Patents

Literature

44 results about "Vacuum grease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum grease is a lubricant with low volatility and is used for applications in low pressure environments. As well as a lubricant, vacuum grease is also used as a sealant for joints in vacuum systems. This is usually limited to soft vacuums, as ultra high vacuum or high temperatures may give problems with the grease outgassing. Grease is most commonly used with glass vacuum systems. All metal systems usually use knife-edge seals in soft metals instead. Where O ring seals are used, these should not be greased (in static seals at least) as it can cause the O rings to become permanently distorted when compressed.

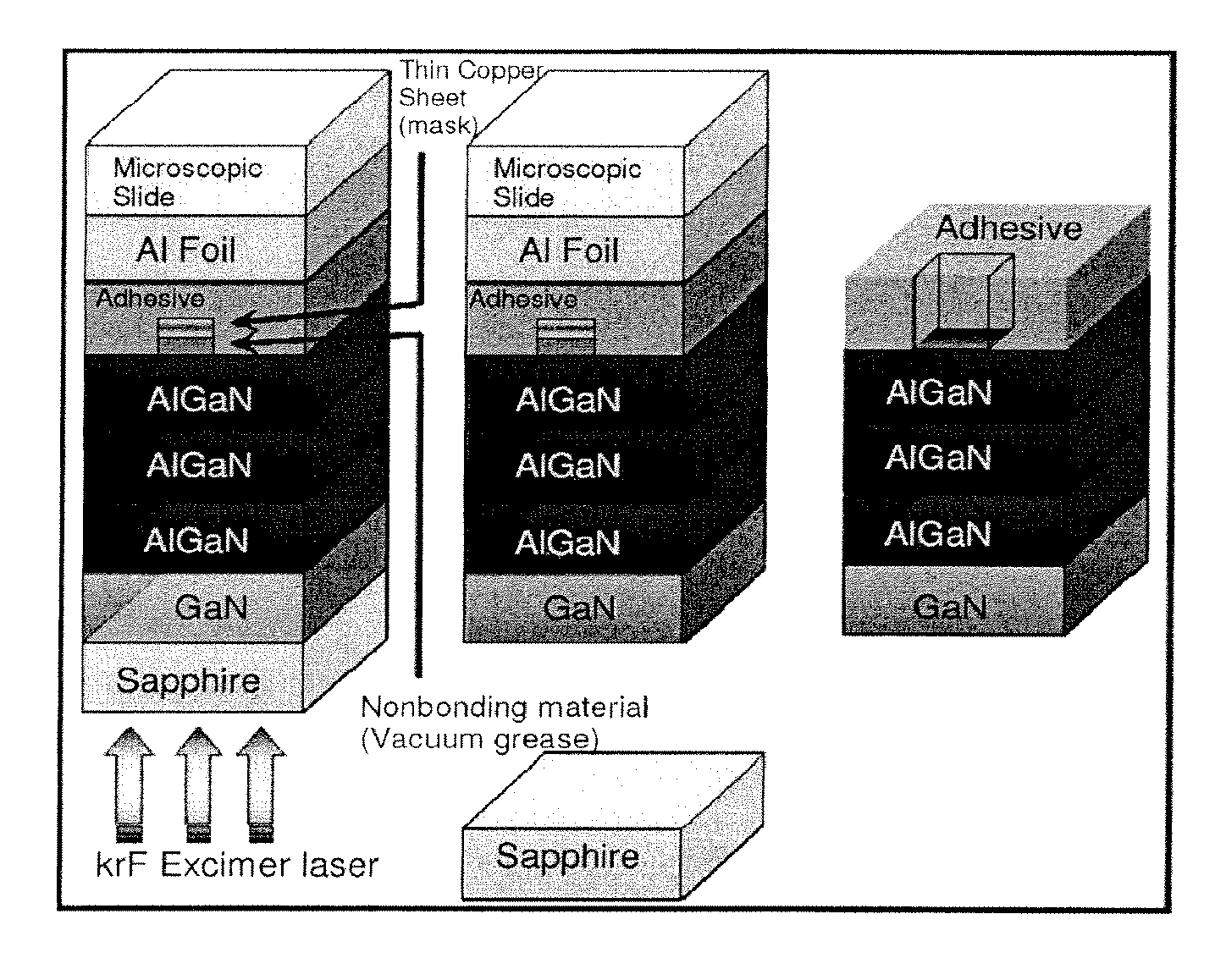

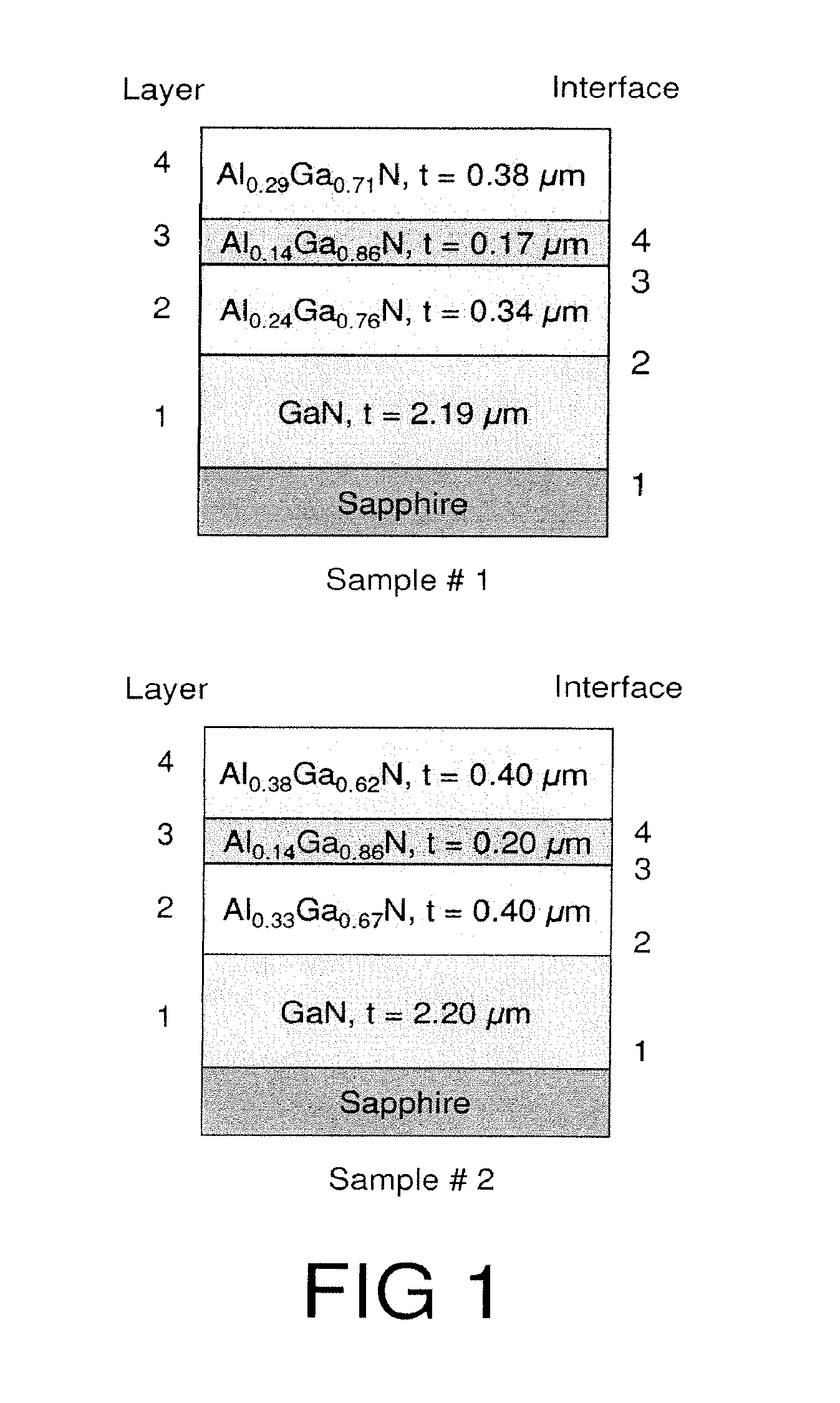

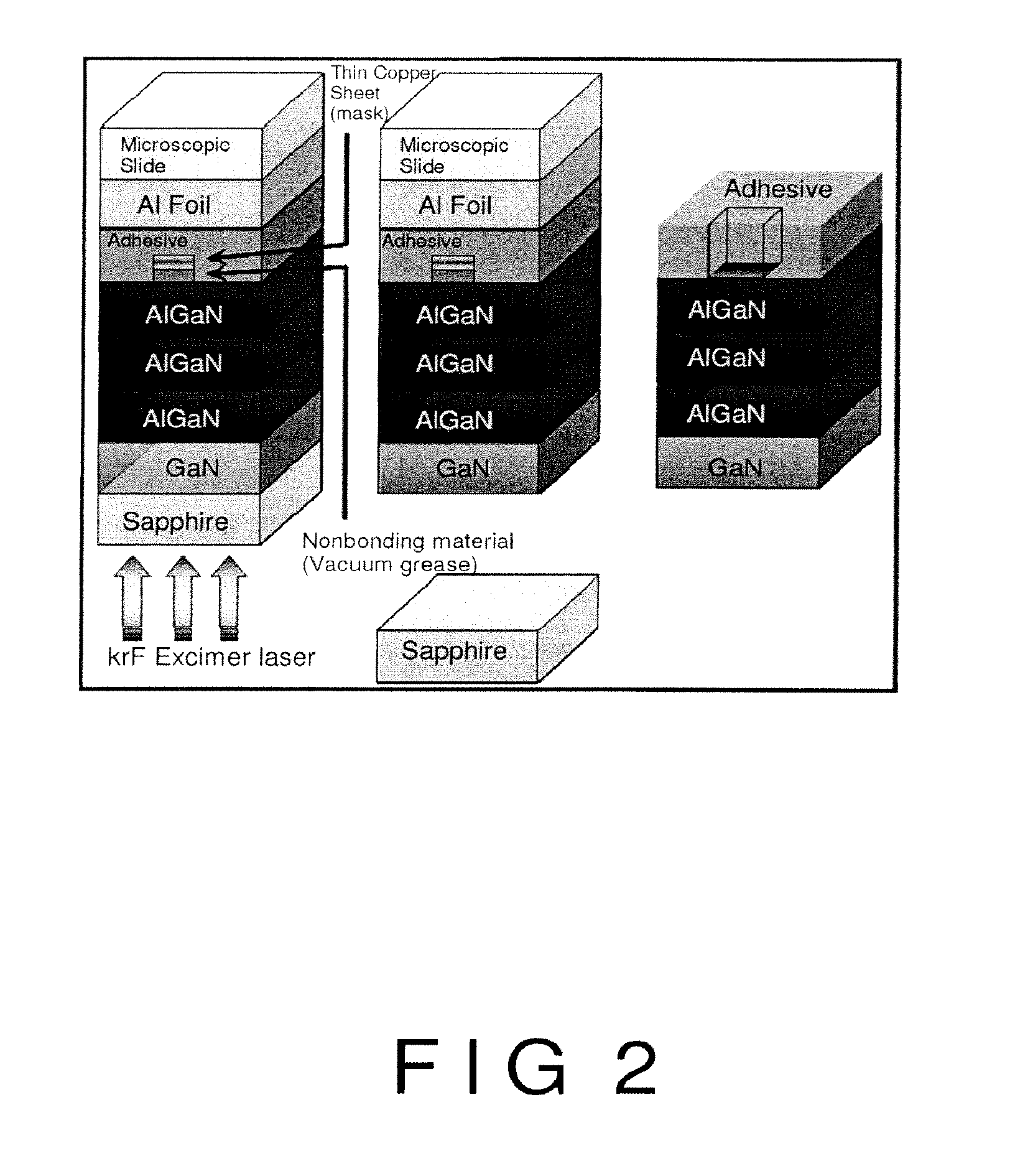

Fabrication of GaN and III-nitride alloys freestanding epilayers membranes using a nonbonding laser

Owner:ELGAWADI AMAL

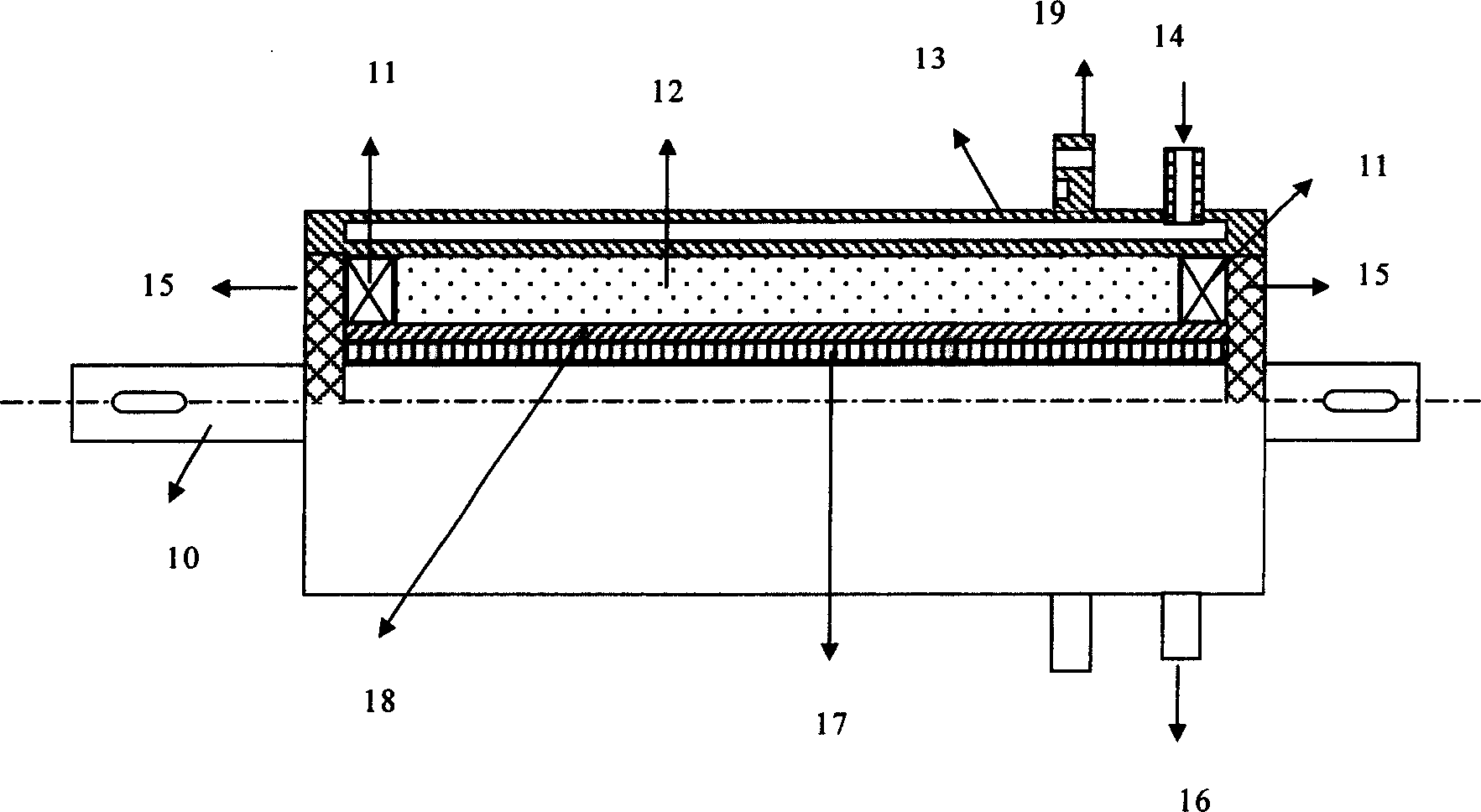

High-temperature superconducting magnet online monitoring system

InactiveCN104198803AMonitor temperatureMonitor currentThermometers using physical/chemical changesMeasurement using digital techniquesManganinHigh-temperature superconductivity

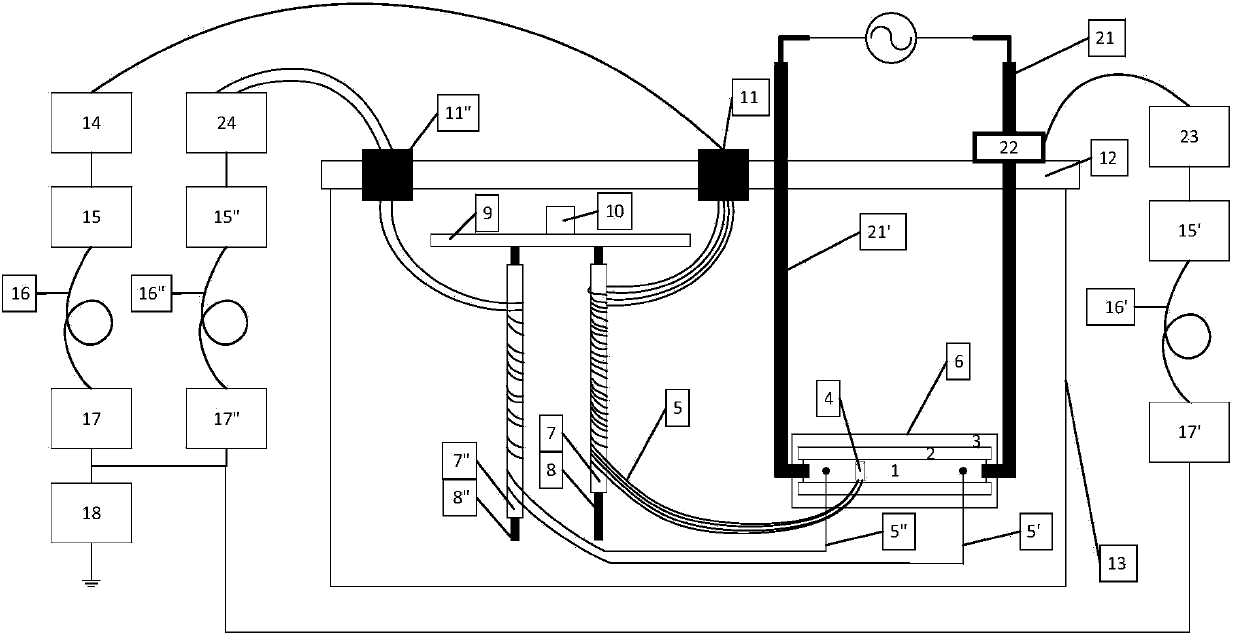

A high-temperature superconducting magnet online monitoring system comprises a high-temperature superconducting magnet system, a conduction cooling refrigeration system, a low-temperature Dewar system, a testing device, a digital voltage meter, a carburizing ceramic temperature sensor, a measuring manganin wire, a heat conduction insulating layer, a temperature transmitter, a fiber converter, a fiber, a compression joint copper sheet and low-temperature high vacuum grease, the cooling refrigeration system comprises a refrigerating machine cold head, a copper cold conduction connecting plate and a copper cold conduction framework, the heat conduction insulating layer coats the copper cold conduction framework, the testing device comprises a computer and a current sensor, the middle of the measuring manganin wire is wound on the heat conduction insulating layer, the carburizing ceramic temperature sensor is directly pressed on the surface of a high-temperature superconducting strip, two ends of the carburizing ceramic temperature sensor are directly fixed on the surface of the high-temperature superconducting strip, gaps among the compression joint copper sheet, the carburizing ceramic temperature sensor and the high-temperature superconducting strip are filled with the low-temperature high vacuum grease for assisting in fixing the carburizing ceramic temperature sensor and conducting heat.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

System of online temperature monitoring for high-temperature superconducting tape

InactiveCN104215355AQuick monitoringAccurate temperatureThermometers using electric/magnetic elementsUsing electrical meansFiberHigh-temperature superconductivity

A system of online temperature monitoring for a high-temperature superconducting tape comprises a high-temperature superconducting magnet system, a conduction-cooled refrigerating system, a low-temperature Dewar system and a temperature measurer; the conduction-cooled refrigerating system comprises a refrigerator cold head, a copper conduction-cooled connecting disc and a copper conduction-cooled frame; the temperature measurer comprises a carburized ceramic temperature sensor, copper-manganese wires for measurement, a temperature transmitter, a first fiber converter, an optical fiber, a second fiber converter, a computer, a crimping copper sheet and low-temperature high-vacuum grease. The middles of the copper-manganese wires wrap a heat transfer insulating layer on the copper conduction-cooled frame. The carburized ceramic temperature sensor is directly crimped on the surface of the high-temperature superconducting tape; two ends of the carburized ceramic temperature sensor are directly fixed on the surface of the high-temperature superconducting tape by welding; gaps among the crimping copper sheet, the carburized ceramic temperature sensor and the high-temperature superconducting tape is filled with the low-temperature high-vacuum grease to assist in fixing the carburized ceramic temperature sensor and transferring heat.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

