Patents

Literature

56results about How to "Improve airtight performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

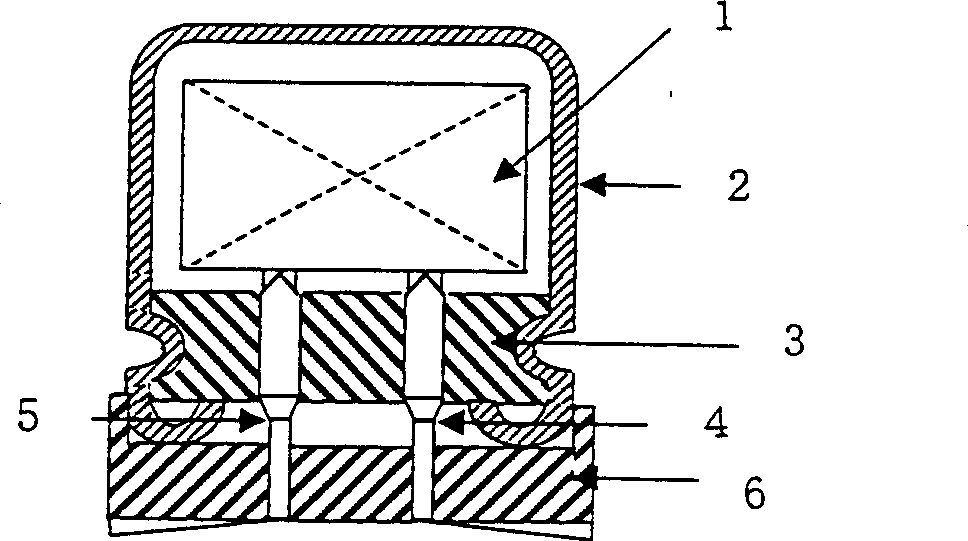

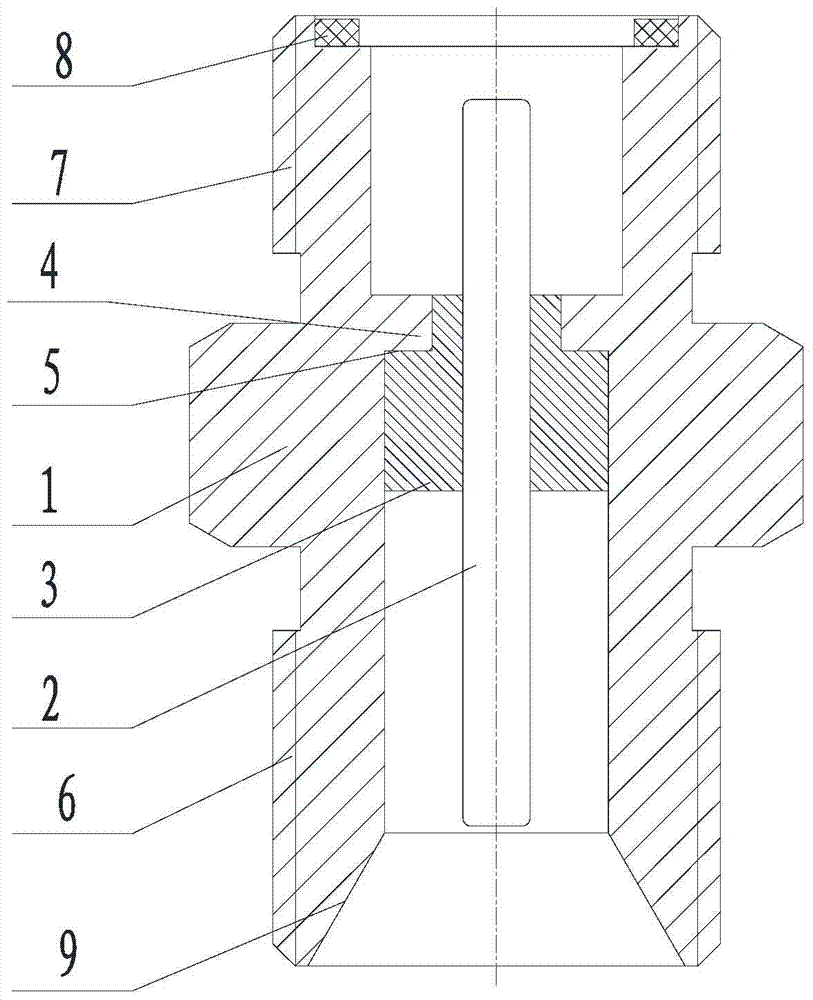

Oil conduit screwed connection structure

InactiveCN101307845AGood airtightnessImprove airtight performanceScrew threaded jointsInterference fitScrew thread

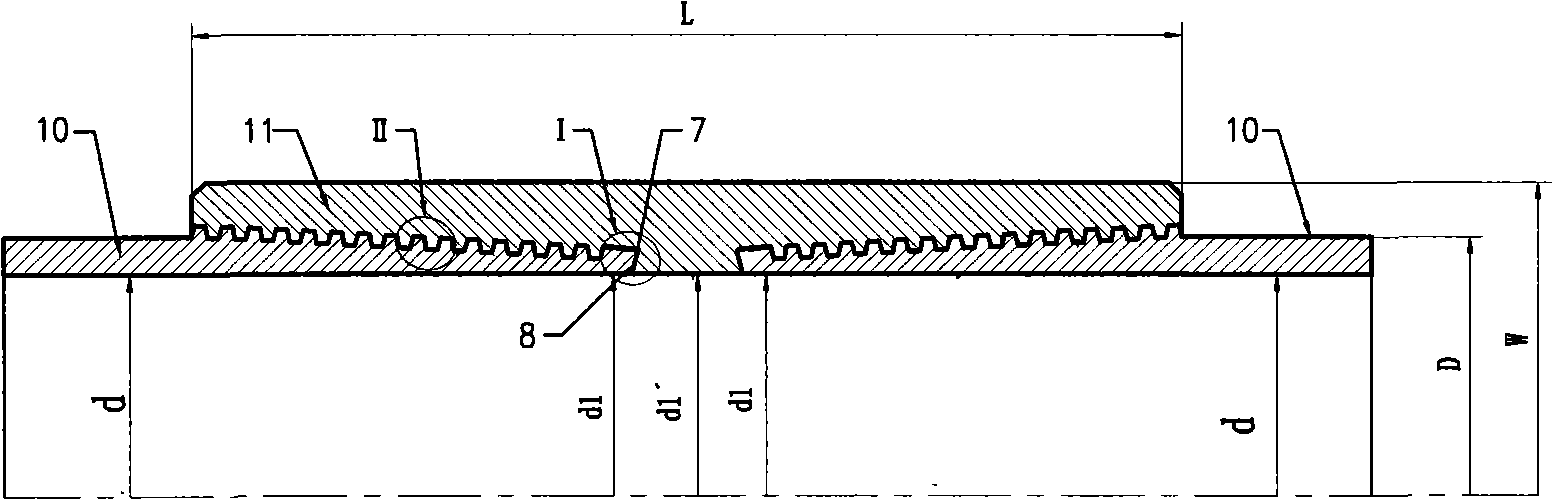

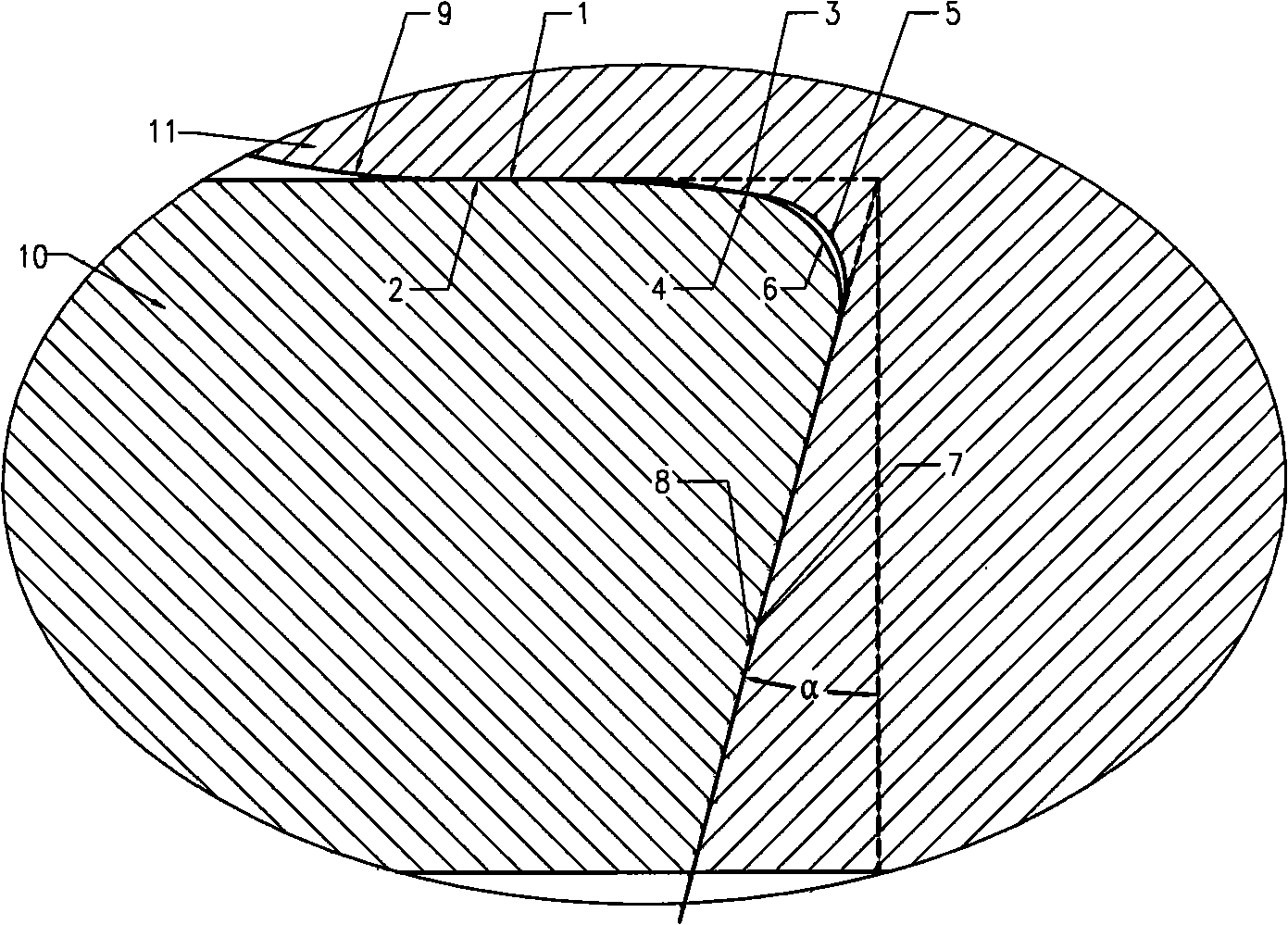

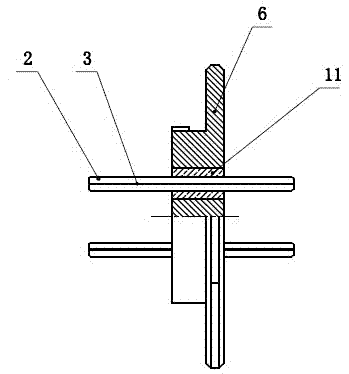

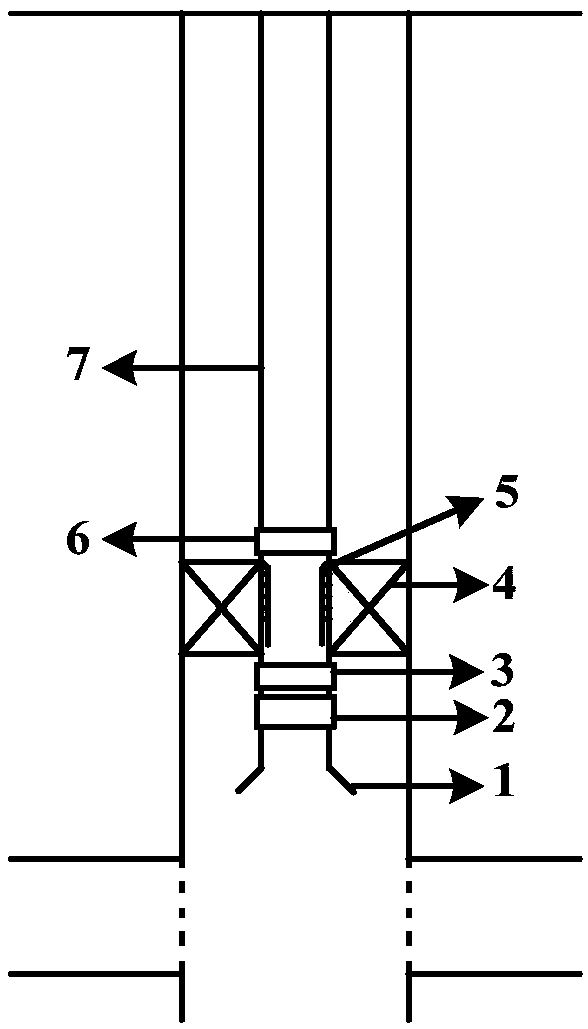

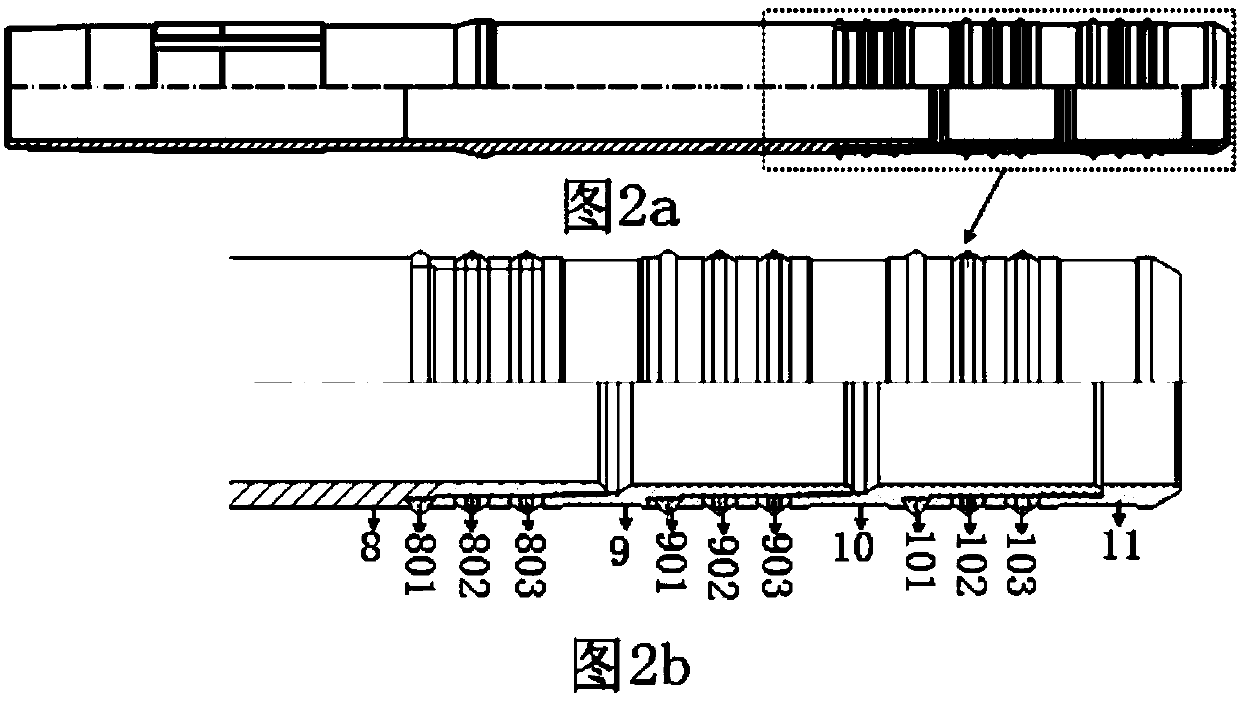

The invention relates to an oil pipe threaded connection structure, which is formed by screwing an oil pipe end (10) with an outer thread together with a pipe joint (11) with an inner thread. The threads adopted by the oil pipe end (10) and the pipe joint (11) are both approximate trapezoidal tapered threads; the head part of the oil pipe end (10) is provided with a circular arc surface (4); a circular conical surface (3) in interference fit with the circular arc surface is arranged on the pipe joint (11); the head part of the oil pipe end (10) is provided with an outer torque step (8); an inner torque step (7) matched with the outer torque step (8) is arranged on the pipe joint (11); the middle segment of the heat part of the oil pipe end (10) is provided with an outer cylindrical surface (2); an inner cylindrical surface (1) in interference fit with the outer cylindrical surface (2) is arranged on the pipe joint (11). The structure has the advantages of high threaded connection strength, good sealing performance, easy buckling, difficult buckling separation, good thread gluing preventing performance, strong over-torque preventing capability, etc.

Owner:JIANGSU CHANGBAO STEELTUBE CO LTD

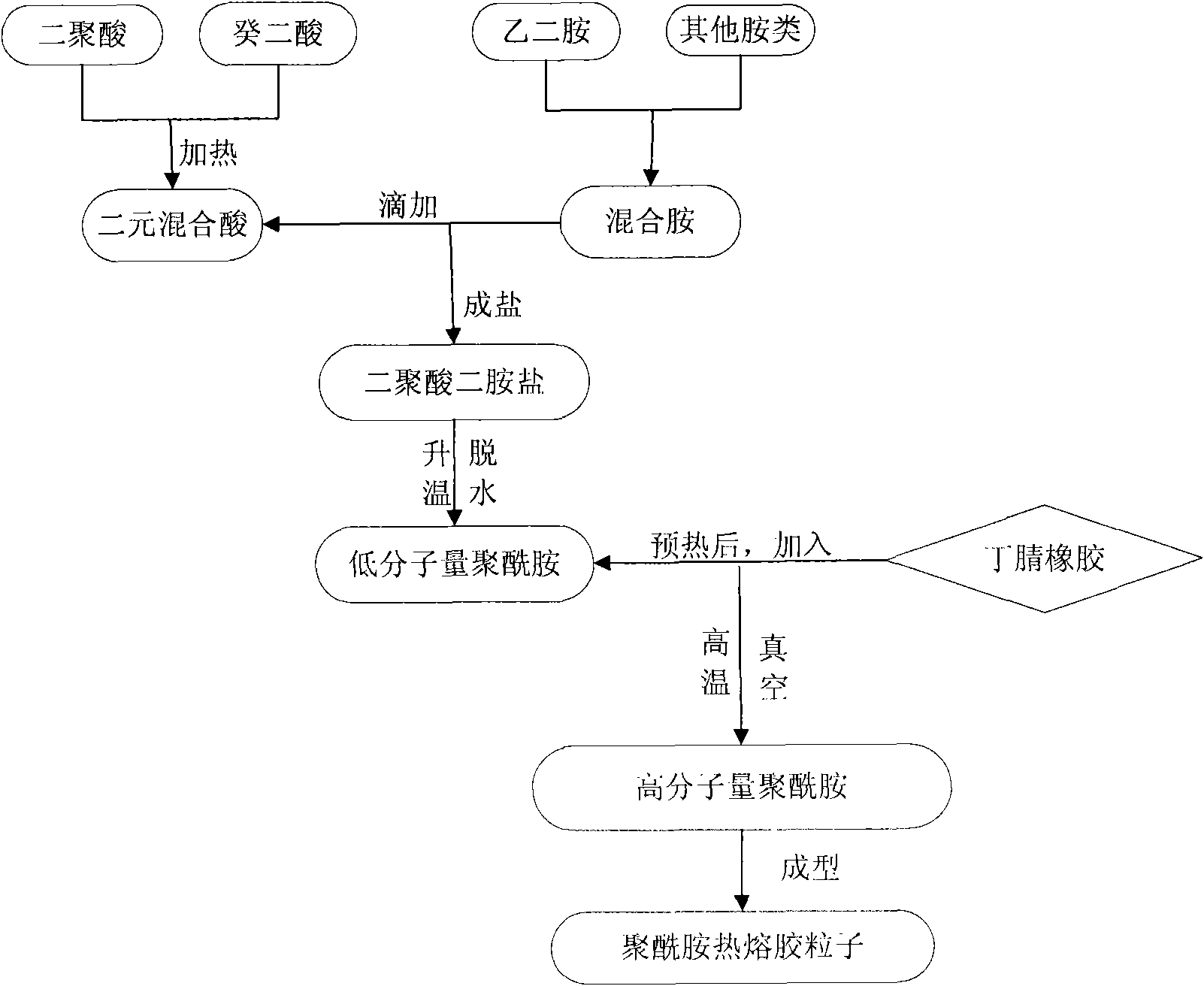

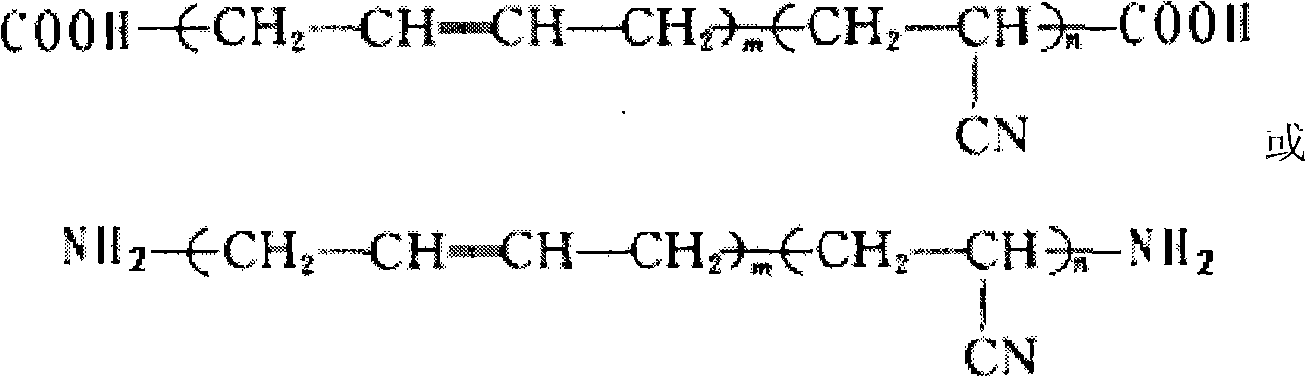

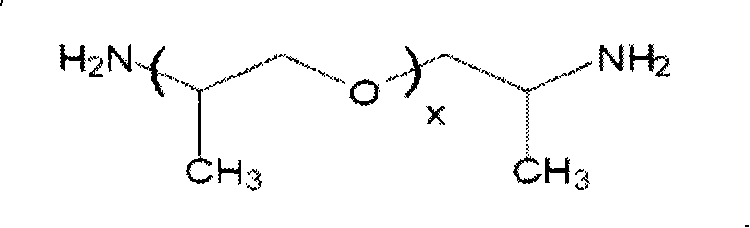

Low temperature resistant daiamid hot melt adhesive with high air tightness and application thereof

ActiveCN101633829AImprove sealingImprove low temperature resistanceAdhesivesPolymer sciencePolyamide

The invention relates to low temperature resistant daiamid hot melt adhesive with high air tightness and application thereof. The daiamid hot melt adhesive comprises a dimer unsaturated fatty acid polymerization unit, a C2-C12 aliphatic diamine polymerization unit, and 1 to 30 molar percent of chemigum polymerization unit by taking total molar number of the dimer unsaturated fatty acid polymerization unit or the aliphatic diamine polymerization unit as reference. Compared with the conventional daiamid hot melt adhesive, the air tightness of the daiamid hot melt adhesive is obviously improved.

