Volume segmentation type liquid pouring and sealing method based on silicone base subfebrile temperature pipe

A technology of silicon-based micro heat pipes and micro heat pipes, which is applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems that the accuracy is difficult to control, it is difficult to ensure that the working liquid is not polluted by the outside air, and the device is simple , safe sealing and simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

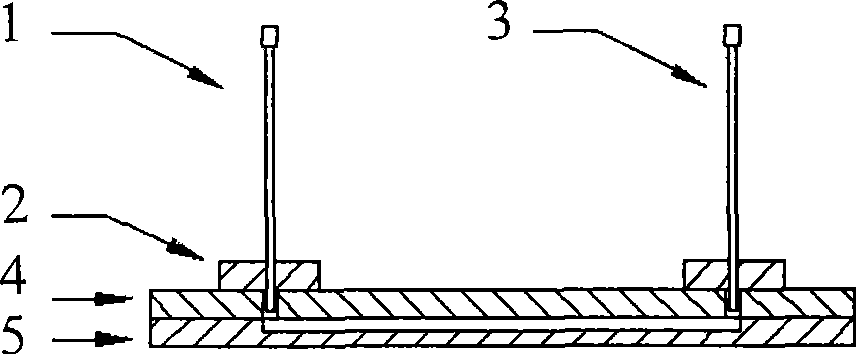

[0015] Such as figure 1 , figure 2 , image 3 As shown, liquid injection holes are respectively processed at both ends of the pipeline of the silicon-based micro heat pipe formed by the heat-resistant glass 4 and the silicon chip 5 engraved with a V-shaped groove through the anode bond, and the diameter of the liquid injection hole is 1-2mm. The injection and sealing method is divided into three steps:

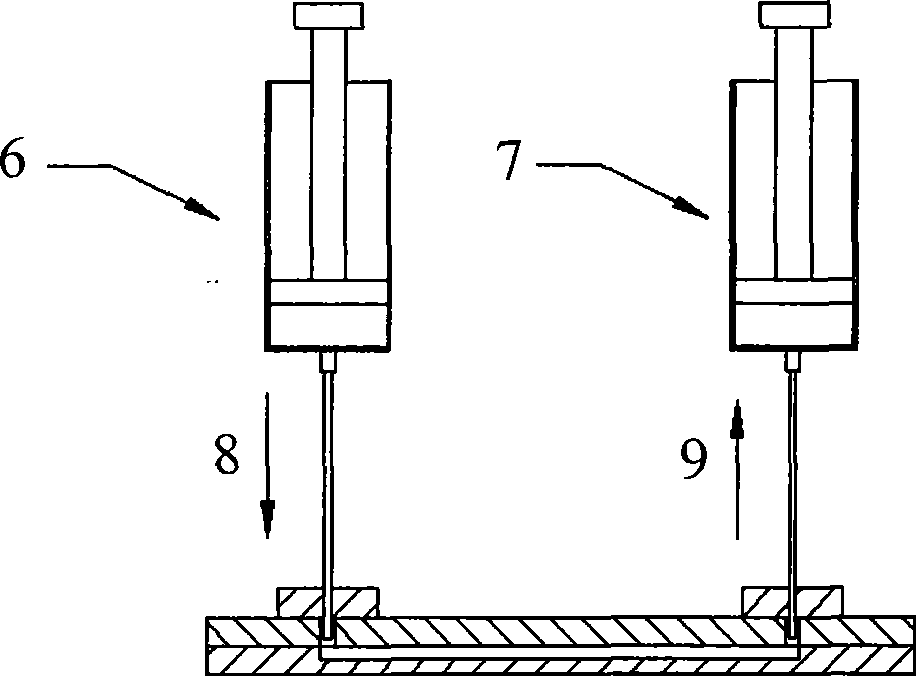

[0016] (1) After the thin metal tubes 1 and 3 connecting the two syringes 6 and 7 are respectively inserted into the two liquid injection holes of the silicon-based micro heat pipe, seal with silicone sealant 2, and the first syringe 6 sucks 3-5ml of working liquid, Avoid mixing air during the process, and the second syringe 7 keeps it at zero position;

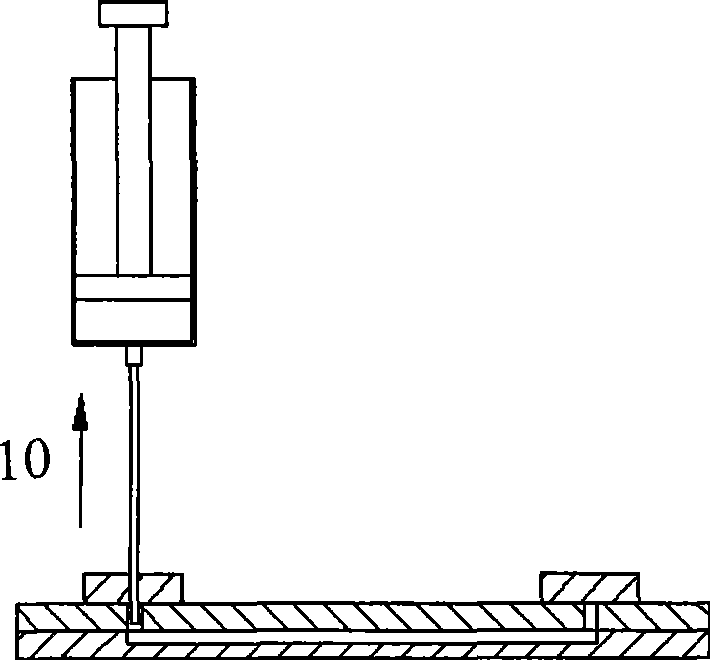

[0017] (2) The first syringe 6 is injected, and the second syringe 7 is drawn simultaneously to obtain a micro ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com