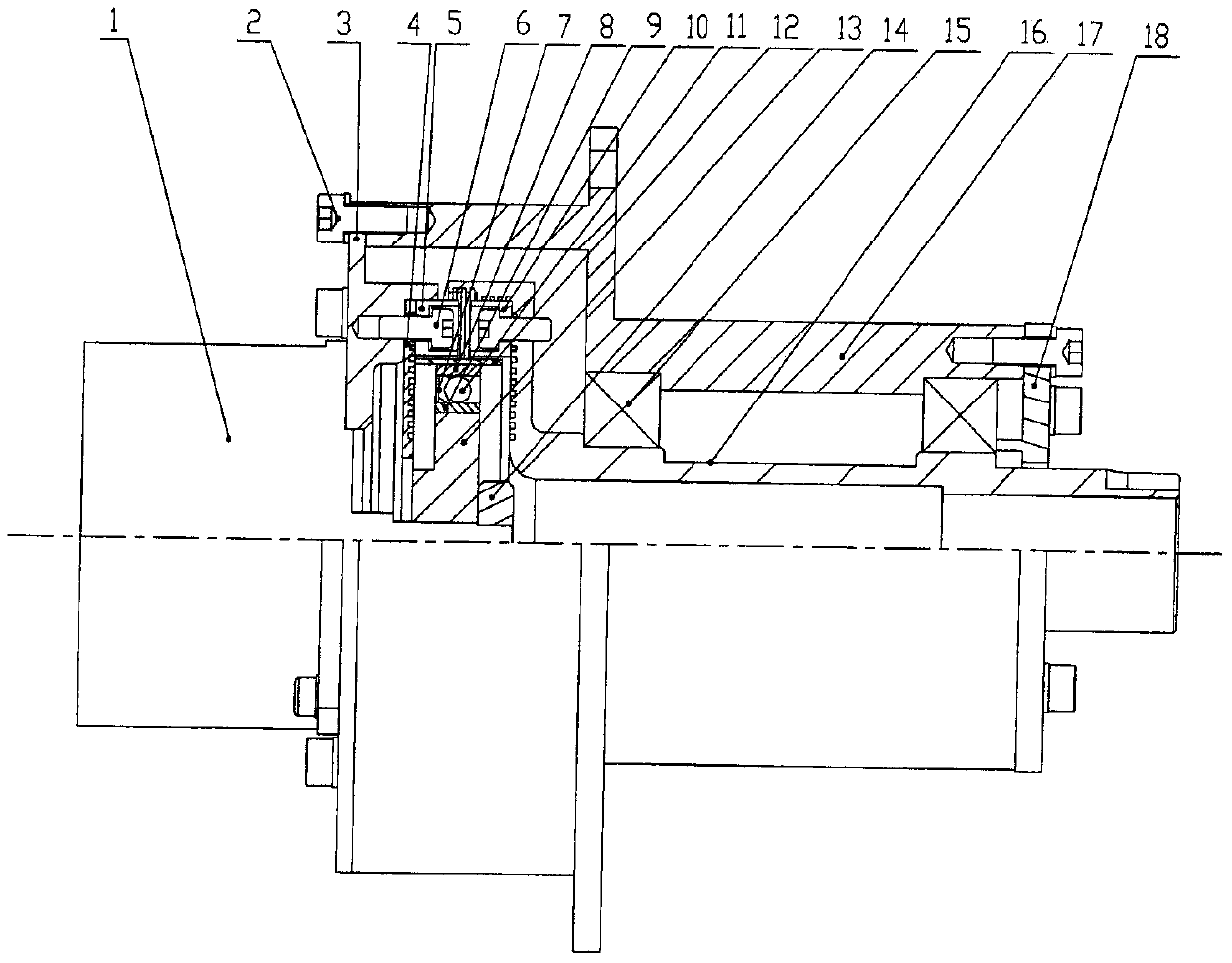

Rotation device for vacuum vertical planet clamp

InactiveCN1702190AExtended service lifeIncrease vacuumVacuum evaporation coatingSputtering coatingVertical planeEngineering

A vacuum vertical planetary holder rotating device, which can improve uniformity of thickness of vacuum coating, works by that directly by hydromagnetic transmission, generator drives planetary holder rotate along vertical plane. Designing Support and location bearing in the double-layer water-cooled container, it prevents vacuum grease in the bearing from volatilizing and charring because of excess temperature, avoids the pollution to vacuum coating, ensures the normal usage of bearing, and improves the vacuum degree and the operation stability. The invented can apply extensively in vacuum coating and the related industry, especially to vertical rotational structure.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

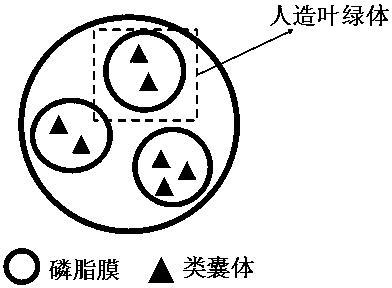

Preparation method of thylakoid-containing artificial cells and photosynthesis simulating method

The invention relates to a preparation method of thylakoid-containing artificial cells and a photosynthesis simulating method, and belongs to the fields of biotechnology, biochemistry and synthetic biology. The method comprises the following steps of extracting thylakoid particles from fresh spinach leaves, and storing the thylakoid particles in a buffer solution for use; smearing a phospholipid solution onto an ITO glass electrode; after the solvent volatilization, forming a layer of phospholipid membrane; fixing a polytetrafluoroethylene framework by vacuum grease; adding liquid phases intothe polytetrafluoroethylene framework; applying alternating current onto the ITO glass electrode for preparing a GUV solution; mixing the GUV solution and a thylakoid solution; preparing the thylakoid-containing artificial cells. The thylakoid-containing artificial cells are prepared through the enlightenment of the natural plant cell structure and function; the model can realize the optical driveelectron transfer process under the artificial sunlight irradiation. Through the model building, the attributes of chloroplasts in nature are doubly simulated from the structure and the function. Thecomplicated cells realize simplified research, so that the development and the progress of the biomimetic chemistry are promoted.

Owner:HARBIN INST OF TECH

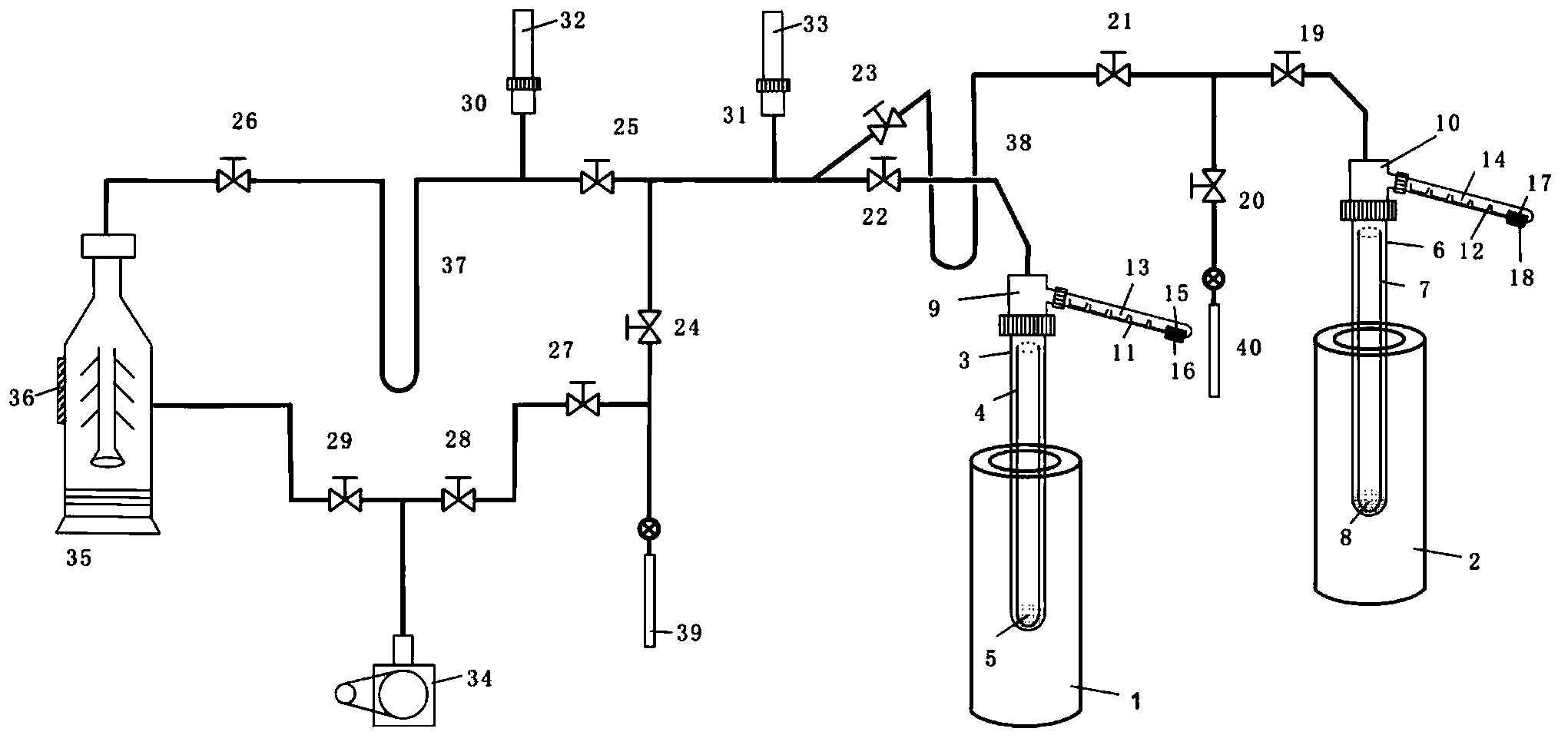

Quick preparation method for synchrotron radiation X-ray diffraction test sample of hydrogen storage material

ActiveCN105571915AReduce dosageEfficient preparationPreparing sample for investigationTest sampleX-ray

The invention relates to a quick preparation method for a synchrotron radiation X-ray diffraction test sample of a hydrogen storage material and relates to the technical field of synchrotron radiation X-ray diffraction test. The quick preparation method comprises the following steps: inserting a capillary tube into a sponge; hermetically covering the sponge in a transparent organic glass fixing bracket; supporting a piece of transparent organic glass on a metal fixing bracket; filling the ground sample powder into the capillary tube through a weighing paper funnel; packaging an opening end of the capillary tube with vacuum grease, wherein the grinding, filling and packaging processes of the sample powder are all performed in an argon glove box. According to the quick preparation method, the dosage of the sample is reduced, the quick efficient preparation for the test sample is realized and the hydrogen storage material is prevented from being oxidized, so as to acquire the high-accuracy synchrotron radiation X-ray spectrums of the material and know the microstructure of the material according to the X-ray spectrums.

