Sealing method of fastener

A process method and fastener technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as lack of experience for reference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

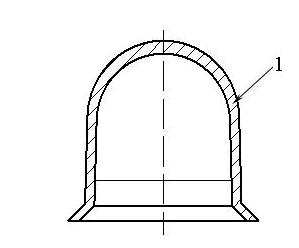

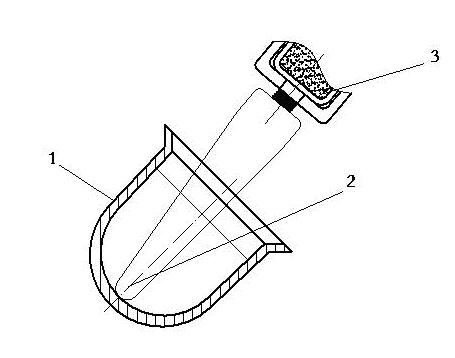

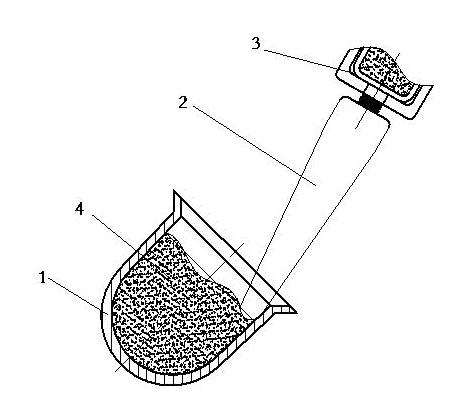

[0016] Referring to the accompanying drawings, the sealing cap 1 is a prefabricated cap-shaped rubber product with small size and soft characteristics. see Figure 4 , on the aircraft body structure 7 there are fasteners 5 that need to be sealed and are made of screws and nuts, and the sealing cap 1 is used to enclose the fasteners 5 . During operation, the size of the sealing cap 1 must be selected to match the fastener 5 that needs to be packaged, and the applicable sealant 4 and injection tool 3 must be selected. The specific sealing process is that the operators hold the sealing cap 1 and use the The mouth of the sealing cap is tilted outward, and the central axis of the sealing cap is at an angle of 45o with the ground; the glue injection nozzle 2 of the glue injection tool is closely attached to the inner bottom surface of the seal cap 1; start the glue injection tool 3 to inject glue, and at the same time Slowly move the glue injection tool 3 outward, and make the glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com