Variable-displacement rotary swash plate compressor

A swash plate and variable displacement technology, which is used in liquid variable capacity machinery, variable capacity pump components, mechanical equipment, etc., can solve the problem of increasing compressor noise and vibration, affecting compressor noise and vibration, and increasing compression. Machine power consumption efficiency and other issues, to achieve the effect of reducing resistance, reducing power consumption, and shortening the effective length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

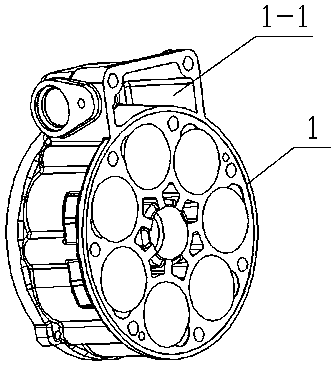

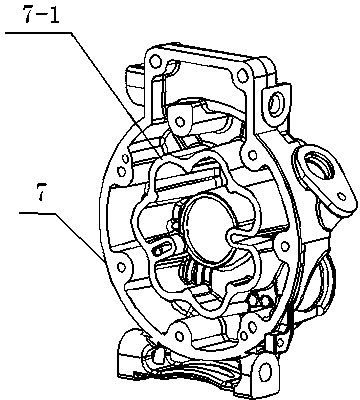

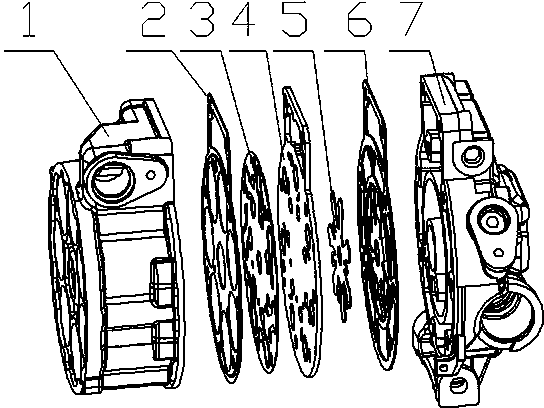

[0030] Such as image 3 As shown, a variable displacement swash plate compressor includes a cylinder body 1 connected with a rear cover 7 through a valve plate assembly, the valve plate assembly is composed of a cylinder body gasket 2, a suction valve plate 3. The valve plate 4, the exhaust valve plate 5, and the exhaust gasket 6 are sequentially sealed and connected; that is, after the exhaust gasket 6 is first connected with the valve plate 4, the cylinder body 1, cylinder body gasket 2, The suction valve plate 3, the valve plate 4, the exhaust valve plate 5, the exhaust sealing gasket 6 and the rear cover 7 are connected in sequence to form a sealing member.

[0031] Such as Figure 4 , 5 As shown, the bottom surface of the suction port 1-1 of the cylinder body 1 is a drag-reducing surface 1-3 arranged obliquely. After the gas enters the suction port 1-1, the airflow in different directions tends to In the same way, it reduces the resistance of the airflow, thereby redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com