Owner:YANGZHOU UNIV

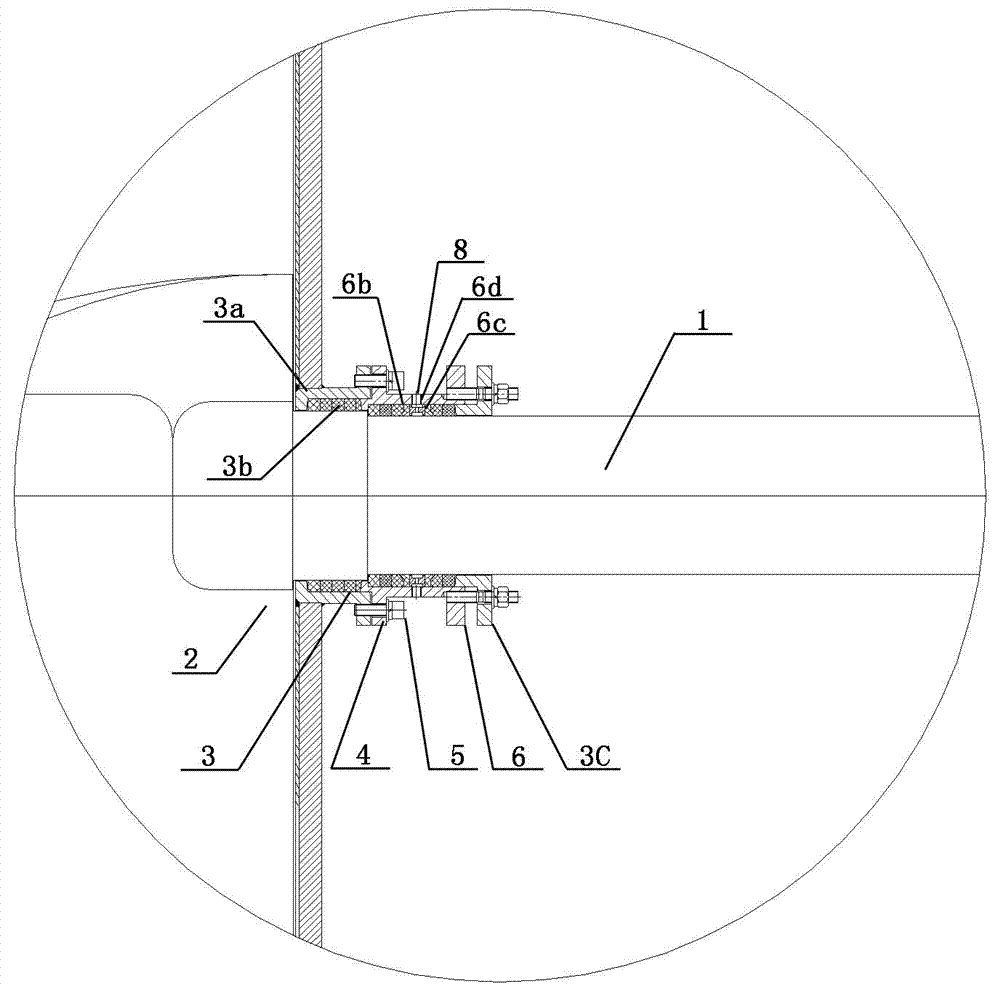

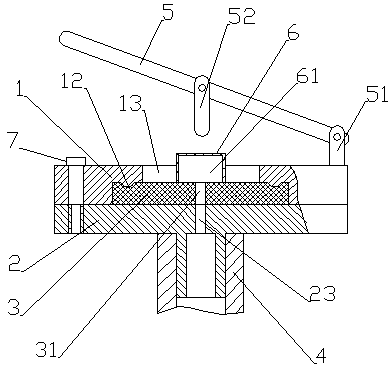

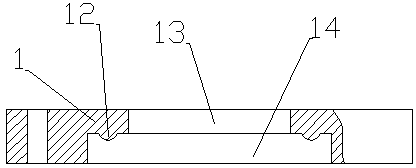

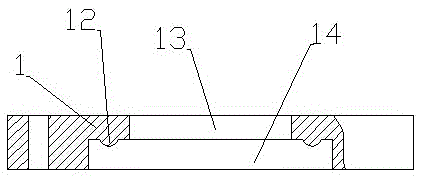

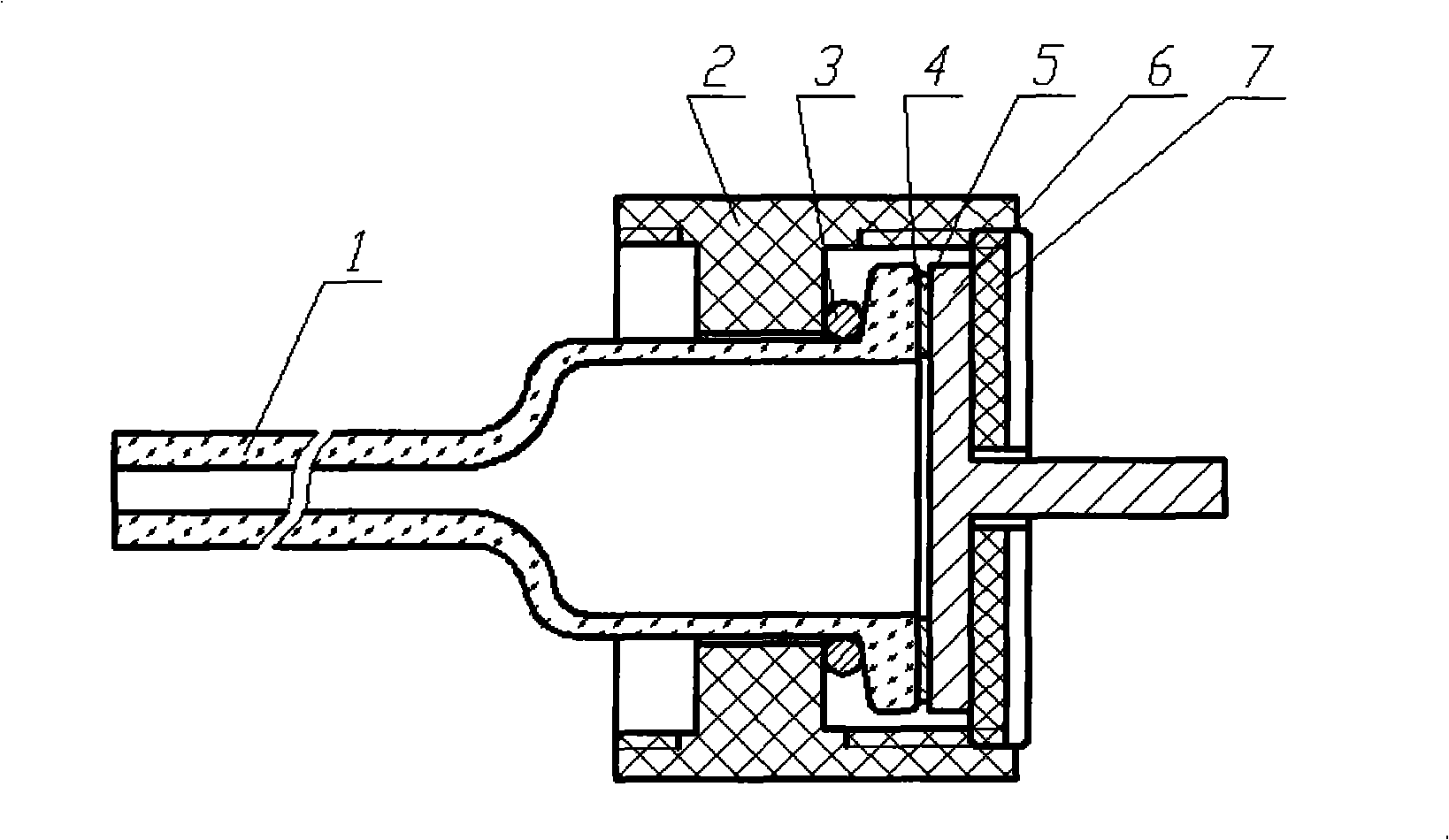

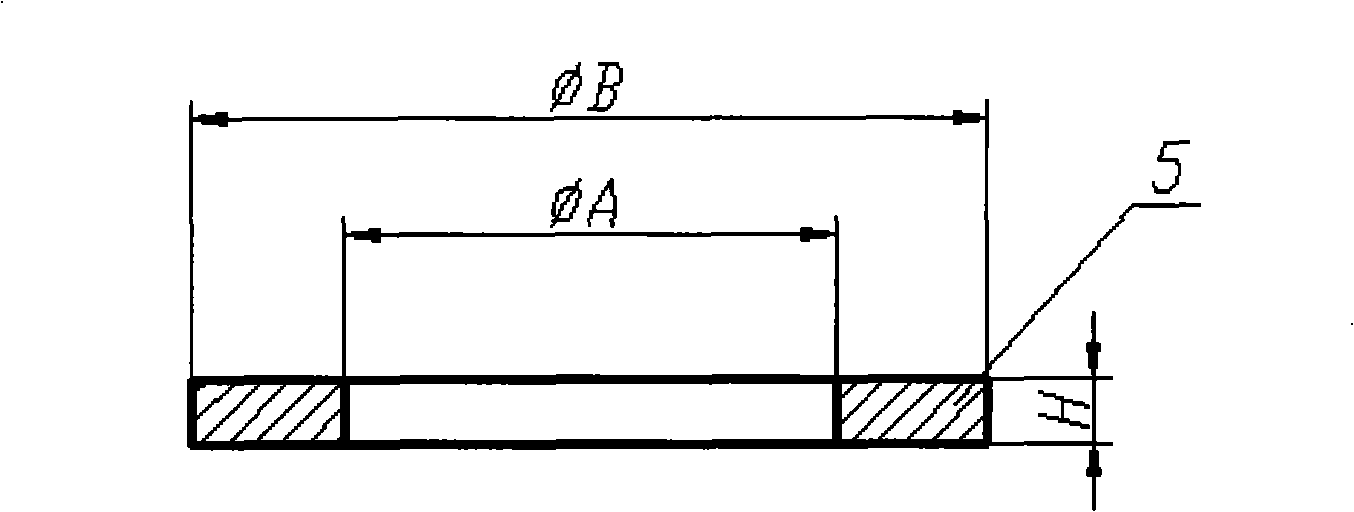

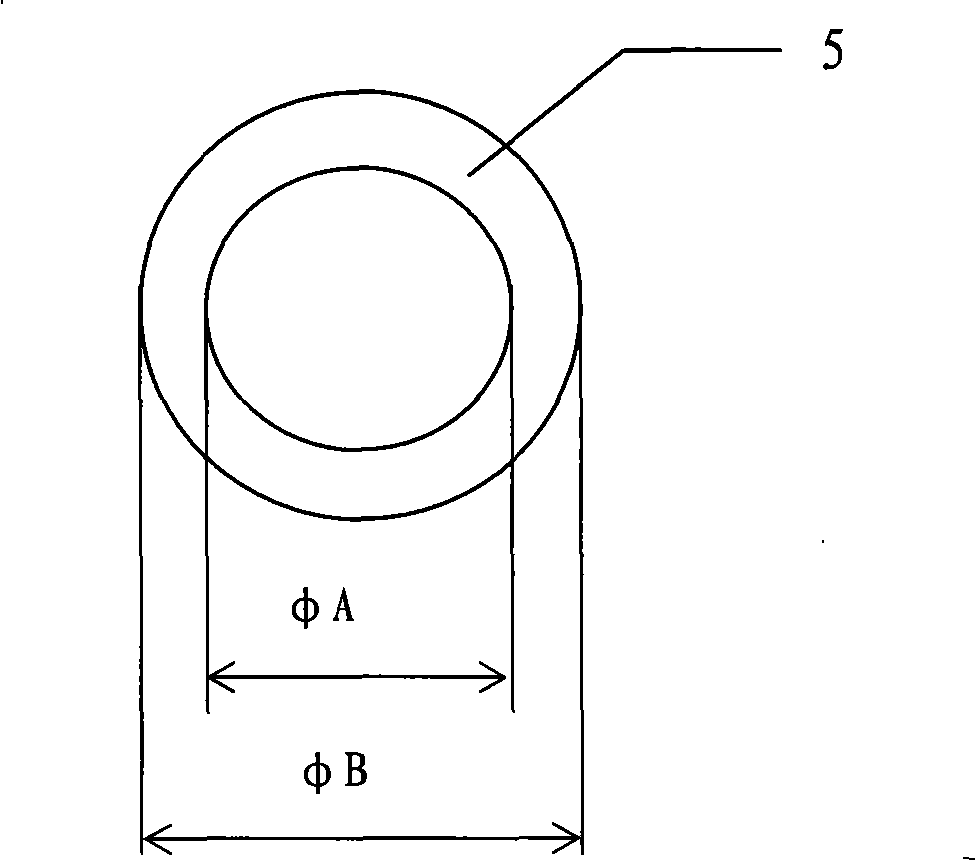

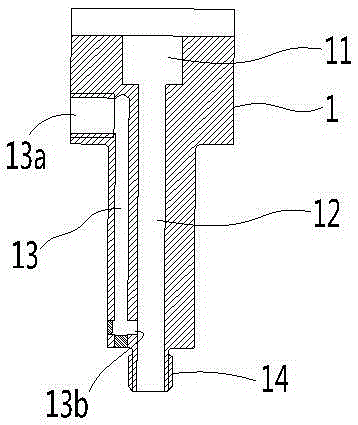

Rotating shaft sealing structure

The invention provides a rotating shaft sealing structure comprising a rotating shaft. A first sealing device is arranged at the connection of the rotating shaft and workpiece and comprises a metal seal ring A, a fluorine rubber ring and a metal locking ring; the metal seal ring A is circular, coats the gap of the connection of the rotating shaft and workpiece and is filled with the fluorine rubber ring; the structure further comprises a second sealing device; the second sealing device is fixedly connected to the first sealing device on the rotating shaft axially in the same row through a threaded hole; the metal locking ring is fixedly connected to the second sealing device through the threaded hole formed in the second sealing device. The structure adopts double seals, the fluorine rubber ring with lips is arranged additionally inside, the two lips can be assembled oppositely during assembly; a grease ring is arranged in the middle and is filled with vacuum grease through a grease feed port, the fluorine rubber ring with the lips can be lubricated constantly and is prevented from dry grinding, the two end sealing effect is fine through the bidirectional lip seal, and leakage is eliminated.

Owner:NANTONG KNEADING MIXING MACHINE

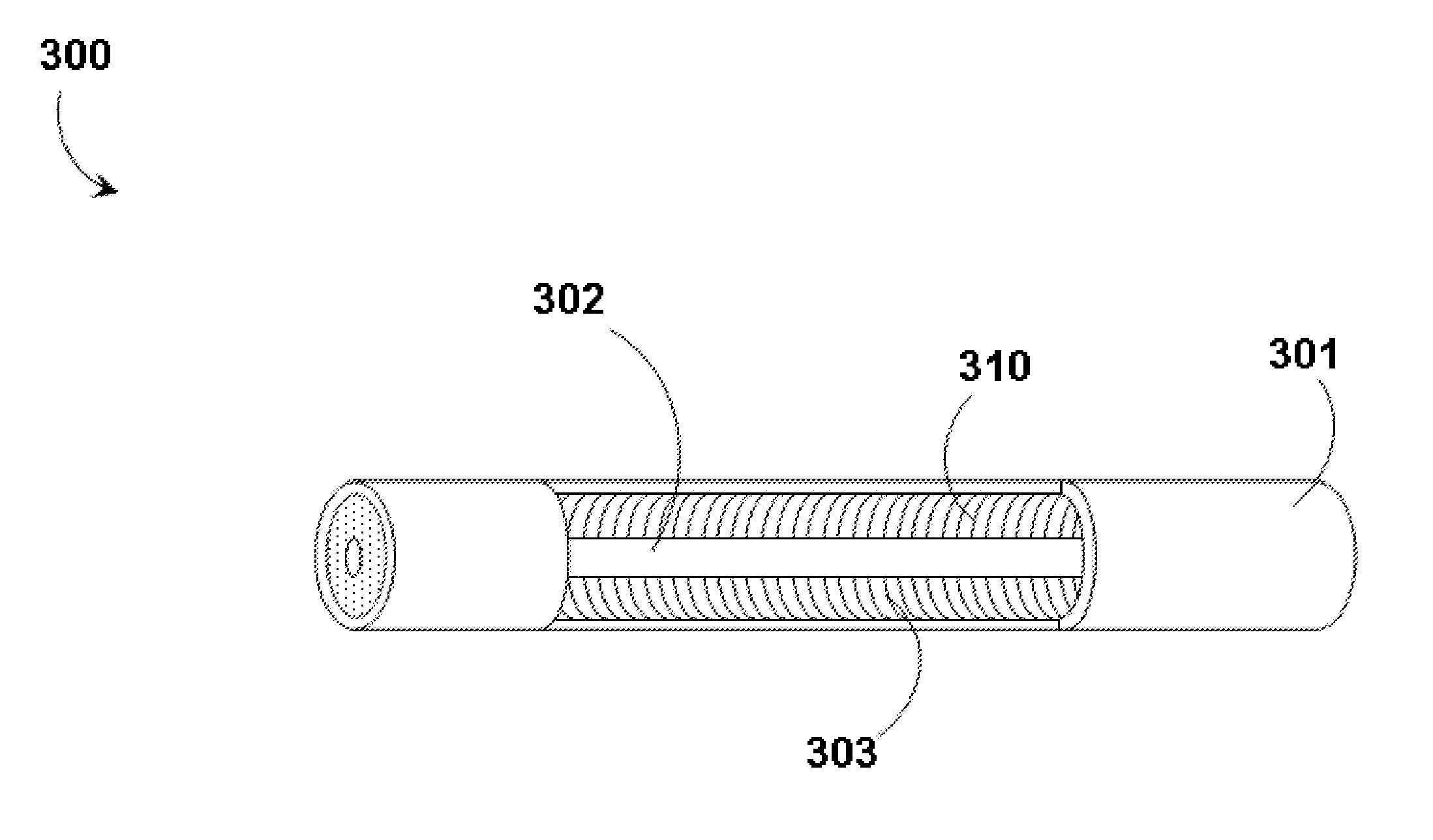

Systems and devices for electrical filters

InactiveUS20120088675A1Semiconductor/solid-state device detailsSolid-state devicesPolyesterChemical composition

Adaptations and improvements to tubular metal powder filters include employing a polyester binder or a binder formed of vacuum grease, employing metal powders of multiple different chemical compositions and / or spanning multiple different ranges of grain-size, replacing the outer conductive housing and metal powder components with a single structure formed of sintered metal powder, and texturing (such as rifling, threading, sanding, or scratching) an inner surface of the outer conductive housing. The various adaptations and improvements are designed to accommodate single-ended and differential signaling, as well as superconducting and non-superconducting applications.

Owner:D WAVE SYSTEMS INC

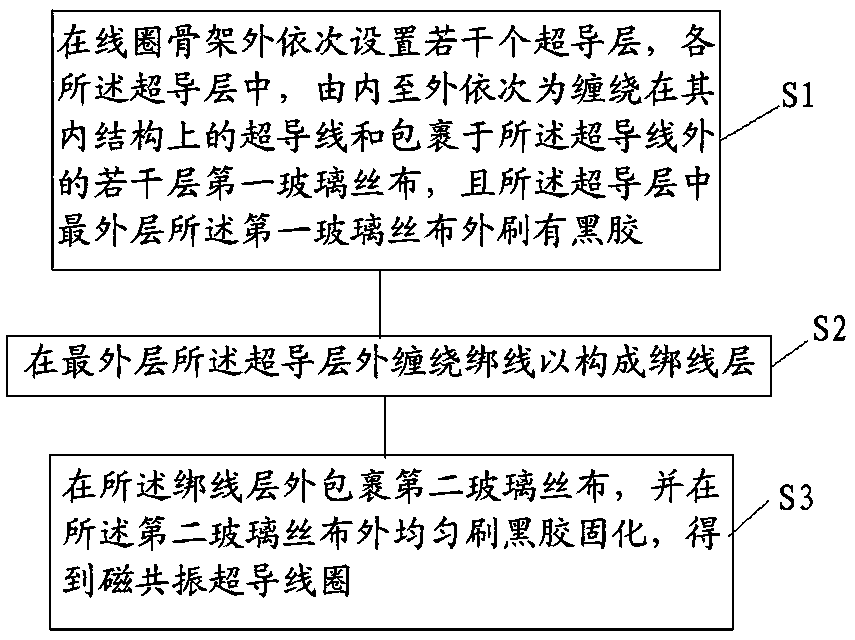

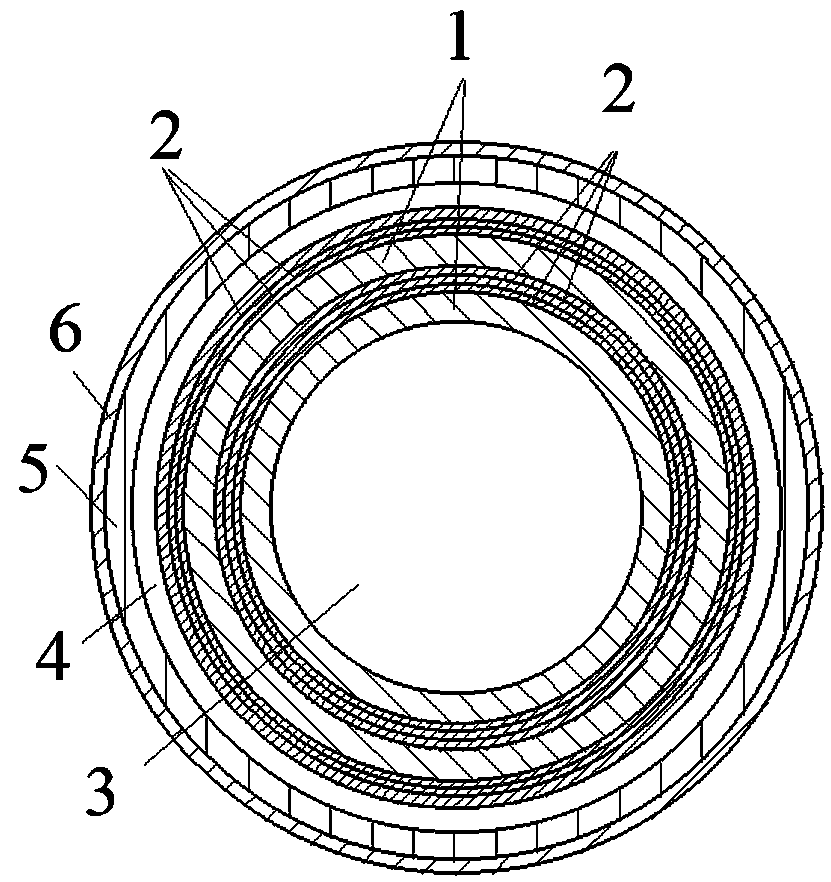

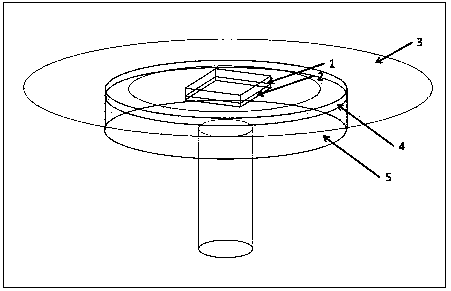

Magnetic resonance superconducting coil winding method and magnetic resonance superconducting coil

ActiveCN111243854AImprove reliabilityCoils manufactureMeasurements using magnetic resonanceSuperconducting CoilsGlass wool

The invention discloses a magnetic resonance superconducting coil winding method and a magnetic resonance superconducting coil. The winding method comprises the steps that a plurality of superconducting layers are sequentially arranged outside a coil framework; each superconducting layer sequentially comprises a superconducting wire wound on the inner structure of the superconducting layer and a plurality of layers of first glass wool cloth wrapping the superconducting wire from inside to outside, and black glue is brushed outside the first glass wool cloth on the outermost layer in the superconducting layers; a binding wire is wound outside the outermost superconducting layer to form a binding wire layer; second glass wool cloth is wrapped outside the wire binding layer, and black glue isuniformly brushed outside the second glass wool cloth for curing to obtain the magnetic resonance superconducting coil. Different layers of superconducting wires are fixed by laying glass wool clothand brushing black glue. Compared with a vacuum grease immersion mode, the method provided by the invention has the advantages that gaps among the superconducting wires can be filled more fully; the fixing effect on the superconducting wires is better; the fixing reliability among the superconducting wires can be guaranteed; and the risk of quench caused by energy generated by energization stressdisplacement of the superconducting wires during excitation is reduced.

Owner:SHANDONG AOXIN MEDICAL TECH CO LTD

Low-temperature preparation method of silicon-rich silicon nitride film

InactiveCN109449076AReduce stressImprove corrosion resistanceSemiconductor/solid-state device manufacturingInductively coupled plasmaChemical vapor deposition

The invention discloses a low-temperature preparation method of a silicon-rich silicon nitride thin film. The low-temperature preparation method of the silicon-rich silicon nitride thin film comprisessteps: step 1, providing a tray and a substrate, smearing vacuum grease at the lower side of the substrate, and pasting the substrate smeared with the vacuum grease on the tray; step 2, performing plasma surface processing on the substrate; and step 3, growing silicon nitride satisfying a preset Si / N content ratio on the substrate by employing an inductive coupling plasma chemical vapor deposition method. According to the preparation method, the inductive coupling plasma vapor deposition method is adopted, the growing speed, the reaction gas proportion, the airflow, the air pressure, and theplasma power are controlled, the silicon-rich silicon nitride thin film with low stress and high anti-corrosion is obtained, the problem that the high-temperature process in the conventional preparation method is difficult to be compatible with a CMOS is solved, and the adaptability of the process is improved.

