Mixer shaft end seal mechanism

An end-sealing and shaft technology, applied in mixers, mixer accessories, dissolving and other directions, can solve the problems of powder spraying at the shaft end of the main shaft, pollute the working environment, affect the mixing effect, etc., and achieve the elimination of potential safety hazards, good sealing effect, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

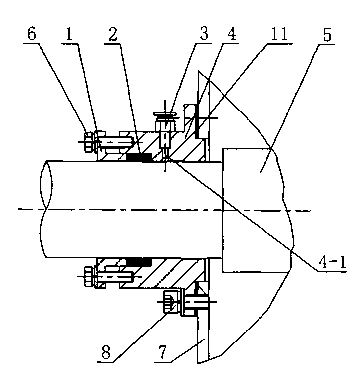

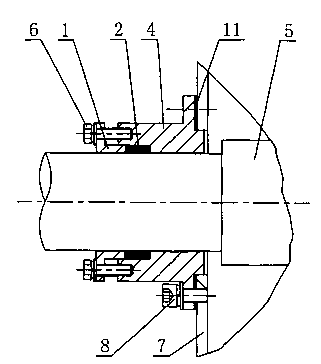

[0014] Such as figure 1 As shown, a shaft end sealing mechanism of a mixing machine includes a sealing seat 4 and a sealing cover 1 fitted on the main shaft 5 , and also includes a sealing gasket 11 . The sealing cover 1 is fixedly connected to one end surface of the sealing seat 4 by screws 6 , and a packing 2 is arranged between the sealing cover 1 and the sealing seat 4 . The gasket 11 is arranged on the other end surface of the sealing seat 4 . The sealing seat 4 is provided with a through hole 4-1, and an air inlet port 3 is arranged at the through hole 4-1. The packing 2 material is rubber.

Embodiment 2

[0016] Such as figure 1 As shown, a shaft end sealing mechanism of a mixer, this embodiment is basically the same as the first embodiment, the difference is: the material of the packing 2 is wool felt.

[0017] When the present invention is installed and used, see figure 1 , The sealing seat 4 is fixed on the mixer wallboard 7 by connecting screws 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com