High-flux array type 3D liquid drop printing method

An array-type, high-throughput technology, applied in the field of 3D printing, can solve problems such as difficulty in ensuring simultaneous shedding and uniform size, damage to the spatial arrangement of droplets, and inability to print droplets, etc., to achieve adjustable printing speed, high-pass The effect of volume preparation and positional disorder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

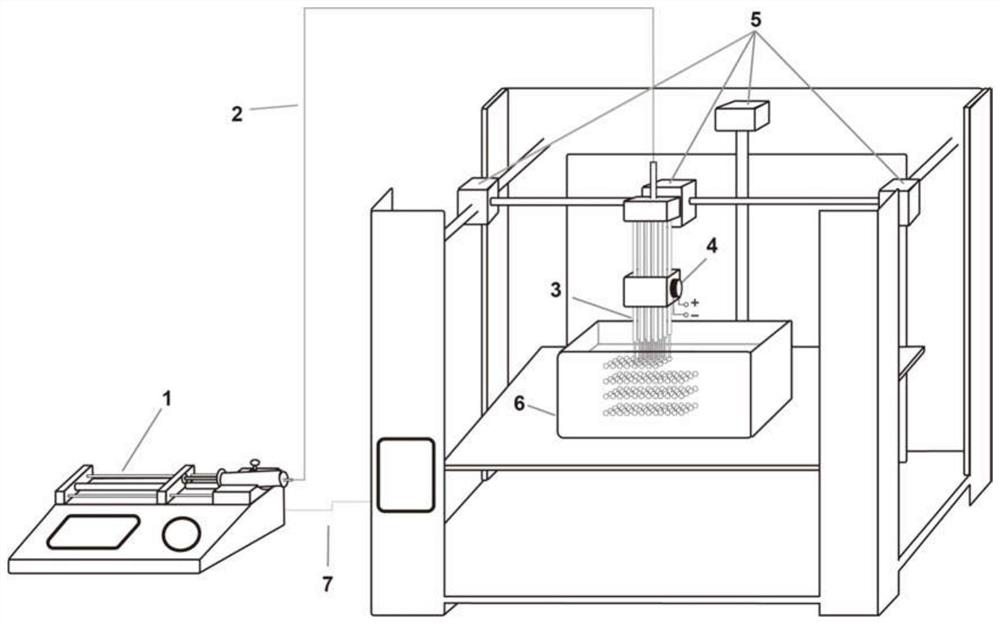

Image

Examples

Embodiment 1

[0042] Example 1: Preparation of a rectangular prism suspended micro-droplet system composed of arrayed droplets.

[0043] Adopt the method of the present invention to prepare suspension droplet, concrete steps are as follows:

[0044] (1) The circuit that controls the feeding of consumables on the traditional fused deposition 3D printer is connected to the syringe pump control system through the serial interface. Select the nested stainless steel needle tube to prepare a 4×4 array printing nozzle with a period interval of 1.5 mm. The inner tube is a stainless steel hollow capillary tube with an inner diameter of 0.3 mm, an outer diameter of 0.6 mm, and a length of 15 mm. The outer tube is a stainless steel hollow capillary tube with an inner diameter of 1.0 mm. , a stainless steel hollow capillary tube with an outer diameter of 1.1mm and a length of 9mm. The harder outer needle tube provides mechanical support for the softer inner needle tube. The needle tube of the printing...

Embodiment 2

[0051] Example 2: Preparation of star-shaped and circular suspended micro-droplet systems composed of arrayed droplets.

[0052] Adopt the method of the present invention to prepare suspension droplet, concrete steps are as follows:

[0053] (1) A fused deposition 3D printer was used to prepare star-shaped and circular array nozzle molds. The inner tube is a stainless steel hollow capillary tube with an inner diameter of 0.3 mm, an outer diameter of 0.6 mm, and a length of 15 mm. The outer tube is a stainless steel hollow capillary tube with an inner diameter of 1.0 mm, an outer diameter of 1.1 mm, and a length of 9 mm as a nested stainless steel needle tube. , fixed at the round hole of the mold and assembled into star-shaped and circular array nozzles.

[0054] (2) The circuit that controls the feeding of consumables on the traditional fused deposition 3D printer is connected to the syringe pump control system through the serial interface. The needle tube of the printing n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com