Owner:SUN YAT SEN UNIV

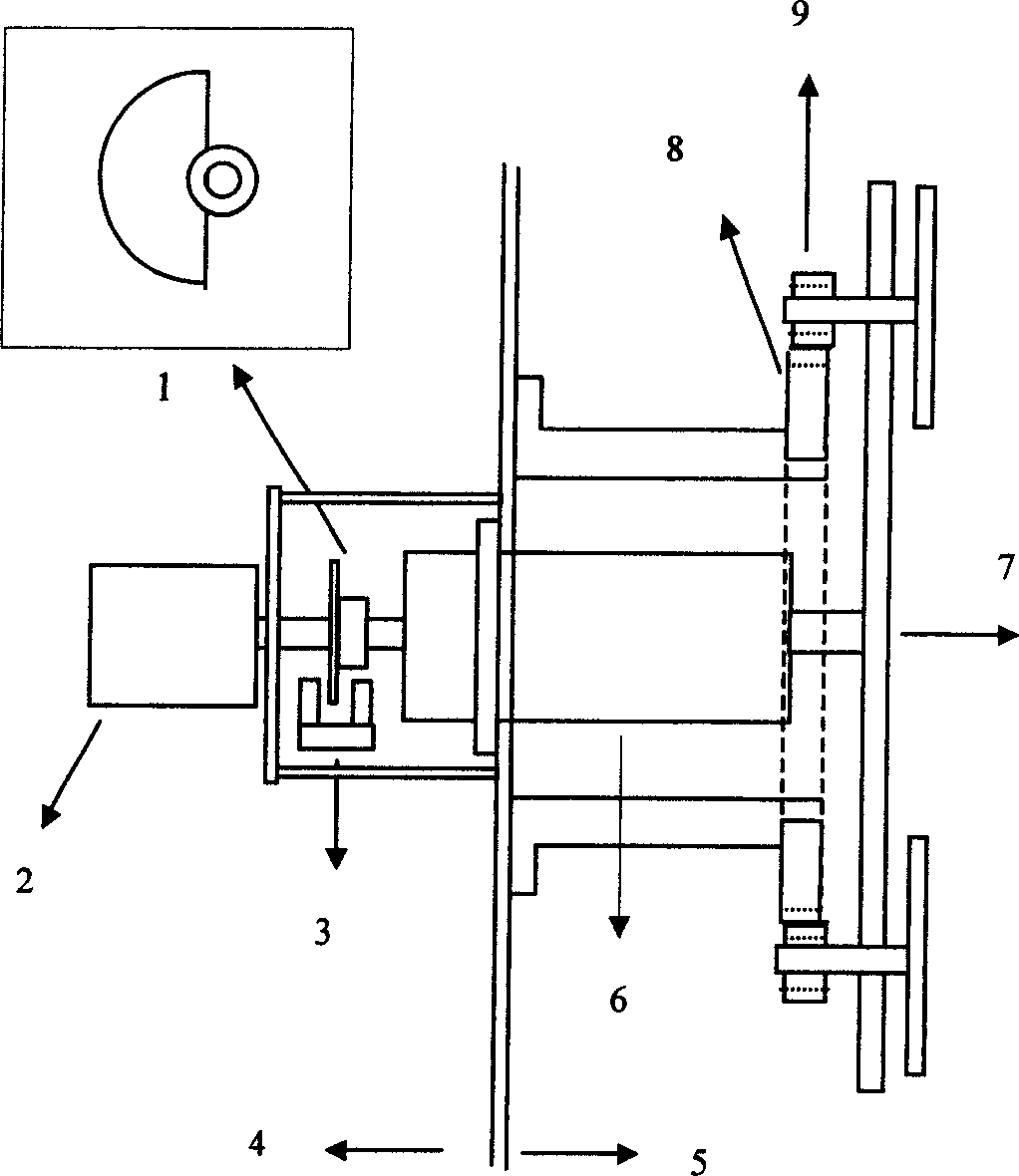

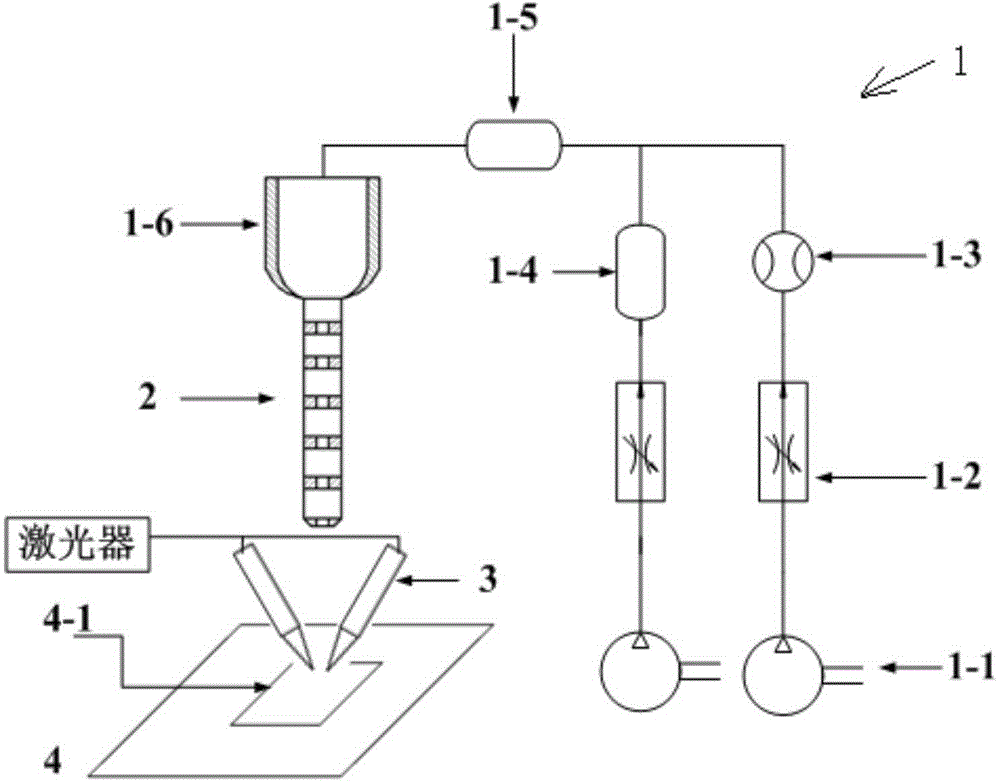

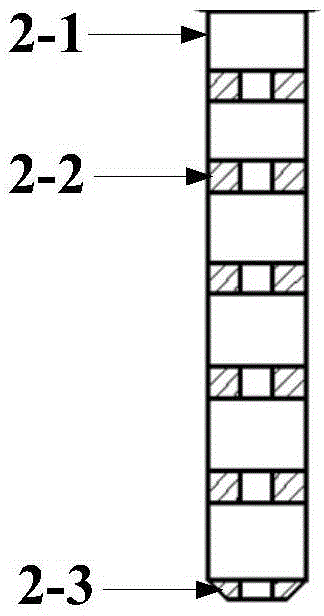

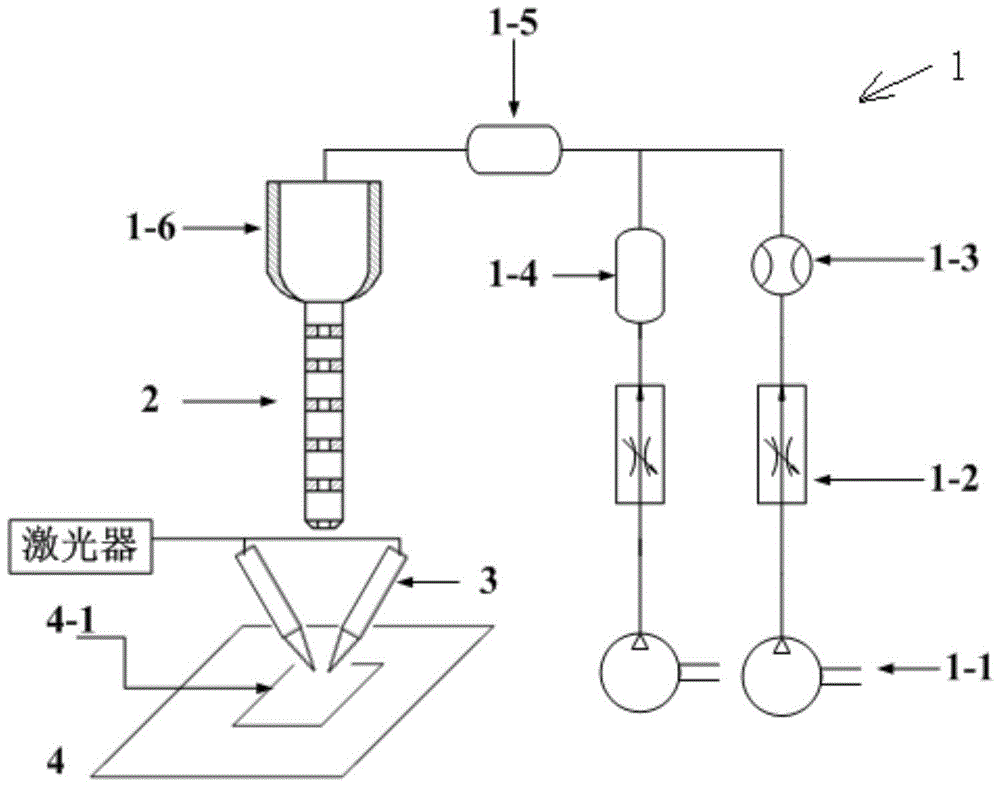

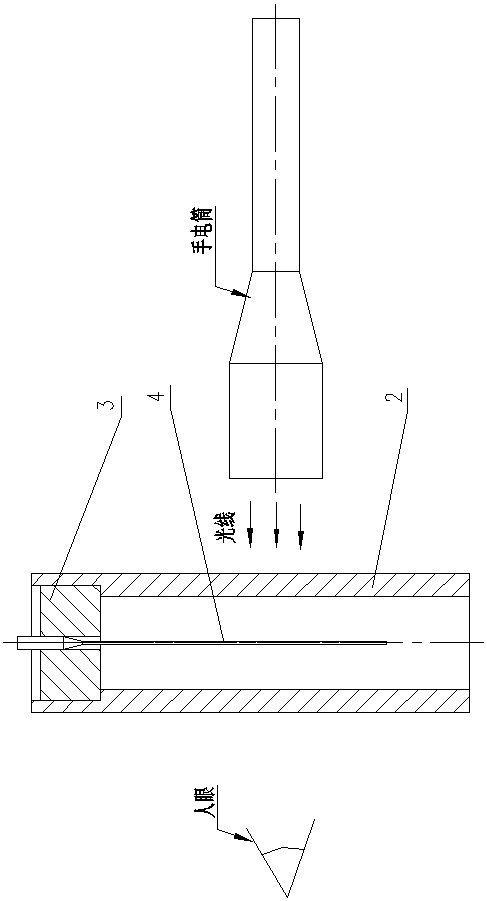

Nanoscale component laser sintering molding method and device

ActiveCN104385605ADroplet cladding position controllableSimple technical meansIncreasing energy efficiencyParticle flowNanoparticle

The invention discloses a nanoscale component laser sintering molding method and device. The nanoscale component laser sintering molding device comprises a mixed sample feeding system, an aerodynamic lens, a confocal laser group and a worktable; the mixed sample feeding system is provided with a buffer cavity. The nanoscale component laser sintering molding method comprises the steps of placing nanoparticle powder into a powder storage cavity, carrying the powder into a mixing cavity through air, adequately mixing the powder and another branch circuit of air, facilitating the obtained aerosol flow to enter the buffer cavity, further mixing the gas and nanoparticle powder, and lowering the pressure and flow rate to obtain a fluid with a Reynolds number of 200 to 700; facilitating the fluid to enter a cylindrical cavity in a laminar flow form, and spraying out the fluid in a single-particle flow form after the fluid passes through gathering holes in each lens and is focused; receiving the particles by a sintering substrate which is coated with vacuum grease on the worktable, and melting the particles by the confocal laser group; acquiring a two-dimensional pattern with nanoscale molding precision by virtue of the movement of the worktable in an X direction and a Y direction; gradually laminating the particles to obtain a component with the nanoscale molding precision by virtue of the movement of the worktable in a Z-axis direction.