Owner:SHANGHAI LIGHT IND RES INST +1

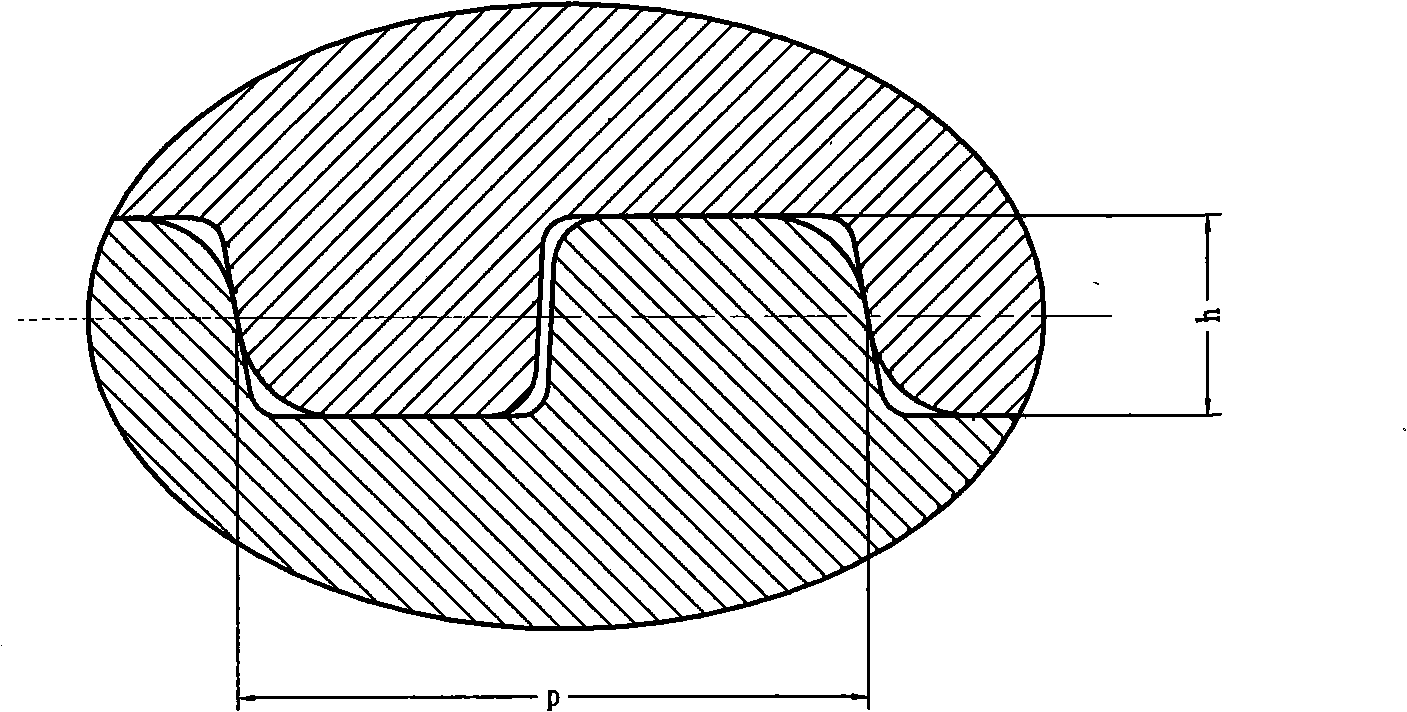

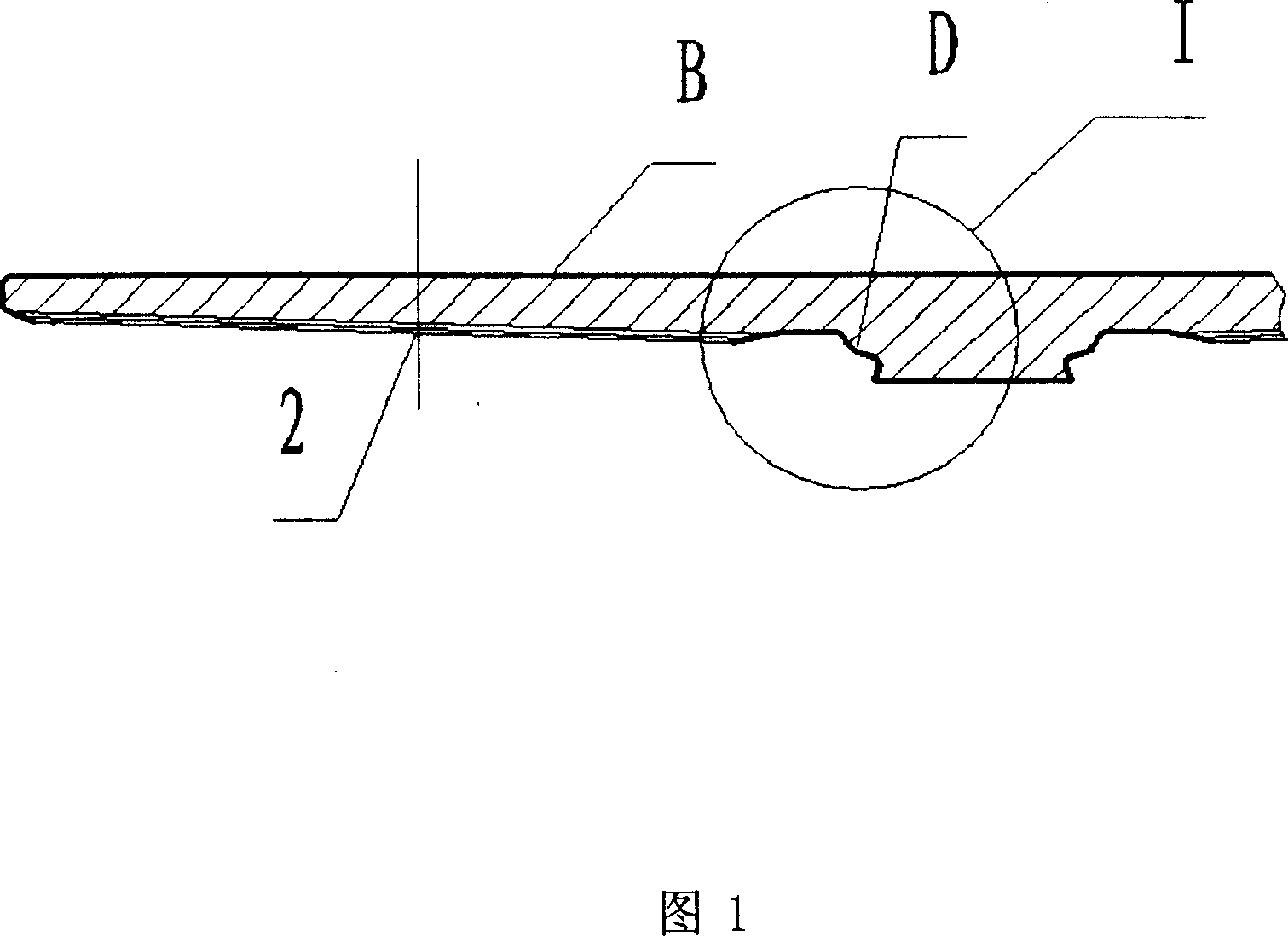

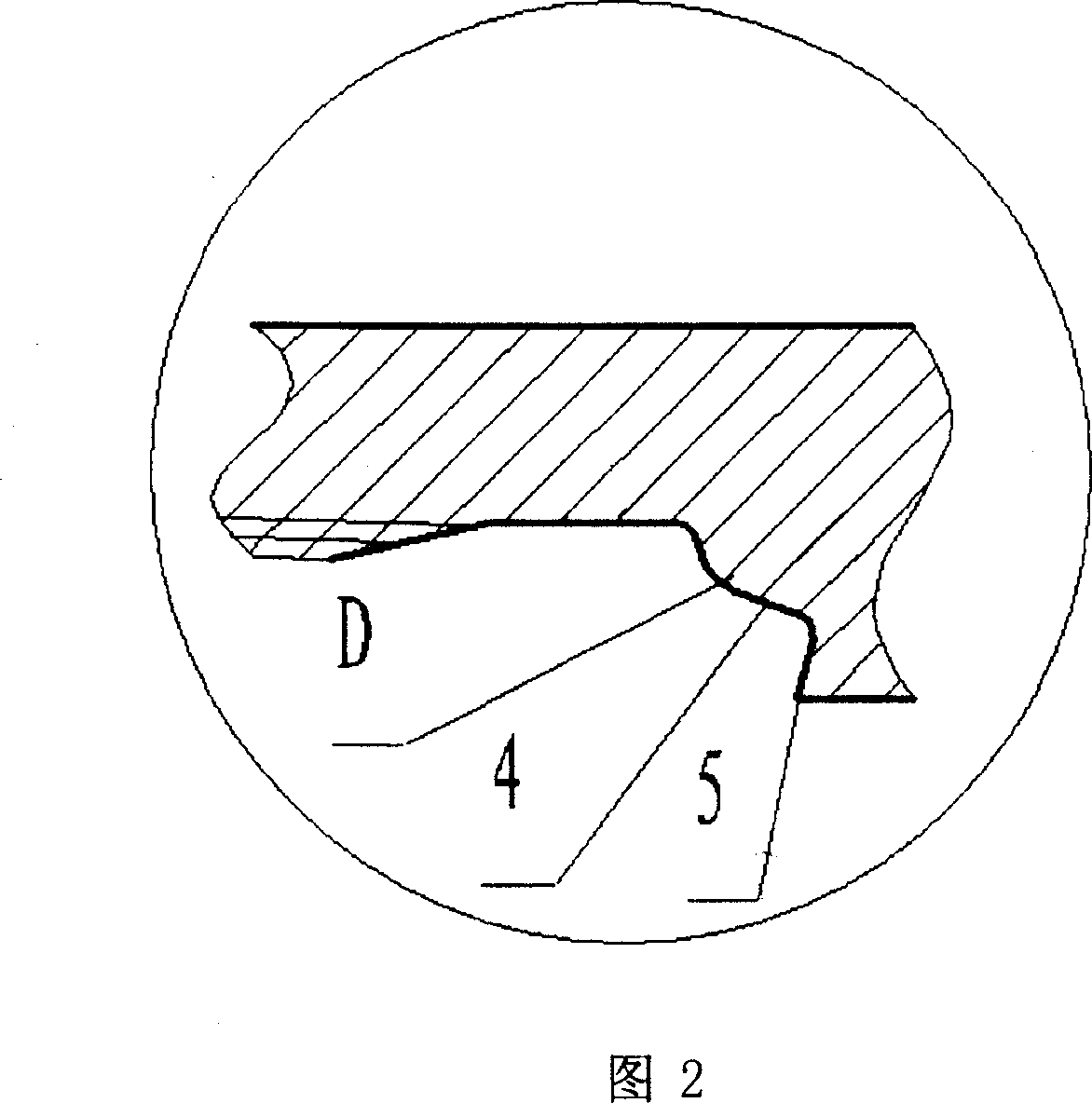

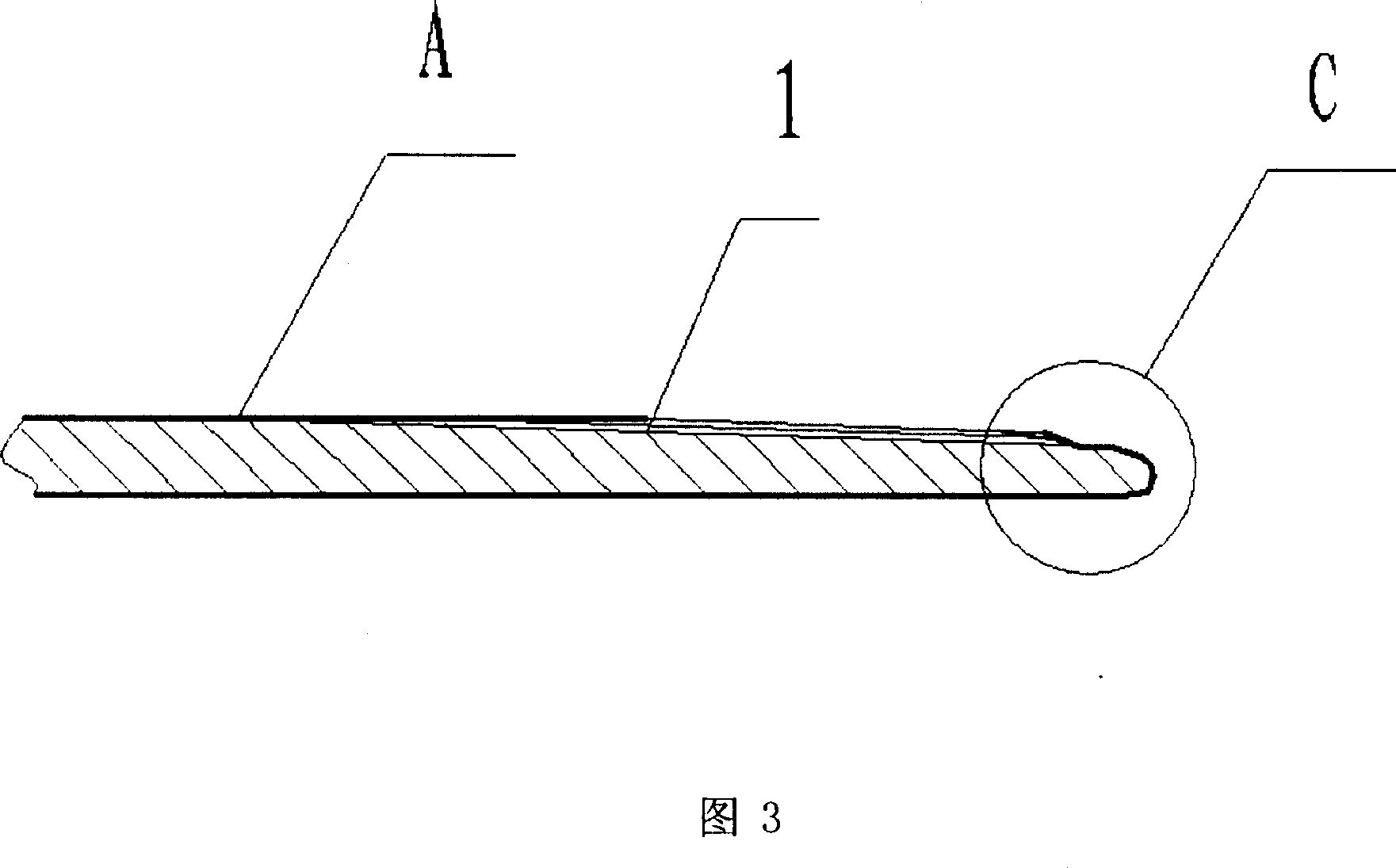

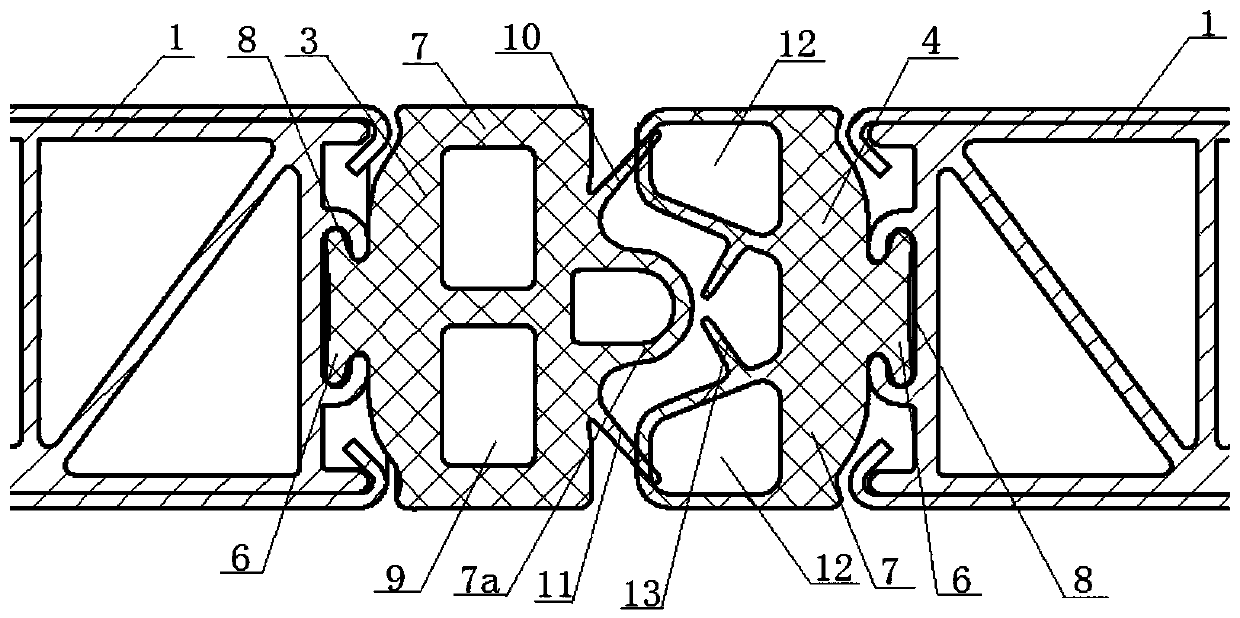

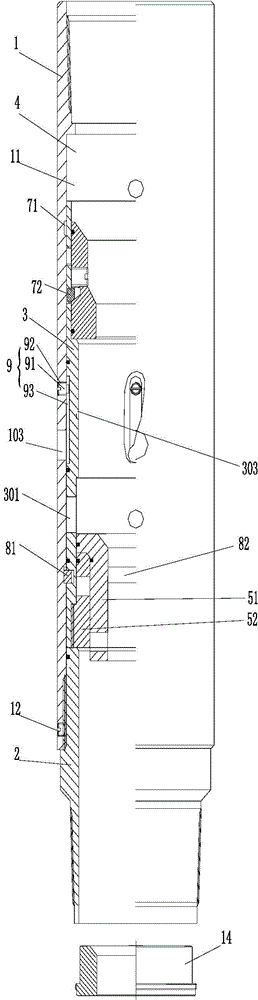

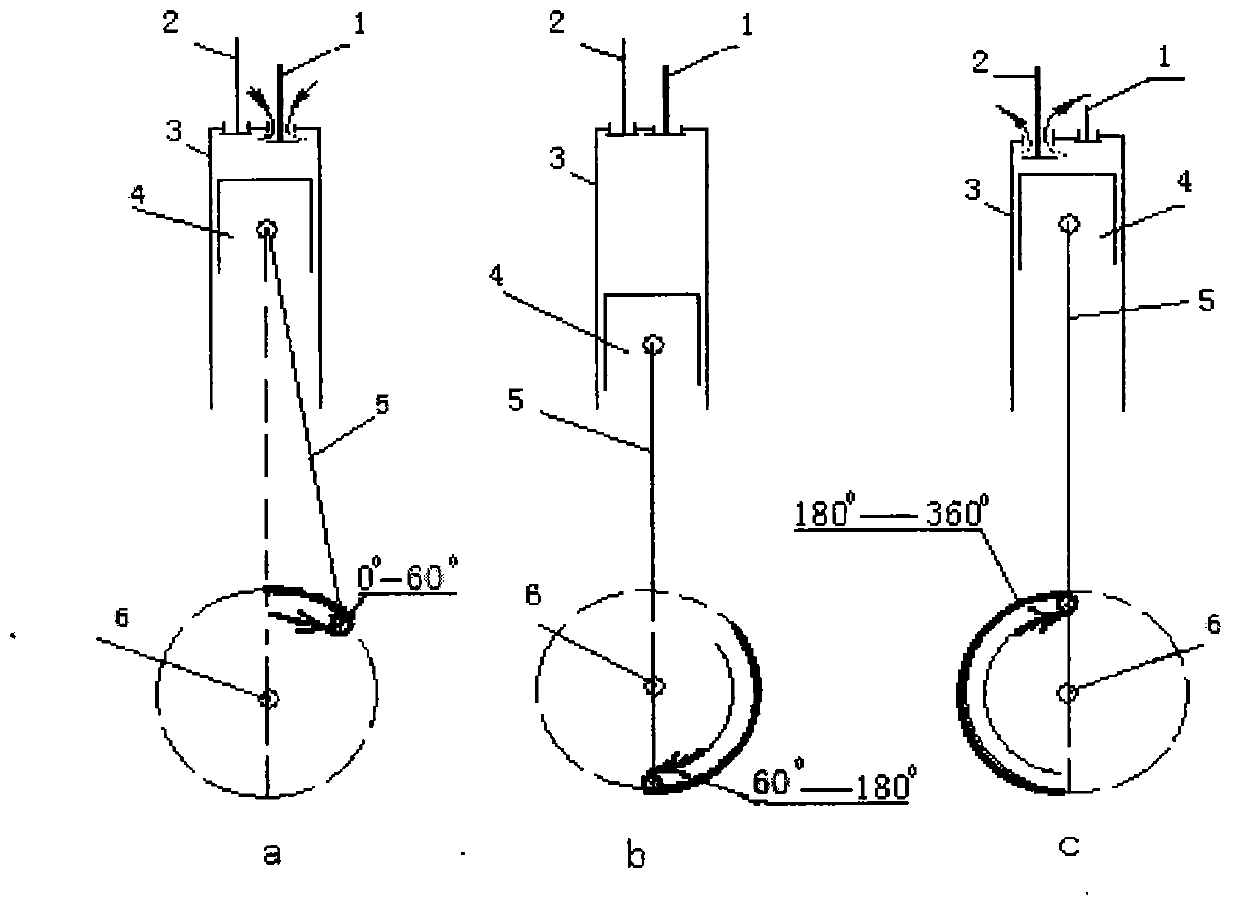

Anticompress and anti-bending shouldered hook-shape teeth screwed connection structure

InactiveCN101063502AImprove performanceAvoid stickingDrilling rodsDrilling casingsC sectionsCoupling

The invention provides a hook-tooth thread connecting structure with resistance to compression and bending, comprising a coupling B with inner thread at two ends, conical sealing surface and torque shoulder and an annular tube A with outer thread at two ends, conical sealing surface and torque shoulder, wherein the outer thread of the end of annular tube A is screwed with inner thread of the end of coupling B by hook-tooth thread, D section of inner thread of the end of coupling B is provided with inner torque shoulder and inner sealing conical surface, C section of outer thread of the end of annular tube A is provided with outer torque shoulder and outer sealing conical surface, and the inner sealing conical surface of the end of coupling and the outer sealing conical surface of the end of annular tube respectively contact the outer and inner torque shoulder. The hook-tooth thread has the advantages that the connecting structure has good property with high-pressure and high bending load, achieves the same compression and collapsing strength with the tube body and realizes the optimizing main sealing surface of metal to metal to achieve higher and more reliable air-impermeability, thereby realizing the non-leaking of gas with high-pressure and high bending load.

