Novel sealing mechanism for shaft end of mixing machine

A technology of end sealing and crankshaft, which is applied in the field of shaft end sealing mechanism of new mixers, can solve the problems of material leakage or powder spraying at the end of the main shaft shaft, affecting the mixing effect, and poor sealing effect, so as to increase the air sealing ability and eliminate Potential safety hazard, safe and reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

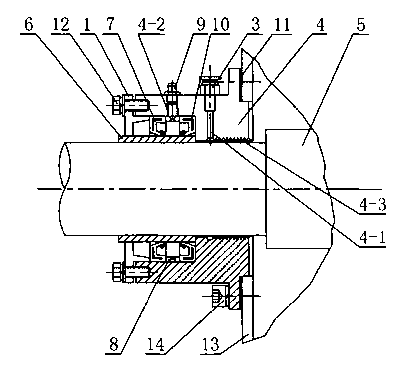

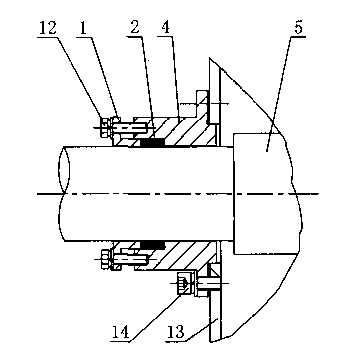

[0019] Such as figure 1 As shown, a new shaft end sealing mechanism of a mixer includes a seal seat 4 and a seal cover 1 set on the main shaft 5, and also includes a wear-resistant sleeve 6, a No. 1 oil seal 7, a spacer 8 and a No. 2 oil seal 10 , also includes oil cup 9, also includes gasket 11. The sealing cover 1 is fixedly connected to one end surface of the sealing seat 4 by screws 12 , and the sealing gasket 11 is arranged on the other end surface of the sealing seat 4 . The sealing seat 4 is provided with a through hole 4-1, and an air inlet port 3 is arranged at the through hole 4-1. The sealing cover 1, the No. 1 oil seal 7 and the No. 2 oil seal 10 are set on the outer diameter of the wear-resistant sleeve 6, and the outer diameters of the No. 1 oil seal 7 and the No. 2 oil seal 10 are clamped in the cavity at the front of the seal seat 4. Spacer ring 8 is housed between No. 1 oil seal 7 and No. 2 oil seal 10. The sealing seat 4 also has a lubricating through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com