Owner:SOUTH CHINA UNIV OF TECH

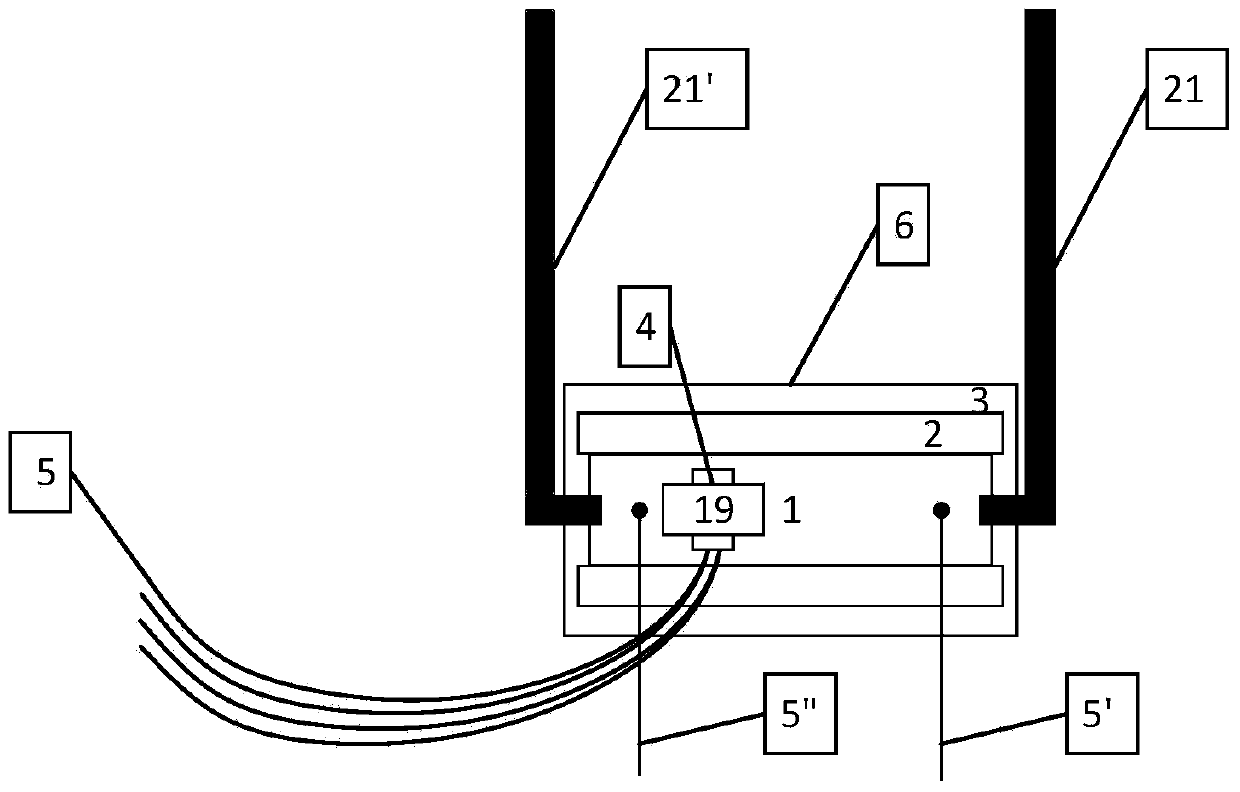

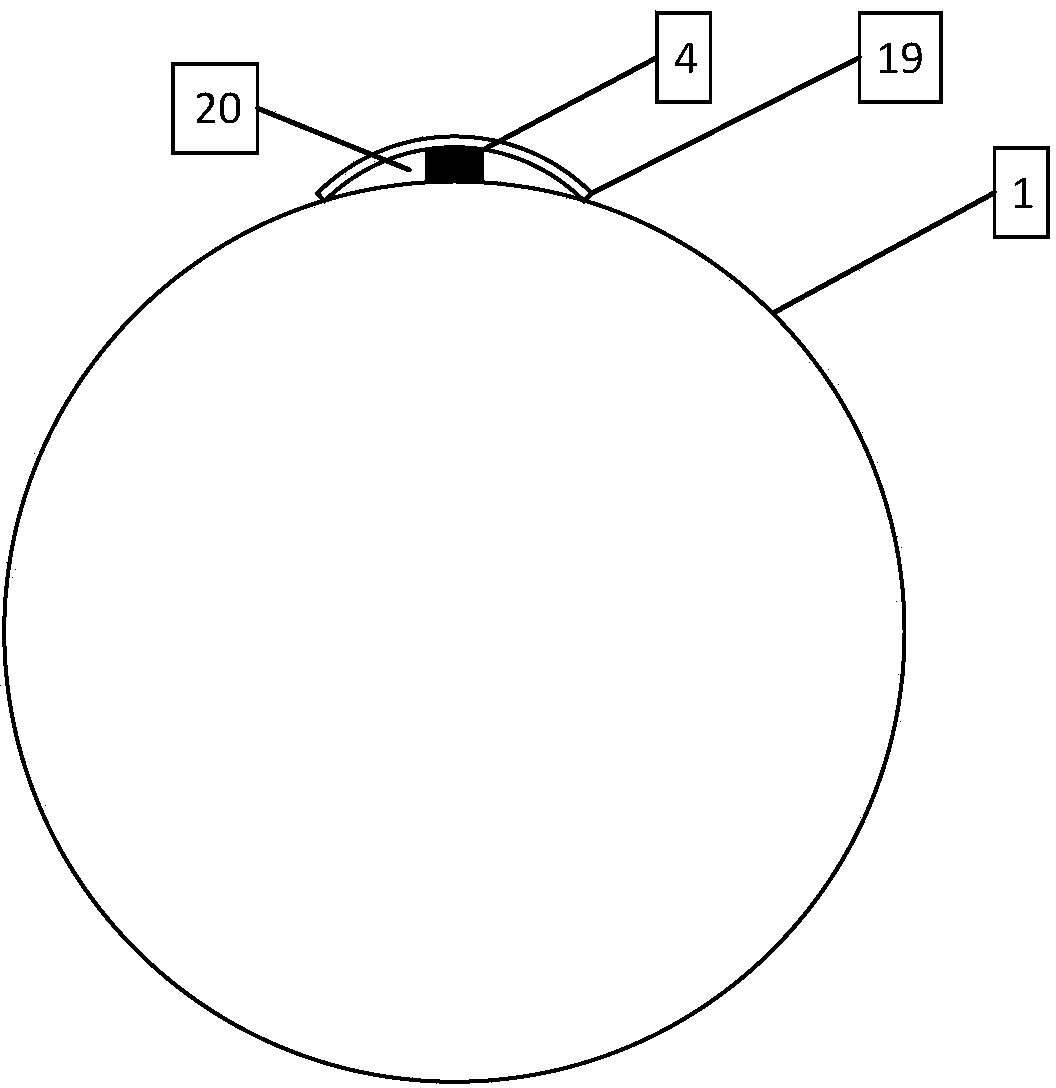

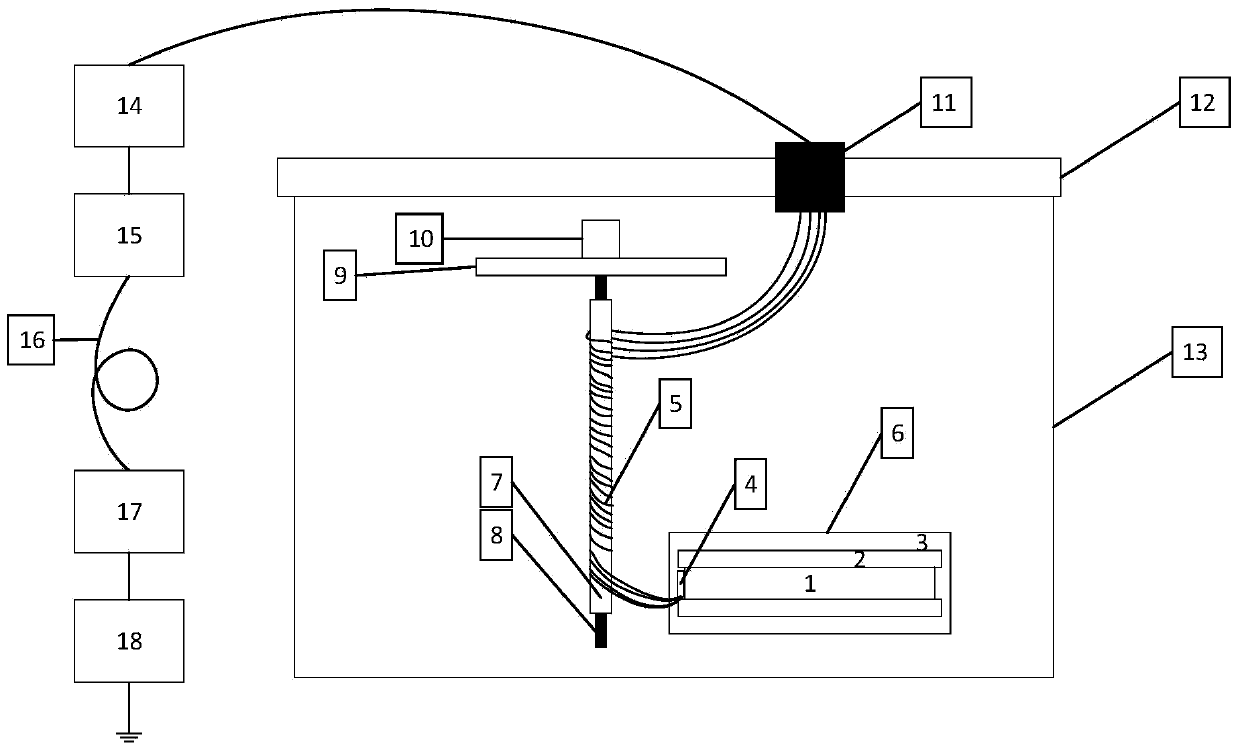

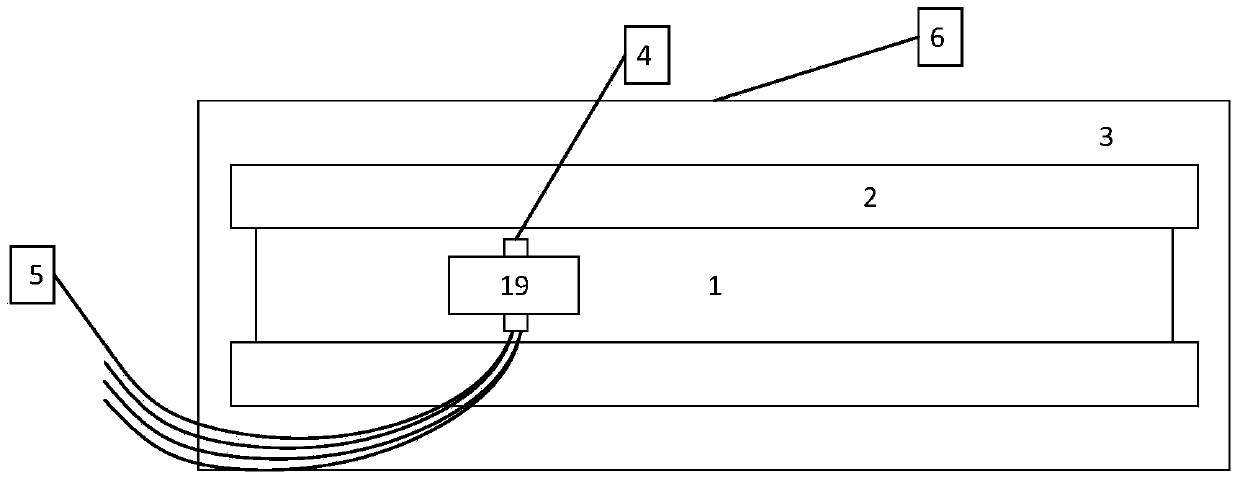

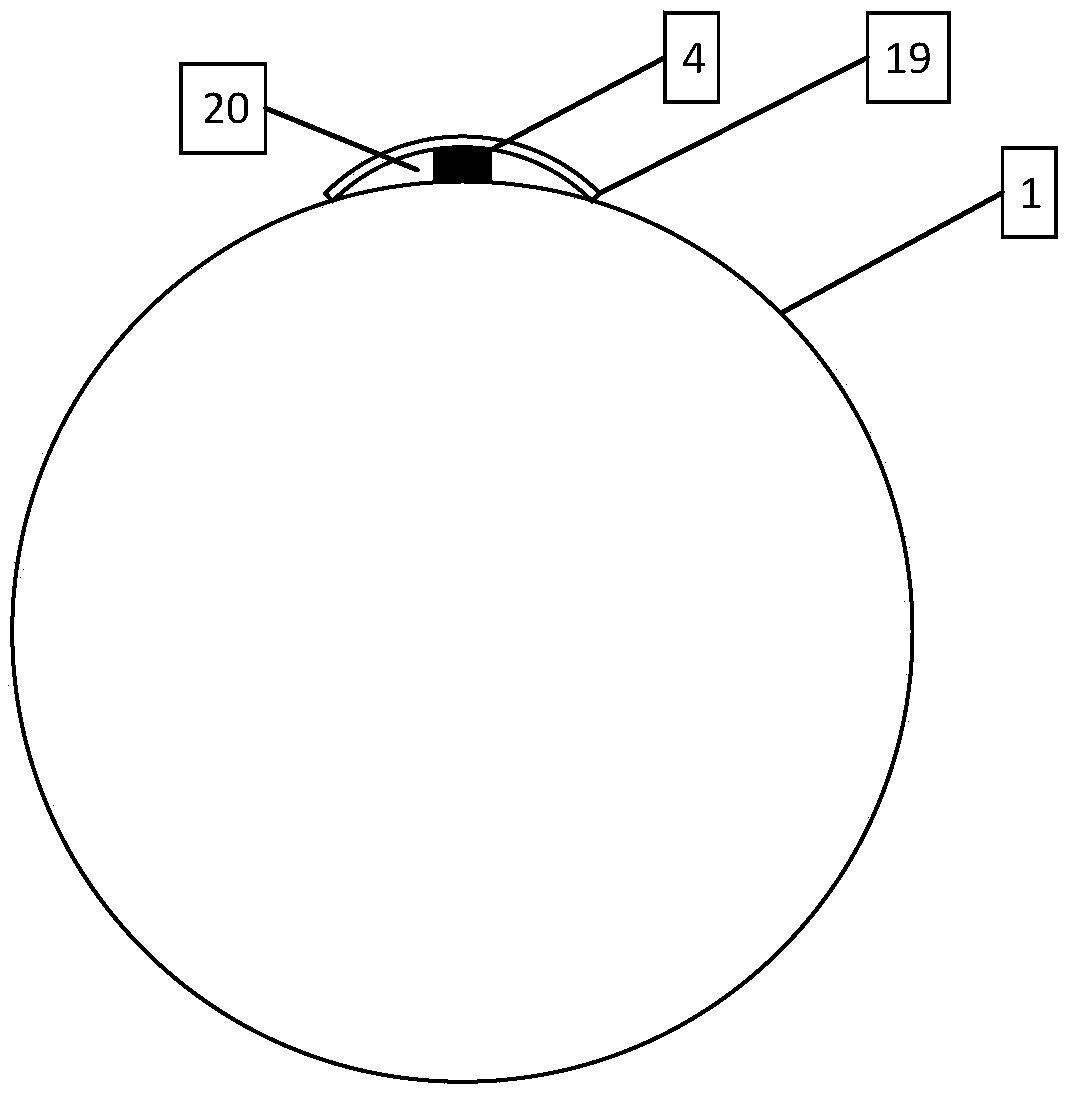

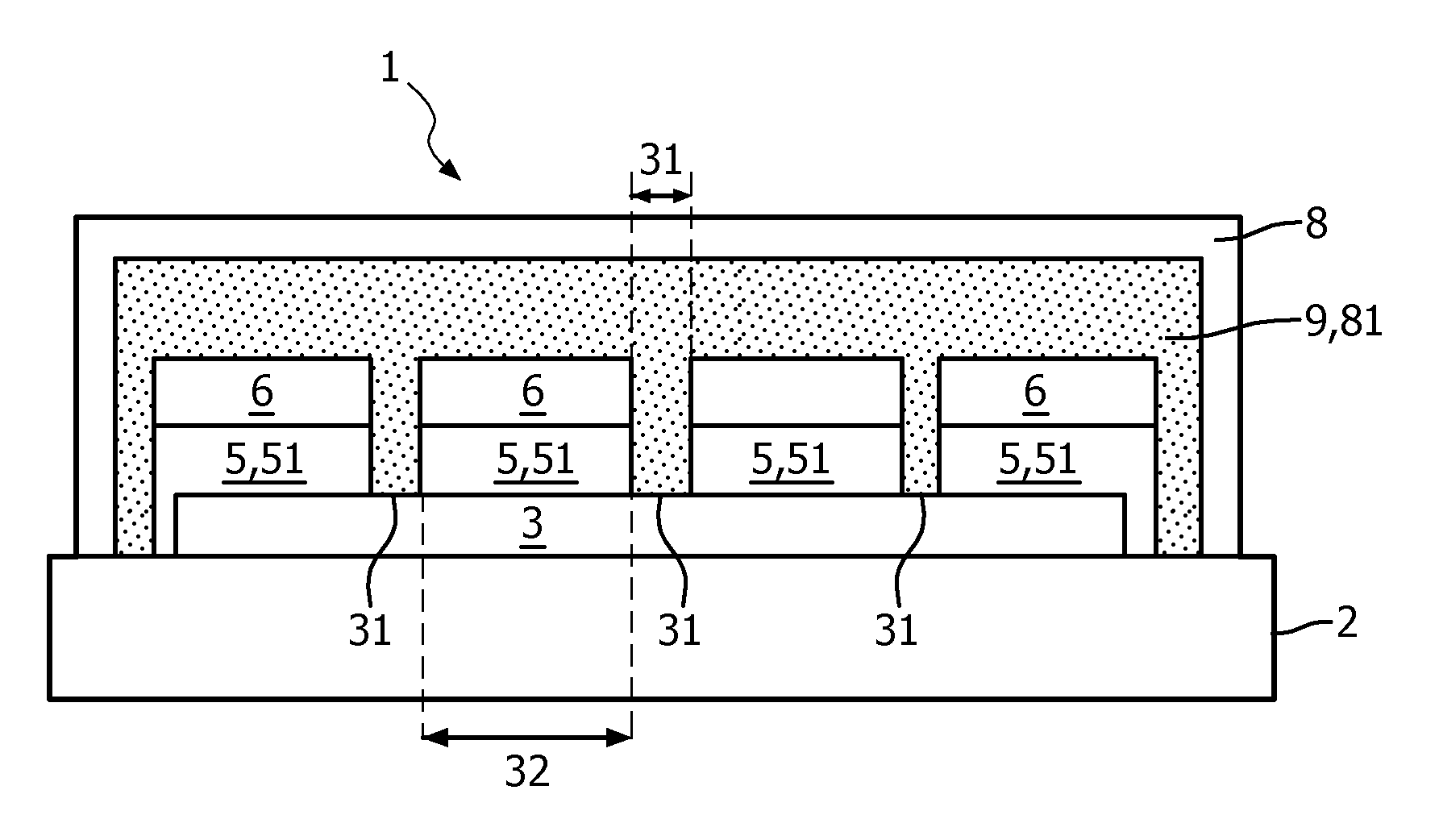

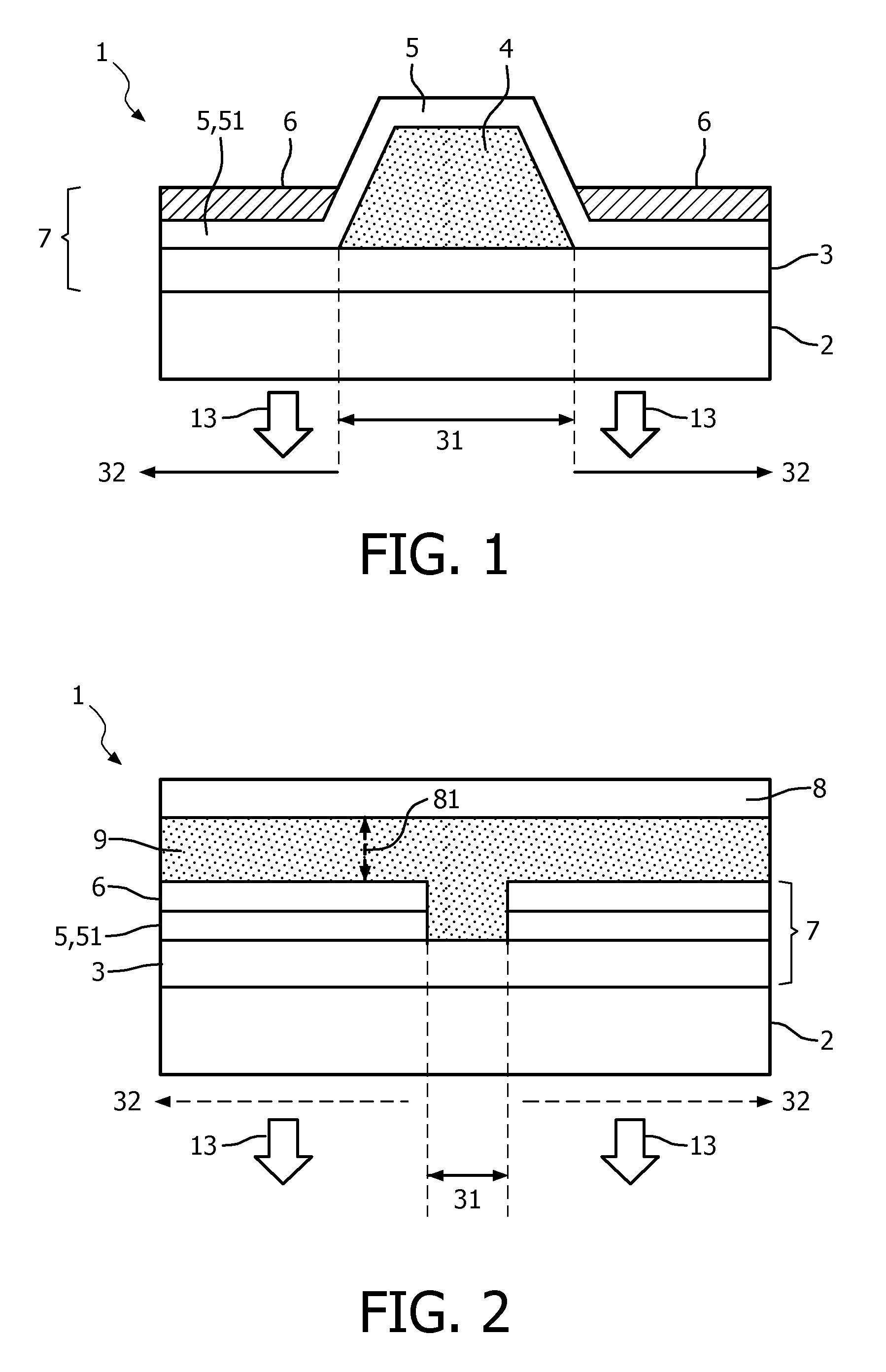

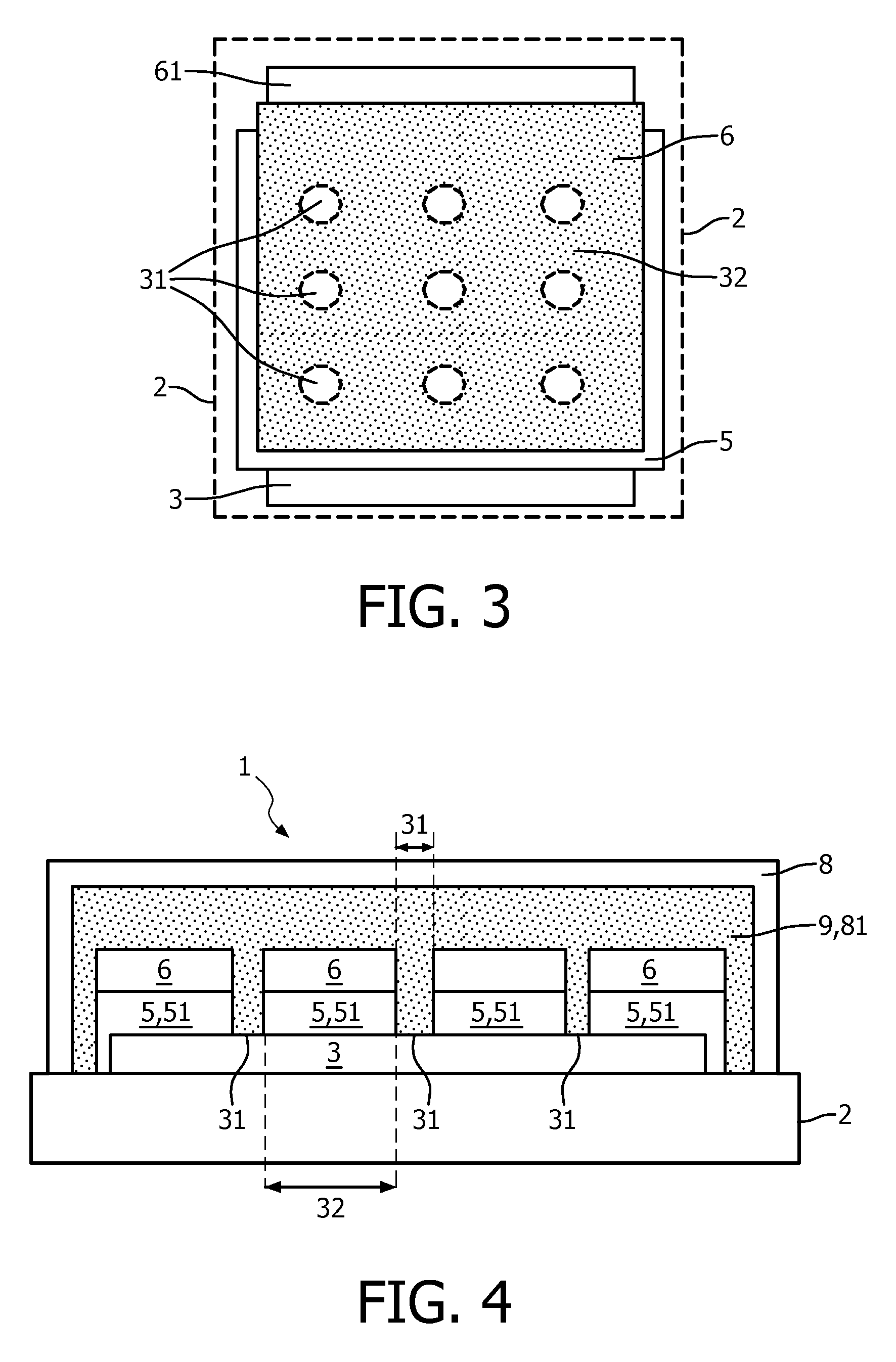

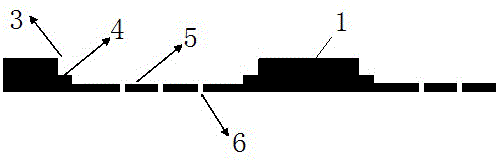

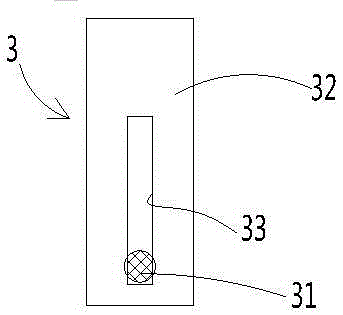

Structuring of OLEDs using stack modification layer comprising perfluorinated vacuum grease and/or perfluorinated vacuum pump oil

ActiveUS9196874B2Easy and flexible and reliableDischarge tube luminescnet screensSemiconductor/solid-state device testing/measurementOrganic layerEngineering

The invention relates to a method for manufacturing structured organic electroluminescent light-emitting devices (OLEDs) comprising light-emitting and non-emitting areas and to OLEDs manufactured according to this method comprising the steps of: Providing (P) a substrate (2) covered at least locally with at least one conductive layer as the first electrode (3); Depositing (D-SML) a stack modification layer (4) locally on top of the first electrode (3) to establish first areas (31) covered with the stack modification layer (4) and non-covered second areas (32) adjacent to the first areas (31) forming the desired structured pattern; —Depositing (D-OLS) the organic layer stack (5) comprising at least one organic light-emitting layer (51) on top of the first electrode (3) locally coated with the stack modification layer (4) providing an organic layer stack (5) being separated from the first electrode (3) by the stack modification layer (4) in between the organic layer stack (5) and the first electrode (3) in the first areas (31) and being in direct electrical contract to the first electrode (3) in the second areas (32); and Depositing (D-SE) a conductive metal layer as the second electrode (6) on top of the organic layer stack (5) to finish a functional layer stack (7), wherein the first areas (31) above the stack modification layer (4) remain free of the conductive metal without masking these first areas (31); —Providing an easy, variable and reliable method of a maskless structuring of the functional layer stack of OLED enabling to maintain the same the same deposition processes for the functional layer stack as applied during mask processing.

Owner:KONINKLJIJKE PHILIPS NV

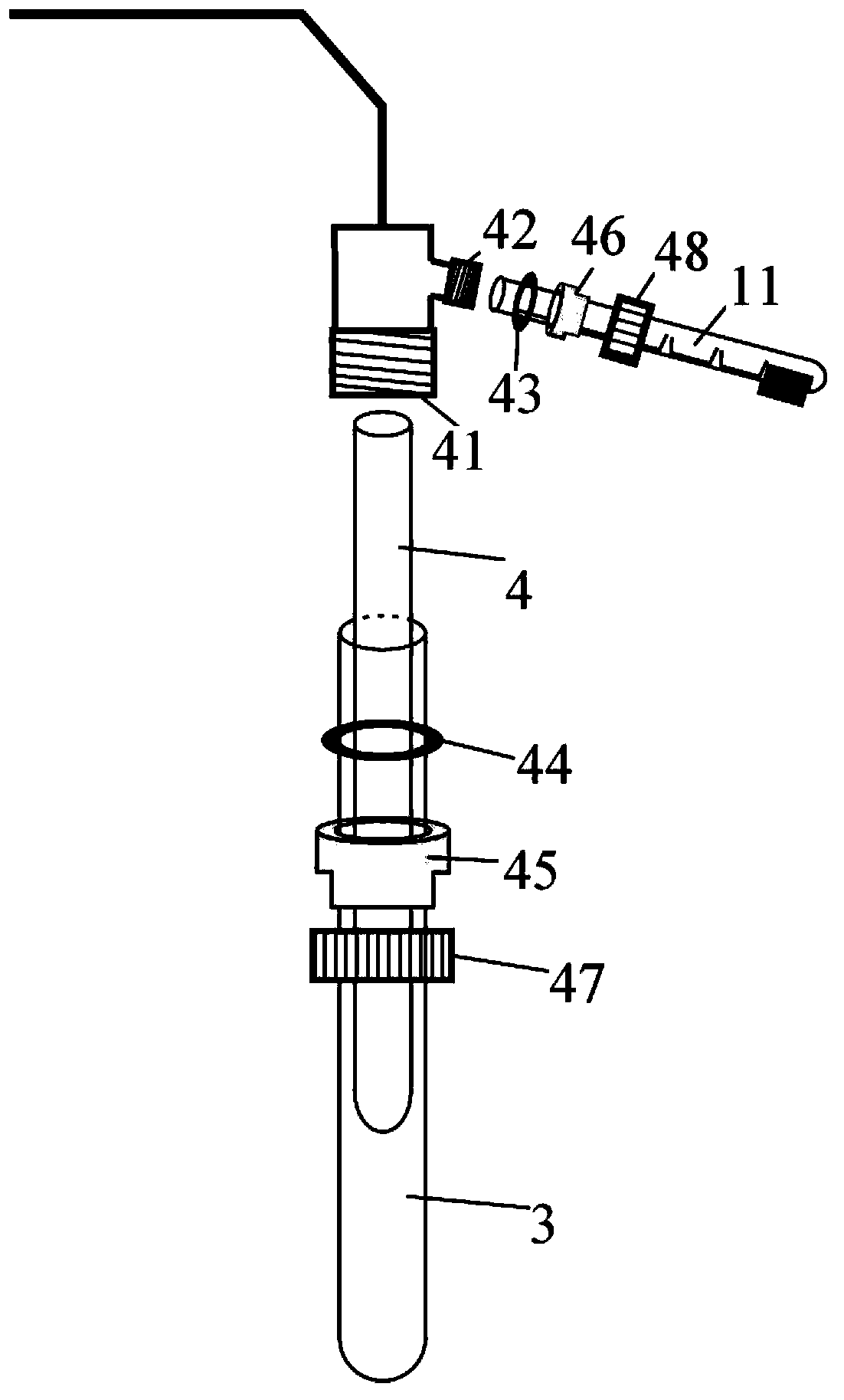

Sample preparation device and sample preparation method for sulfur isotope analysis

ActiveCN104048860AReduce usageReduce the impactPreparing sample for investigationIsotopeSulfur containing

The invention relates to a sample preparation device and a sample preparation method for sulfur isotope analysis, and especially relates to an experiment device and method for conversion of sulfur in sulfur-containing mineral into sulfur dioxide gas. The device and method are mainly used for pre-treatment of sulfur isotope gas mass spectrometry. The device is characterized in that the original quartz reactor is divided into multiple parts, a stainless steel reactor joint is used, a quartz reaction tube is installed at the bottom, a quartz sample introduction tube is installed at the side, an O-shaped ring is used for sealing a quartz device and a metal device so that quartz reaction tube replacement is convenient and vacuum grease use is reduced, the original glass tube is replaced by a stainless steel tube, and the stainless steel tube is not broken easier than the glass tube and can be repaired easily without special technicists. The device and method can effectively reduce vacuum grease use and greatly reduce the influence produced by vacuum grease on an experiment test in the experiment.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

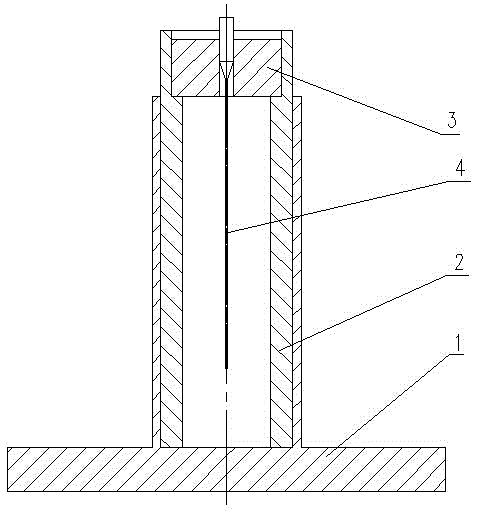

Clamp for sealing detection of electronic packaging shell

The invention relates to a clamp, in particular to a clamp for sealing detection of an electronic packaging shell. The clamp for sealing detection of the electronic packaging shell comprises a pressing board, a detection platform and a pressing rod. The pressing board is installed on the detection platform through a bolt, and the lower side of the detection platform is connected with a leak detector connector. A circular hole is formed in the center of the upper surface of the pressing board, a counter bored hole is formed in the lower surface of the pressing board, the diameter of the counter bored hole is larger than that of the circular hole, and the counter bored hole is communicated with the circular hole. The counter bored hole is filled with a soft rubber board, a ventilation hole is formed in the center of the soft rubber board, a through hole is formed in the center of the detection platform, a workpiece is buckled to the ventilation hole inversely, the upper edge of the workpiece and the soft rubber board are sealed, and a cavity of the workpiece is communicated with the leak detector connector. One end of the pressing rod is fixed to the upper surface of the pressing board through a support, a pressing head is installed on the pressing rod, and when the pressing rod is pressed downwards, the pressing head presses the bottom surface of the workpiece. The clamp for sealing detection of the electronic packaging shell can correspond to workpieces in various sizes flexibly, and a detection port and a detected product can be well sealed without using vacuum grease.

