Sample preparation device and sample preparation method for sulfur isotope analysis

A technology of sulfur isotope and sampling, applied in the preparation of test samples, etc., can solve the problems of easy damage of glass pipes, pollution of combustion pipe walls, cracking of quartz pipe walls, etc., to save costs and maintenance time, and reduce vacuuming The effect of time, convenient disassembly and washing or replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

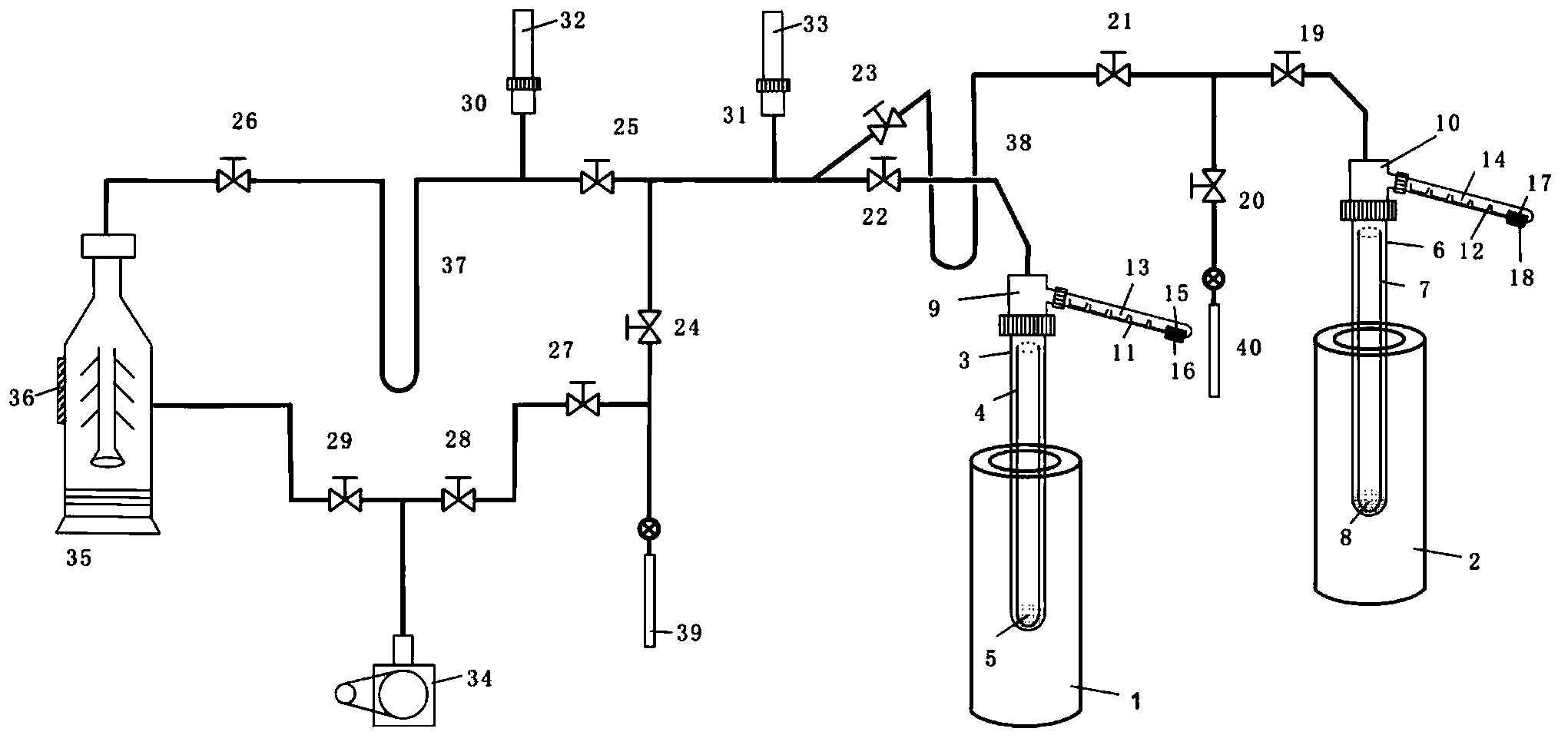

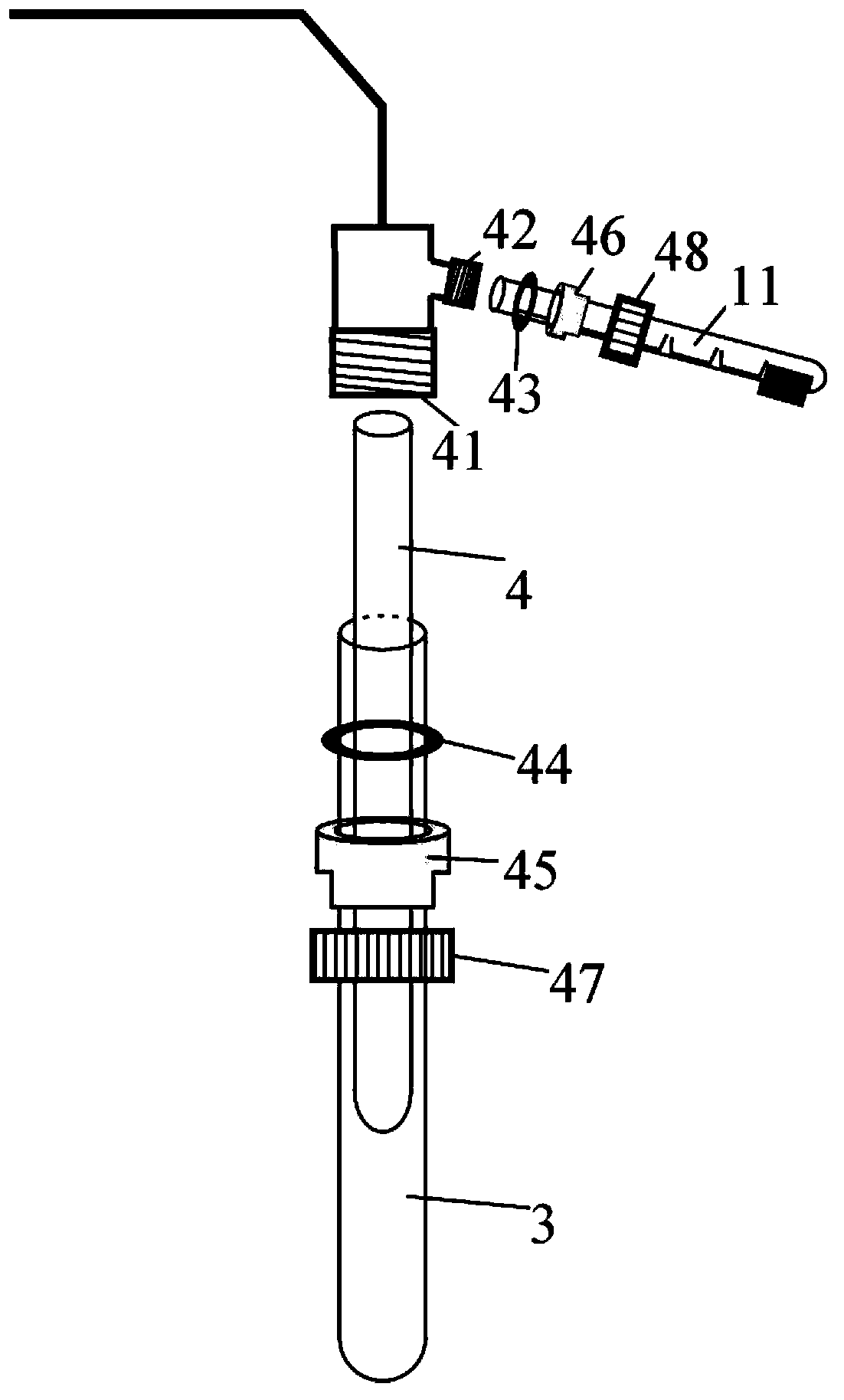

[0047] Such as figure 1 Shown, the composition connection relation of the sample preparation device of sulfur isotope analysis of the present invention is as follows:

[0048] A cooling fan 36 is installed on the diffusion pump 35, and the air inlet of the diffusion pump 35 is connected with one end of the cold trap A37 through a pipeline, which is provided with a spherical valve H26; One end is connected, the second end of the three-way pipe is connected to the thermocouple vacuum gauge 32 through the gauge joint A30, the third end of the three-way pipe is connected to the spherical valve G25; the exhaust port of the diffusion pump 35 is connected to the spherical valve through the pipeline One end of K29 is connected, the other end of the spherical valve K29 is connected with the first end of the three-way pipe, the second end of the three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com