Valve component

A technology of valve components and shell parts, which is applied in the field of valve components, can solve the problems of expensive construction methods, high manufacturing costs of external threads and internal threads, and high assembly costs, and achieve the effects of simplifying the assembly process, saving costs, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

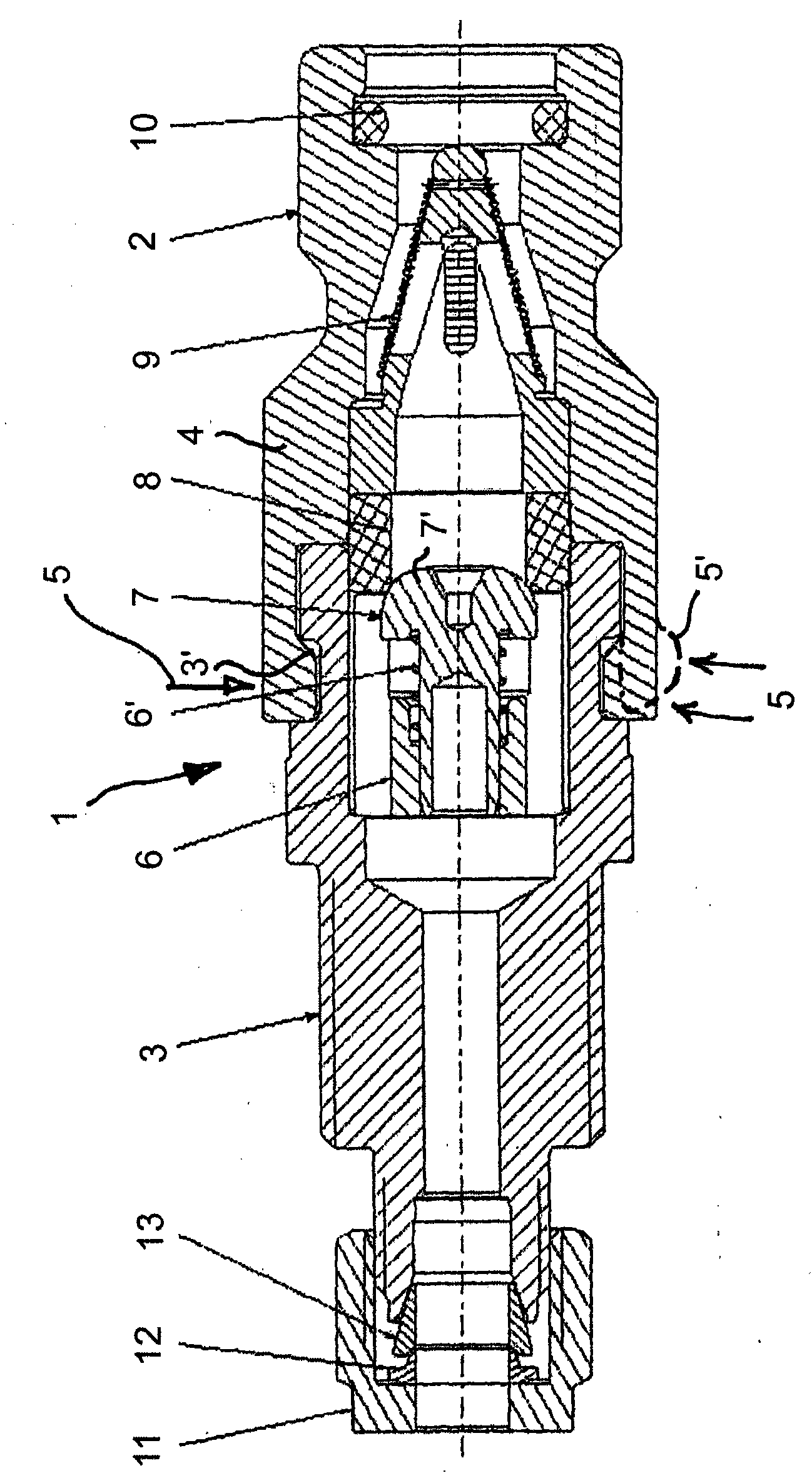

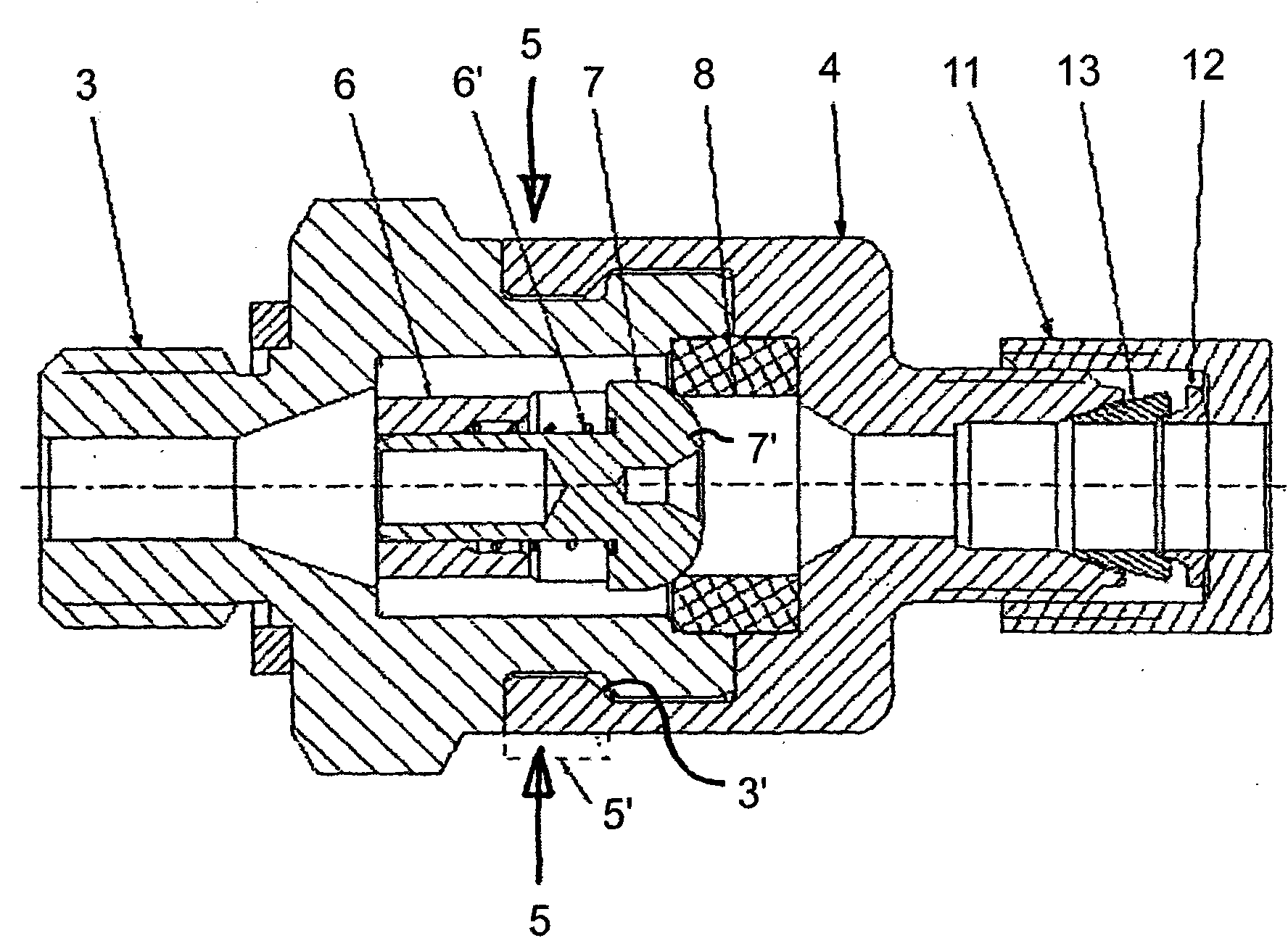

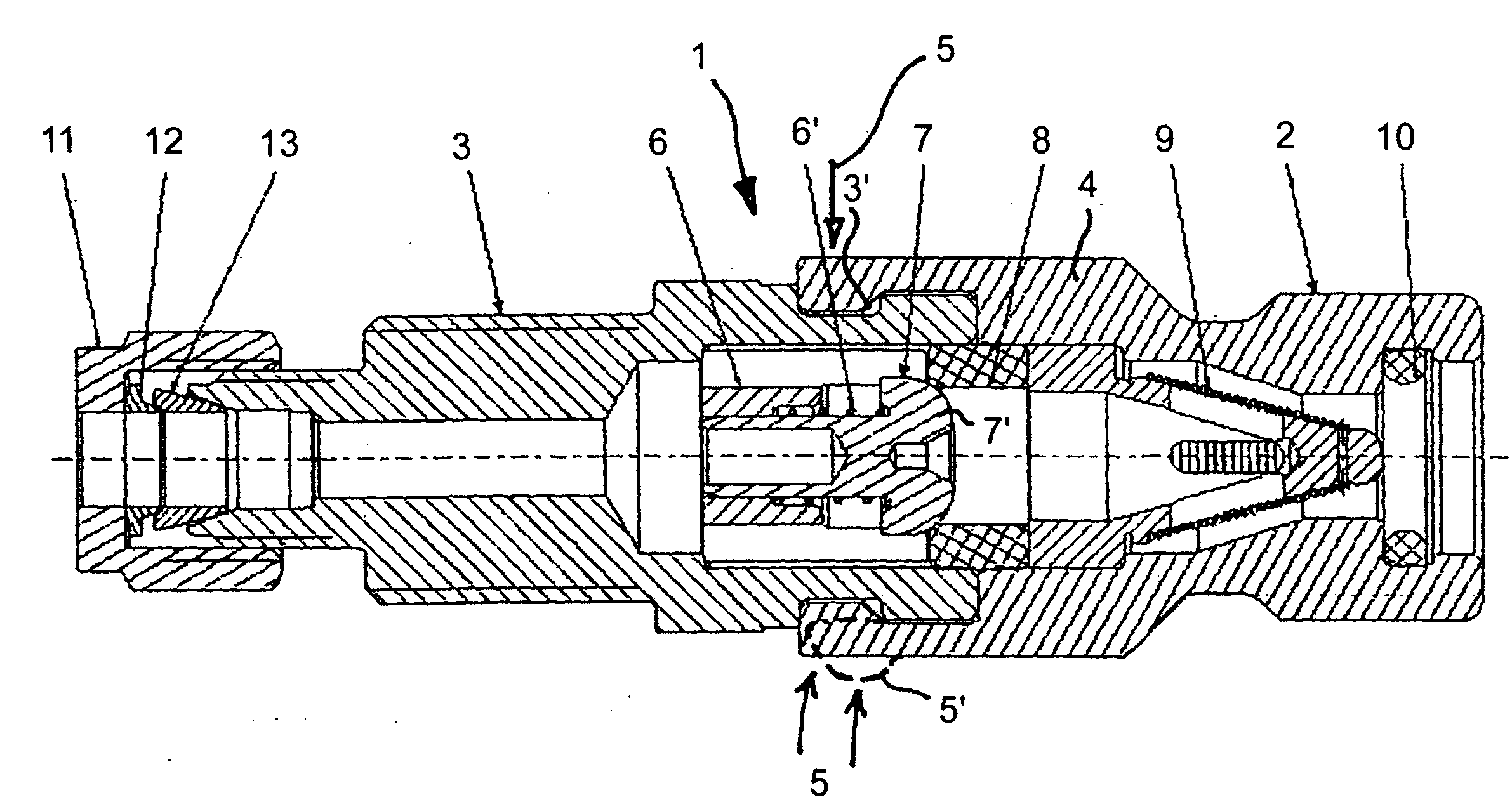

[0011] exist figure 1 A half-section of the valve member 1 in the form of a connecting sleeve is shown in . The connection sleeve has a connection profile 2 for receiving a plug connector, on which a plug connector is positively connected for a pressure-tight connection, as disclosed by the applicant in EP 1 271 039 Show. The valve component 1 is composed of two main components, ie two sleeve-shaped housing parts 3 , 4 , which are securely connected to each other by means of a pinch (as indicated by arrow 5 ). For this reason, a ring groove 3 ′ is turned on one of the two housing parts (the left housing part 3 here), and after the housing part 4 is sleeved on the housing part 3, the A milled or turned bead 5 ′ (shown in dashed lines in the lower region) is pressed into the ring groove 3 ′. The two housing parts 3 and 4 are thus securely and stably connected via the extrusion or flange 5 .

[0012] A sealing sleeve 8 is also securely clamped in the interior of the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com