Owner:宜兴市吉泰电子有限公司

Sealing grease for electrolytic cell and sealing method of the electrolytic cell by using sealing grease

ActiveCN109988545APrevent drynessAvoid situations where adhesions cannot be removedOther chemical processesWax adhesivesMoistureVacuum grease

The invention discloses a method for sealing an electrolytic cell of a micro moisture analyzer by using vacuum grease, and belongs to the field of electrolytic cell sealing. The sealing grease for theelectrolytic cell is prepared through mixing of existing vacuum grease and Vaseline at a mass ratio of 5:1. The sealing grease for the electrolytic cell is prepared through mixing of the existing vacuum grease and Vaseline, so that the current problems of failure and hardening of the grease after use of a period are solved effectively, and the situation that the electrolytic cell cannot be takenout due to adhesion of the electrolytic cell with a cathode electrode, an anode electrode and a drying column when the electrolytic cell needs to be replaced can be avoided effectively, so that replacement of an electrolyte is more convenient and quicker.

Owner:DATANG HUAIBEI POWER PLANT

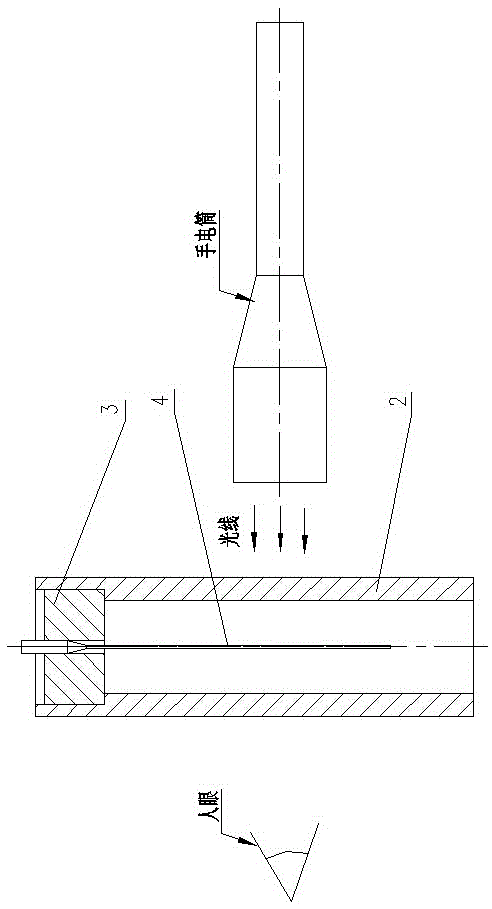

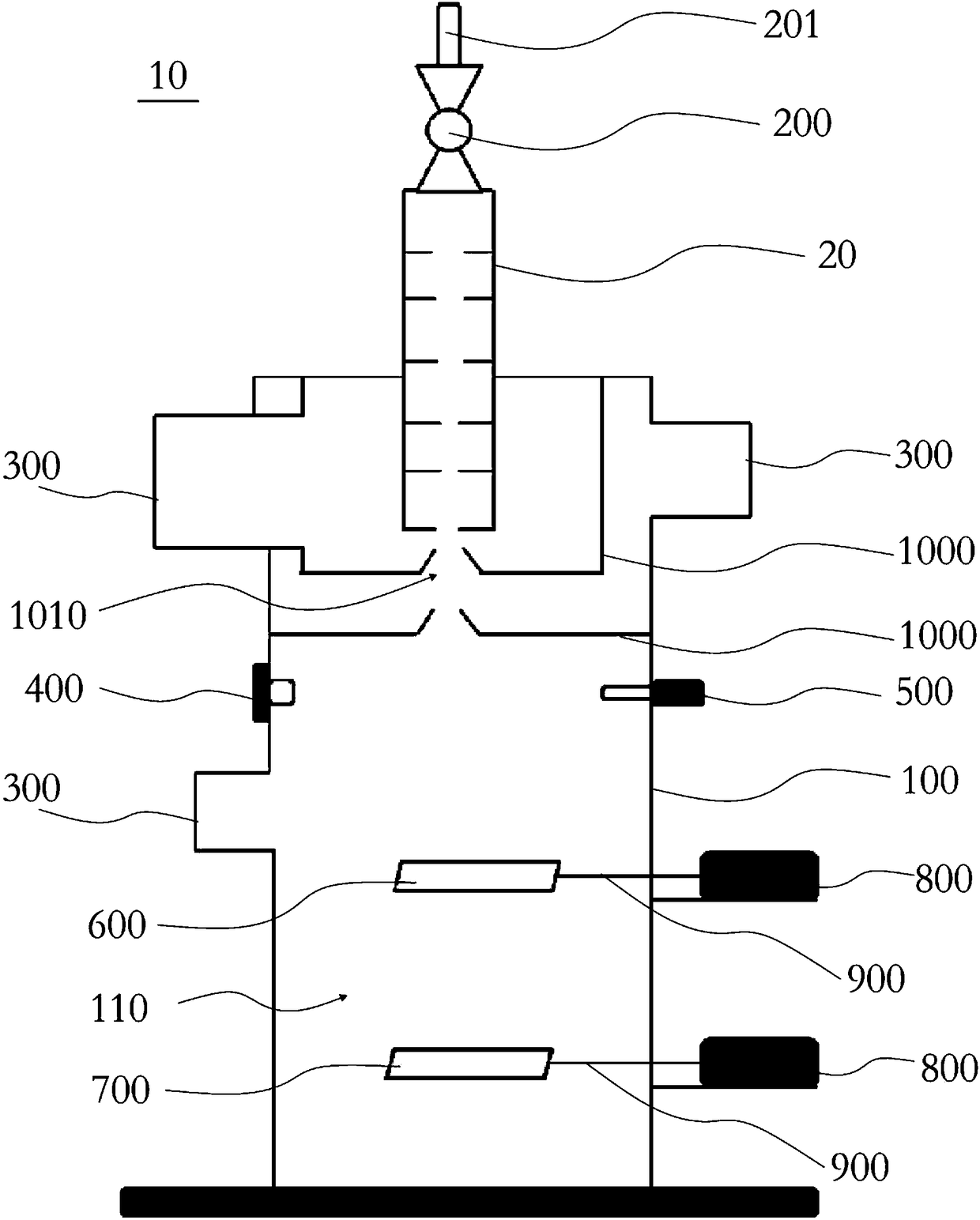

Aerodynamic lens focusing particle beam width and divergence angle detection device

The invention discloses an aerodynamic lens focusing particle beam width and divergence angle detection device. The device comprises a detector, a stop valve, a molecular pump, a detection part, a light emitting part, a first target plate and a second target plate. The detector comprises a detection cavity and an installation opening communicating with the detection cavity. The installation opening is used for installation of a to-be-detected aerodynamic lens. One end of the aerodynamic lens communicates with the detection cavity and the other end communicates with an aerosol generator. The stop valve is arranged on a sample charging pipe of the aerodynamic lens. The molecular pump is connected to the exterior of the detector and communicates with the detector. The first target plate and the second target plate are sequentially arranged in the detection cavity and the first target plate is close to the installation opening. Vacuum grease layers are arranged on the first target plate and the second target plate. The detection part and the light emitting part are connected to the detector and installed between the installation opening and the first target plate. According to the invention, detection results are precise; cost is low; and operation and maintenance are simple.

Owner:GUANGZHOU HEXIN INSTR CO LTD

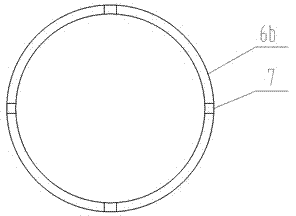

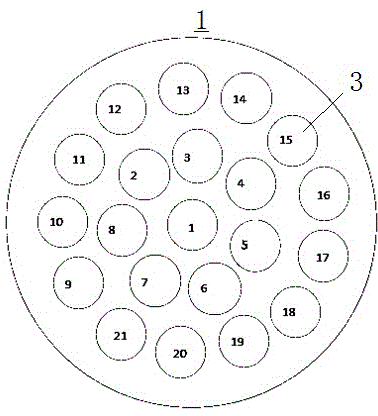

Integral PSS etching tray fixture

InactiveCN104979251APromote improvementSimple and fast operationSemiconductor/solid-state device manufacturingMetallic materialsEngineering

The invention discloses an integral PSS etching tray fixture, which comprises an integral tray and press rings made of metal, wherein the integral tray is provided with multiple wafer grooves; each wafer groove is internally provided with a step for placing a wafer; a cooling cavity is arranged below the step in the wafer groove; the cooling cavity is provided with multiple cooling holes; the cooling holes are communicated with a cooling gas; each press ring is arranged above the wafer inside each wafer groove; and the press ring is annular and covers the circumferential edge of the wafer. By adopting the above technical scheme, advantages of a quartz element and advantages of a metal element are combined, edge effects can be well improved, no extra tools such as a positioning disc need to be used, sealing material such as vacuum grease does not need to be used, the operation is simple and convenient, the work efficiency can be improved, and labor cost is saved.

