Fixture for electronic package enclosure sealing inspection

A technology of sealing detection and electronic packaging, which is applied in the direction of detecting the appearance of fluid at the leakage point and using liquid/vacuum to measure the liquid tightness, etc., which can solve the problems of polluting products and difficult to achieve sealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

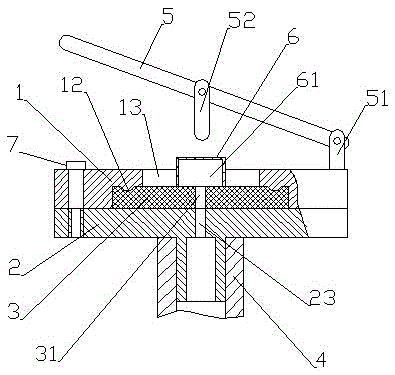

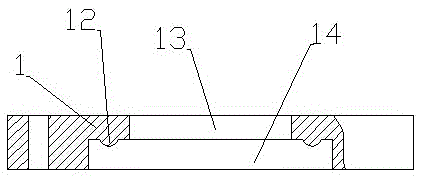

[0010] The specific embodiment of the present invention is described in conjunction with accompanying drawing, as figure 1 , as shown in 2, the jig used for sealing detection of the electronic packaging shell includes a pressure plate 1, a detection platform 2 and a pressure bar 5; the pressure plate 1 is installed on the top of the detection platform 2 through bolts 7, and a leak detector interface 4 is connected to the bottom of the detection platform 2; the pressure plate 1 There is a round hole 13 in the center of the upper surface, and there is a counterbore 14 on the lower surface of the pressure plate 1. The diameter of the counterbore 14 is larger than the diameter of the round hole 13, and the counterbore 14 is connected with the round hole 13; the counterbore 14 is filled with a soft rubber plate 3 , the center of the soft rubber plate 3 has a vent hole 31, the center of the detection platform 2 has a through hole 23, the vent hole 31 communicates with the leak detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com