Owner:TIANJIN PIPE (GROUP) CORP

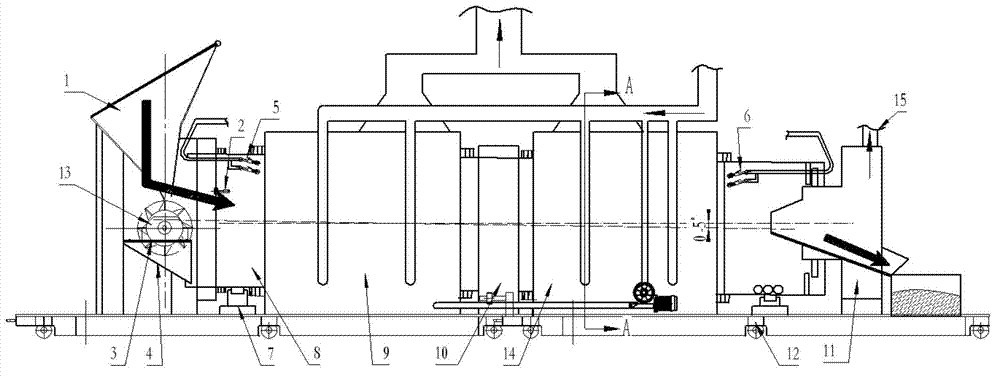

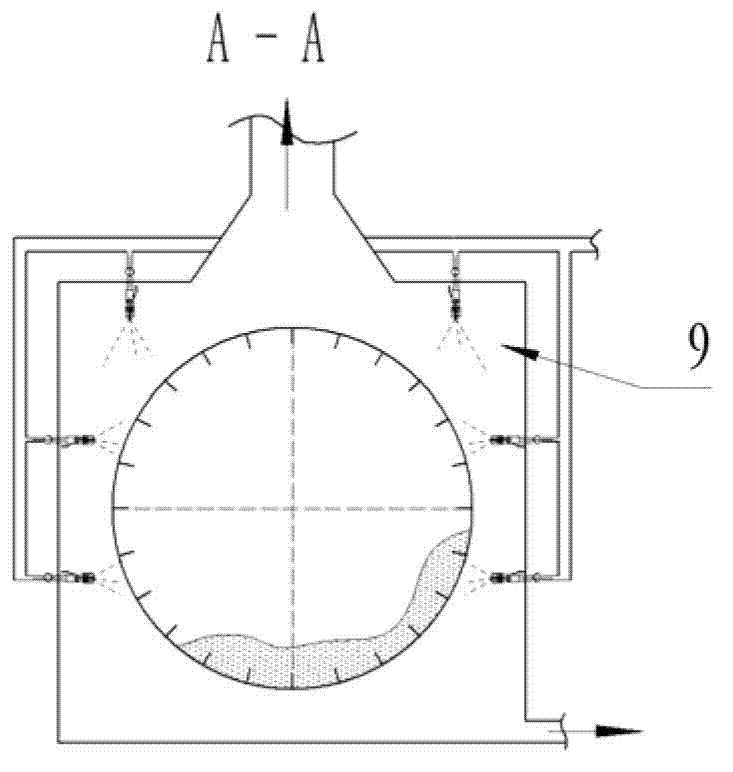

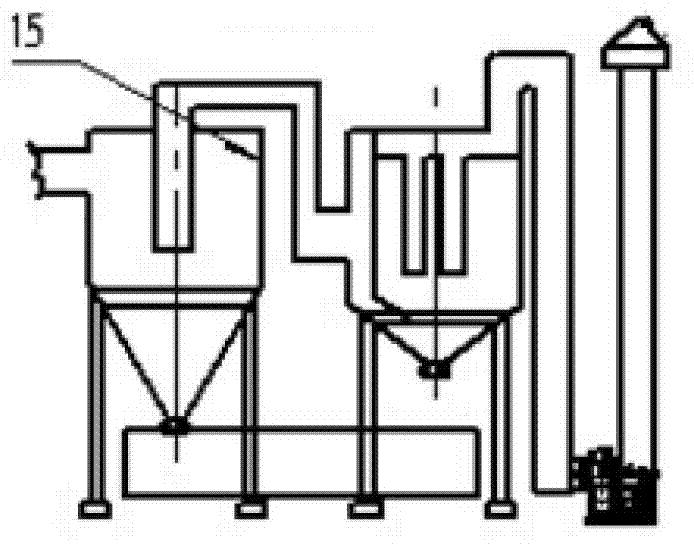

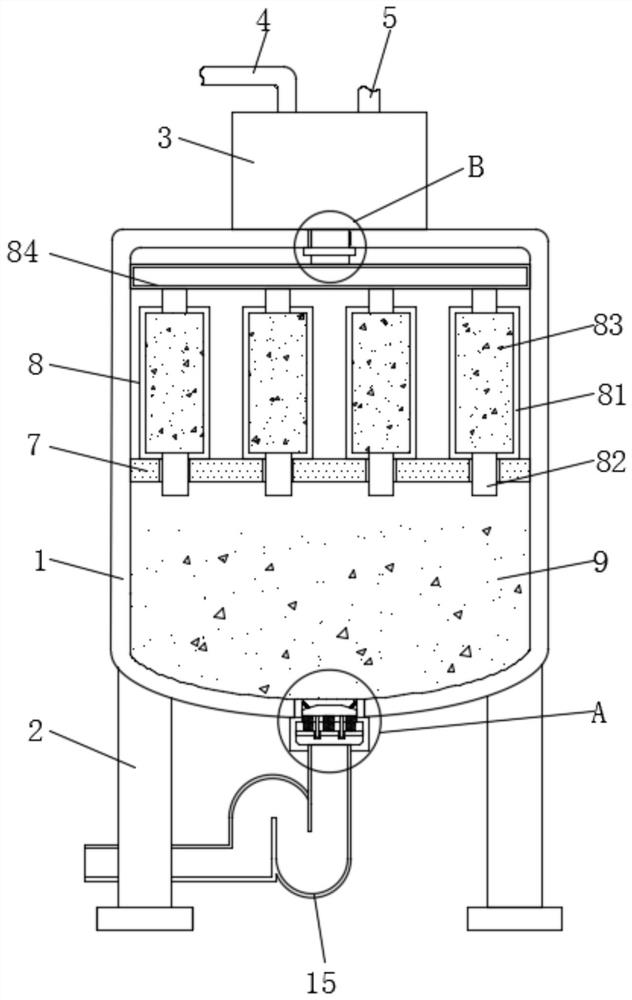

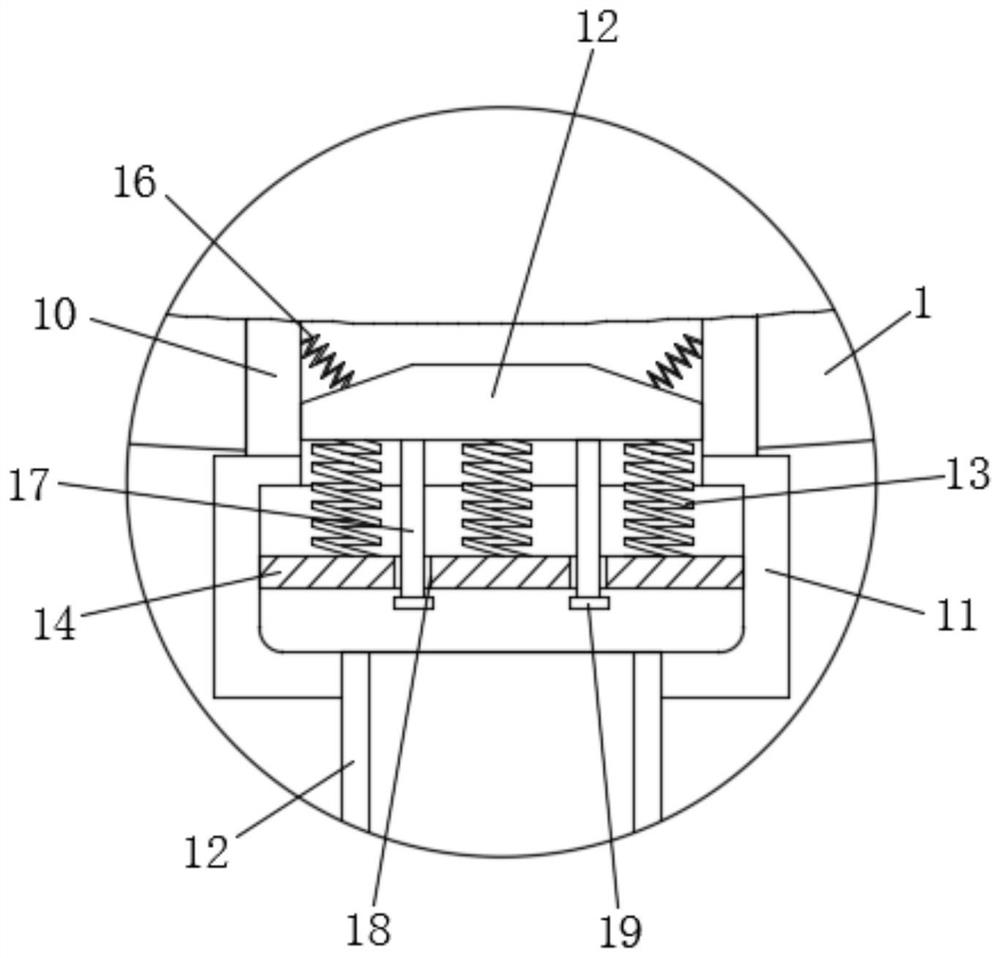

On-line KR desulfuration residue treatment device and method applied to hot metal pretreatment process

ActiveCN103173590AHigh sulfur contentLow recovery rateCasting cleaning apparatusThermal statePre treatment

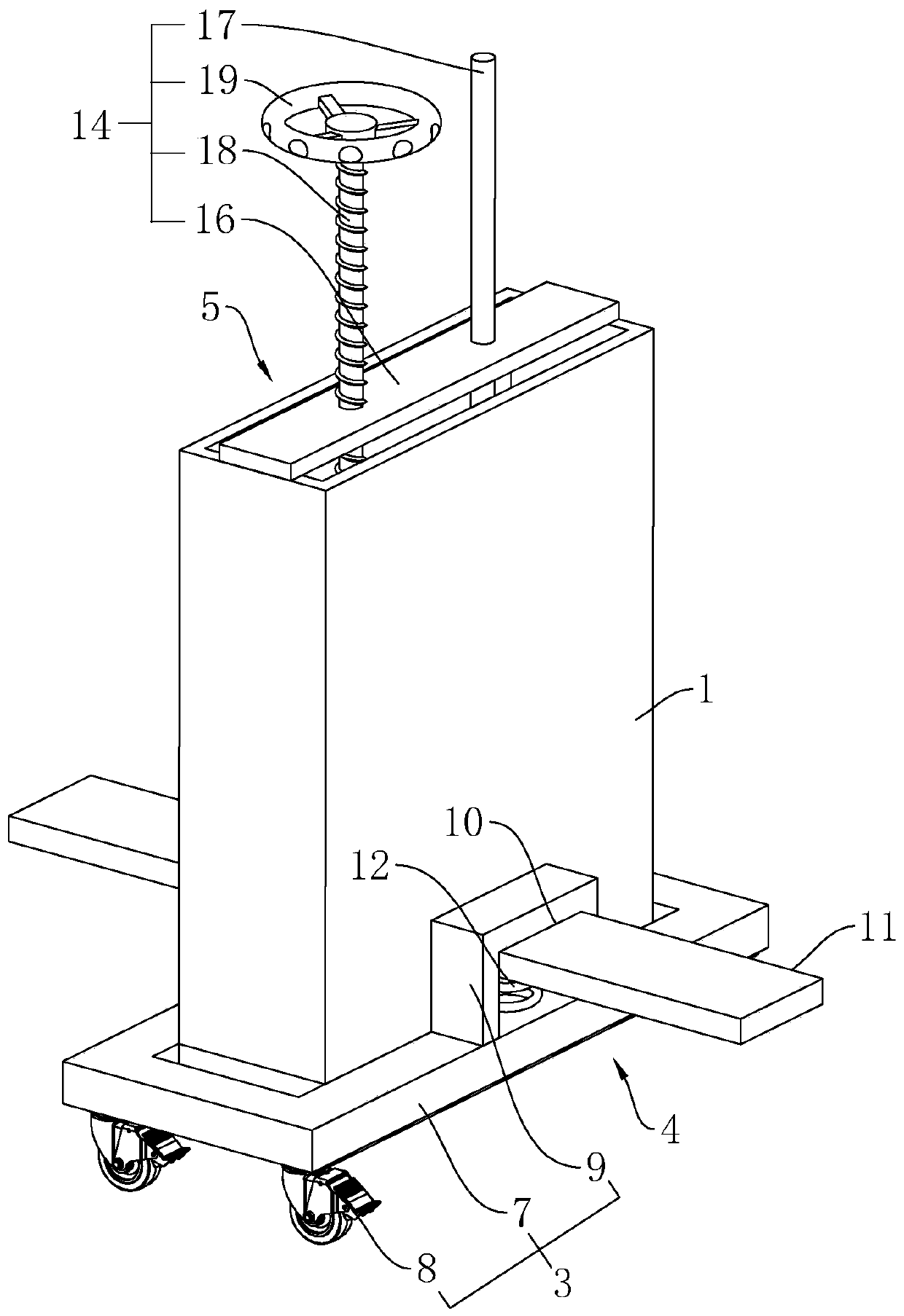

The invention discloses an on-line KR desulfuration residue treatment device applied to hot metal pretreatment process. The on-line treatment device comprises a breaking-up system, a residue cooling system, a dedusting system, a walking system and an electronic control system, wherein the walking system is arranged at the bottoms of the breaking-up system and the residue cooling system, and a residue receiving bucket is arranged at the front end of the breaking-up system; KR desulfuration residues enter the on-line treatment device directly after being subjected to KR desulfuration treatment by the hot metal pretreatment process, and the hot KR desulfuration residues at a high temperature enters the breaking-up system through the residue receiving bucket; the breaking-up system is connected with the residue cooling system which is provided with a double-cooling system. Compared with the prior art, the on-line KR desulfuration residue treatment device can perform on-line KR desulfuration residue treatment and break up the KR desulfuration residues in a thermal state; and by virtue of a quick cooling process, the quality of iron particles is improved, the content of impurities in the iron particles is greatly reduced, and the production efficiency is improved. The on-line KR desulfuration residue treatment device causes tiny environment pollution, is simple and convenient to operate and maintain, and has a high automation degree.

Owner:MAANSHAN SHUANGYI MACHINERY MFG

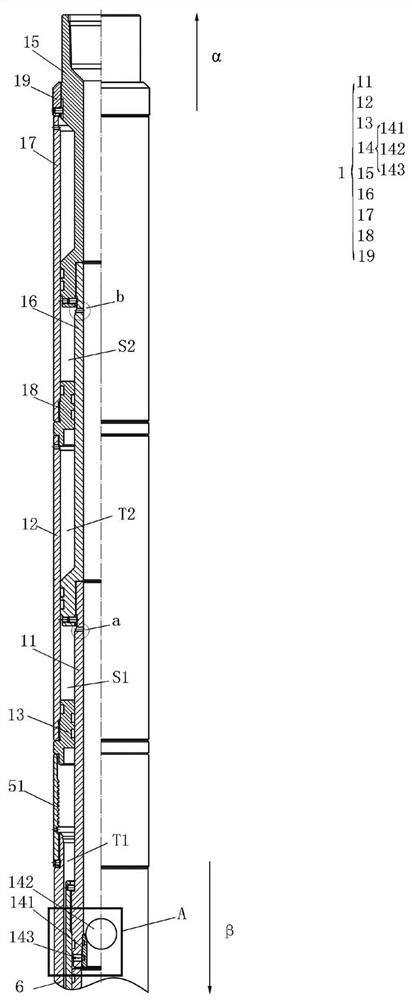

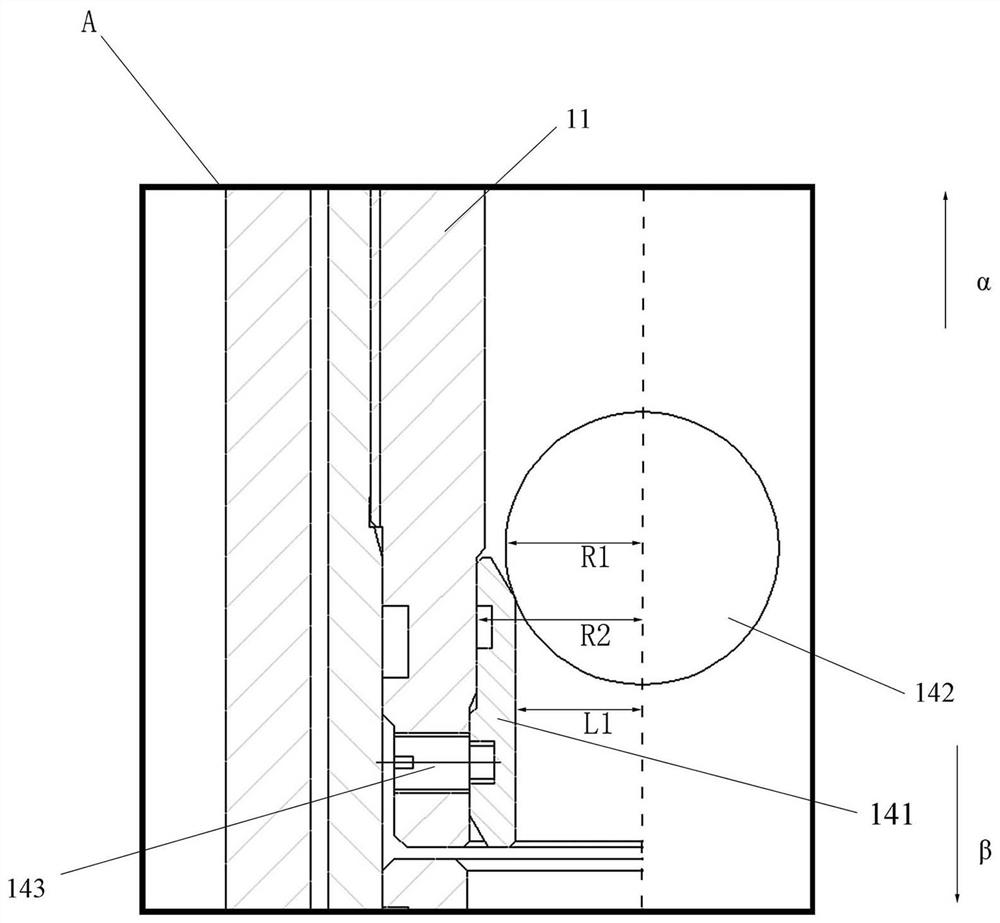

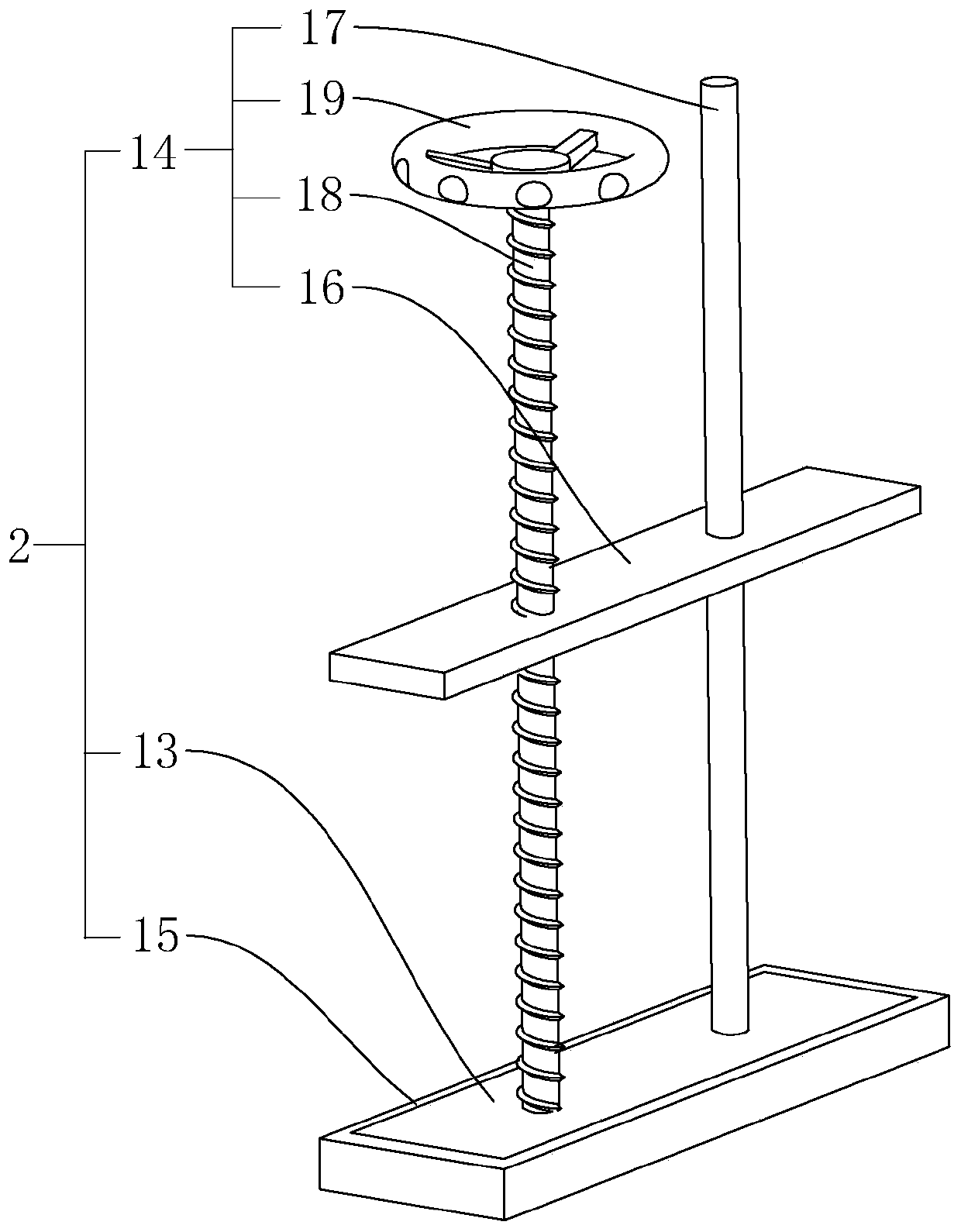

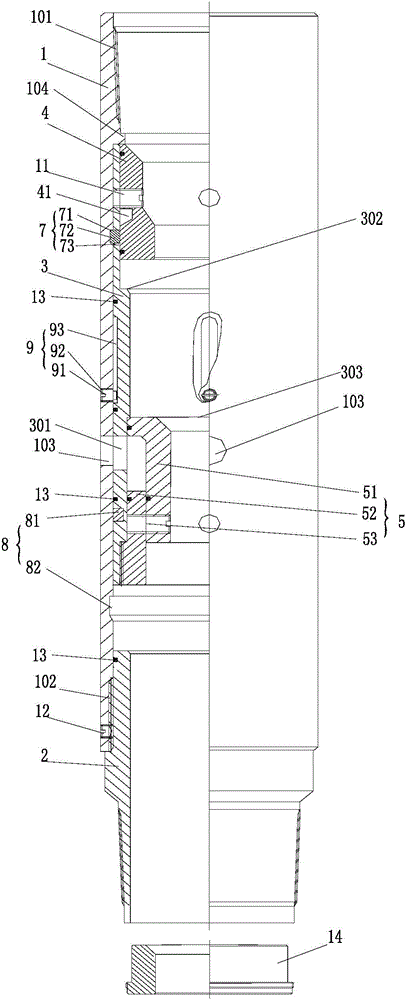

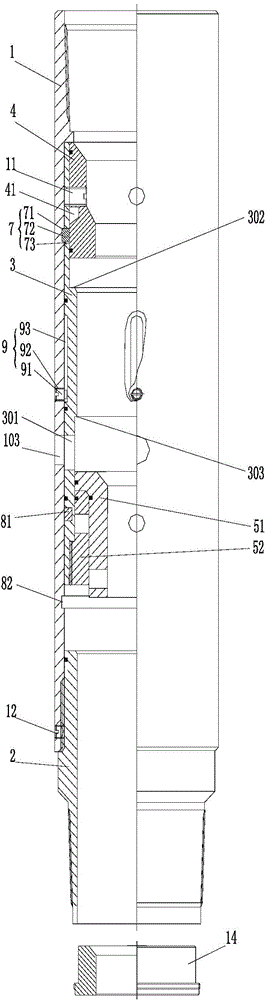

Suspension well completion integrated packer and well completion pipe string

ActiveCN113250647AIndependentFunctionality is not affectedSealing/packingCompressive resistanceMechanics

