Novel material pressure-out ball used in staged fracturing pitching slide sleeve opening

A segmented fracturing and ball-throwing sliding sleeve technology, which is applied in the field of petroleum exploration, can solve the problems of unreliable sealing, difficult sealing of the ball and valve seat, poor impact resistance, etc., to reduce construction risks, safe and reliable sealing, forming high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

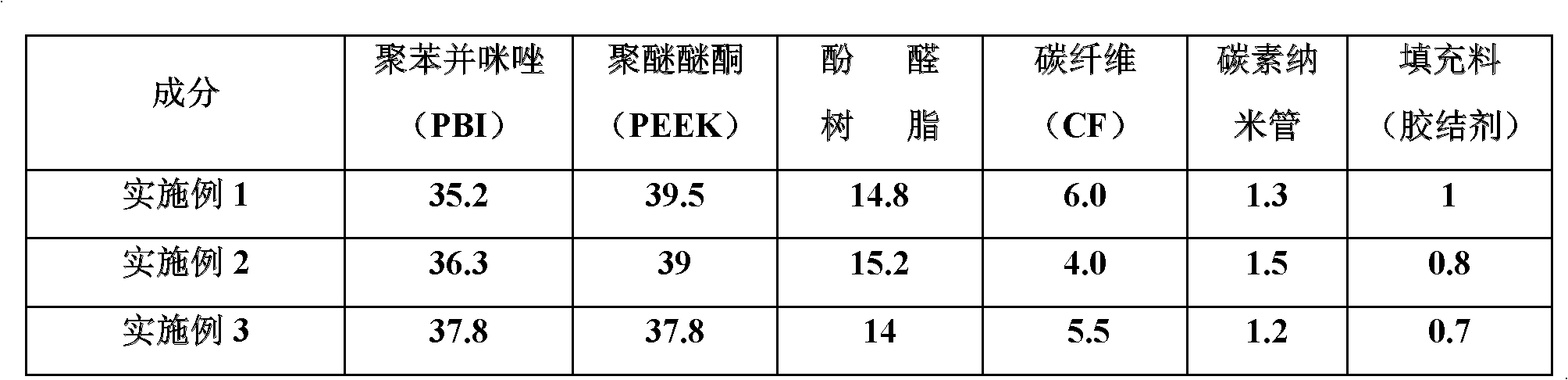

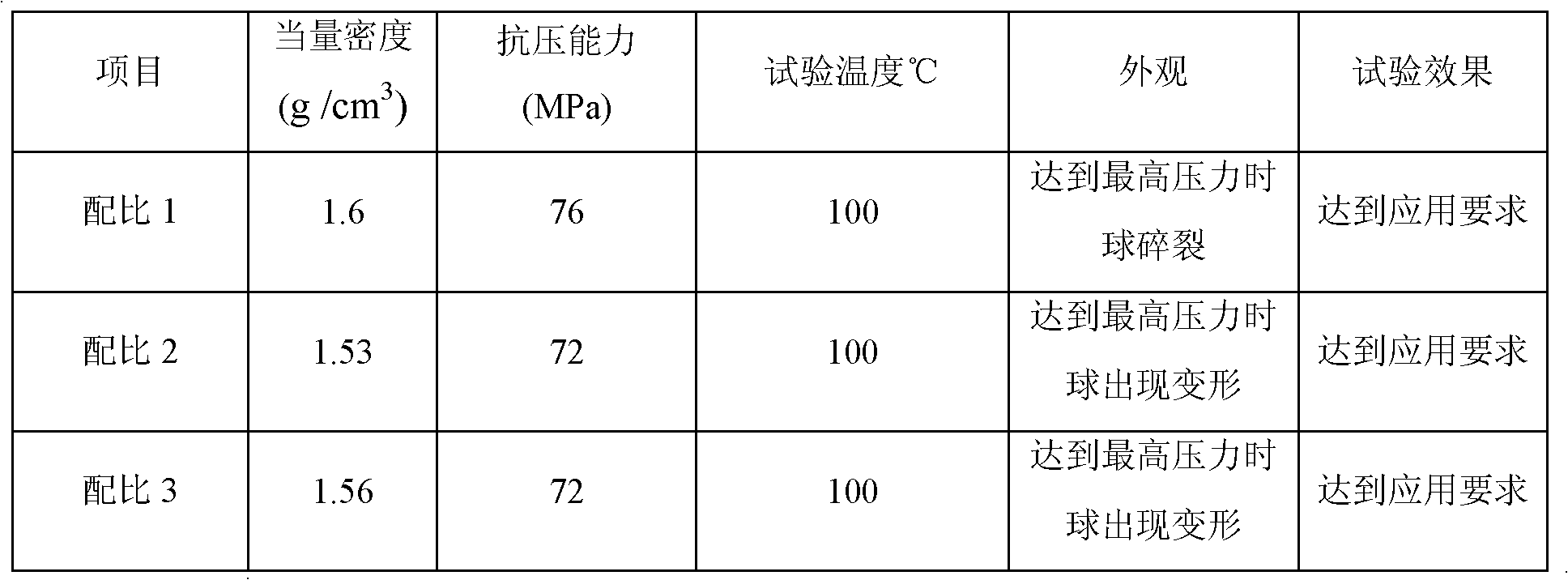

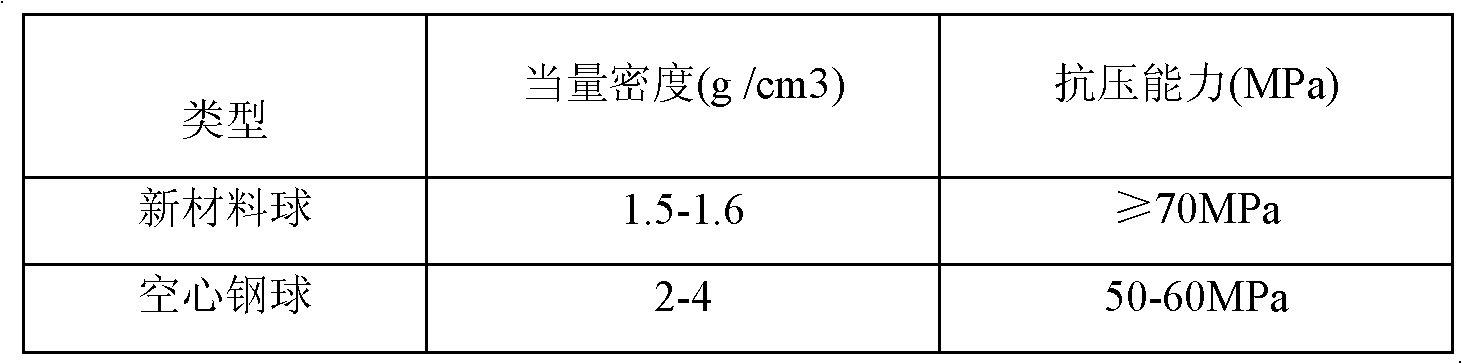

[0017] The composition ratio of the new material used in the pressure holding ball of the present invention is that the remaining components are polyethylene. They are shown in Table 1 respectively.

[0018]

[0019] Table 1

[0020] The working principle of the pressure-suppressing ball of the present invention is as follows: during the construction process, a low-density pressure-suppressing ball of new material is put into the ball feeder, and pumped to the fracturing ball sliding sleeve, and sealed with the valve seat to increase the pressure in the oil pipe until The seal with the valve seat plays the role of pressure suppression. When the pressure rises, the shear pin is cut to open the sliding sleeve, and the pressure holding ball and the sliding sleeve go down together, closing the lower part to open the oil layer, and fracturing begins. After the fracturing is completed, the pressure holding ball is flowed back with the fracturing fluid to complete the fracturing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com