Owner:HAIDIKE NANTONG OPTOELECTRONICS TECH CO LTD

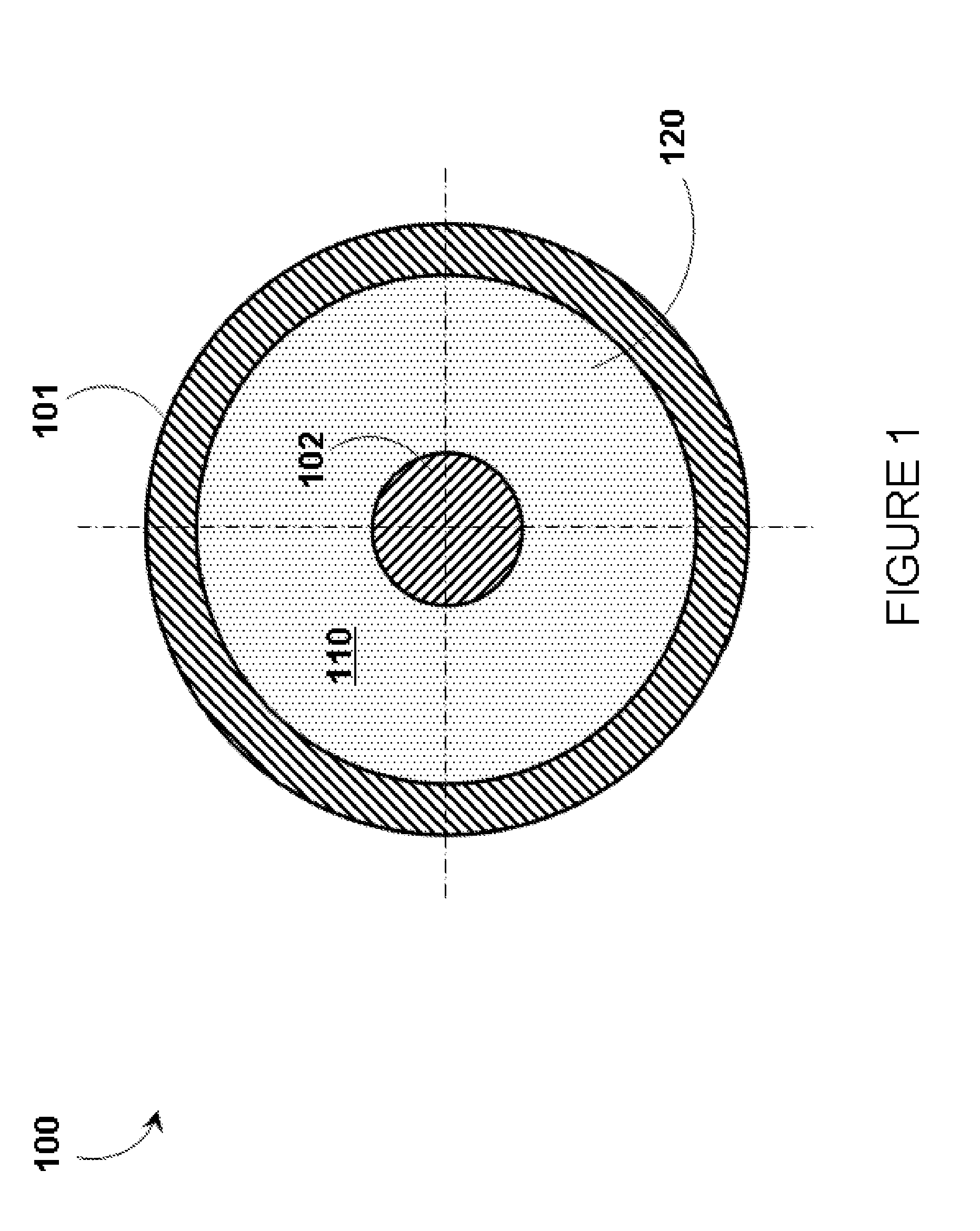

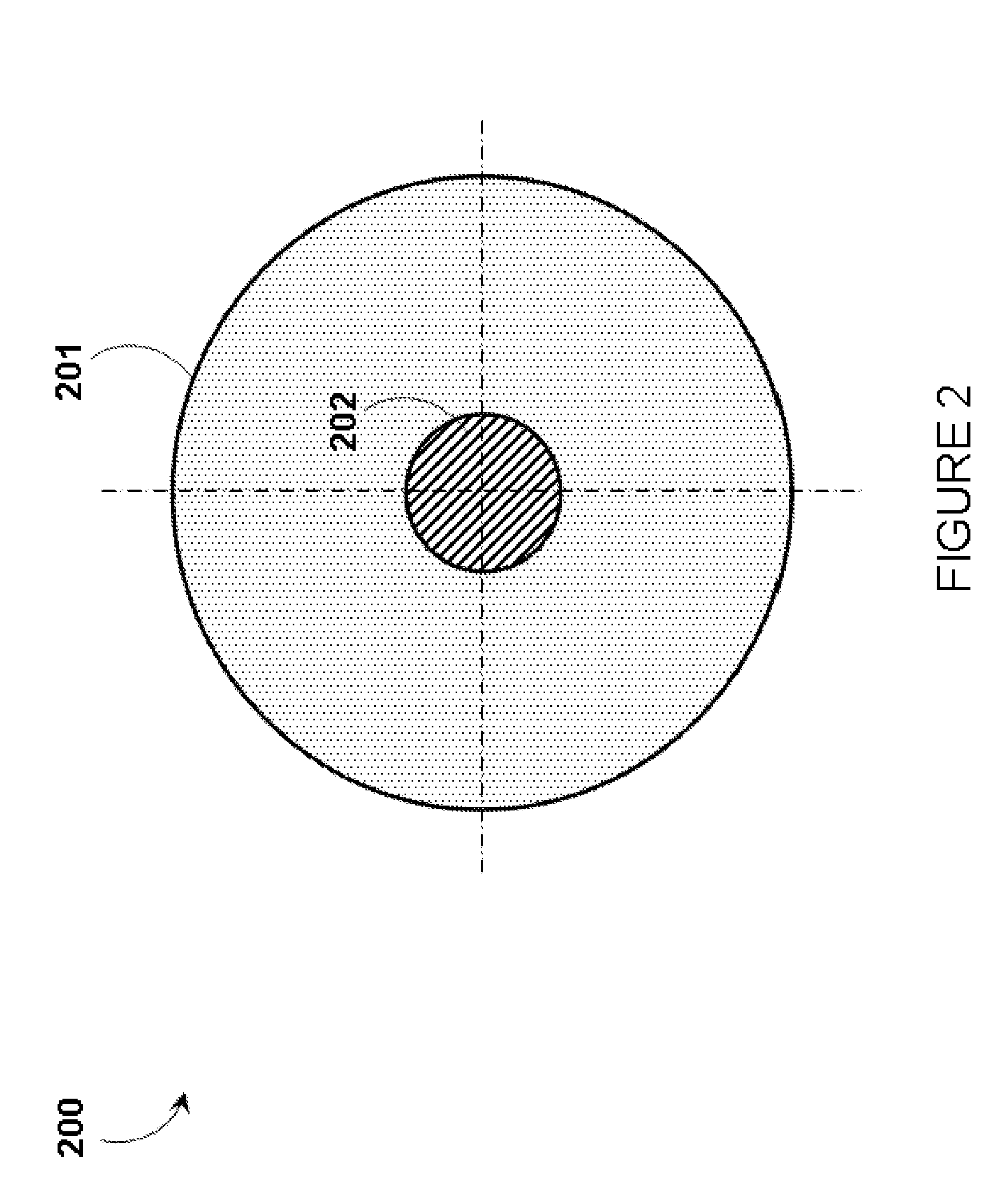

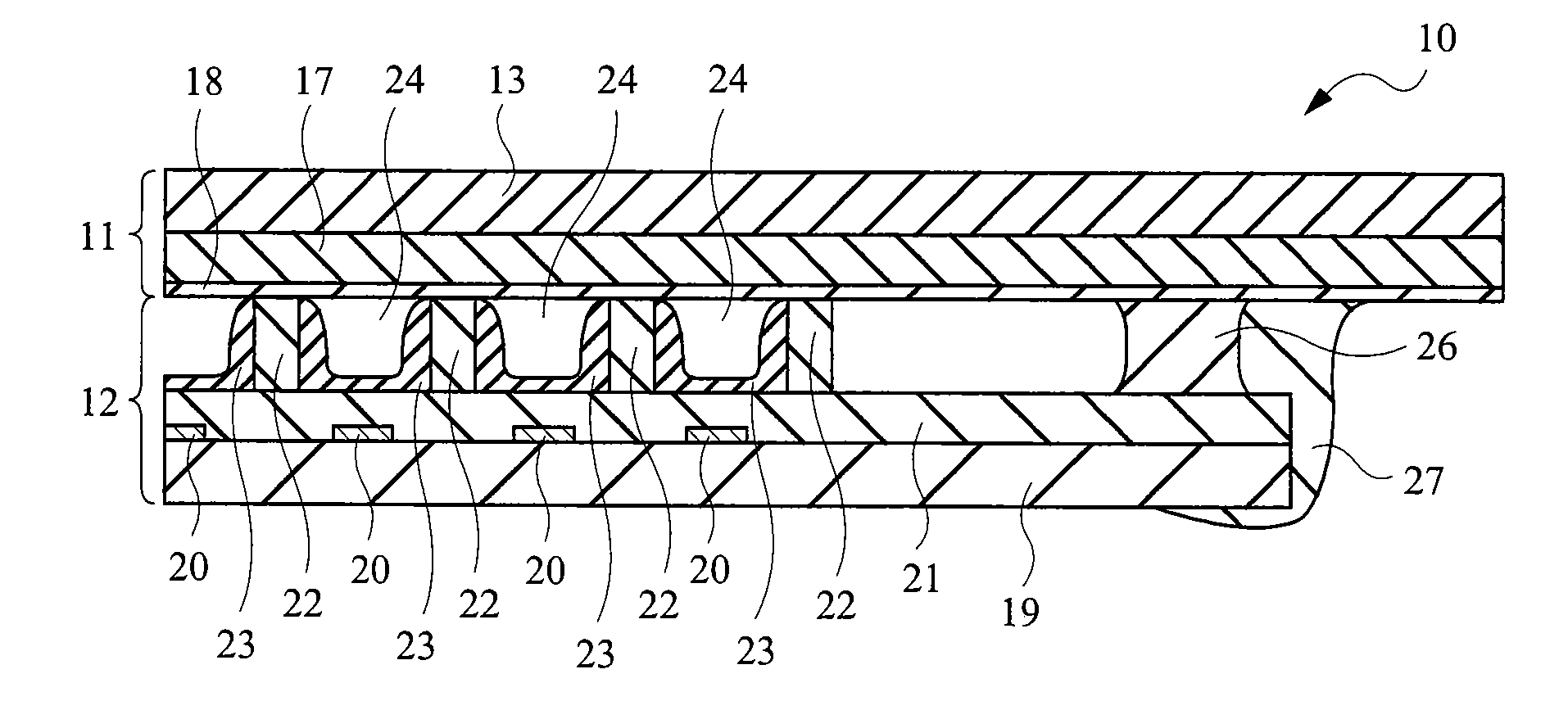

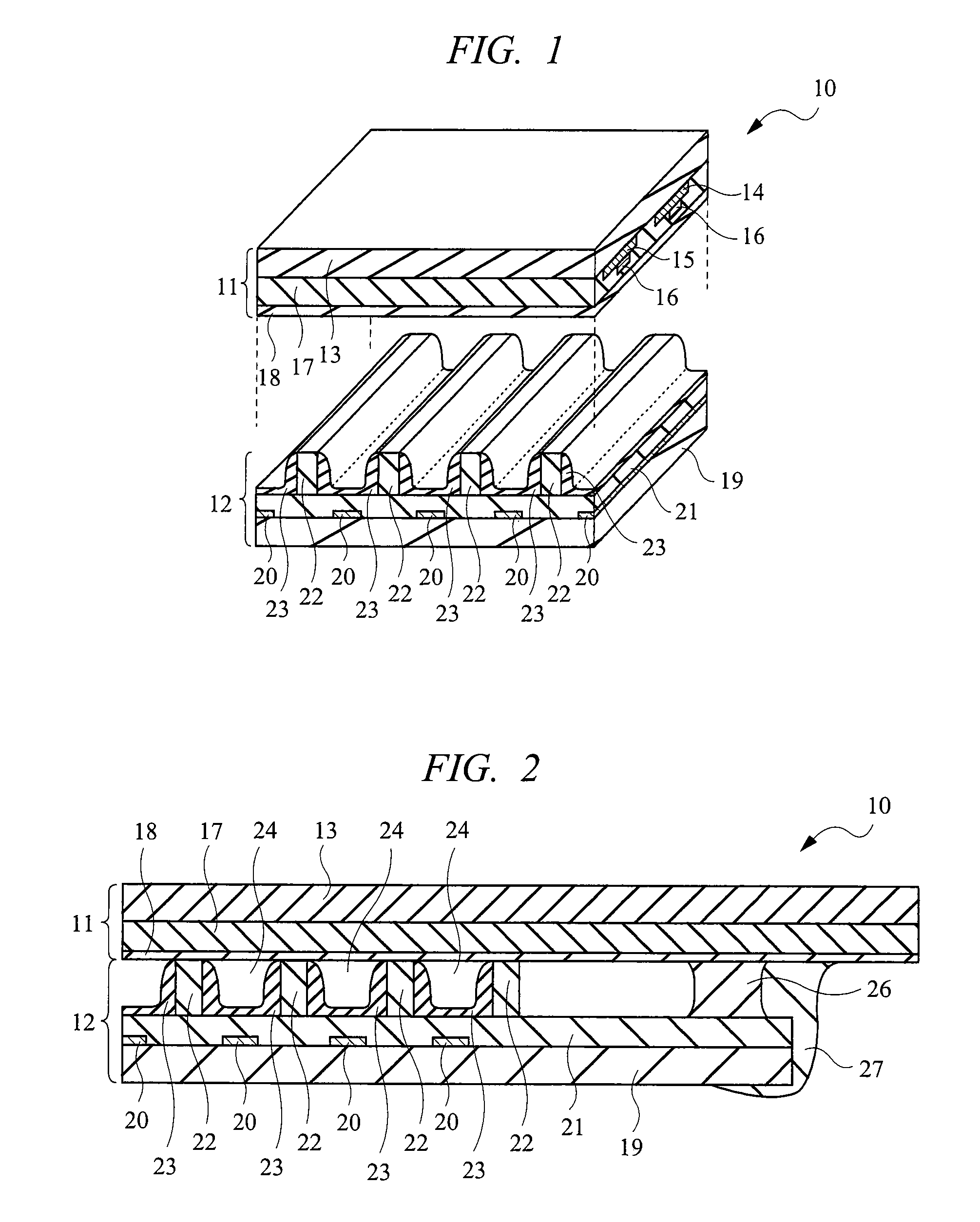

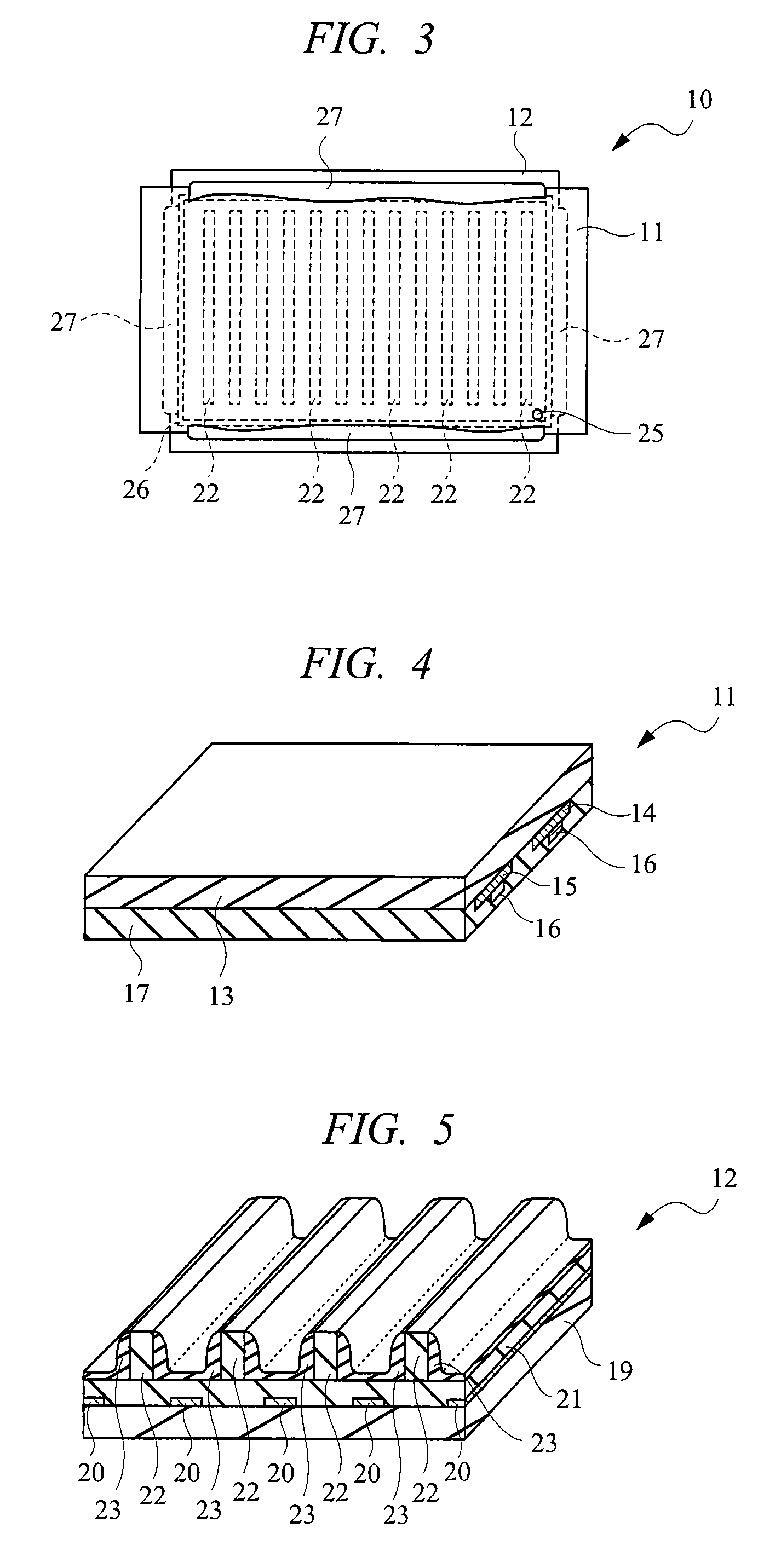

Plasma display panel and manufacturing method of the same

InactiveUS20090102380A1Low viscosityReduce power consumptionSustain/scan electrodesGas discharge vessels/containersViscosityVacuum grease

The present invention improves a manufacturing efficiency of a plasma display panel. In a plasma display panel (PDP) having a front structure (first structure) and a rear structure (second structure) which are disposed so as to be opposed to each other, the front structure and the rear structure are sealed with vacuum grease (sealing material) which is disposed so as to surround a plurality of barrier ribs formed on one surface of the rear structure and has a gas barrier characteristic, and they are fixed to each other with an adhesive agent which is disposed on an outer side of the vacuum grease with respect to the barrier ribs and has a lower viscosity than the vacuum grease.

Owner:HITACHI LTD

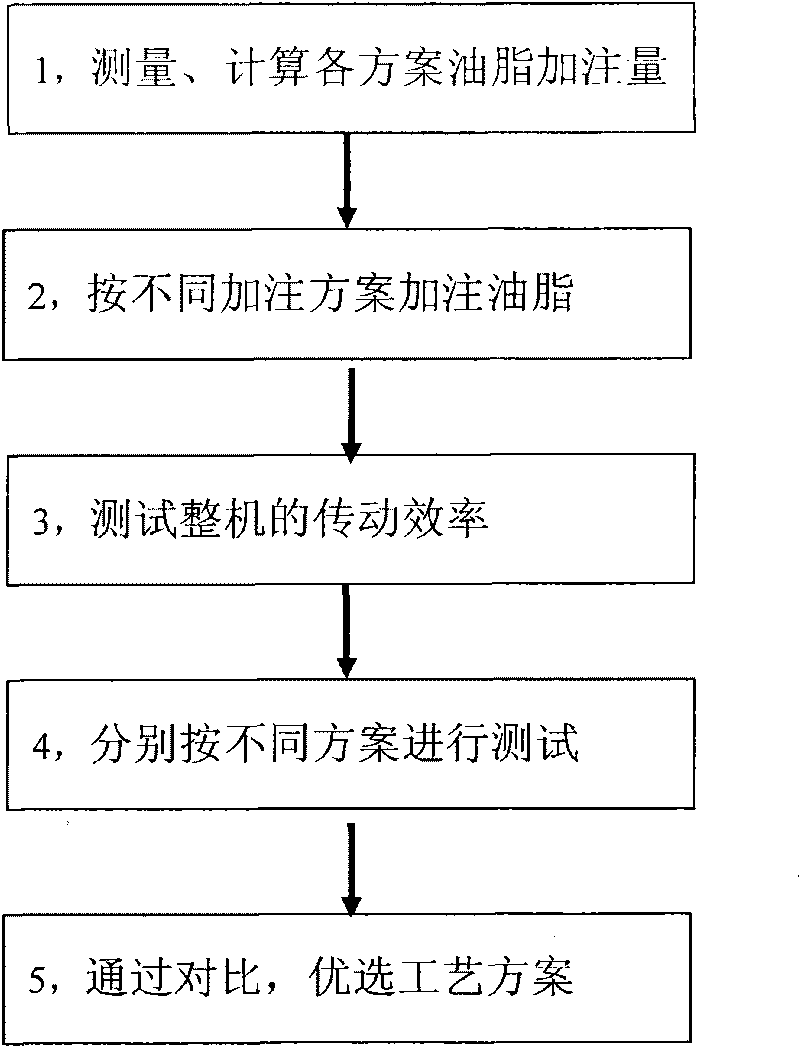

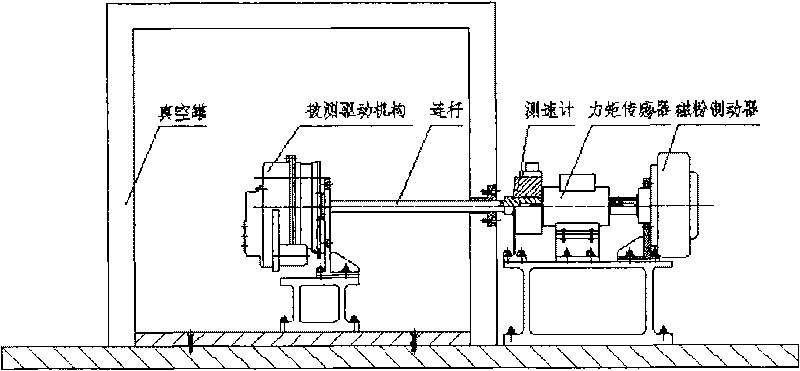

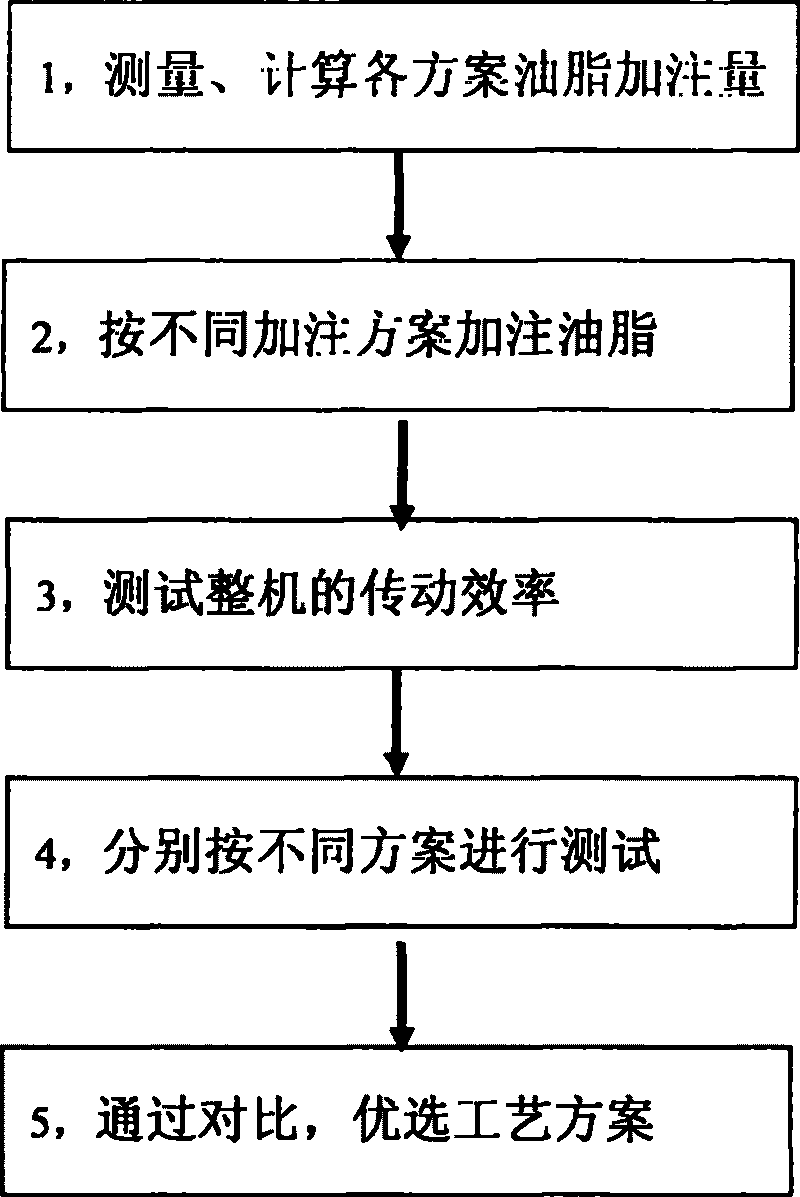

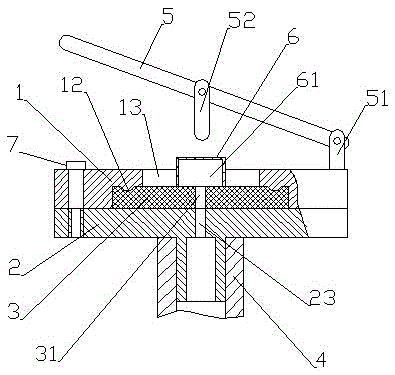

Method for confirming vacuum grease adding amount in spatial mechanism bearing

ActiveCN101749530ASolve blindnessSure easyProportioning devicesMachine bearings testingValidation methodsEngineering

The invention relates to a vacuum lubricating grease adding process and discloses a method for confirming vacuum grease adding amount in a spatial mechanism bearing, and the method comprises the following steps: 1) measuring and calculating the grease adding amounts of different schemes; 2) adding the grease according to different adding amounts; 3) measuring the transmission efficiency of a whole machine; 4) testing according to different grease adding amounts; and 5) comparing and optimizing the adding process schemes. By adopting the verification method of comparing the adding schemes, the grease adding effects can be reflected visually, thus solving the blindness problem of adding vacuum grease of the prior art and achieving accurate, visual and effective beneficial effects.

Owner:上海航天技术研究院

Fixture for electronic package enclosure sealing inspection

The invention relates to a clamp, in particular to a clamp for sealing detection of an electronic packaging shell. The clamp for sealing detection of the electronic packaging shell comprises a pressing board, a detection platform and a pressing rod. The pressing board is installed on the detection platform through a bolt, and the lower side of the detection platform is connected with a leak detector connector. A circular hole is formed in the center of the upper surface of the pressing board, a counter bored hole is formed in the lower surface of the pressing board, the diameter of the counter bored hole is larger than that of the circular hole, and the counter bored hole is communicated with the circular hole. The counter bored hole is filled with a soft rubber board, a ventilation hole is formed in the center of the soft rubber board, a through hole is formed in the center of the detection platform, a workpiece is buckled to the ventilation hole inversely, the upper edge of the workpiece and the soft rubber board are sealed, and a cavity of the workpiece is communicated with the leak detector connector. One end of the pressing rod is fixed to the upper surface of the pressing board through a support, a pressing head is installed on the pressing rod, and when the pressing rod is pressed downwards, the pressing head presses the bottom surface of the workpiece. The clamp for sealing detection of the electronic packaging shell can correspond to workpieces in various sizes flexibly, and a detection port and a detected product can be well sealed without using vacuum grease.

Owner:宜兴市吉泰电子有限公司

A kind of high and low temperature resistant siloxane vacuum grease composition and its preparation method

ActiveCN103710080BReduce the temperatureLow temperature resistanceThickenersSilicon dioxideLubrication

The invention relates to a high and low temperature resistant siloxane vacuum grease composition and its preparation method. The high and low temperature resistant siloxane vacuum grease composition is used for lubrication and sealing of high-low temperature vacuum systems and high-low temperature vacuum valves, and comprises the following components by weight: 84-93% of organosilicon polymer oil, 3-15% of silicon dioxide powder, 0.5-7% of a surface covering agent, and 0.05-2.0% of an additive. The high and low temperature resistant siloxane vacuum grease composition has excellent sealing performance and long-term storage stability, and at the same time has good compatibility with a contact surface, high and low temperature performance, adhesion performance, chemical inertness, and water resistance. The high and low temperature resistant siloxane vacuum grease composition can be used for lubrication and sealing of high vacuum systems, sealing of glass valves, ceramic ground joints, pistons, and faucets, as well as sealing elements of air pressure valves, vacuum equipment and pneumatic brakes, etc.

Owner:SUZHOU HUIFENG LUBRICANT

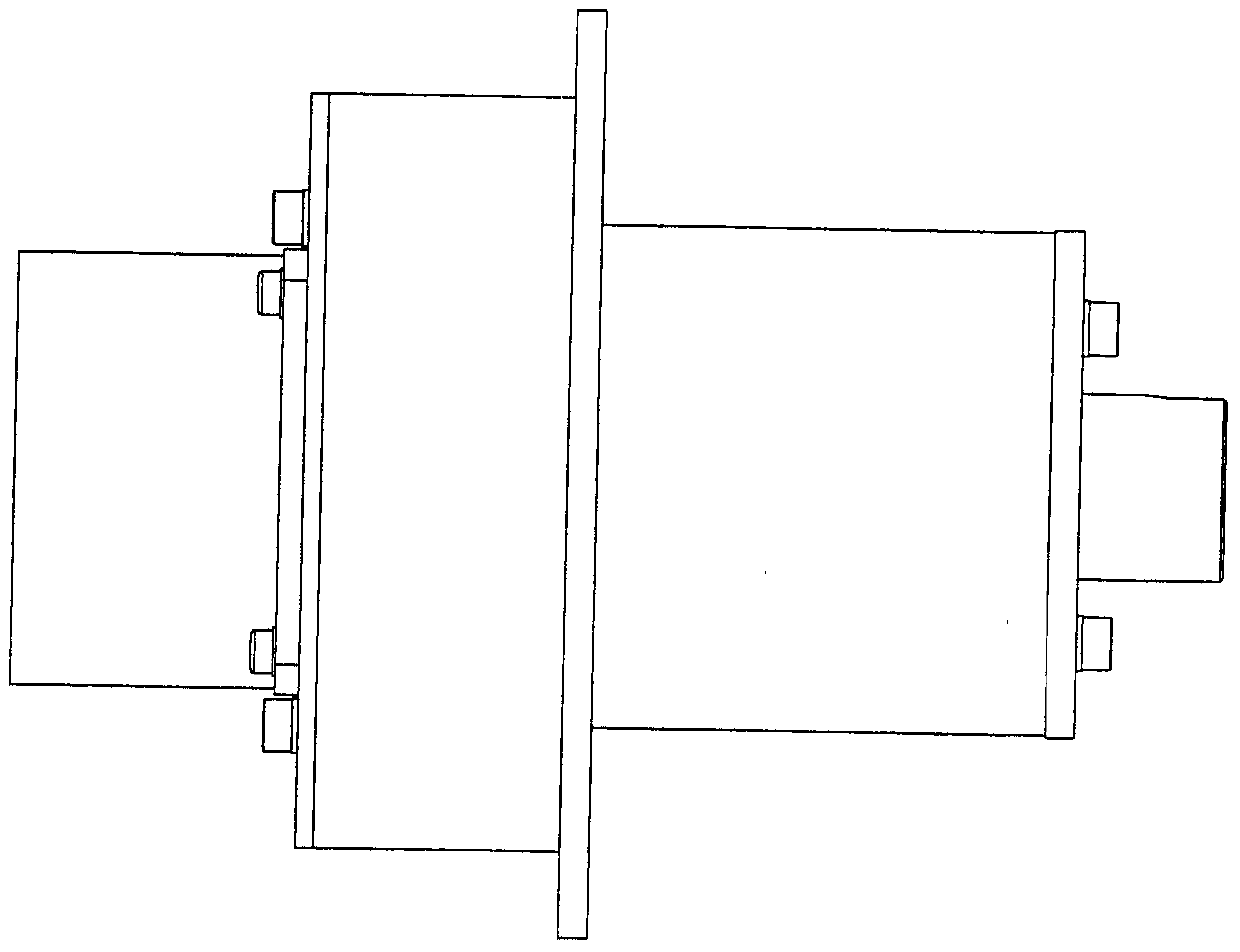

Grease lubricated harmonic deceleration drive device and lubricating method thereof

InactiveCN109743899BNot volatileNot easy to loseToothed gearingsEngine lubricationDrive shaftPerfluoropolyether

The invention discloses a grease-lubricated harmonic deceleration drive device and a lubricating method thereof. The motor output shaft drives a wave generator to rotate, and the teeth of the flexible wheel mesh with the teeth of the output rigid wheel, so that the output rigid wheel rotates and the output rigid wheel rotates. The wheel is connected with the drive shaft, and drives the drive shaft to rotate after deceleration, and provides radial and axial support to the drive shaft through the bearing. The drive shaft is supported by the bearing and rotates freely around the center line of rotation. The input rigid wheel and the output are on the gear meshing surface. Perfluoropolyether grease (601EF) is applied to the meshing part of the rigid wheel and the flexible gear teeth for vacuum grease lubricating film treatment, and the flexible bearing cage is treated with vacuum oil immersion; the oil immersion rate is controlled at 15% of the weight of the cage. 20%; creates a tortuous path between the drive shaft and stop lubricating surface and the outer surface. The use of the lubricant of the invention is not easy to volatilize and run off, greatly reduces the loss of the lubricant under the condition of low air pressure, and effectively increases the service life of the lubricant.