The invention provides a suspension well completion integrated packer and a well completion pipe string. The suspension well completion integrated packer comprises a setting mechanism, a tie-back cylinder, a releasing mechanism and a setting mechanism which are coaxially connected; the setting mechanism comprises a setting center pipe, a setting assembly, a first setting cylinder sleeve and a first annular setting piston; the setting mechanism comprises a setting center pipe, a thrust sleeve, a starting shearing fixing piece and a setting sealing assembly; and the releasing mechanism comprises a releasing elastic lock pipe, a releasing lock head, a releasing shearing fixing piece and a releasing assembly. The suspension well completion integrated packer can further comprise a tie-back mechanism; and the tie-back mechanism comprises a tie-back lock sleeve and a tie-back insertion pipe assembly. The setting mechanism of the suspension packer can achieve independent setting, the functions of other tools in the open hole segmented well completion pipe string are not affected, the releasing mechanism is high in compressive strength, and unsetting can be achieved after setting.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

Electron component

InactiveCN1366318AImprove reliabilityExtend your lifeCapacitor housing/encapsulationHigh humiditySilanes

An electronic component, comprising a container with an opening, an electronic component and an electrolyte disposed in the container, and a sealing member arranged at the opening and capable of sealing the opening; Combination structure; the above-mentioned complex contains isobutylene rubber polymer as the main component, phenolic additives and silane additives; thereby improving the airtightness of the sealing part and reducing the volatilization of the electrolyte. Also, the electronic component having such a sealing member has good mountability; as a result, an electronic component having long-term high reliability even under high temperature, high temperature and high humidity can be obtained.

