Preparation method of carbon quantum dots with blue-green fluorescence

A technology of blue-green fluorescence and carbon quantum dots, which is applied in the field of preparation of fluorescent nanomaterials, can solve the problems of single fluorescence color and low quantum yield of carbon quantum dots, and achieve high quantum yield, simple and easy method, and excellent reaction conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1 Preparation of carbon quantum dots

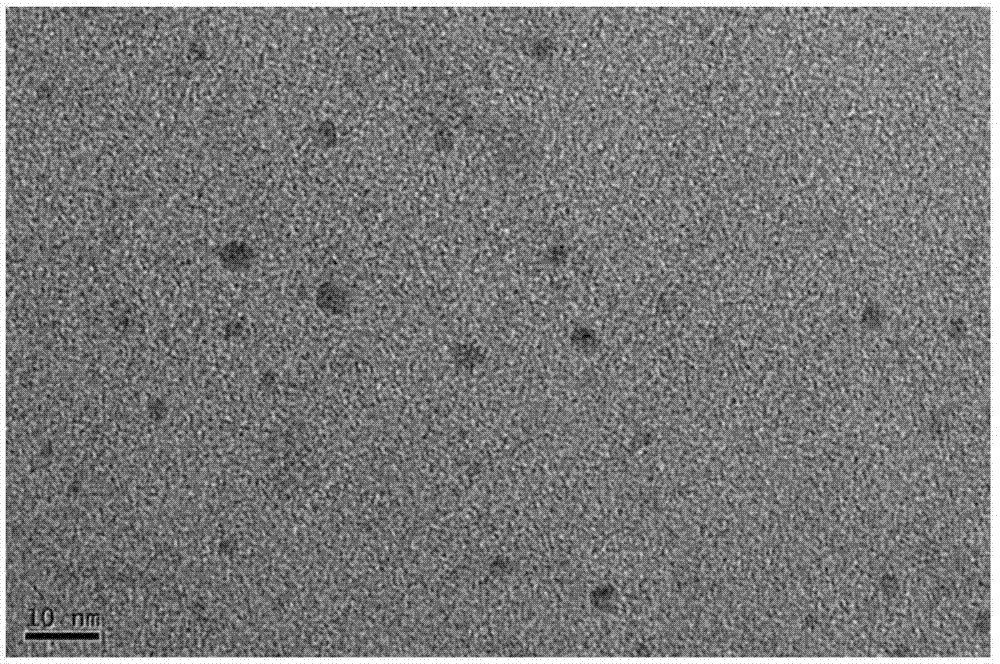

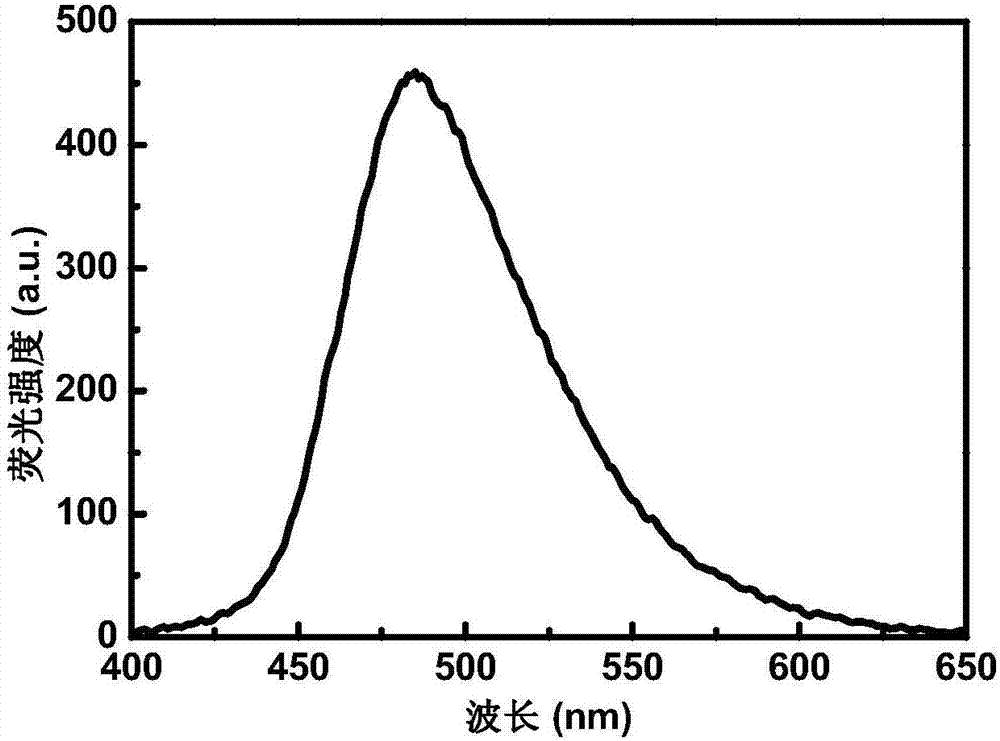

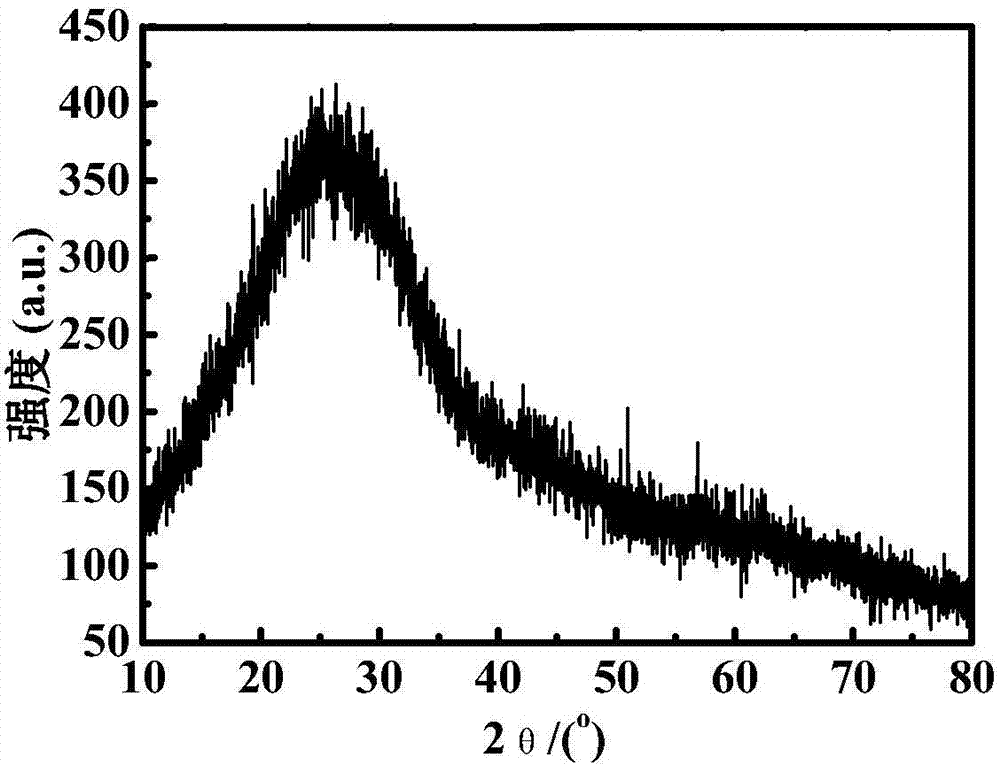

[0034] Take 0.036g of Kapton-type polyimide (PI), 10g of purified water, put them in a 15ml hydrothermal kettle, and set the hydrothermal condition at 180°C for 3 hours. After the reaction, the clear liquid was taken as the obtained carbon quantum dot solution. Measure main peak at 485nm through fluorescence spectrometer (as figure 2 Shown), the half peak width is about 50nm, measured by X-ray diffractometer, its spectrum (such as image 3 shown) shows a broad (002) peak at 2θ = 25°, which further proves the amorphous structure of white light-emitting carbon quantum dots. by transmission electron microscopy (e.g. figure 1 Shown) It can be seen that the white light carbon quantum dots are uniform in size and well dispersed, similar to a spherical shape. According to its size distribution diagram, we obtained that the average diameter of white light carbon quantum dots is 3.4nm. by transmission electron microscopy (e.g. Figur...

Embodiment 2

[0038] 1 Preparation of carbon quantum dots