Owner:SHANGHAI AEROSPACE SYST ENG INST

Laser sintering molding method and device for nanoscale components

ActiveCN104385605BHigh precisionIncrease the diameterIncreasing energy efficiencyParticle flowNanoparticle

The invention discloses a nanoscale component laser sintering molding method and device. The nanoscale component laser sintering molding device comprises a mixed sample feeding system, an aerodynamic lens, a confocal laser group and a worktable; the mixed sample feeding system is provided with a buffer cavity. The nanoscale component laser sintering molding method comprises the steps of placing nanoparticle powder into a powder storage cavity, carrying the powder into a mixing cavity through air, adequately mixing the powder and another branch circuit of air, facilitating the obtained aerosol flow to enter the buffer cavity, further mixing the gas and nanoparticle powder, and lowering the pressure and flow rate to obtain a fluid with a Reynolds number of 200 to 700; facilitating the fluid to enter a cylindrical cavity in a laminar flow form, and spraying out the fluid in a single-particle flow form after the fluid passes through gathering holes in each lens and is focused; receiving the particles by a sintering substrate which is coated with vacuum grease on the worktable, and melting the particles by the confocal laser group; acquiring a two-dimensional pattern with nanoscale molding precision by virtue of the movement of the worktable in an X direction and a Y direction; gradually laminating the particles to obtain a component with the nanoscale molding precision by virtue of the movement of the worktable in a Z-axis direction.

Owner:SOUTH CHINA UNIV OF TECH

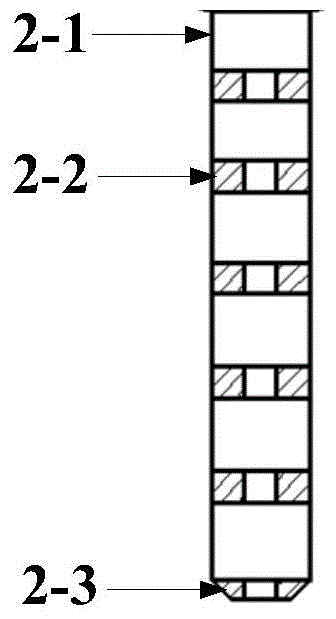

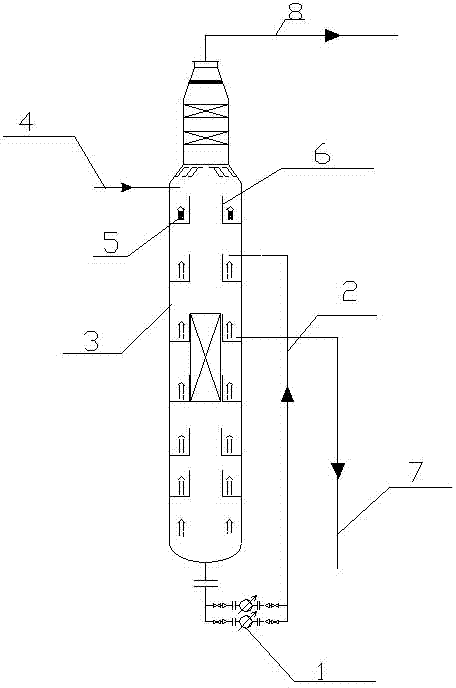

A grease deodorization device under high vacuum

The invention relates to a high-vacuum grease deodorization device, particularly relates to a high-vacuum grease deodorization device for grease deodorization. The device solves the problems of low deodorization ratio, higher grease trans fatty acid, deep color of deodorized oil and the like in application of the existing deodorization tower, and aims to create a reasonable and feasible novel deodorization technological facility for the grease deodorization technique. In order to solve the technical problems, the technical scheme is as follows: the high-vacuum grease deodorization device comprises a device shell, heaters and an oil return pipe, wherein the heater is arranged at the center in the device shell from top to bottom; a plurality of circular heater sets are arranged around the inner shell; and the upper end of the device shell is provided with an oil inlet pipe, the side surface is provided with an oil outlet, and the lower end of the device shell is provided with a circulating oil pipe.

Owner:九三食品股份有限公司

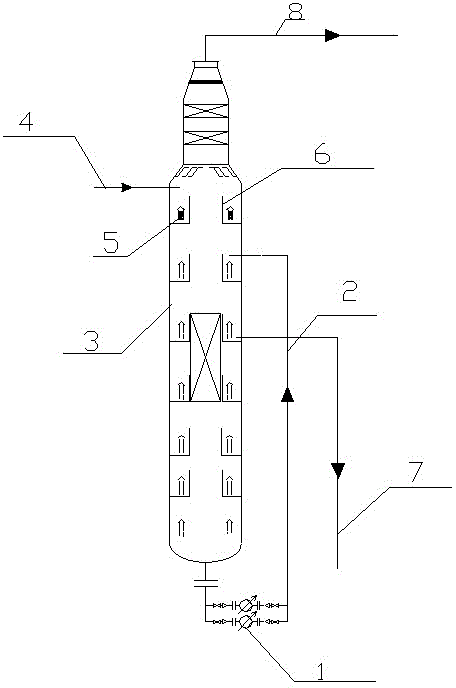

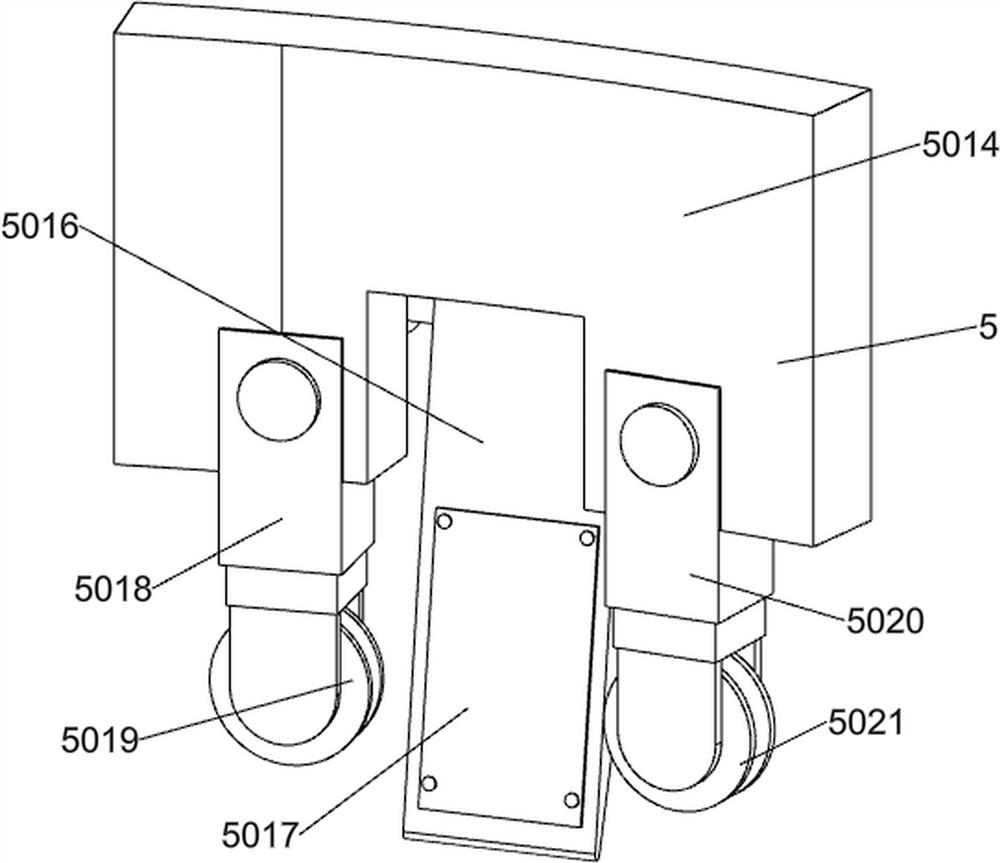

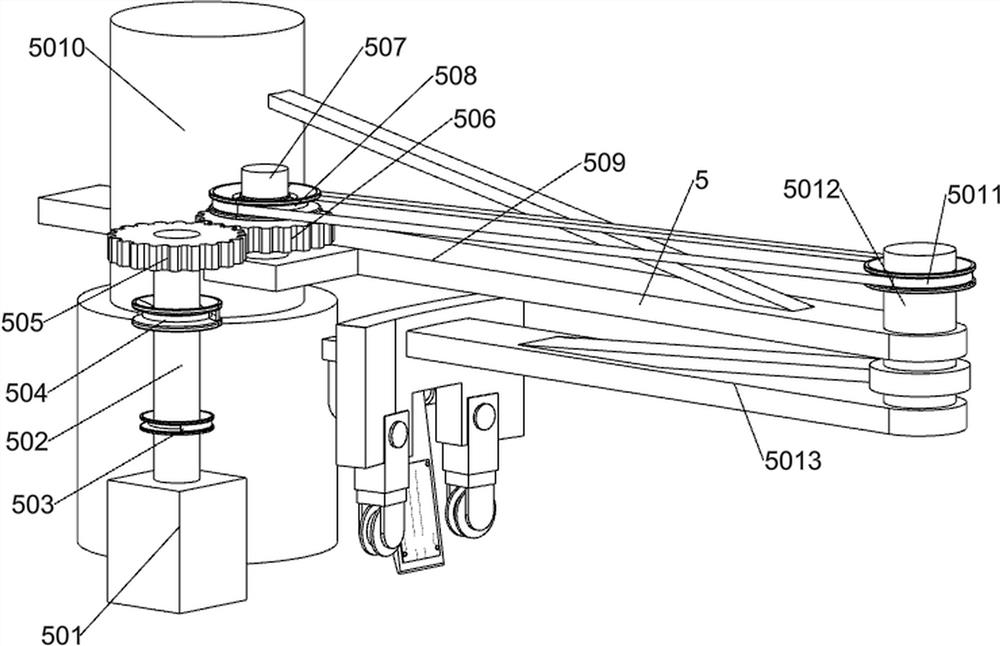

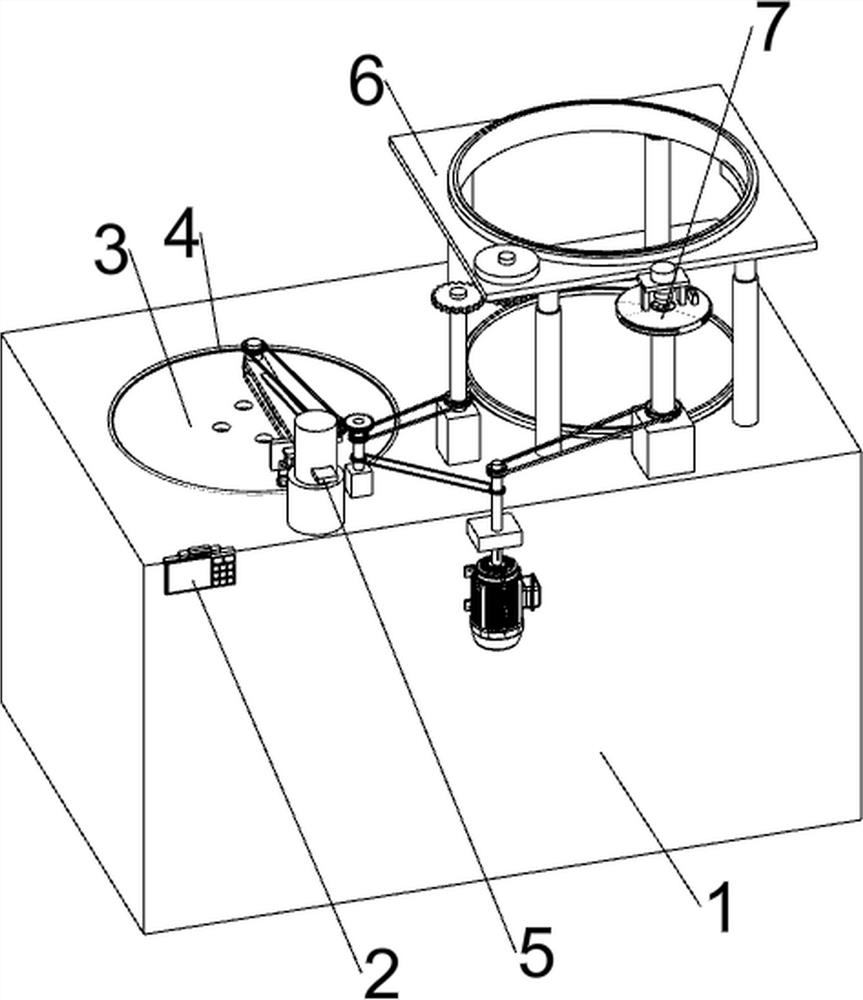

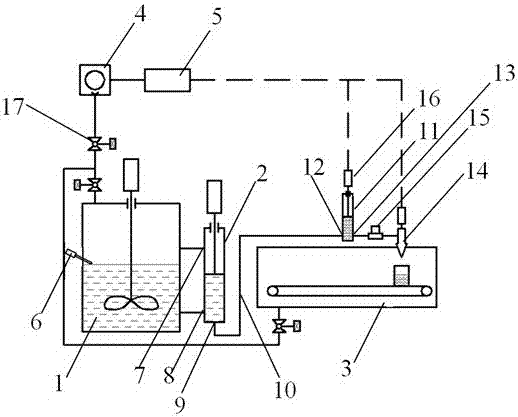

Vacuum grease smearing and sealing device for freeze dryer

ActiveCN113198671AReduced tightnessRealize automatic applicationLiquid surface applicatorsCoatingsGlass coverFreeze-drying

The invention relates to the field of freeze dryers, in particular to a vacuum grease smearing sealing device for a freeze dryer. The invention aims to provide the vacuum grease smearing sealing device for the freeze dryer. According to the technical scheme, the vacuum grease smearing sealing device for the freeze dryer comprises a freeze dryer body, an operation control screen, a cold trap cover, a cold trap sealing ring, a sealing ring smearing system, a glass cover smearing system and a residual grease wiping system; and the freeze dryer body is connected with the operation control screen. According to the vacuum grease smearing sealing device, automatic vacuum grease smearing of the freeze dryer sealing ring after freeze drying is completed is achieved, vacuum grease smearing operation is carried out on the whole annular bottom of the sealing ring under the condition that the sealing ring is not moved, the problem that the sealing ring is difficult to reset after being separated is avoided, vacuum grease smearing is carried out on the edge of the bottom of a glass cover, and redundant vacuum grease can be wiped.

Owner:临沂长青化工有限公司

High-vacuum grease deodorization device

The invention relates to a high-vacuum grease deodorization device, particularly relates to a high-vacuum grease deodorization device for grease deodorization. The device solves the problems of low deodorization ratio, higher grease trans fatty acid, deep color of deodorized oil and the like in application of the existing deodorization tower, and aims to create a reasonable and feasible novel deodorization technological facility for the grease deodorization technique. In order to solve the technical problems, the technical scheme is as follows: the high-vacuum grease deodorization device comprises a device shell, heaters and an oil return pipe, wherein the heater is arranged at the center in the device shell from top to bottom; a plurality of circular heater sets are arranged around the inner shell; and the upper end of the device shell is provided with an oil inlet pipe, the side surface is provided with an oil outlet, and the lower end of the device shell is provided with a circulating oil pipe.

Owner:九三食品股份有限公司

Method for sealing sample room of mercury porosimeter

InactiveCN101504350BWill not polluteExtended service lifePermeability/surface area analysisGraphiteQuartz

The invention discloses a method for sealing a sample room of a mercury injection apparatus and relates to technology for sealing the sample room of the mercury injection apparatus. The invention provides a method which has simple operation, can be repeatedly used, does not pollute a sample and is used for sealing the sample room of the mercury injection apparatus. A hollow annular washer is arranged between a plane of a polished mouth of a quartz glass sample cell of the mercury injection apparatus and a plane of a stainless steel contact component as an electrode; the size of the inside diameter and the outside diameter of the washer is the same as the polished mouth of the quartz glass sample cell; and the thickness of the washer is between 0.1 and 1.0 mm. The washer can be a molecularmaterial washer, a soft metal washer or a graphite washer. The method adopts the washer to replace vacuum grease to realize the sealing of the sample room; and as the washer is a solid flake with a regular shape, the washer has good deformation and buffering capacity, is simple to operate, does not pollute the sample and can be repeatedly used. Moreover, as the thickness and the diameter of the washer are controllable, the quality of the injected mercury is relatively stable and the accuracy and the precision of the test are improved. Simultaneously, the method is safe and reliable and can prevent the sample cell breaking.

Owner:XIAMEN UNIV

A Rapid Preparation Method for Synchrotron Radiation X-ray Diffraction Samples of Hydrogen Storage Materials

ActiveCN105571915BReduce dosageEfficient preparationPreparing sample for investigationTest sampleX-ray

Owner:YANGZHOU UNIV

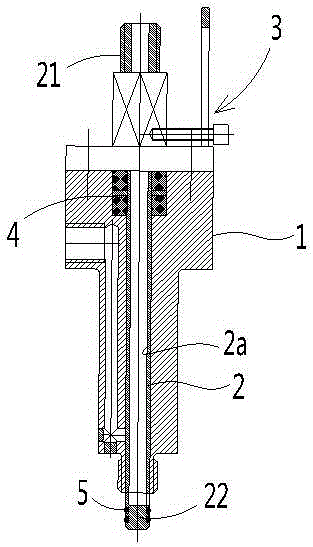

Precision volumetric vacuum automatic oiling equipment

The invention discloses a precision volumetric vacuum automatic oiling equipment, which comprises a vacuum degassing tank, a feeding pump, an automatic vacuum chamber, a vacuum pump group and a PLC controller. A liquid level sensor and a vacuum pump are installed on the side wall of the vacuum degassing tank. The groups are respectively connected with the vacuum degassing tank and the automatic vacuum chamber. The feed pump is installed on the side wall of the vacuum degassing tank. The oil supply port formed at the bottom of the feed pump is connected with the input port of the metering cylinder through the oil supply pipeline. The metering cylinder The output port of the precision filter is connected with the inlet of the precision filter, and the outlet of the precision filter is connected with the inlet of the oil injection valve; the oil injection valve is installed above the automatic vacuum chamber, and the outlet of the oil injection valve is located in the automatic vacuum chamber; a servo motor is installed above the metering cylinder, controlled by PLC The controller is respectively connected with the vacuum pump group, the servo motor and the oil injection valve through signal lines. The invention makes the oiling precision reach ±0.25g, improves the oiling precision and precision stability, and realizes that the vacuum degree of oiling can be adjusted within the range of 1-30Pa according to the technical requirements.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

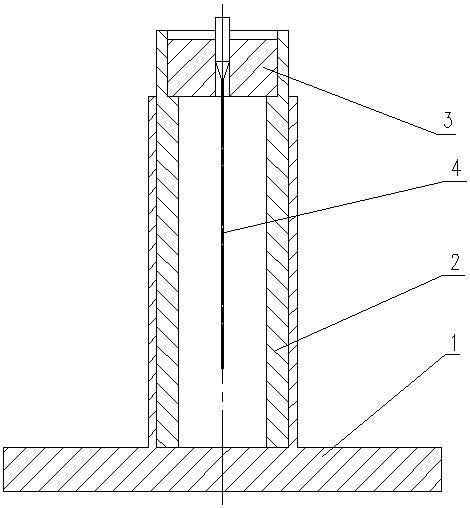

Vacuum oiling nozzle, vacuum oiling system and vacuum oiling method

InactiveCN103438343BSimple structureEasy to operateConduits/junctionsLubrication check valvesInlet channelInjection equipment

The invention relates to the field of oil injection equipment, in particular to a vacuum oil injection mouth, a vacuum oil injection system and a vacuum oil injection method. According to the vacuum oil injection mouth, a cavity of a valve core is a vacuumizing channel, an oil inlet channel is arranged on a valve body, the oil inlet channel is in a closed state during vacuumizing, oil cannot be injected into a vacuum pump pipeline in a pumping mode, and when oil is injected in a vacuum state, due to the fact that the vacuumizing channel and an oil injection channel departs from each other, oil cannot be injected into the vacuum pump pipeline in a pumping mode. The vacuum oil injection system is simple in structure and convenient to operate.

Owner:HUBEI MILALION METALLURGICAL MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com