Owner:PANASONIC CORP

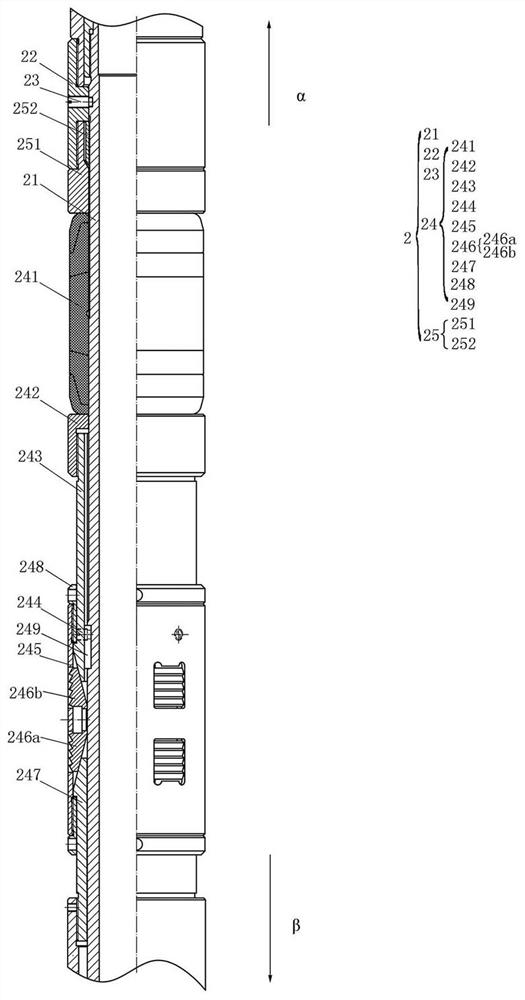

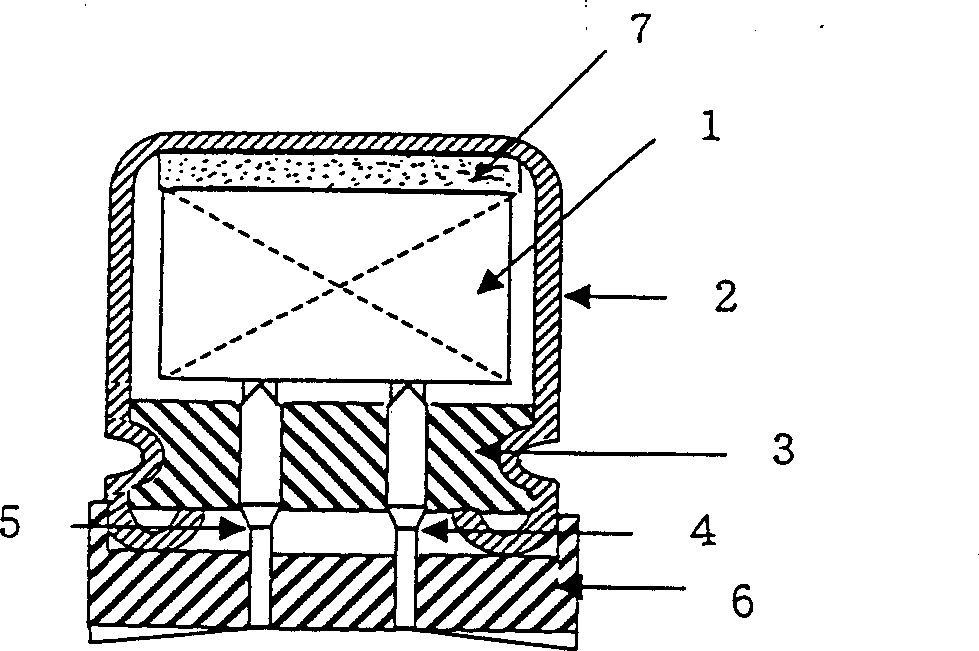

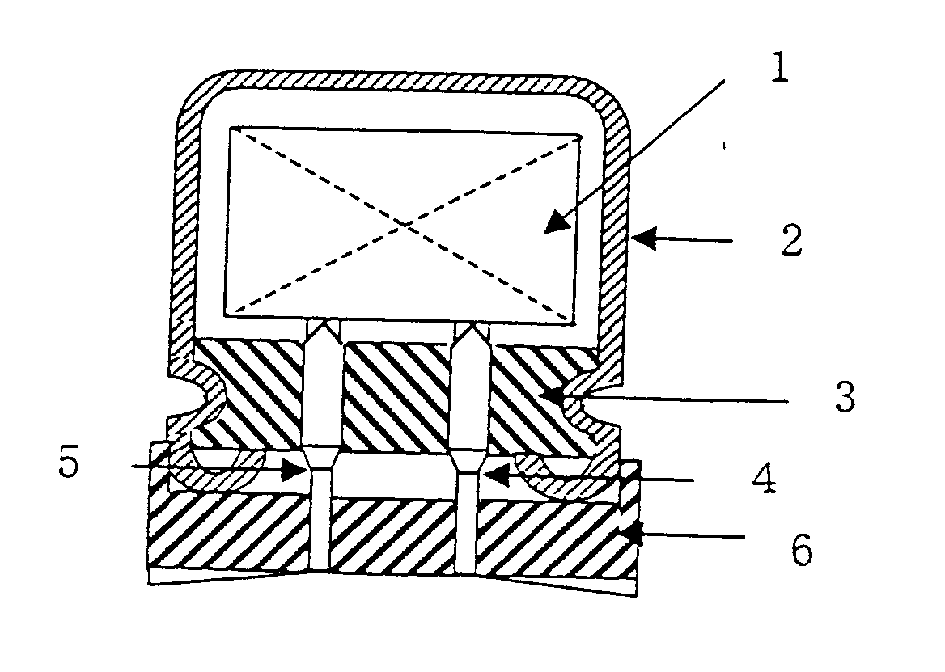

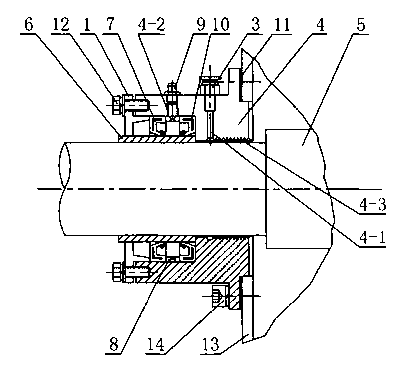

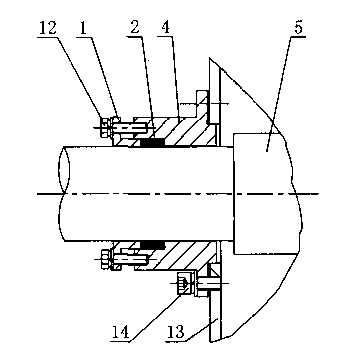

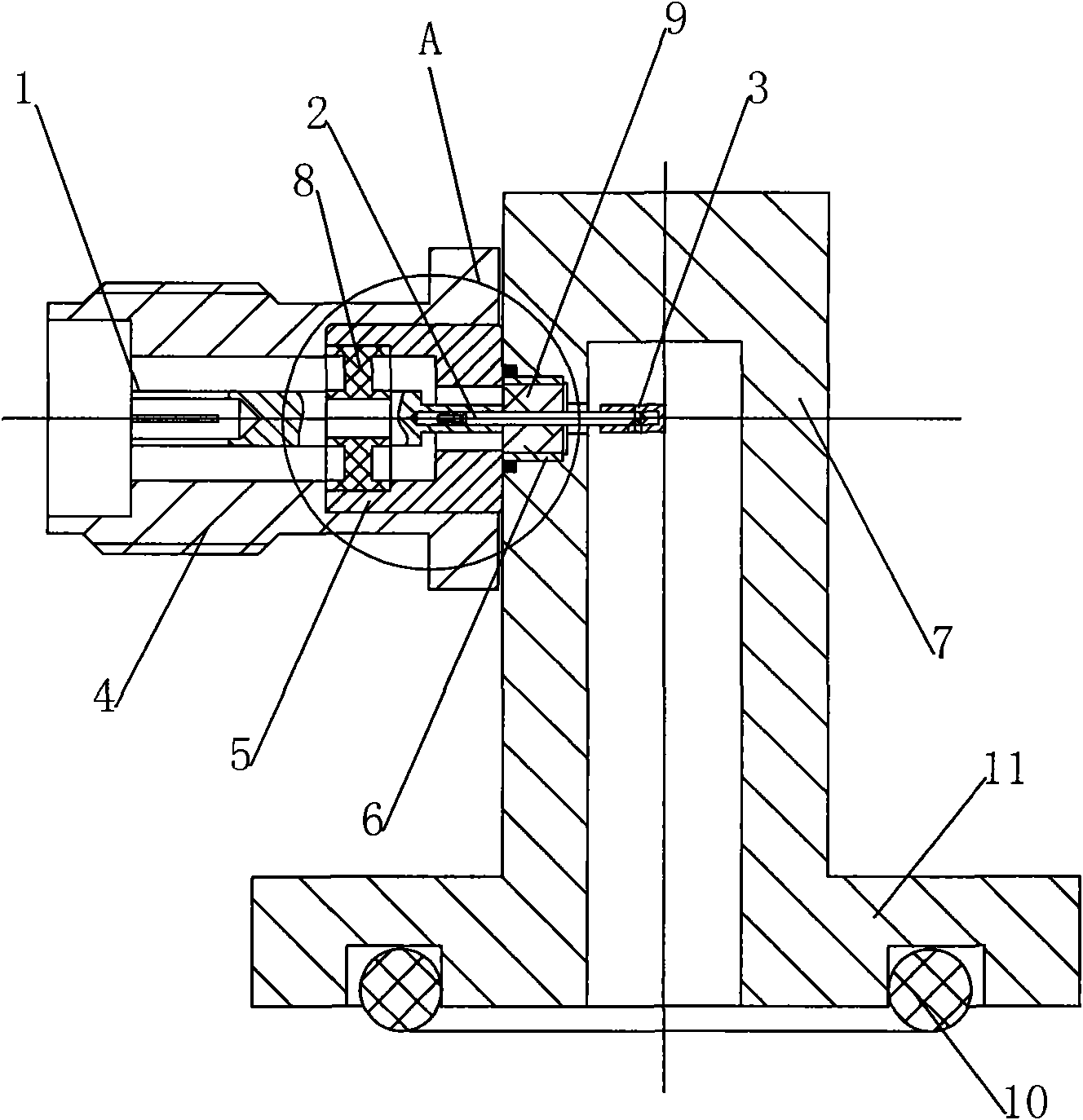

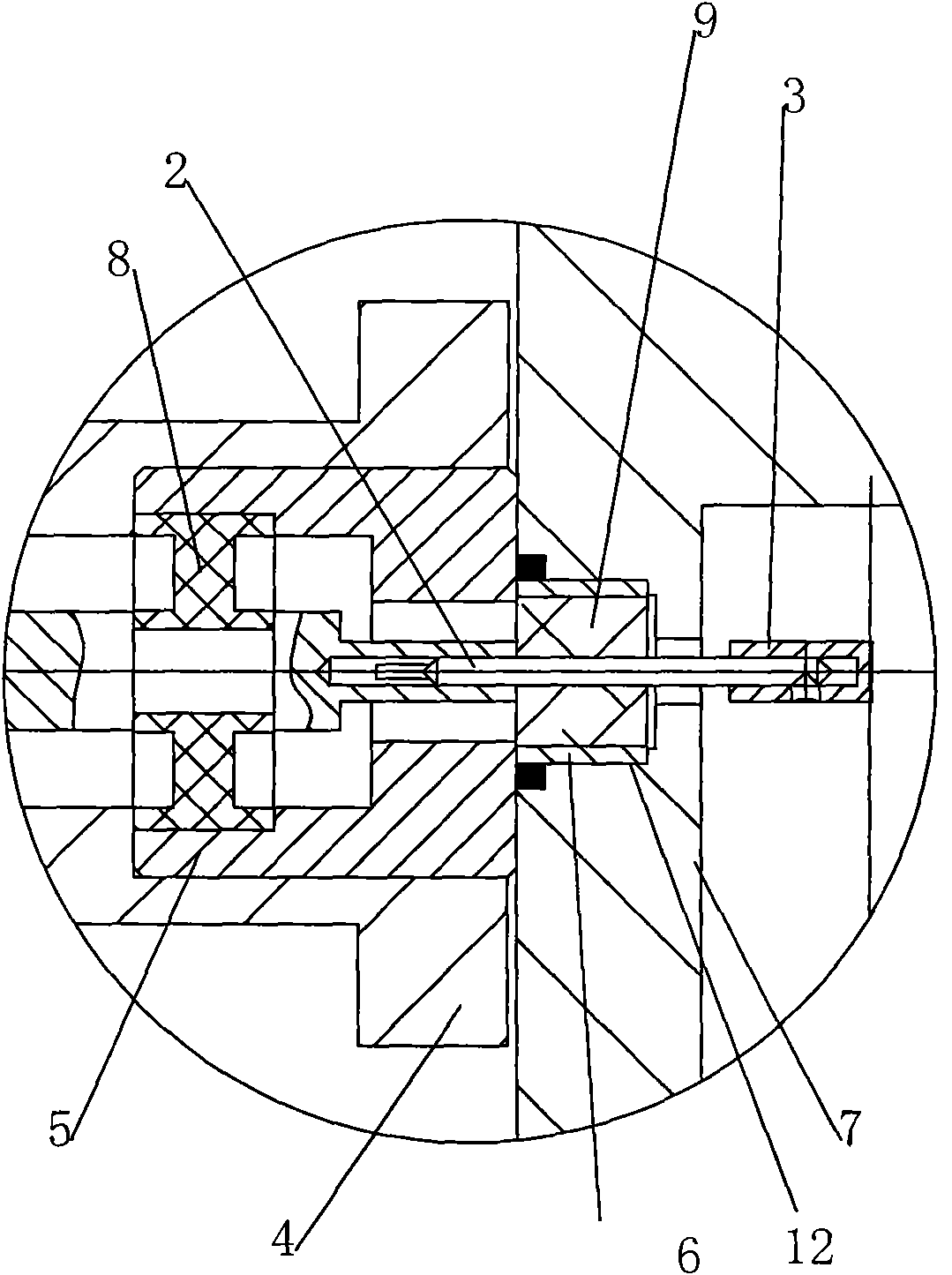

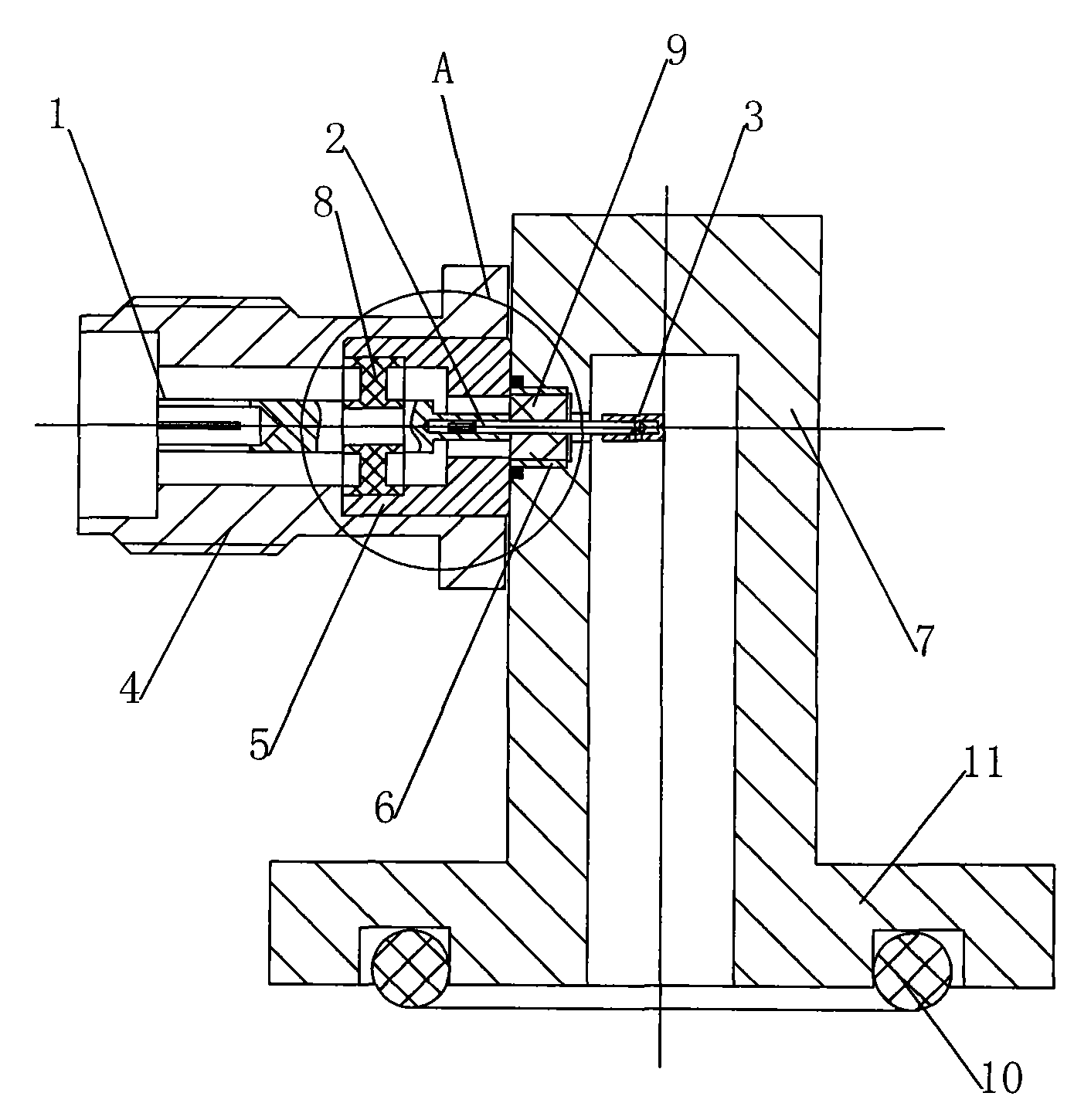

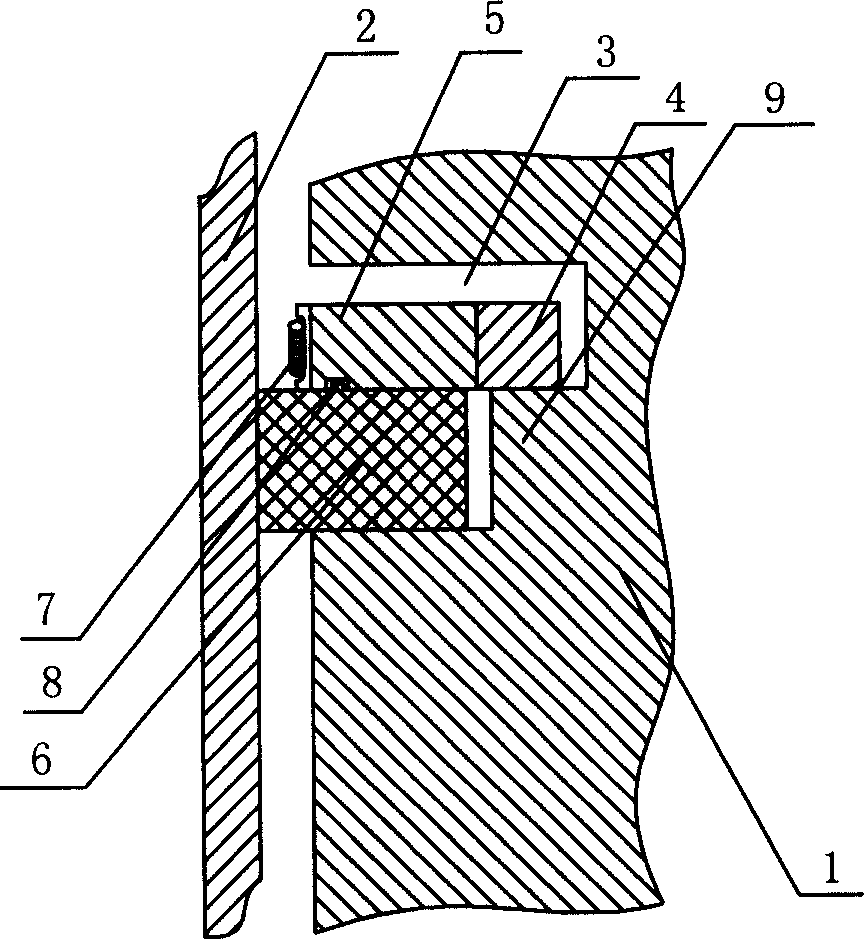

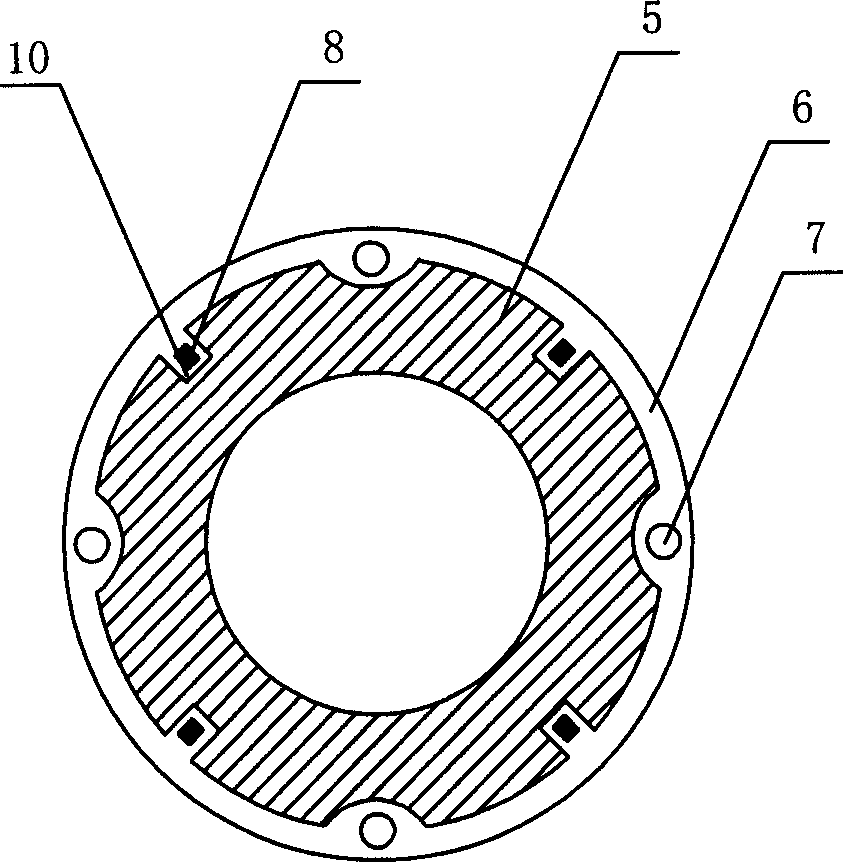

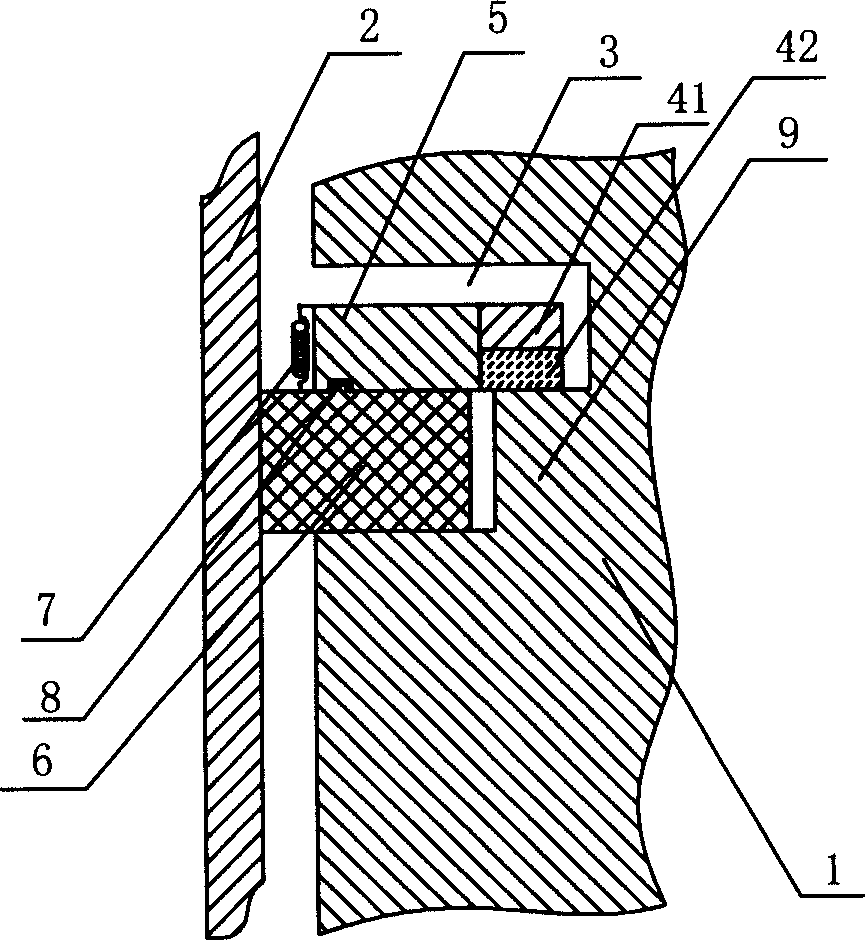

Novel sealing mechanism for shaft end of mixing machine

InactiveCN103122999AIncrease the airtight structureImprove sealingEngine sealsEngineeringMechanical engineering

The invention relates to a mixing machine, in particular to a novel sealing mechanism for a shaft end of the mixing machine. The novel sealing mechanism for the shaft end of the mixing machine comprises a sealing seat (4) and a sealing cover (1), wherein the sealing seat (4) and the sealing cover (1) are installed on a main shaft (5) in a sleeved mode. The novel sealing mechanism further comprises an abrasion-resistant sleeve (6), a first oil seal (7), a space ring (8) and a second oil seal (10). The sealing cover (1) is connected on the end face of one side of the sealing seat (4). A through hole (4-1) is formed in the sealing seat (4), an air inlet connector (3) is arranged at the position of the through hole (4-1), the sealing cover (1), the first oil seal (7) and the second oil seal (10) are installed on the outer diameter of the abrasion-resistant sleeve (6) in a sleeved mode, the outer diameters of the first oil seal (7) and the second oil seal (10) are installed in a hollow cavity on the front portion of the sealing seat (4) in a clamping mode, and the space ring (8) is installed between the first oil seal (7) and the second oil seal (10). The novel sealing mechanism is provided with multiple and various seals, the phenomenon of material leakage or powder injection does not occur, a sealing effect is good, and sealing is safe and reliable.

Owner:LIYANG HONGYUE MASCH MFG CO LTD

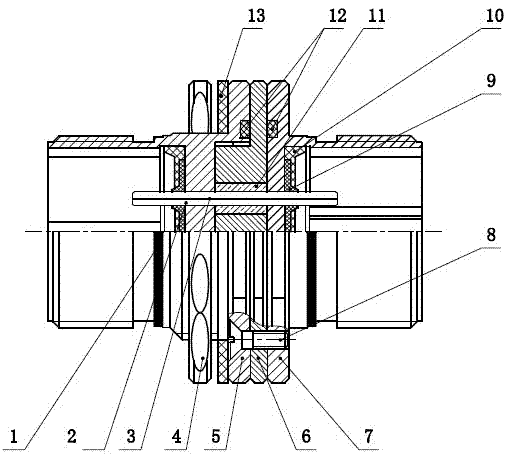

Coaxial millimeter wave adaptor with air-tight waveguide

The invention relates to a coaxial millimeter wave adaptor with air-tight waveguide, which solves the technical problem that the existing coaxial millimeter wave adaptor with waveguide can not provide the air-tight property. The adaptor comprises a first inner conductor, a second inner conductor, a third inner conductor, a first outer conductor, a second outer conductor, a third outer conductor, a fourth outer conductor, a first insulator and a second insulator, wherein the first inner conductor is arranged in the first insulator; the first insulator is arranged in the second outer conductor; the second outer conductor is embedded into the first outer conductor; the second inner conductor is arranged in the second insulator; the second insulator is arranged in the third outer conductor; the two ends of the second inner conductor are respectively and coaxially connected with the first inner conductor and the third inner conductor; the third inner conductor is arranged in the cavity of the fourth outer conductor; the second insulator is prepared by sintering a glass medium; and the third outer conductor is welded in the fourth outer conductor. Thus, the air-tight property is greatly enhanced, and the requirement that the adaptor can not cause the leakage of gas under a certain pressure difference can be satisfied.

Owner:西安金波科技有限责任公司

Sintered gas-sealed optical fiber socket

ActiveCN102736188AAchieve sealingThe installation position is accurateCoupling light guidesEngineeringOptical fiber cable

The invention discloses a glass sintered gas-sealed optical fiber socket. Optical fiber contact pins of the glass sintered gas-sealed optical fiber socket are mounted in an intermediate shell, a left shell and a right shell; contact pin holes are respectively arranged in the intermediate shell, the left shell and the right shell; the contact pin holes arranged in the intermediate shell, the left shell and the right shell are matched with the optical fiber contact pins in a clearance fit way; five-key grooves are arranged on circumferences at the inner sides of the left shell and the right shell; the five-key grooves position and guide a plug; an external thread is arranged on the left shell; and a mounting nut and a sealing gasket are arranged on the external thread. The glass sintered gas-sealed optical fiber socket has the advantages that the structure is simple and the gas sealing effect is good; a detachable shell design structure breaks through a difficult problem of grinding a sintered contact pin; a glass sintered structure has better compression resistance, ageing resistance and corrosion resistance compared with an elastic sealing component structure; the sintered structure is positioned and realized through a die; a more accurate contact pin mounting position can be obtained; two occasions that a connector prevents gas leakage and liquid leakage can be realized; and by means of the structures of the mounting nut and the sealing gasket, the connector simultaneously realizes the sealing at an open pore position after fixation and mounting.

Owner:南京全信光电系统有限公司

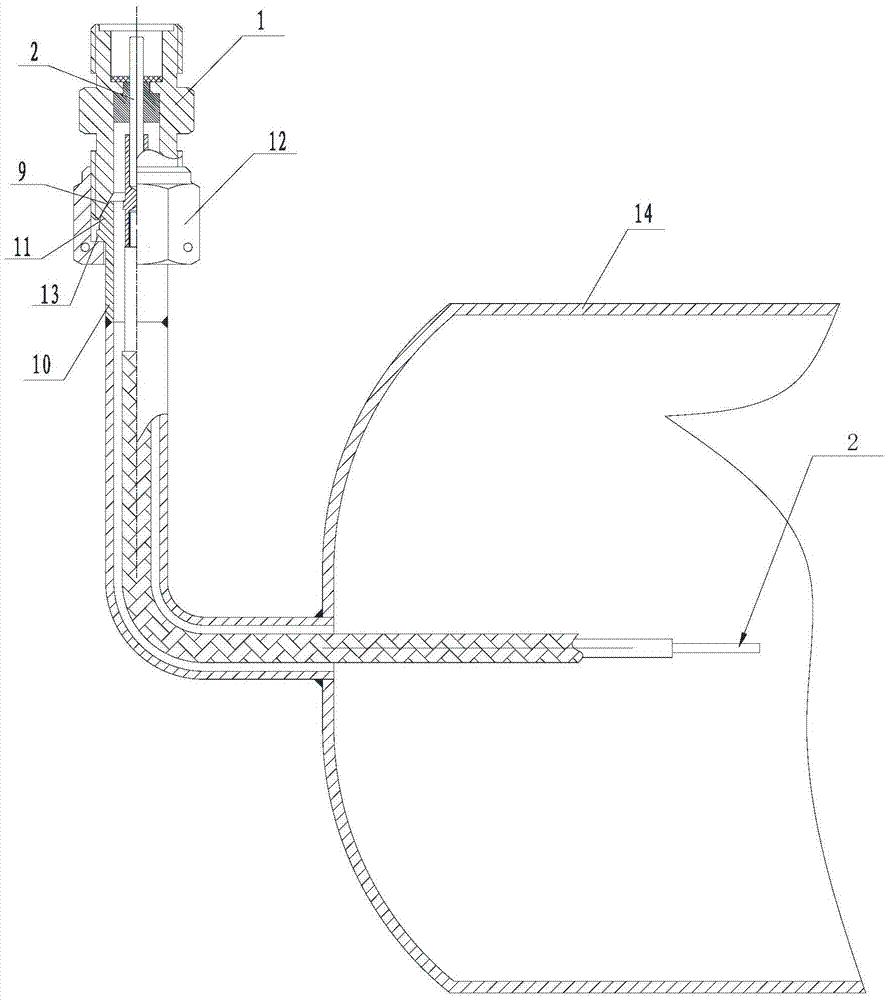

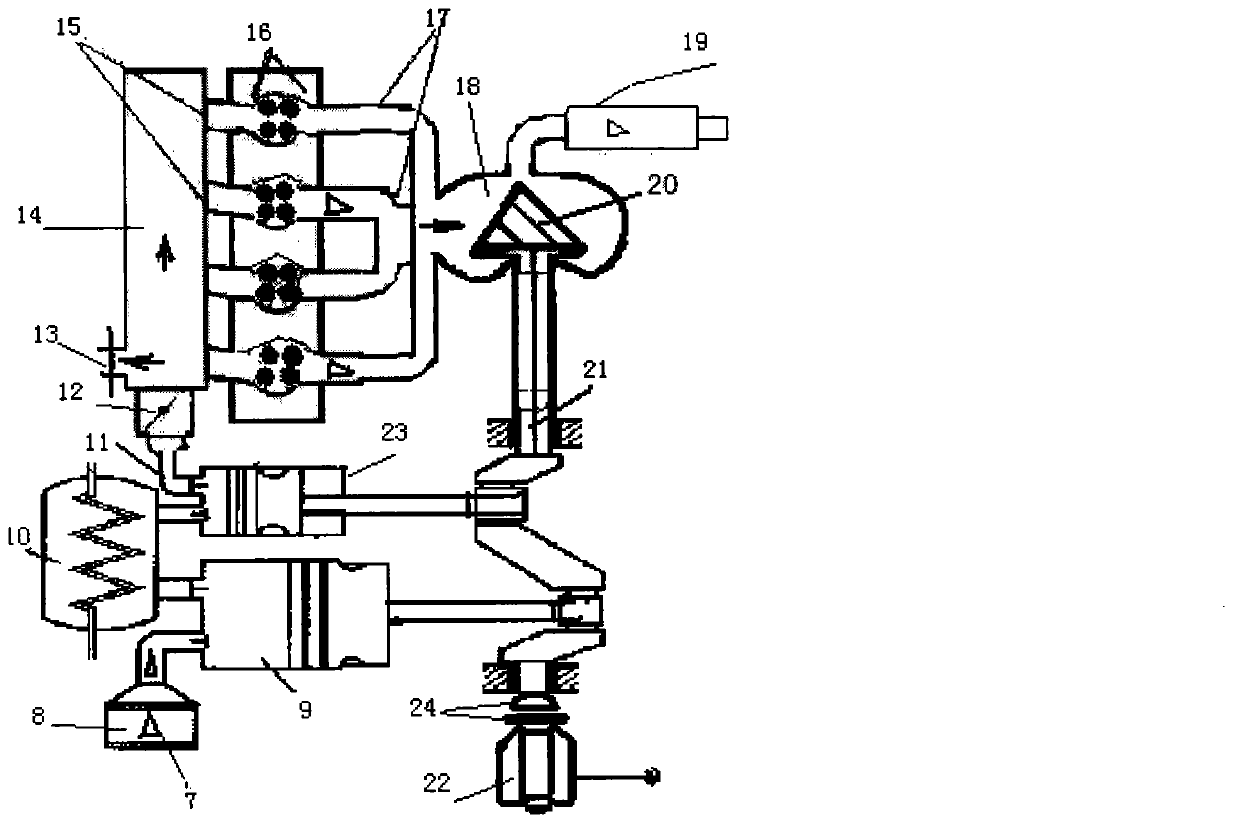

Pipe column structure for CO2 flooding gas injection process

ActiveCN107605443AImprove airtight performanceImprove work efficiencyFluid removalSealing/packingWell killCo2 flooding

The invention discloses a pipe column structure for the CO2 flooding gas injection process. The pipe column structure comprises a guiding shoe, a check valve, a setting ball seat, a Y445 packer, an inserting pipe, a reverse circulation valve and an oil pipe. The guiding shoe is connected with the check valve; the upper end of the check valve is connected with the setting ball seat; the upper end of the setting ball seat is connected with the Y445 packer; the Y445 packer is connected with the inserting pipe; and the upper end of the inserting pipe is connected with the reverse circulation valveand the oil pipe in sequence. During working, the parts are connected in sequence, a pipe column is put downwards, an annulus is filled with a conventional oil-based annulus protection fluid in a reverse circulation mode, a quick-dissolving soluble ball is put, pressure injection for setting is conducted, and thus gas can be injected normally; when the pipe column is taken out, through the checkvalve, the oil pipe is directly emptied so that pressure can be released, the pipe column is lifted up, the inserting pipe is pulled out, and thus a pipe string can be taken out; if pressure relief ofthe oil pipe fails, a well killing fluid is injected in a reverse circulation mode for well killing, then the pipe column is lifted up, and thus the pipe string can be taken out; after pipe string checking work, the parts are connected in sequence, the pipe column is put downwards, the inserting pipe is inserted into the packer, and thus sealing well-completion can be conducted.

Owner:PETROCHINA CO LTD

Bridge crack repairing method

ActiveCN110295549AQuick fixImprove airtight performanceBridge erection/assemblyBridge strengtheningGroutRepair method

The invention relates to a bridge crack repairing method. The bridge crack repairing method comprises the following construction steps that 1, crack measuring and recording are conducted; 2, target crack surface cleaning treatment is conducted; 3, grout is poured into cracks through grouting equipment; 4, maintaining is conducted; and 5, structure surface treatment is conducted. The bridge crack repairing method has the effect that fine cracks can be repaired more quickly.

