Deodorizing floor drain

A floor drain and deodorization technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve the problems of small water output, slow water output, and untimely water output, and achieve effective contact, safe and reliable sealing, and prevent odor from overflowing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

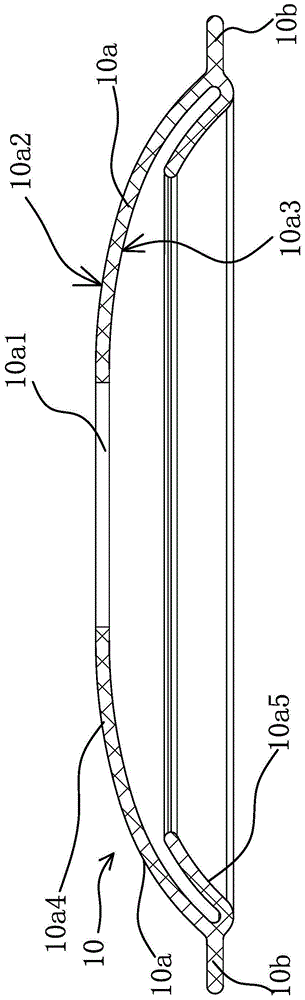

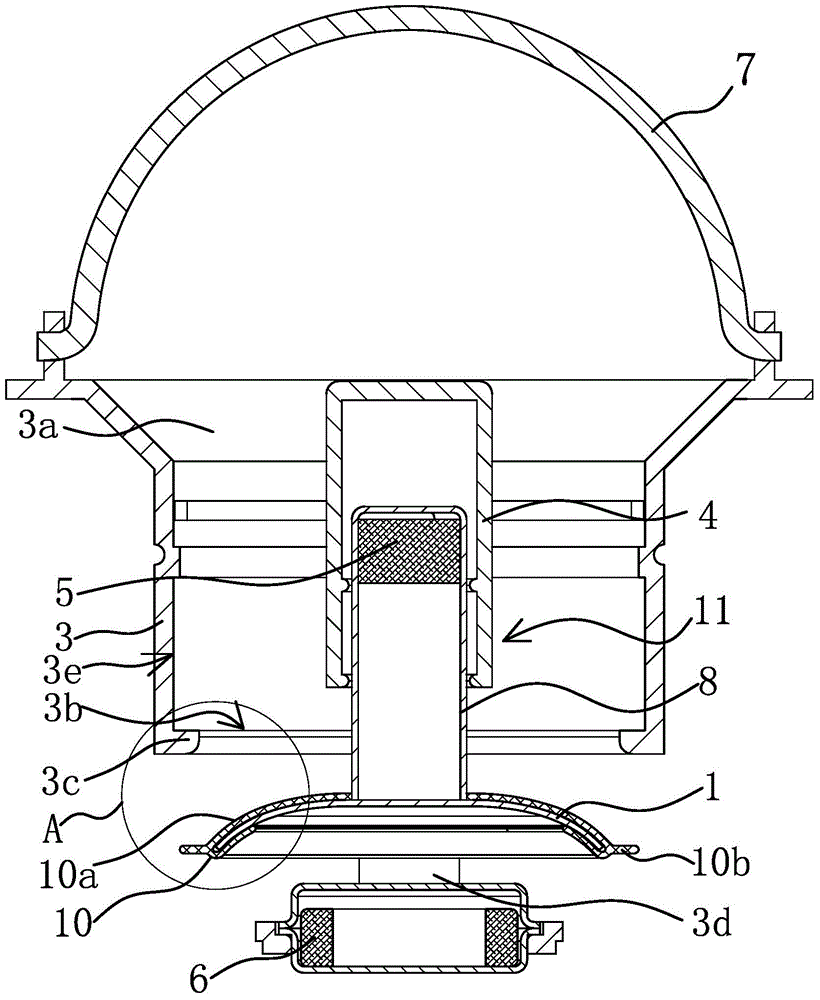

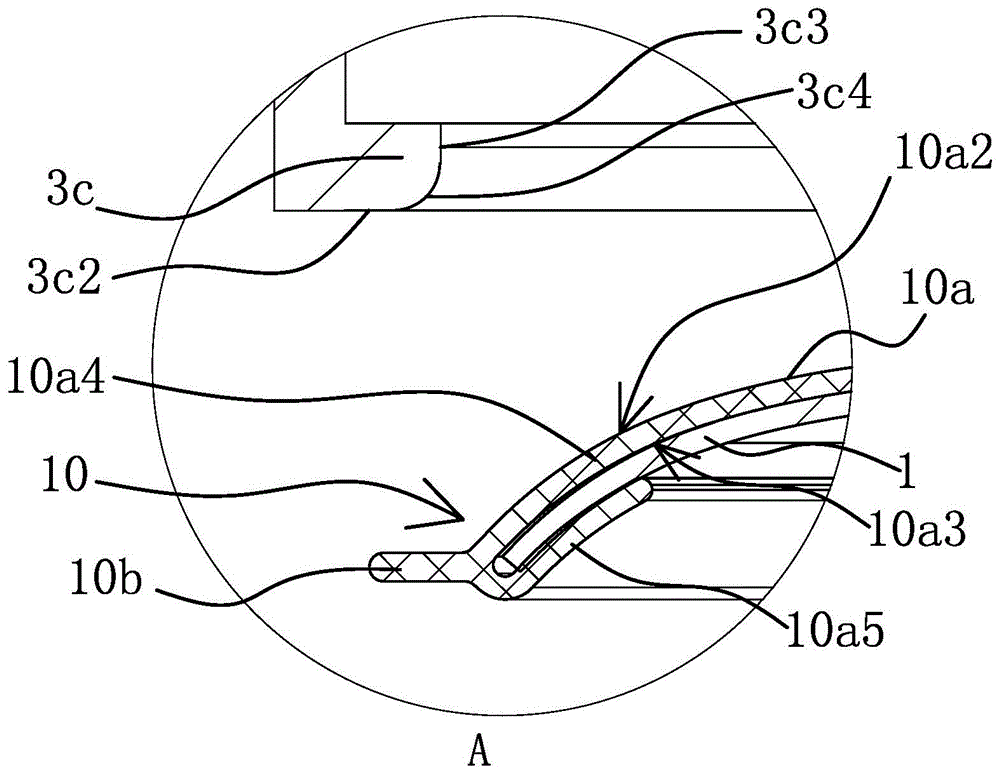

[0043] like Figure 1 to Figure 5 As shown (the following content is only for the convenience of illustrating the floor drain in the illustration, and it is actually not the only structure), the floor drain includes an outer cylinder 9, an inner cylinder 3 with a water inlet 3a and a water outlet 3b, a panel 2, and a panel 2 is located above the inner cylinder 3 and the water inlet 3a communicates with the panel 2 (outer cylinder 9 and panel 2 can refer to Figure 7 ), the panel 2 in this case can be integrally formed with the inner cylinder 3 or can be designed to be detachably connected, which can be determined according to the actual situation. A guide mechanism 11 is fixed inside the inner cylinder 3 to allow the sealing plate 1 to slide up and down in the vertical direction. 6 is located below the sealing plate 1, so that the sealing plate 1 is connected with a permanent magnet one 5 and the permanent magnet one 5 is located at the top of the sealing plate 1, and the fir...

Embodiment 2

[0054] like Figure 6 to Figure 8 As shown, the structure and principle of this embodiment are basically the same as those of Embodiment 1, the difference lies in: the central hole 10a1 in this embodiment also has an extension part 10c and a gathering part 10d extending upward from the main body 10a, for example, like Image 6 As shown, the extension part 10c and the gathering part 10d also cover the permanent magnet-5, and the entire sealing member 10 can not only play an elastic sealing role, but also effectively isolate the permanent magnet-5 from sewage and dirt. Therefore, its service life is ensured and the water outlet 3b is prevented from being blocked, and the permanent magnet-5 can also be prevented from being corroded by sewage. In addition, the cross-section of the annular retaining edge 3c in this embodiment is stepped, including two annular steps 3c1, which can more effectively perform segmental sealing. And what is shown in the figure is a schematic diagram of...

Embodiment 3

[0056] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: the water outlet of the inner cylinder 3 is not provided with an annular retaining edge 3c, but is directly installed at the lower port of the inner cylinder 3 There is an arc surface 3c4 matched with the sealing part 10 to realize the effect of increasing the sealing area. And the caliber of the water outlet 3b in this solution will be correspondingly much larger, which can ensure that more sewage is discharged per unit time and prevent clogging, so as to ensure smooth water outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com