Ink jet printer with ink-path and method for forming ink path

A technology of inkjet printers and ink channels, which is applied in printing and other directions, and can solve problems such as a large number of components and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] An embodiment of the present invention is described below in conjunction with the accompanying drawings.

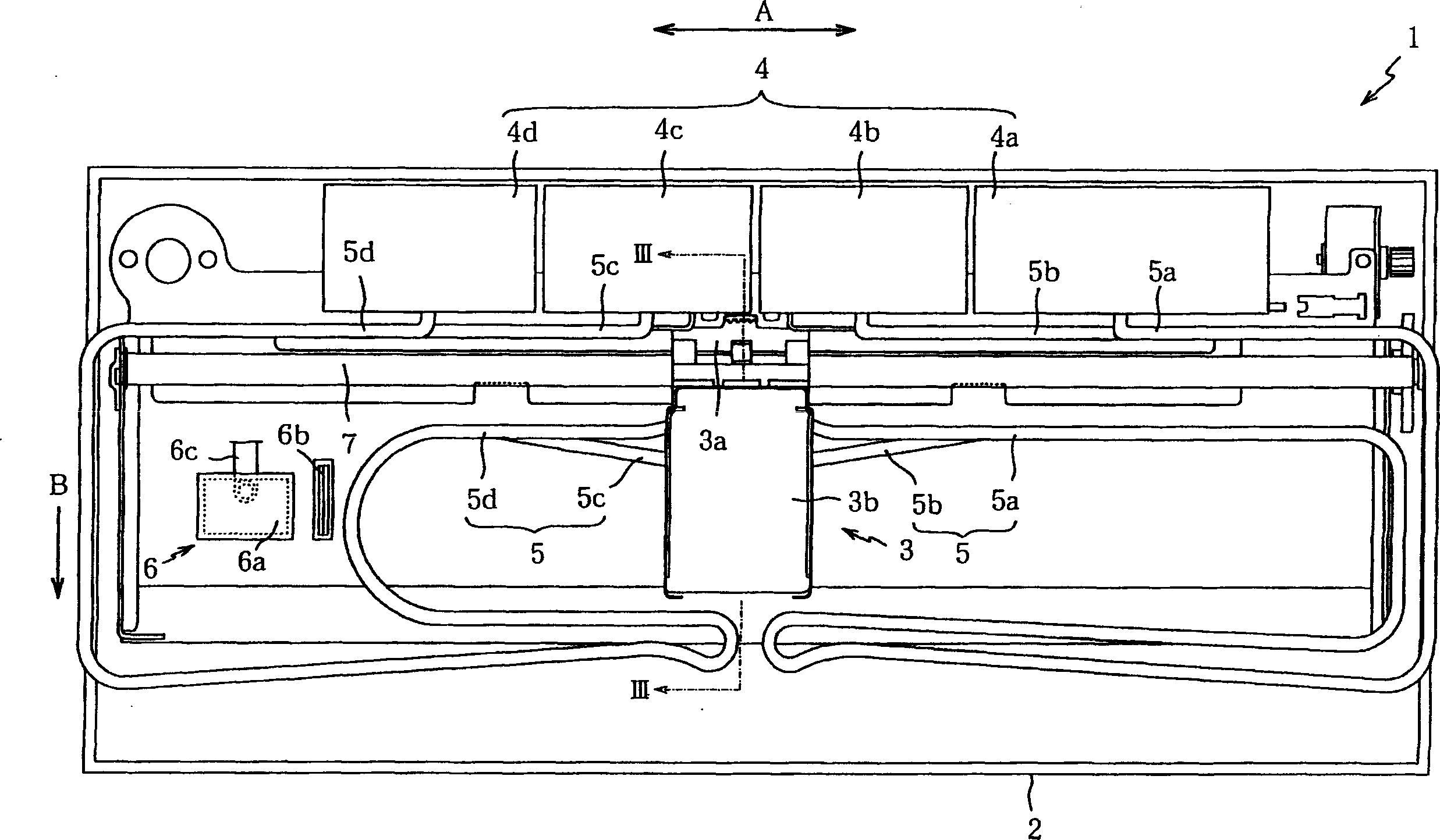

[0030] figure 1 is a plan view showing the internal structure of the ink jet printer 1 of an embodiment of the present invention. The inkjet printer 1 includes in its main frame 2: a print head unit 3 that ejects ink onto a sheet of paper; an ink tank 4 that stores ink to supply ink to the print head unit 3; A tank 4 is supplied to a pipe 5 of the print head unit 3; a return unit 6 and a paper feeder for supplying paper.