Owner:杭州交通工程监理咨询有限公司

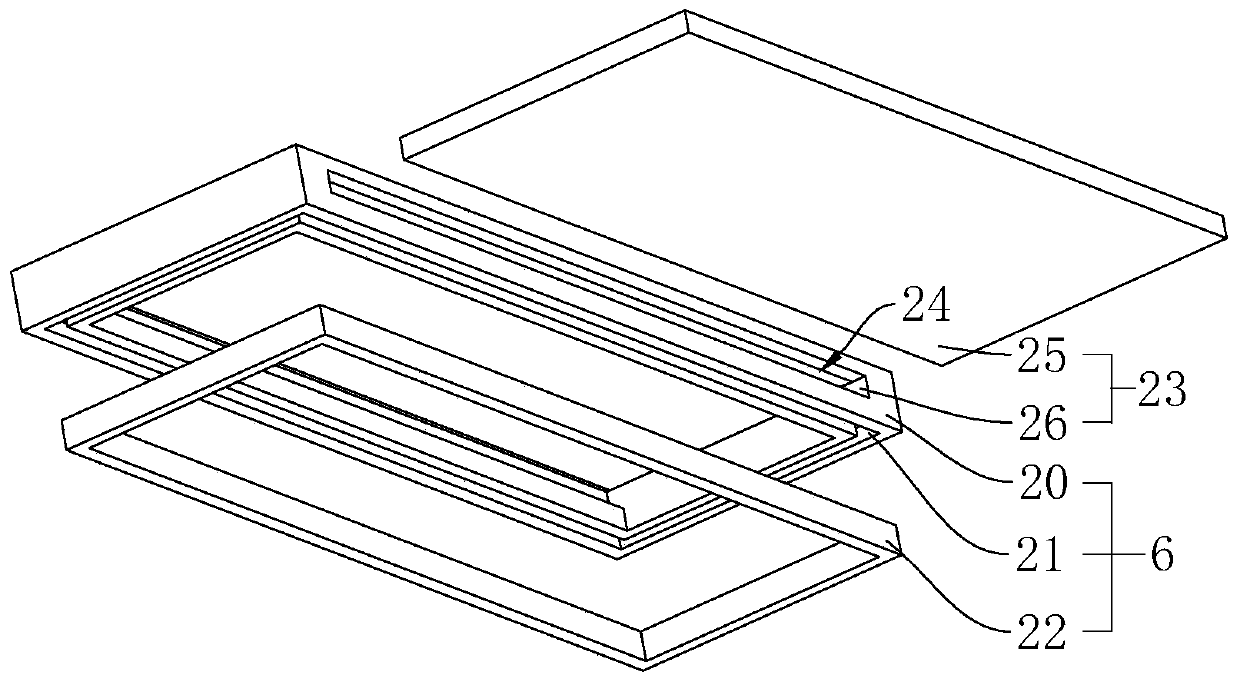

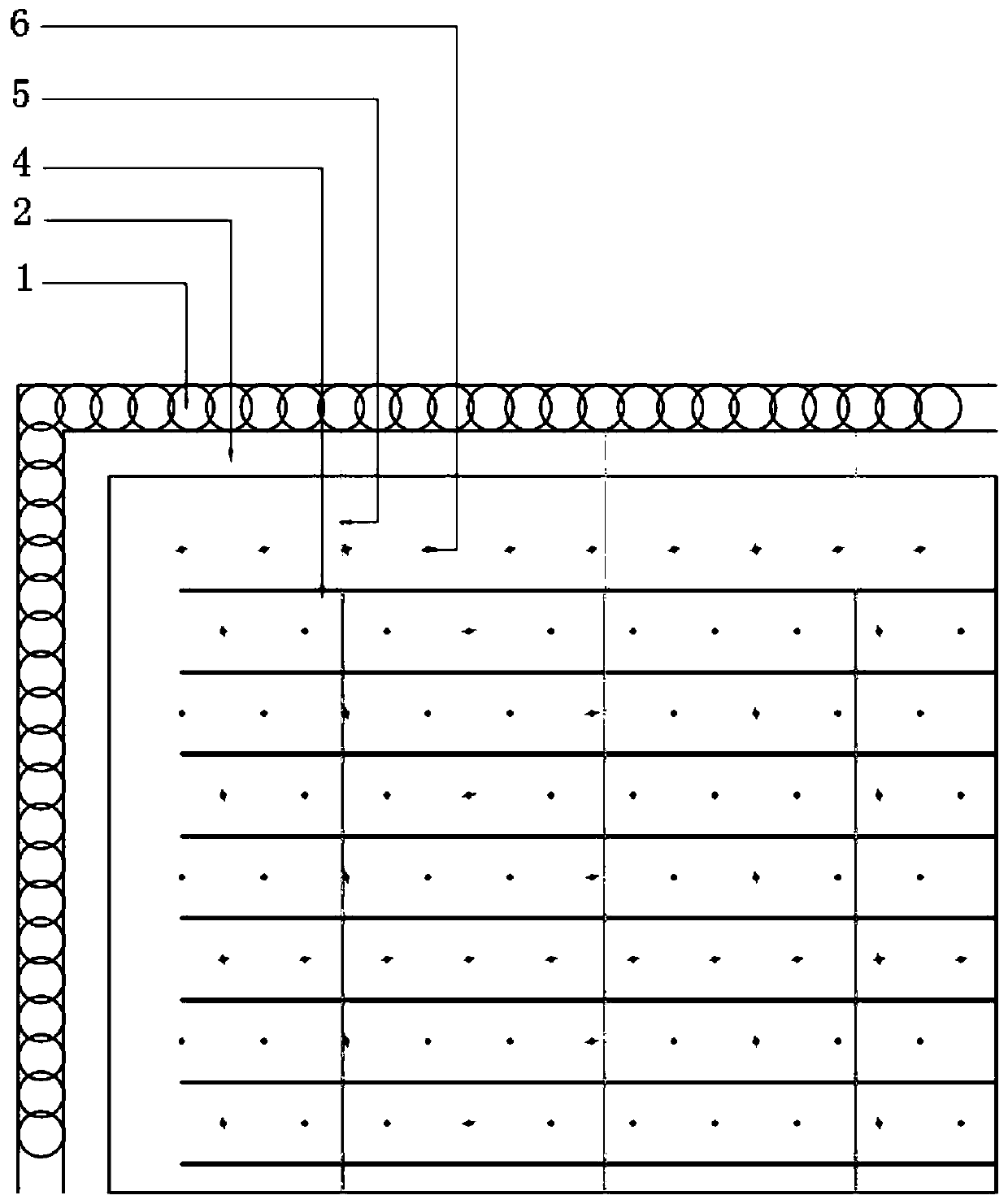

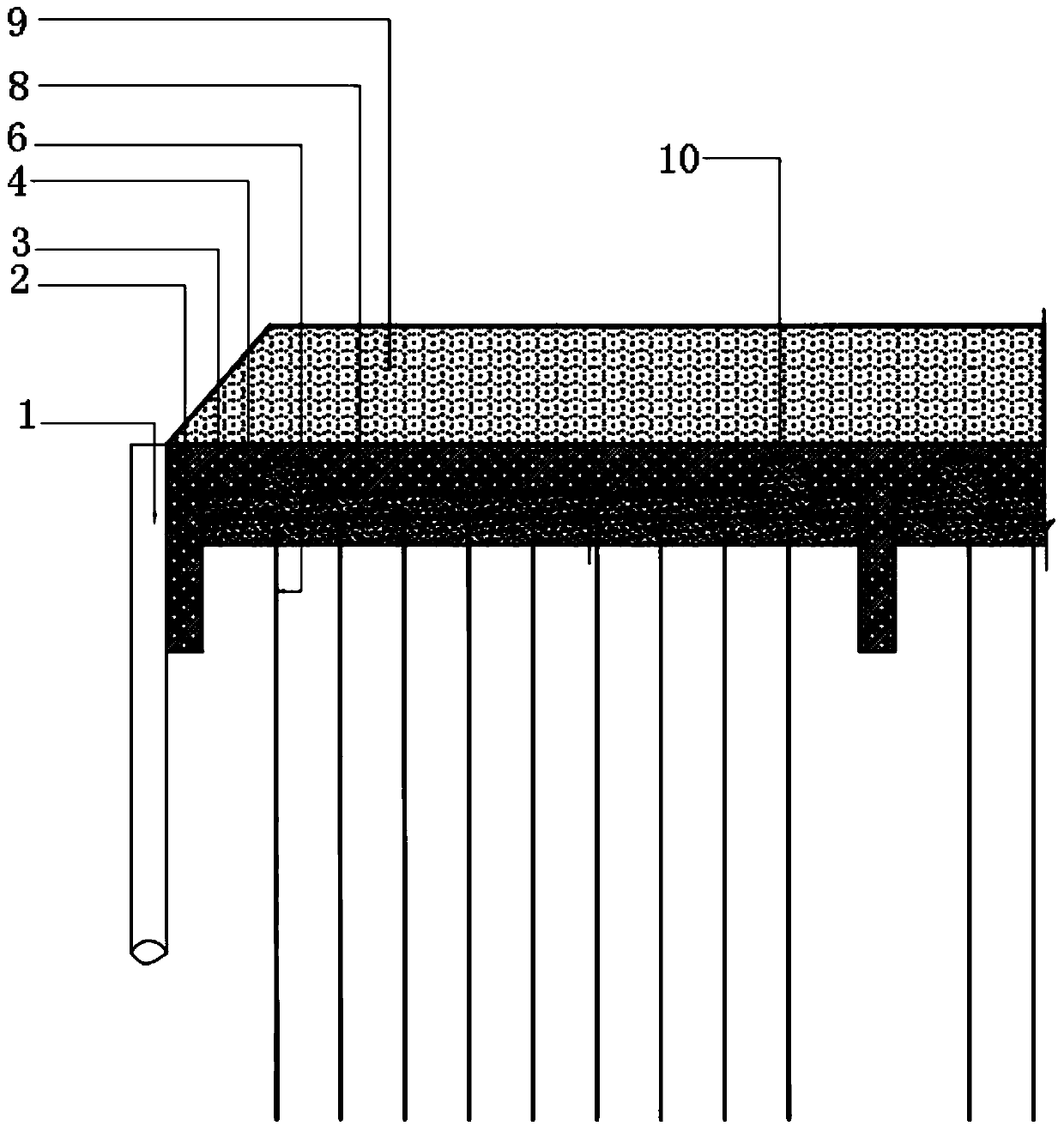

Technology for high-vacuum treatment of deep soft soil foundation through composite film

InactiveCN111441336AOvercoming the problem of sharp vacuum decayImprove airtight performanceSoil preservationSoil scienceComposite film

The invention discloses a technology for high-vacuum treatment of a deep soft soil foundation through a composite film. The technology comprises the following steps that (1) a vacuum system is arranged; (2) vacuum and water overload pre-pressing are performed for the first time through water-film compounding; (3) vacuum, overload and impact compaction are performed for the second time through soil-film compounding; and (4) post-construction intermittent vacuum drainage is carried out. According to the technology for high-vacuum treatment of the deep soft soil foundation through the composite film, the water-film compounding and soil-film compounding two-stage composite film sealing technology is adopted, the sealing and air closing effects are improved, and high-vacuum-degree prepressing is achieved. In the first stage, the overload preloading vacuum degree load is 90 kpa or above; and in the second stage, the overload preloading vacuum degree is 80 kpa, and the problem that the post-pile vacuum degree is sharply attenuated in the later stage in the traditional vacuum degree technology is solved.

Owner:曾国海

Piston with pressure-reducing piston ring

InactiveCN1818365AImprove sealingReduce contact areaPiston ringsMachines/enginesPiston ringHigh pressure

The invention relates to an engine piston, which includes a piston body, a piston ring groove disposed on the piston body and a piston ring disposed in the piston ring groove. The piston ring groove consists of the upper and lower notches. An inner ring and an outer ring are disposed in the upper notch. A externally-braced ring is disposed in the lower notch.

Owner:廖伯成

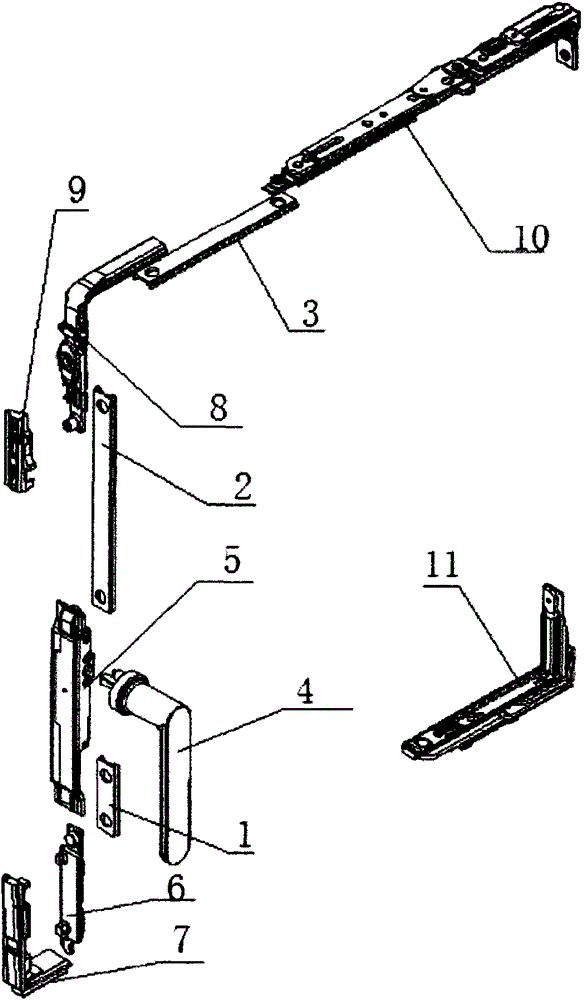

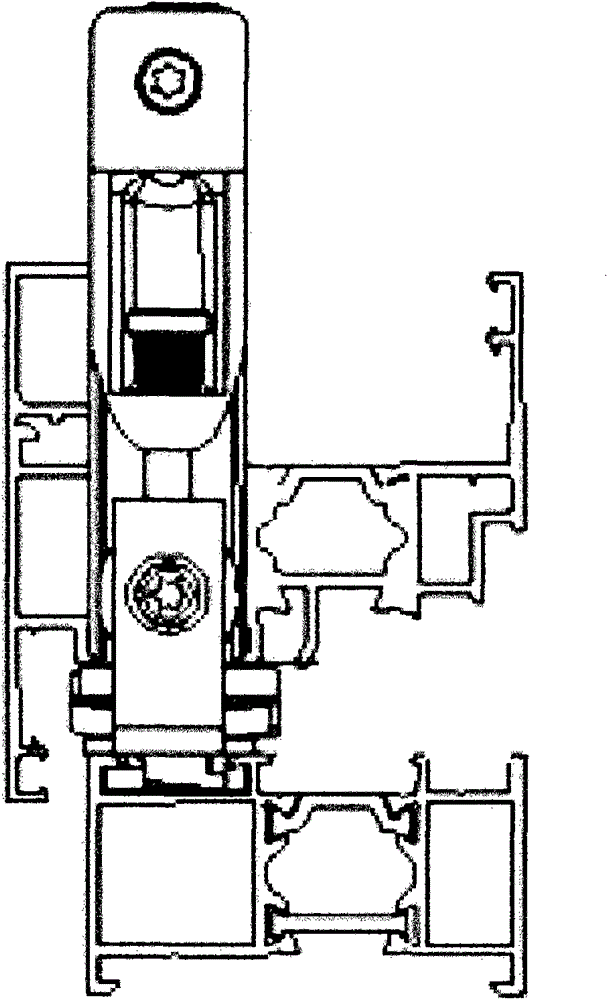

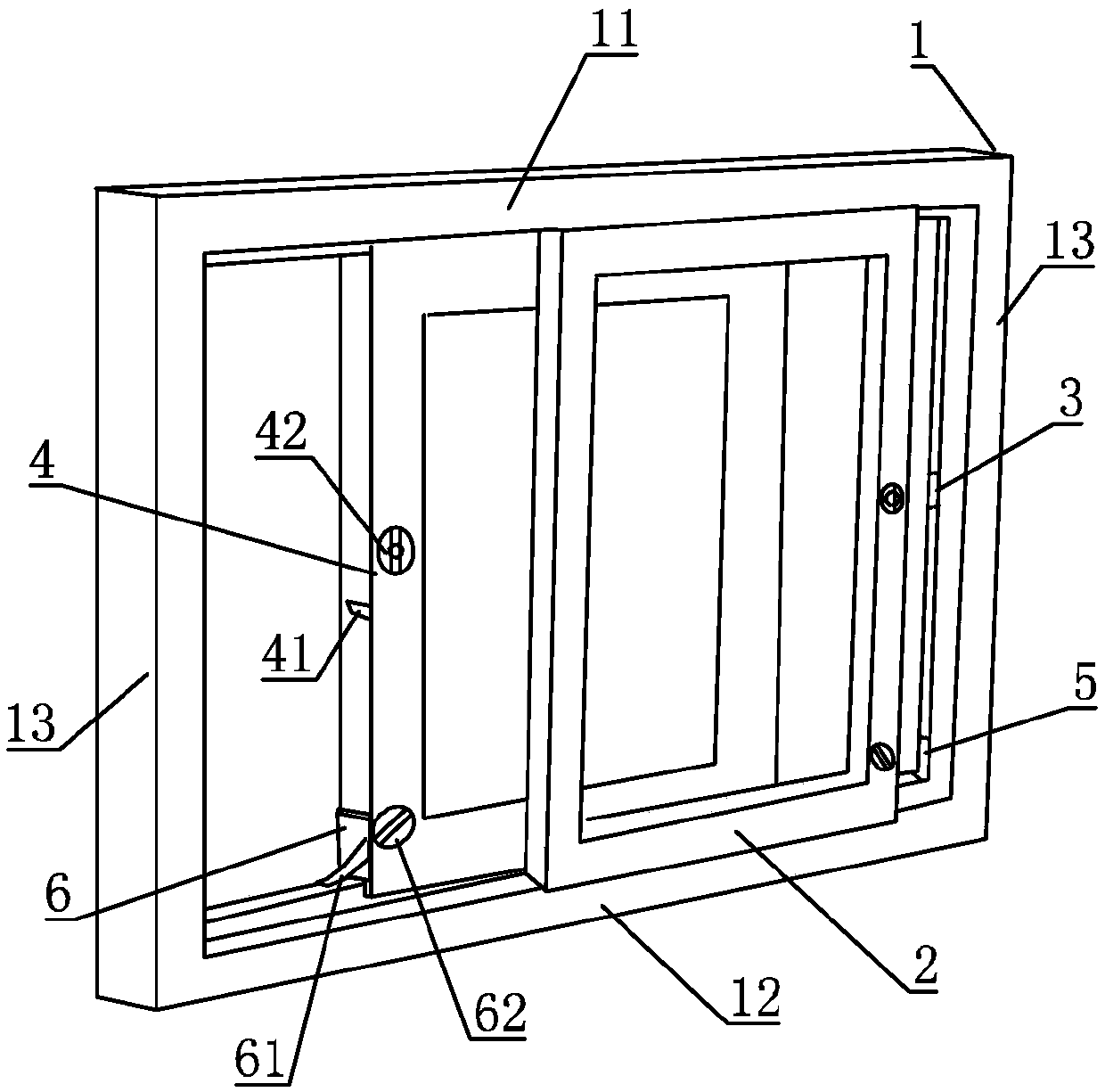

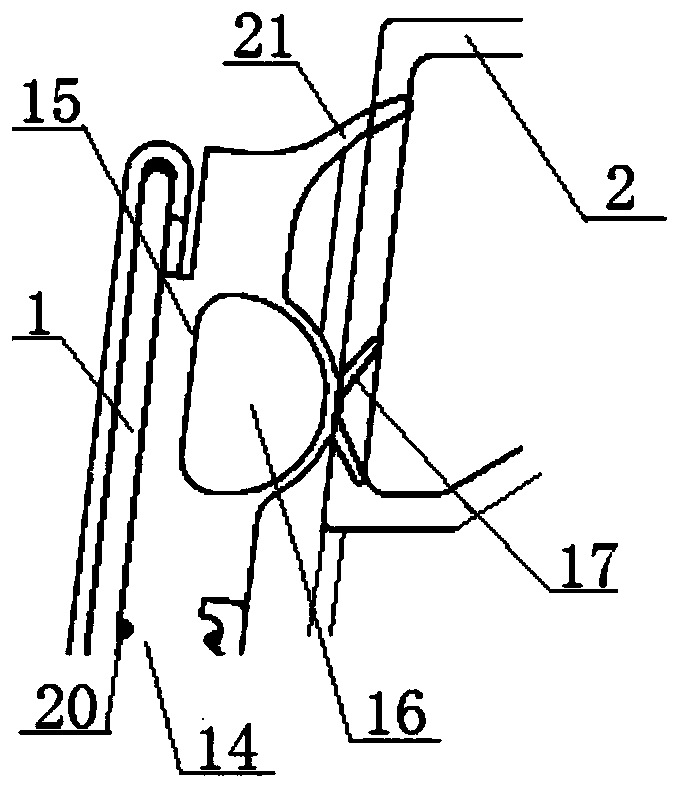

European-standard C-slot concealed hinged top-hung casement hardware system

InactiveCN104420762AImprove anti-theft performanceImprove airtight performanceMan-operated mechanismAnti theftElectrical and Electronics engineering

Disclosed is an European-standard C-slot concealed hinged top-hung casement hardware system. The e European-standard C-slot concealed hinged top-hung casement hardware system comprises an European-standard slot transmission bar, a linkage rod, a connecting rod, a handle, a lock body, a connecting component, a lower corner connector, an upper corner connector, a lock seat, a multi-point lock and a crank rocker. One end of the European-standard slot transmission bar is connected with a lock body, and the other end of the European-standard slot transmission bar is connected with the connecting component; the connecting component is provided with a fastening point and connected with the lower corner connector through the fastening point; one end of the linkage rod is connected with the lock body, and the other end of the linkage rod is connected with the upper corner connector; the upper corner connector is provided with a fastening point and connected with the lock seat through the fastening point; the lock seat is connected with the transmission bar and the lock catch of the multi-point lock through the connecting rod; the inside of the multi-point lock is provided with a transmission block and a positioning block and connected with the crank rocker through the transmission block and the positioning block; the handle is connected with the lock body. The European-standard C-slot concealed hinged top-hung casement hardware system improves the anti-theft performance, enhances the air tightness, is concise and simple in appearance and capable of meeting the requirements on exterior wall decoration, simplifies mounting and debugging tools and improves the mounting efficiency.

