Vacuum grease smearing and sealing device for freeze dryer

A technology of sealing device and freeze dryer, which is applied in the field of freeze dryers, and can solve problems such as the difficulty of sealing rings, affecting the freeze dryer, and the inability to fill and seal the seal ring and the glass cover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

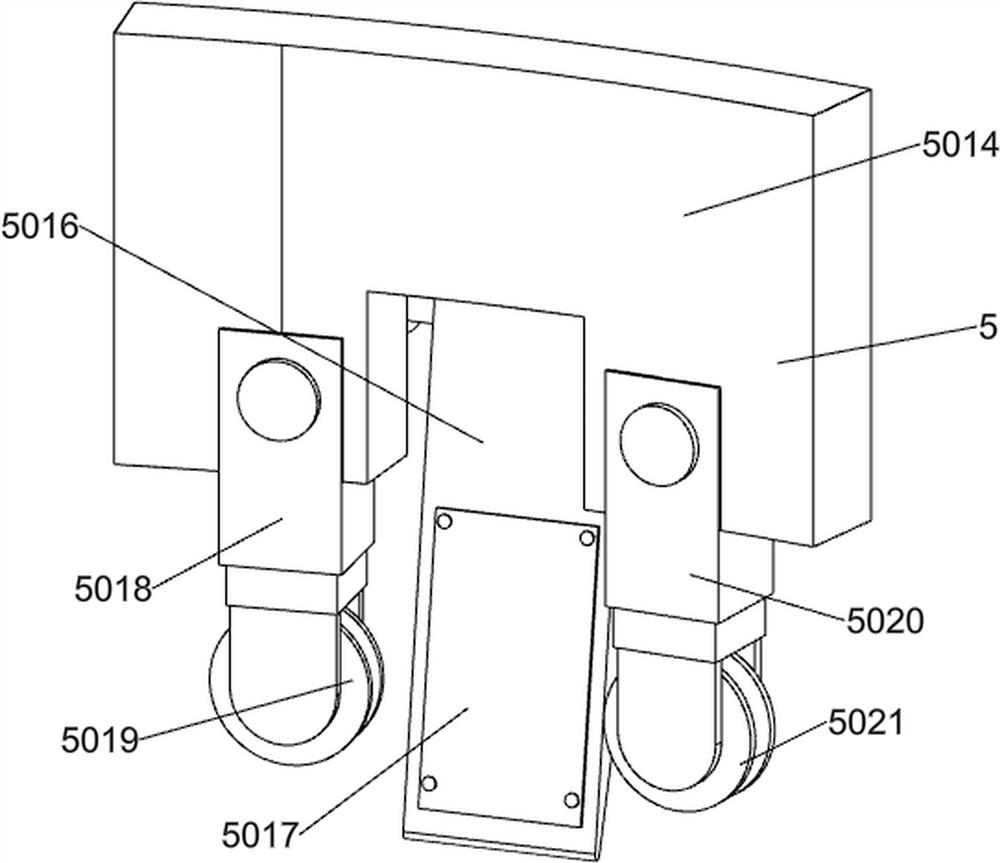

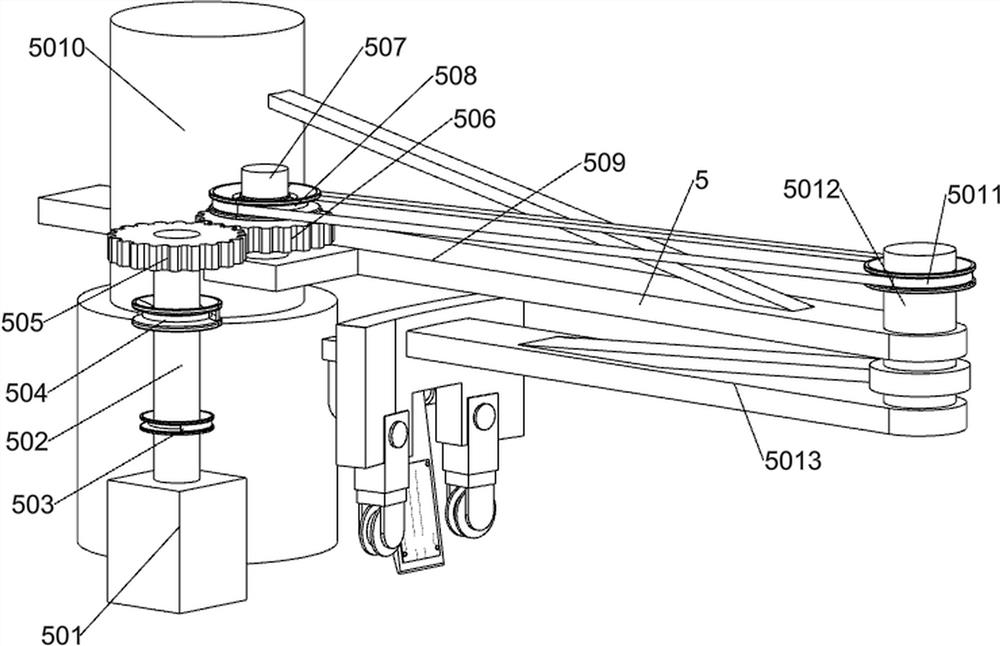

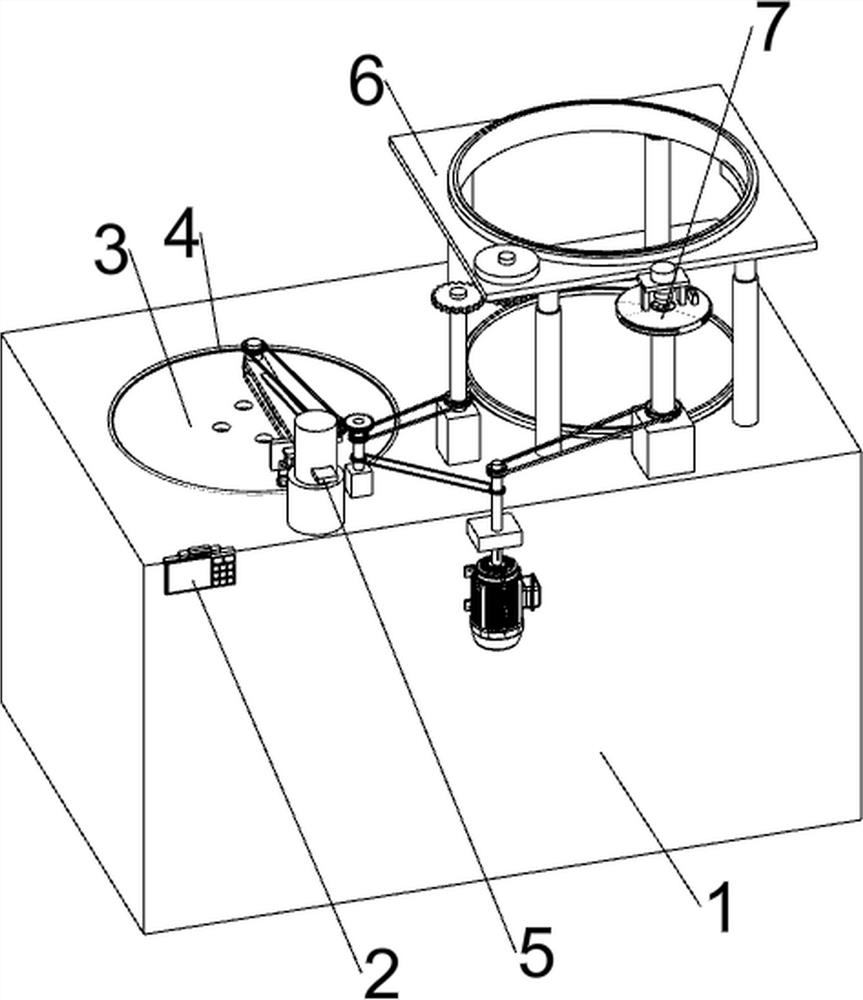

[0026] A vacuum grease coating sealing device for a freeze dryer, such as Figure 1-9 As shown, it includes a freeze dryer body 1, an operation control panel 2, a cold trap cover 3, a cold trap seal ring 4, a seal ring application system 5, a glass cover application system 6 and a fat removal system 7; the freeze dryer body 1 is connected with the operation control panel 2; the freeze dryer body 1 is in contact with the cold trap cover 3; the freeze dryer body 1 is connected with the cold trap sealing ring 4; the lower part of the sealing ring application system 5 is connected with the freeze dryer body 1 The bottom of the glass cover application system 6 is connected with the freeze dryer body 1; the glass cover application system 6 is connected with the sealing ring application system 5; the bottom of the excess fat erasing system 7 is connected with the freeze dryer body 1; System 7 is connected to sealing ring application system 5 .

[0027] Working steps: When using the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com