[0031] The main frame 2 is basically box-shaped and made of flame-retardant plastic. A guide bar 7 is horizontally provided in the longitudinal direction of the main frame 2, and supports the print head unit 3 so that the print head unit 3 is in the direction A perpendicular to the paper feeding direction B (in figure 1 Left and right direction) reciprocating movement.

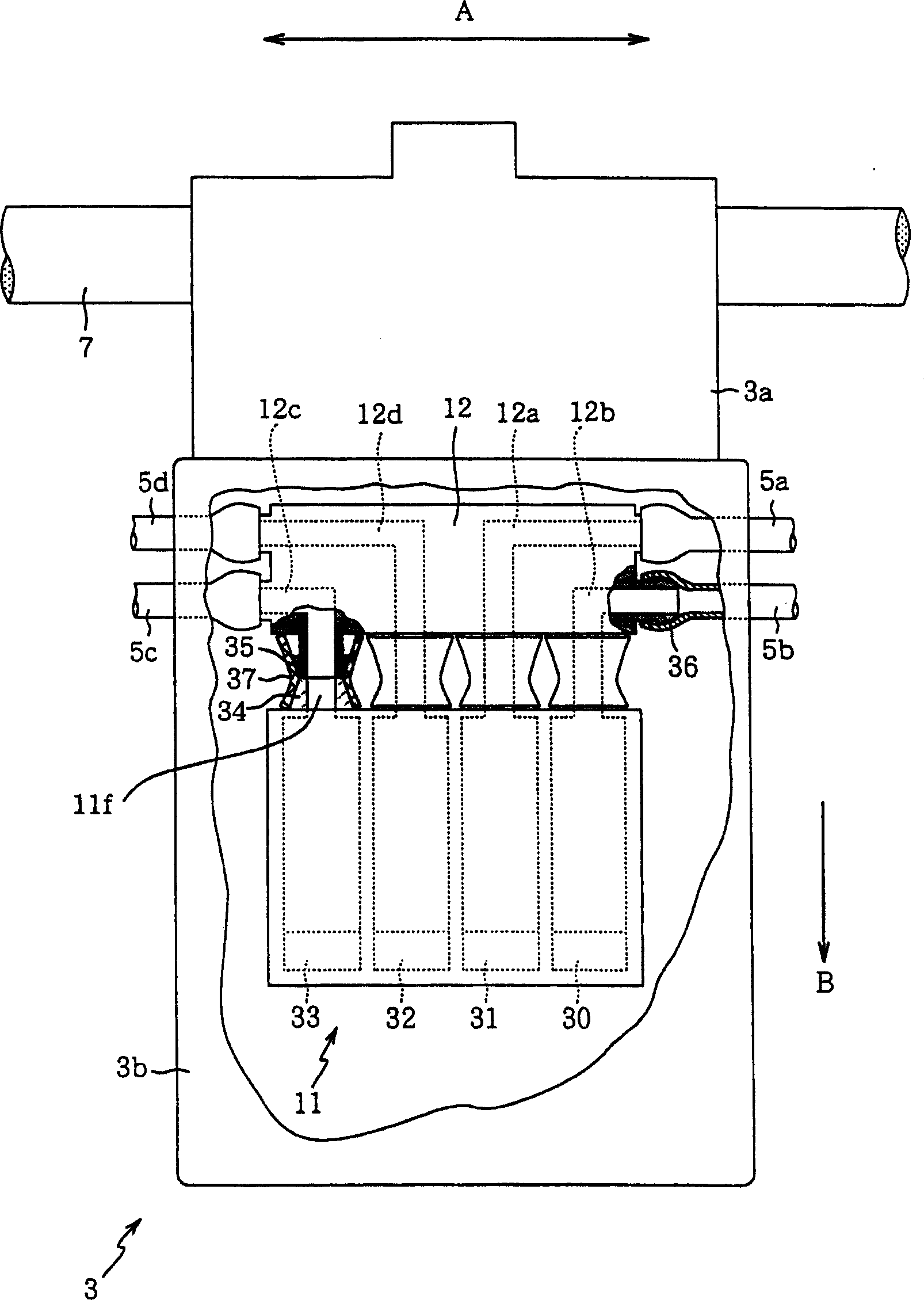

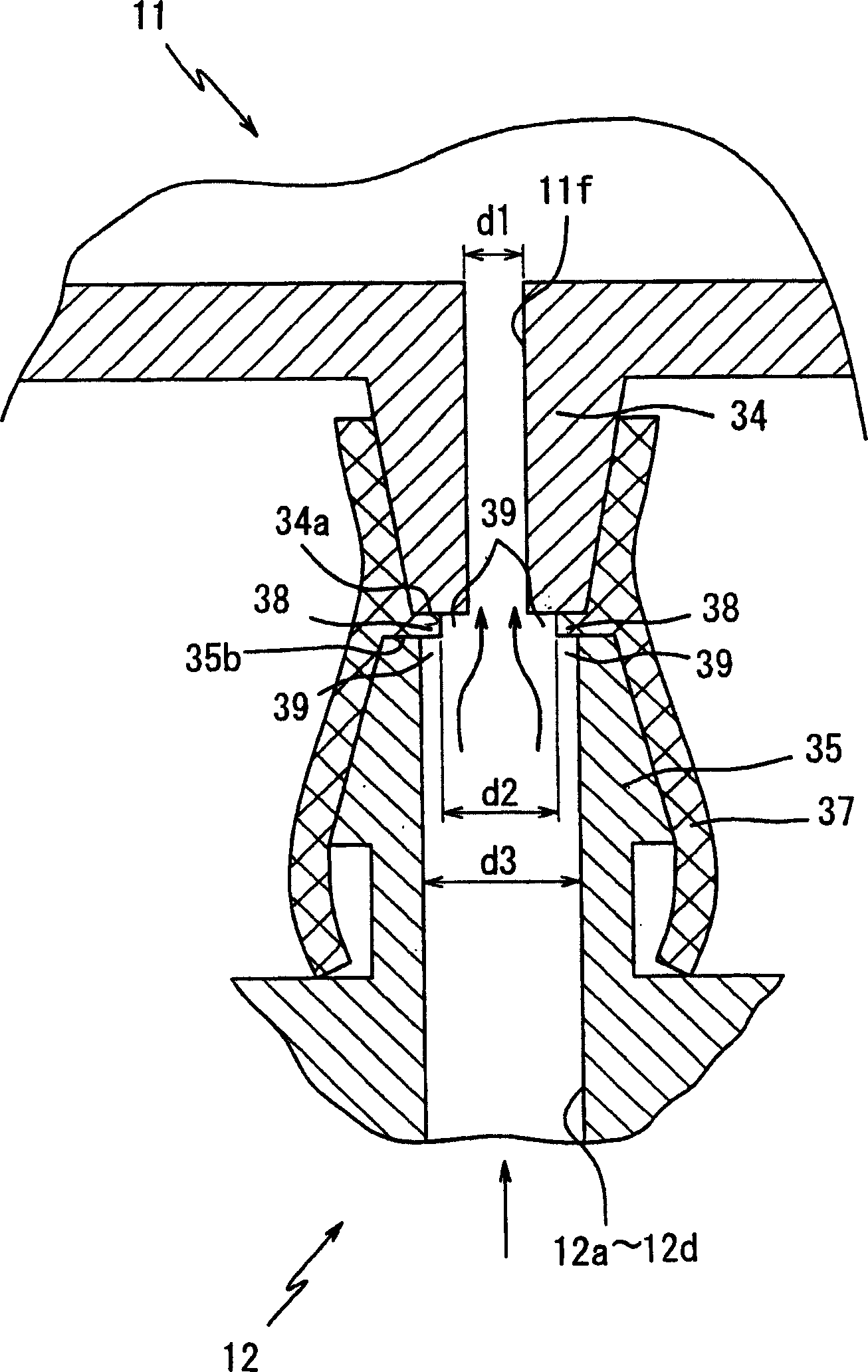

[0032] The print head unit 3 is substantially box-shaped, and includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com