Owner:俞斌

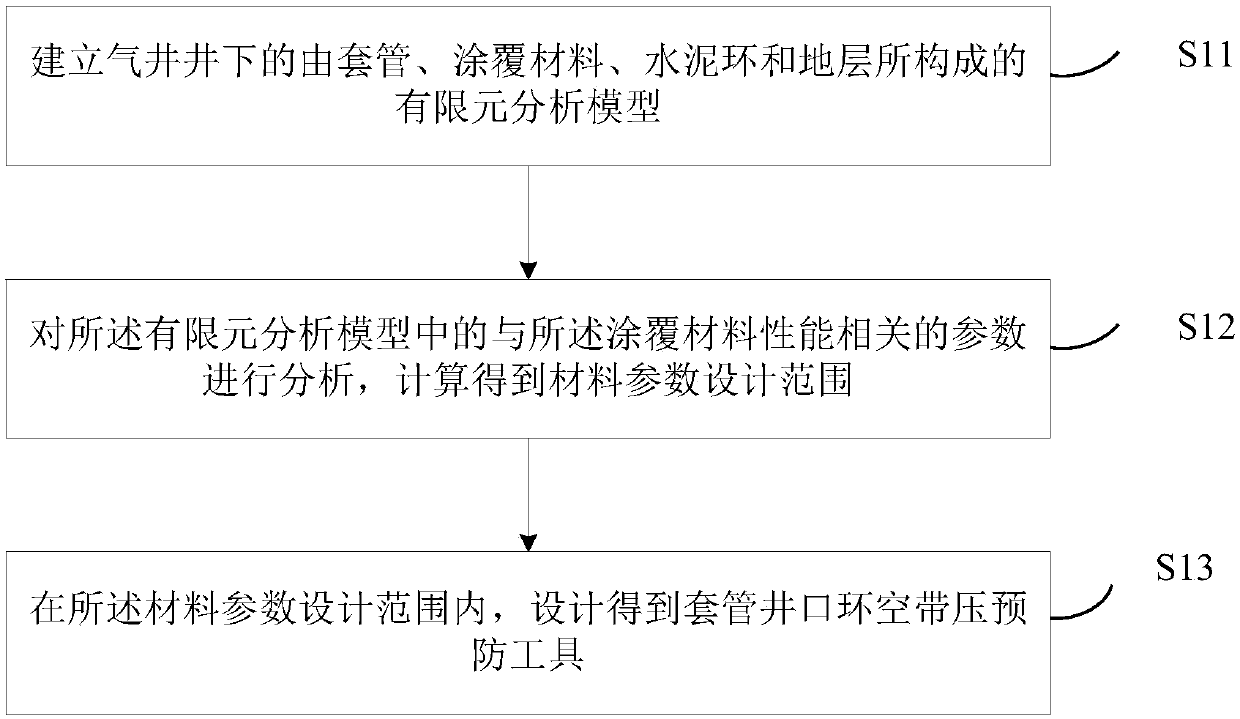

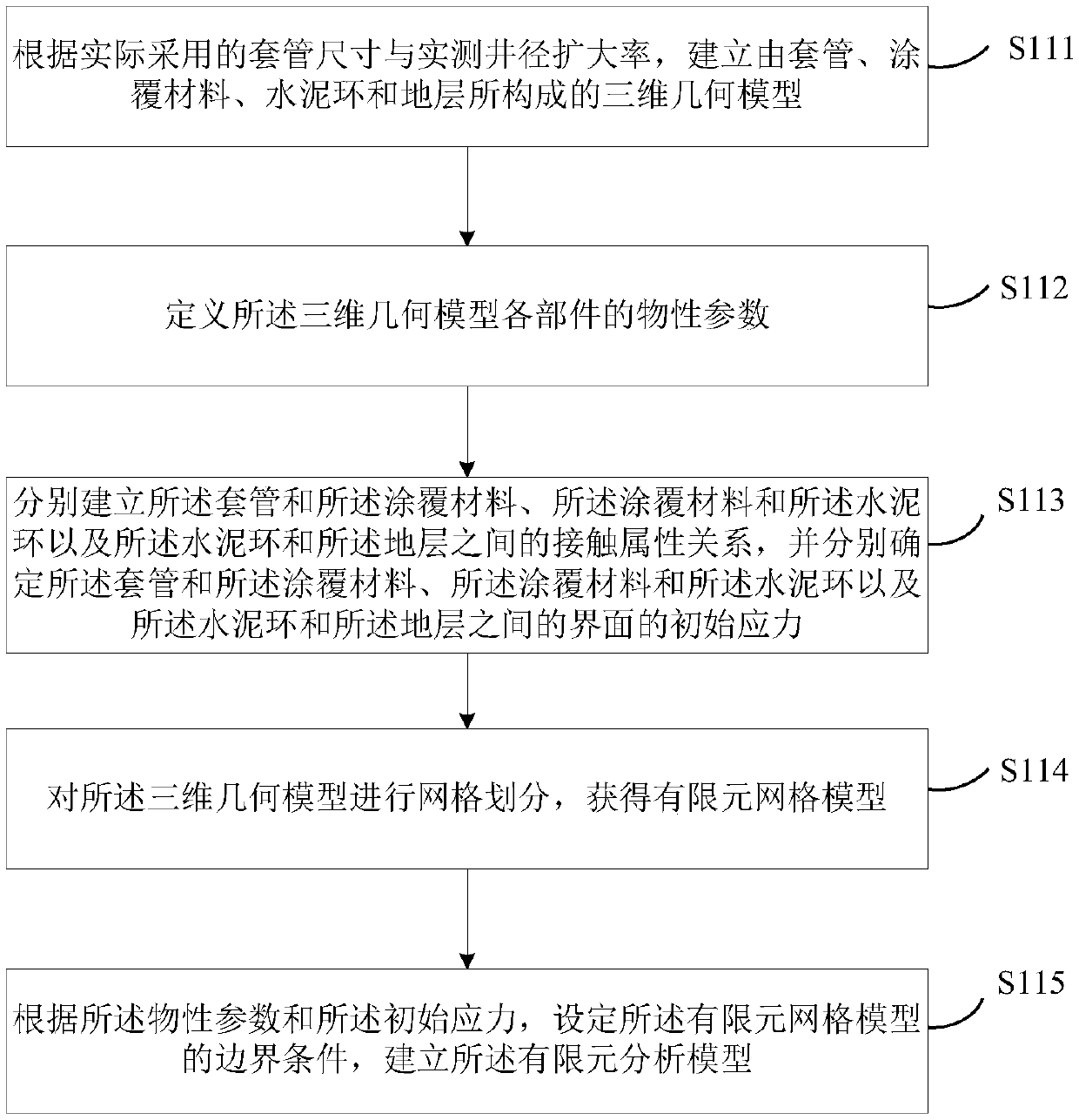

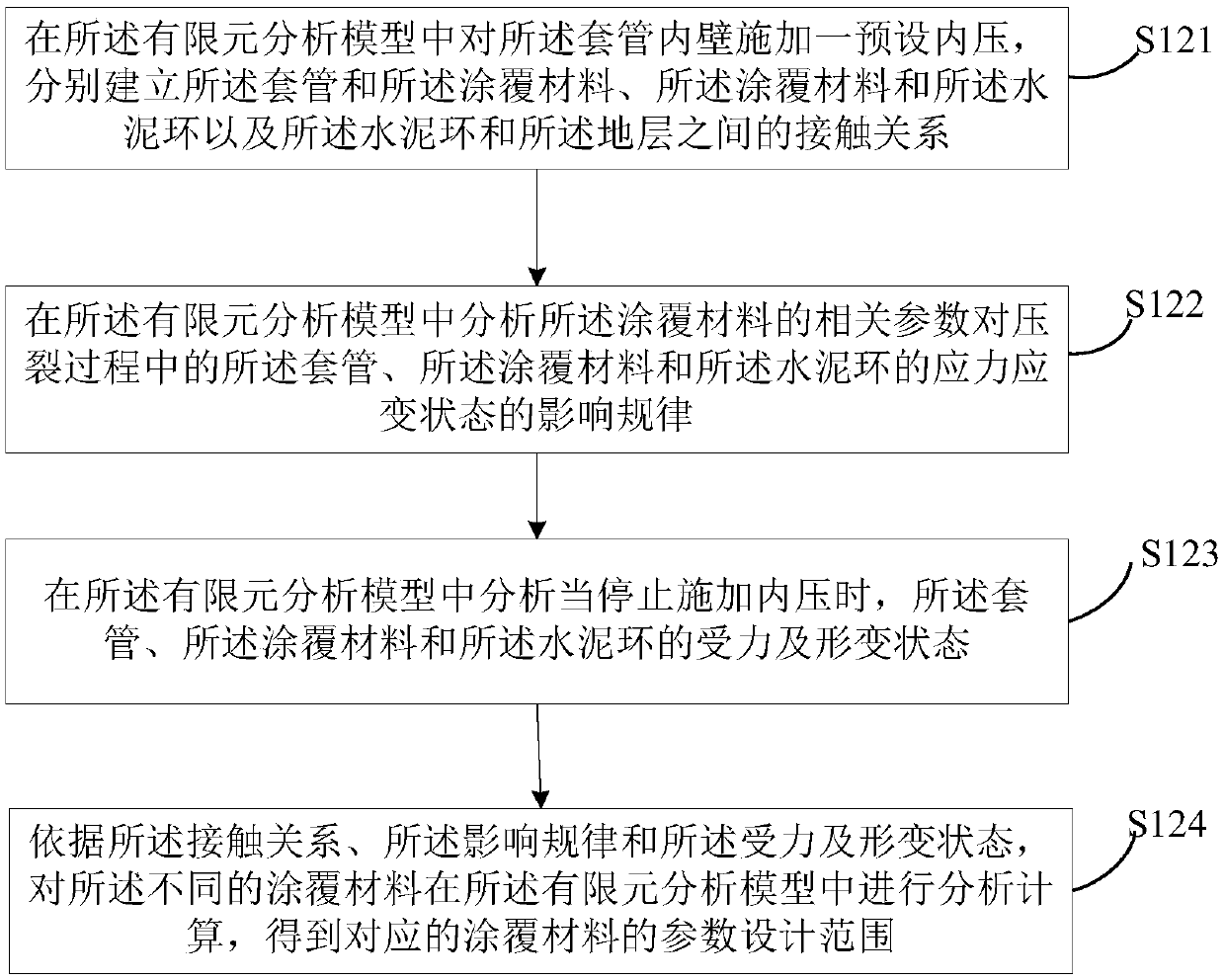

A design method and device for a casing wellhead annulus pressure prevention tool

ActiveCN109657253AReduce deformationImprove airtight performanceDesign optimisation/simulationSpecial data processing applicationsElement analysisEngineering

The invention discloses a design method and device for a casing wellhead annulus pressure prevention tool. The method comprises the steps: establishing a finite element analysis model composed of a casing, a coating material, a cement sheath and a stratum under a gas well; Analyzing parameters related to the performance of the coating material in the finite element analysis model, and performing calculating to obtain a material parameter design range which meets the parameter range of gas well pressure test and fracturing for keeping the sealing performance of the cement sheath; And in the material parameter design range, designing and obtaining the casing wellhead annulus pressure prevention tool. The purpose of restraining the annulus belt pressure of the wellhead of the gas well is achieved by keeping the sealing integrity of the cement sheath and reducing the micro annulus.

Owner:中石化石油工程技术服务有限公司 +1

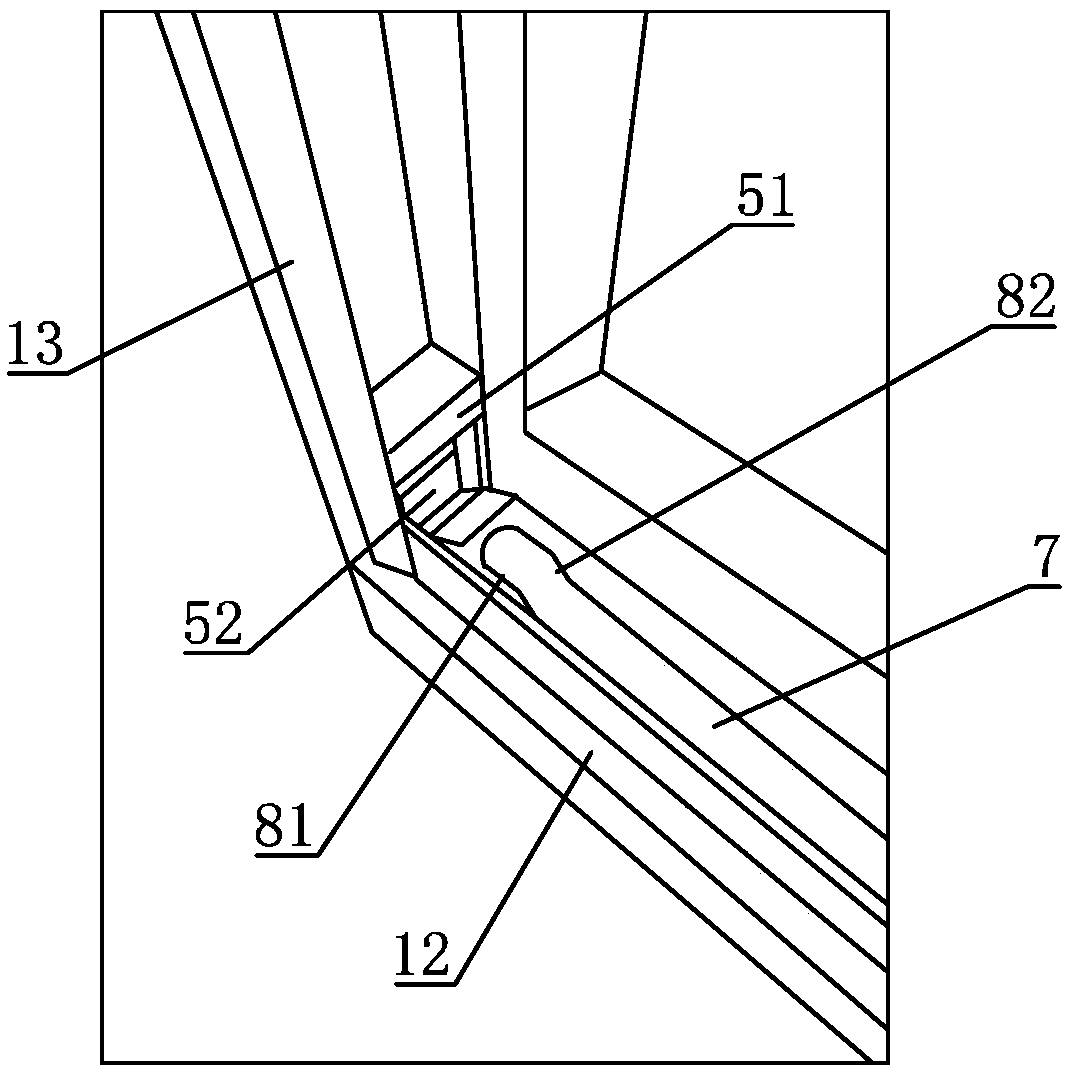

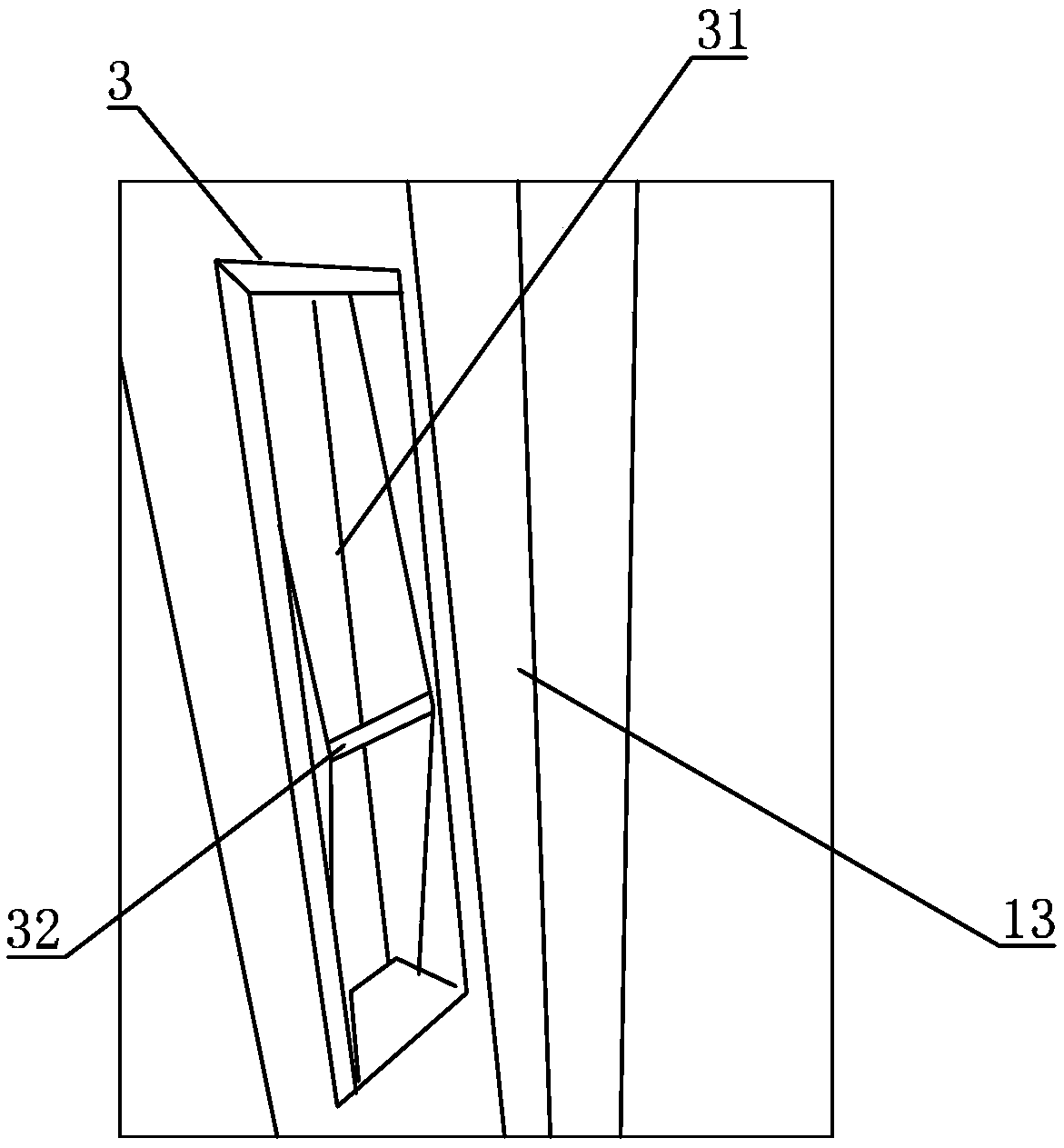

High-air-sealed sliding door and window

InactiveCN109577803AReduce gapImprove airtight performanceWing fastenersWing arrangementsElectrical and Electronics engineeringPulley

The invention discloses a high-air-sealed sliding door and window which comprises a door and window frame and door and window sashes. The door and window frame comprises an upper frame, a lower frameand two side frames, sliding grooves are formed in the upper frame and the lower frame, the door and window sashes horizontally slides through the sliding grooves, guide grooves for improving air sealing performance are formed in the tail ends, close to the corresponding side frames, of the sliding grooves, lock seats are arranged on the side frames, locking mechanisms matched with the lock seatsare arranged on the side surfaces of the door and window sashes, and pulleys matched with the sliding grooves and the guide grooves are arranged on the upper top surface and the lower bottom surface of the door and window sashes. The sliding door and window is high in air sealing performance and has good heat insulation effects.

Owner:海南派成铝业科技有限公司

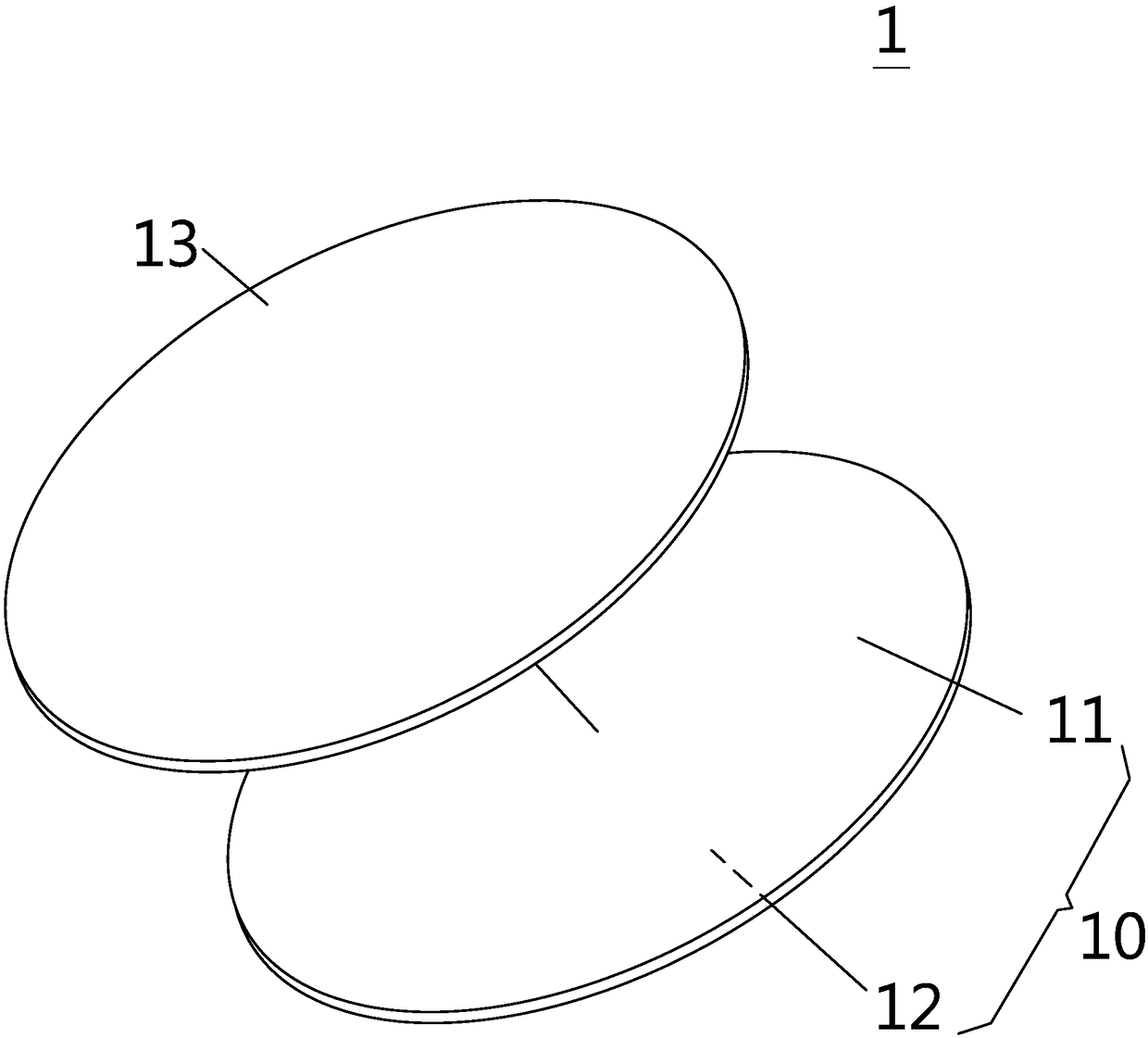

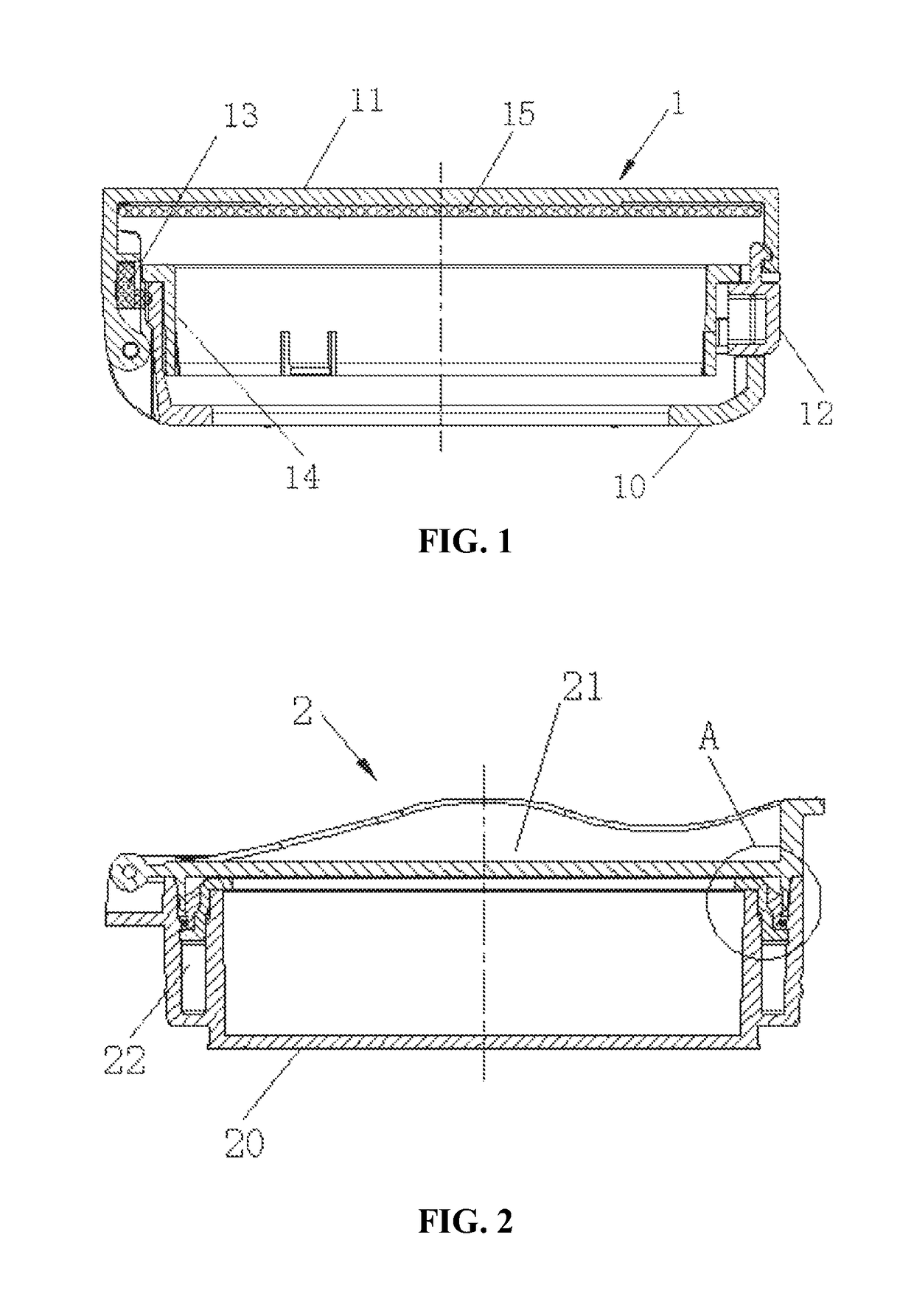

Vibrating membrane, method of manufacturing vibrating membrane, and stethoscope applied to vibrating membrane

InactiveCN109462801AReduce churnImprove airtight performancePolymeric diaphragmsStethoscopeVibrating membraneAir tightness

The invention relates to a vibrating membrane, a method of manufacturing the vibrating membrane, and a stethoscope applied to the vibrating membrane. The invention relates to a vibrating membrane having a flat vibrating portion, wherein the vibrating portion is provided with a first surface; the structure of the vibrating membrane further includes a soft structural layer disposed on the first surface. When the vibrating membrane is combined with a sound collecting head, the soft structural layer is in contact with the sound collecting head to enhance the airtightness of the vibrating membraneand the sound collecting head, so as to prevent the acoustic vibration energy from being lost. The invention also relates to a method of manufacturing the vibrating membrane, which can quickly producea large number of vibrating membranes by a simple process.

