

InactiveUS6224032B1Disadvantageous length change is thus preventedSimple designOperating means/releasing devices for valvesMachines/enginesElectricityCombustion

A valve for controlling fluids, which in order to be actuated, cooperates with a fluid-filled membrane actuator. A coupling chamber provided in the membrane actuator is sealed by two membranes as dividing walls. In order to compensate for fluid losses produced by pressure acting on the membrane actuator, a filling valve is provided, which is disposed in the region of one of the two membranes. A refilling of the membrane actuator during the closed phase of the control valve is assured by way of the filling valve. A filling of this kind can also compensate for length changes of the piezoelectric actuator, the valve, or the valve housing. The valve is designated for use in fuel injection devices for internal combustion engines of motor vehicles.

Owner:ROBERT BOSCH GMBH

Single mechanical seal with elastic sealing ring and double mechanical seal with elastic sealing ring

InactiveCN103883733ATo promote floatingReduce manufacturing difficultyEngine sealsEngineeringEnd face mechanical seal

A single mechanical seal with an elastic sealing ring and a double mechanical seal with an elastic sealing ring are used for preventing fluid with certain pressure in a working container from leaking out of the working container along a rotary shaft penetrating through the working container. The single mechanical seal with the elastic sealing ring and the double mechanical seal with the elastic sealing ring respectively comprise a shaft sleeve installed on the rotary shaft in a sleeved mode, a sealing box located outside the shaft sleeve and a friction pair arranged between the sealing box and the shaft sleeve, wherein the friction pair comprises a floating ring assembly and a fixed ring assembly, and a floating friction ring in the floating ring assembly achieves the sealing and floating supporting by means of the elastic sealing ring arranged outside the floating friction ring, a sealing ring leaning piece on the lower pressure side of the floating friction ring and a spring abutting against the non-friction end of the floating friction ring. The floating effect of the floating friction rings is good, good sealing performance can also be kept even when the rotary shafts jump or swing by a large amplitude, the manufacturing difficulty of the parts is small, cost is reduced, and meanwhile the size of the mechanical seals is reduced so that design and installation are facilitated and materials are saved.

Owner:浙江长城搅拌设备股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com