Cylinder assembly and piston for a longitudinally flushed stroke piston combustion engine

A technology of reciprocating pistons and internal combustion engines, applied in the direction of cylinders, pistons, cylinder heads, etc., can solve the problems of lubricating oil loss, receiving space pollution, disadvantages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

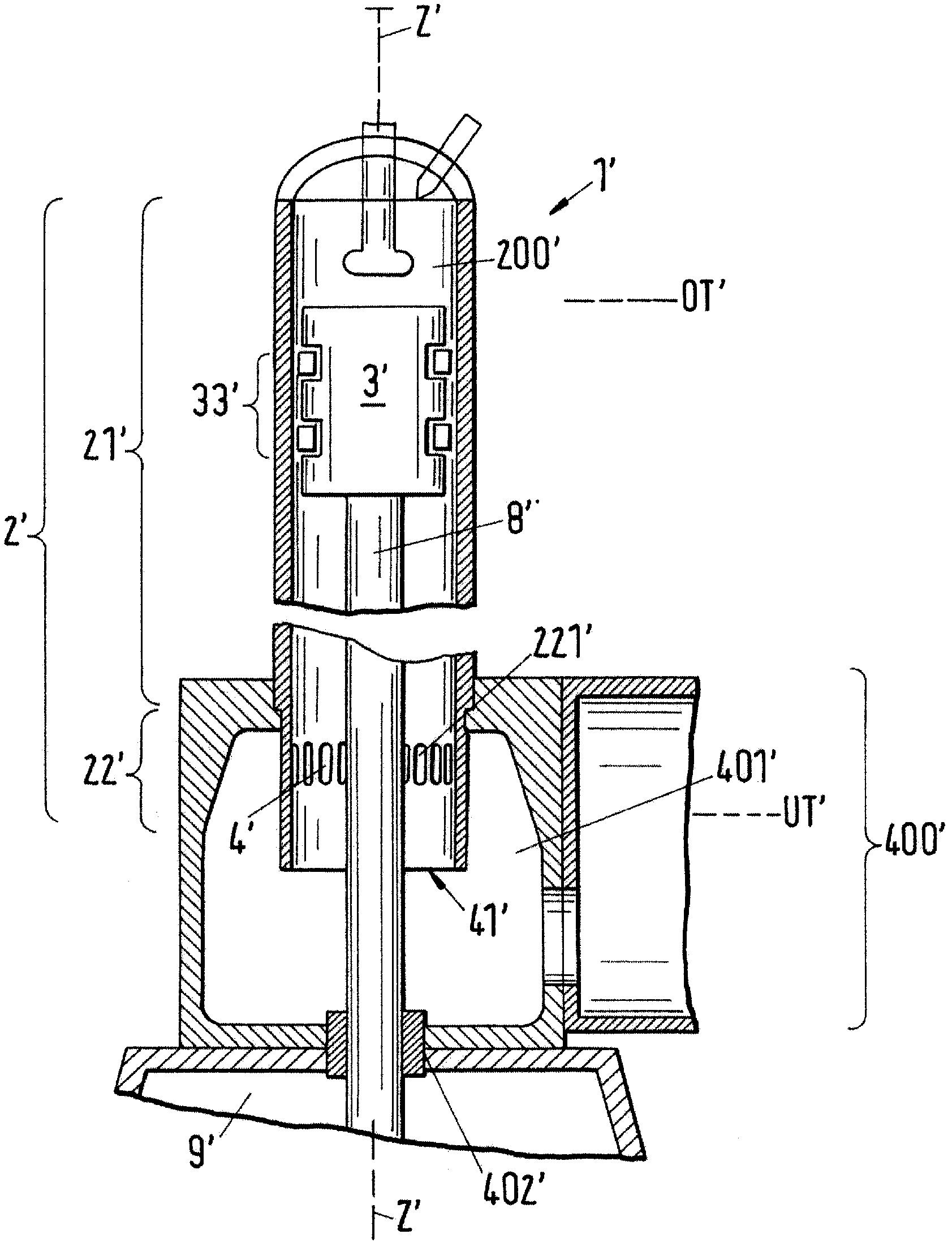

[0044] figure 1 A partially cutaway schematic view of a cylinder arrangement 1' with a cylinder liner 2', a piston 3' and a fresh air supply system 400' is shown.

[0045] For large longitudinally scavenged two-stroke diesel engines, figure 1 The cylinder device 1' is a typical device as known in the prior art. For a better distinction from known cylinder arrangements, the corresponding reference numbers are provided with single quotation marks, while the reference numbers which are characteristic of the cylinder arrangement according to the invention do not have single quotation marks.

[0046] The device comprises a cylinder 2', also called a cylinder liner 2', wherein a piston 3' is movably arranged to move back and forth along the cylinder wall of the cylinder 2'. The piston 3' comprises a piston ring assembly 33', which is shown schematically in this example with only two piston rings.

[0047] According to the view, the combustion chamber 200' present in the combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com