[0039] Take 0.047g of Kapton type polyimide (PI), 10g of purified water, 0.003g of ethylenediamine, 0.03g of γ-methacryloxypropyl trimethoxysilane (KH570), put them in a 15ml water heating kettle, set Set the hydrothermal condition as 170°C for 6h. After the reaction, take the solution in the still and centrifuge the centrifuge tube at 12000rpm for 20min to obtain the supernatant. The obtained clear liquid is filtered with a 30KD ultrafiltration molecular membrane, and the filtrate is collected as the obtained carbon dots. The fluorescence emission peak of the prepared carbon dots is at 495nm, the fluorescence lifetime is 4ns, and the diameter is 5nm.

[0040] 2 screen printing

[0041] Take 2ml of the carbon quantum dots prepared above, weigh 8g of polyvinylpyrrolidone (K-30), mix the two, and magnetically stir for 2h, let stand for 2h, take 2g of the solution on the screen of the screen printing instrument, and Filter paper w...

Embodiment 3

[0043] 1 Preparation of carbon quantum dots

[0044] Take 0.029g Kapton-type polyimide (PI), 10g purified water, 0.008g ethylenediamine, 0.07g γ-methacryloxypropyltrimethoxysilane (KH570), put them in a 15ml water heating kettle, Set the hydrothermal condition as 195°C for 5h. After the reaction, take the solution in the still and centrifuge the centrifuge tube at 12000rpm for 20min to obtain the supernatant. And filter the obtained clear liquid with a 30KD ultrafiltration molecular membrane, collect the filtrate, and obtain carbon dots. The fluorescence emission peak of the prepared carbon dots is at 505nm, the fluorescence lifetime is at 5.2ns, and the diameter is at 6.5nm.

[0045] 2 screen printing

[0046] Take 2ml of the carbon quantum dots prepared above, weigh 8g of polyvinylpyrrolidone (K-30), mix the two, and magnetically stir for 2h, let stand for 2h, take 2g of the solution on the screen of the screen printing instrument, and Filter paper was placed under the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com