Owner:IMEDI PLUS

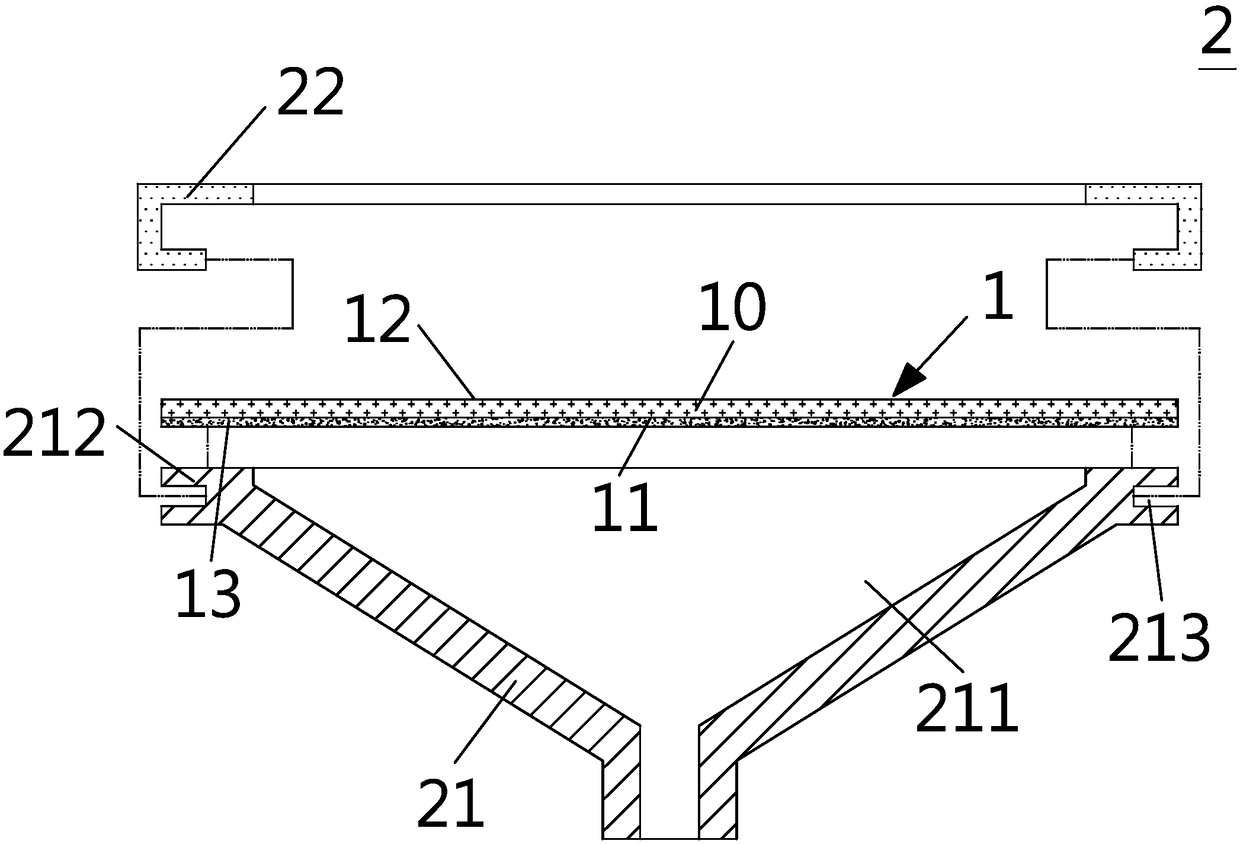

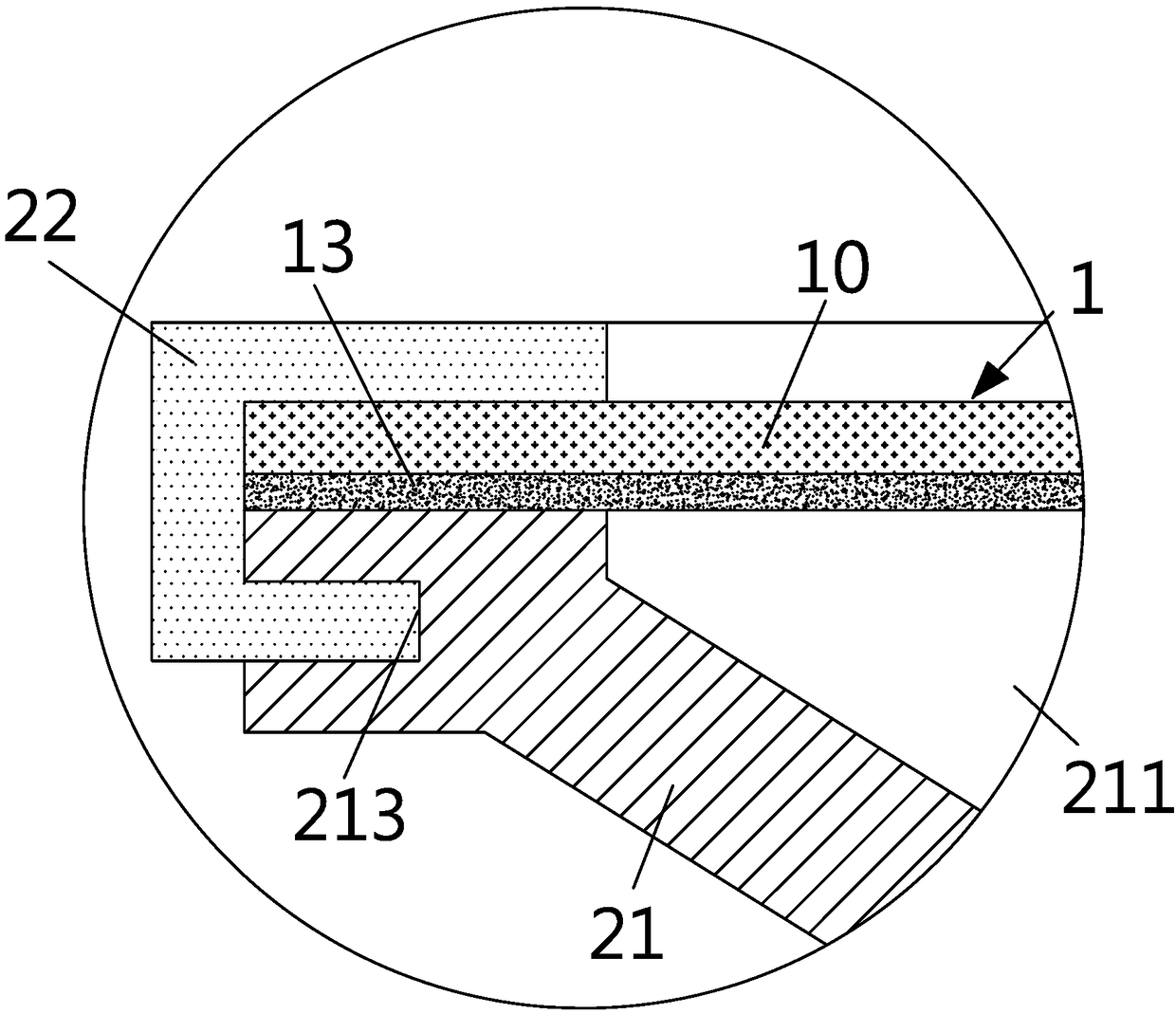

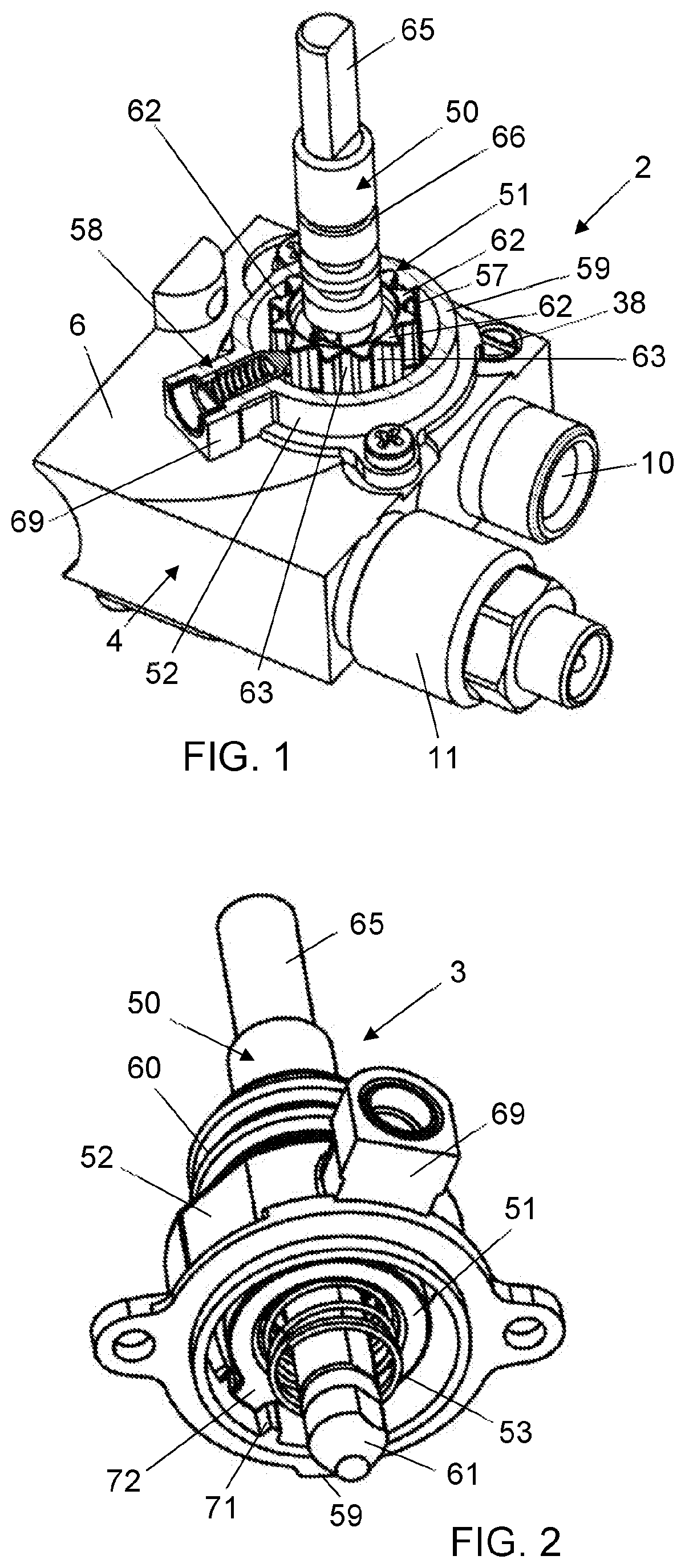

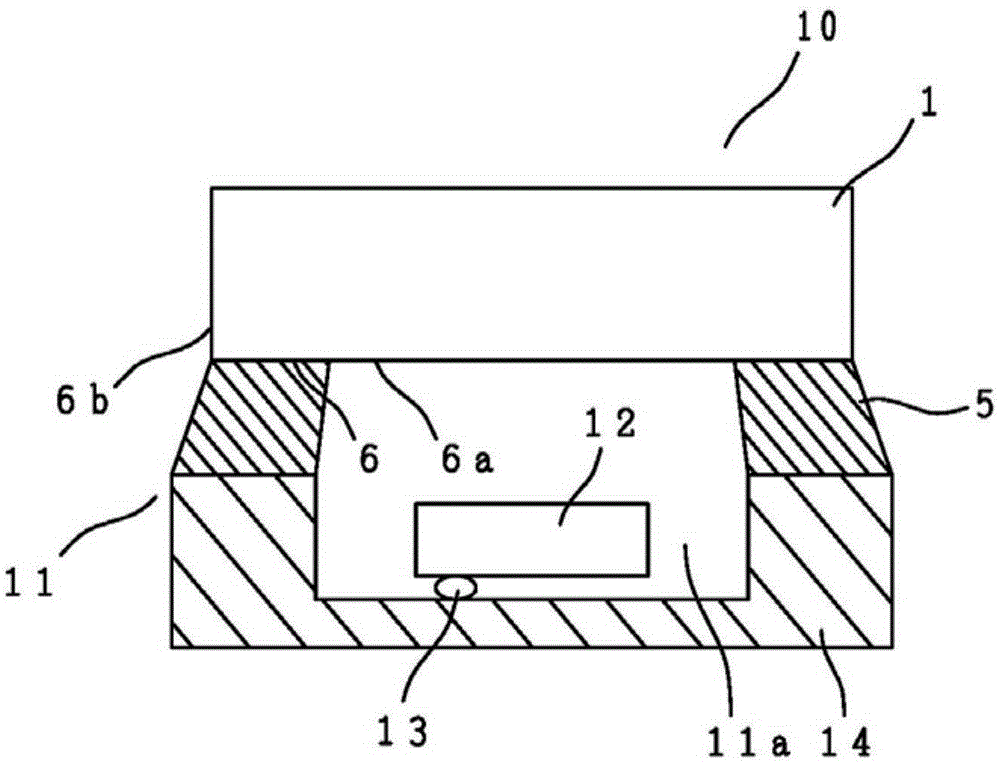

Cosmetic case

ActiveUS10034532B2Improve air tightnessImprove airtight performanceClosure with auxillary devicesSealingEngineeringMechanical engineering

A cosmetic case including an outer case assembly and an inner disk assembly. The outer case assembly includes a case body and a case cover. the case body includes a first accommodation chamber having an opening. The inner disk assembly includes a disk body, a disk cover, an outer slot, and a seal ring. The disk body includes a second accommodation chamber for accommodating cosmetics. The case cover is hinged to the case body and adapted to open and close the opening of the first accommodation chamber. The inner disk assembly is disposed detachably in the first accommodation chamber. The disk cover is hinged to the disc body and adapted to open and close the opening of the second accommodation chamber. The outer slot is positioned around the outer side wall of the second accommodation chamber and the seal ring is housed in the outer slot.

Owner:COPOLYMER & COSMETICS TECH KUNSHAN

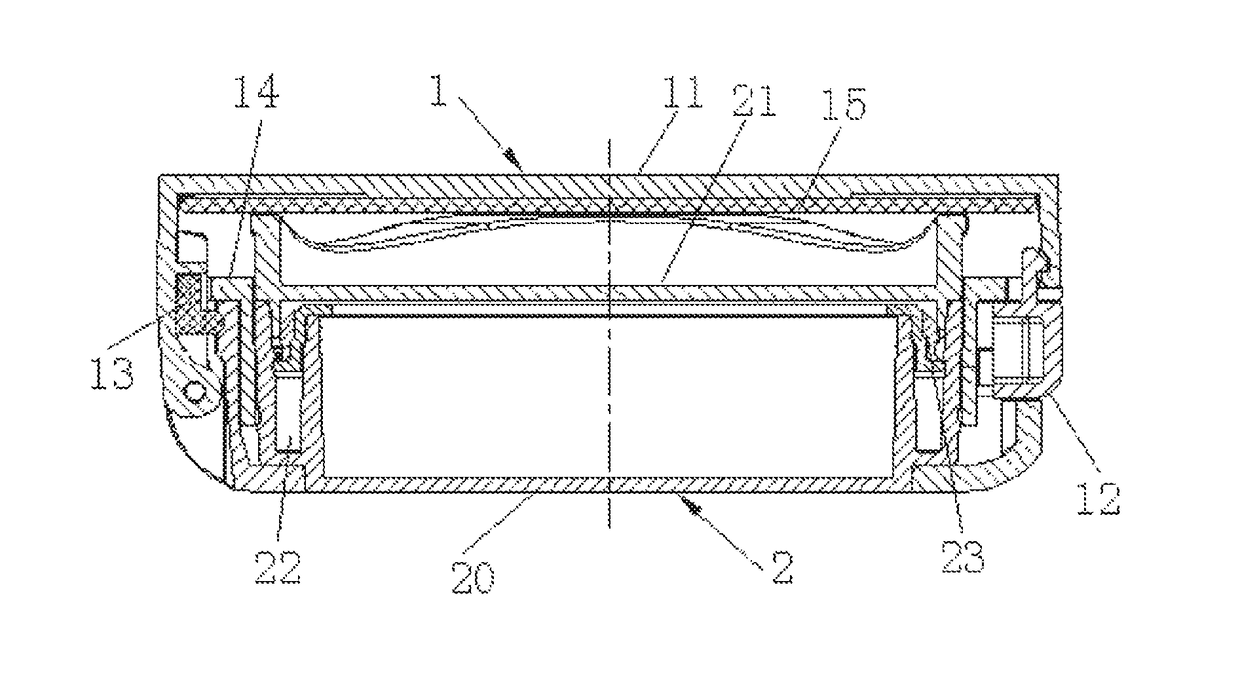

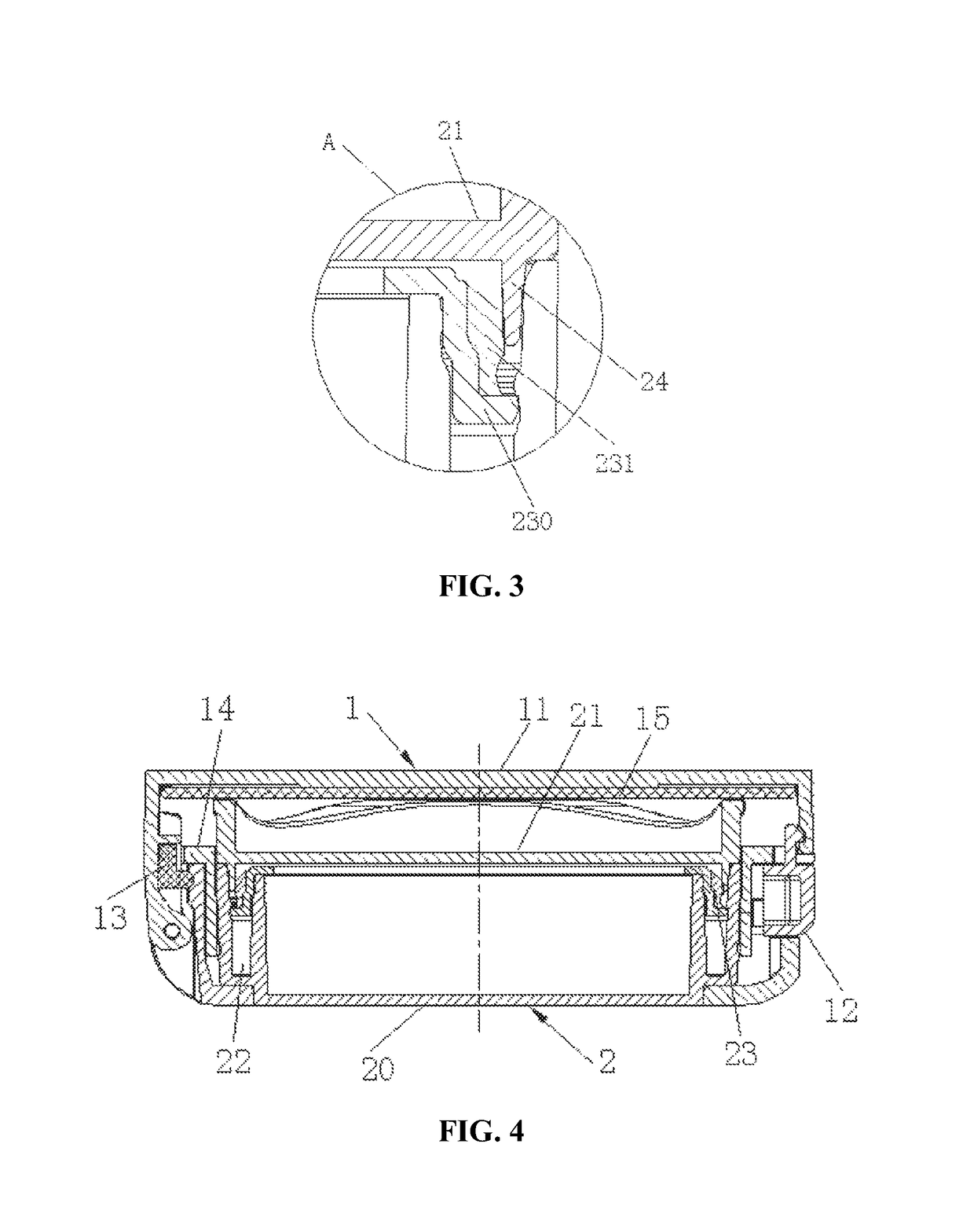

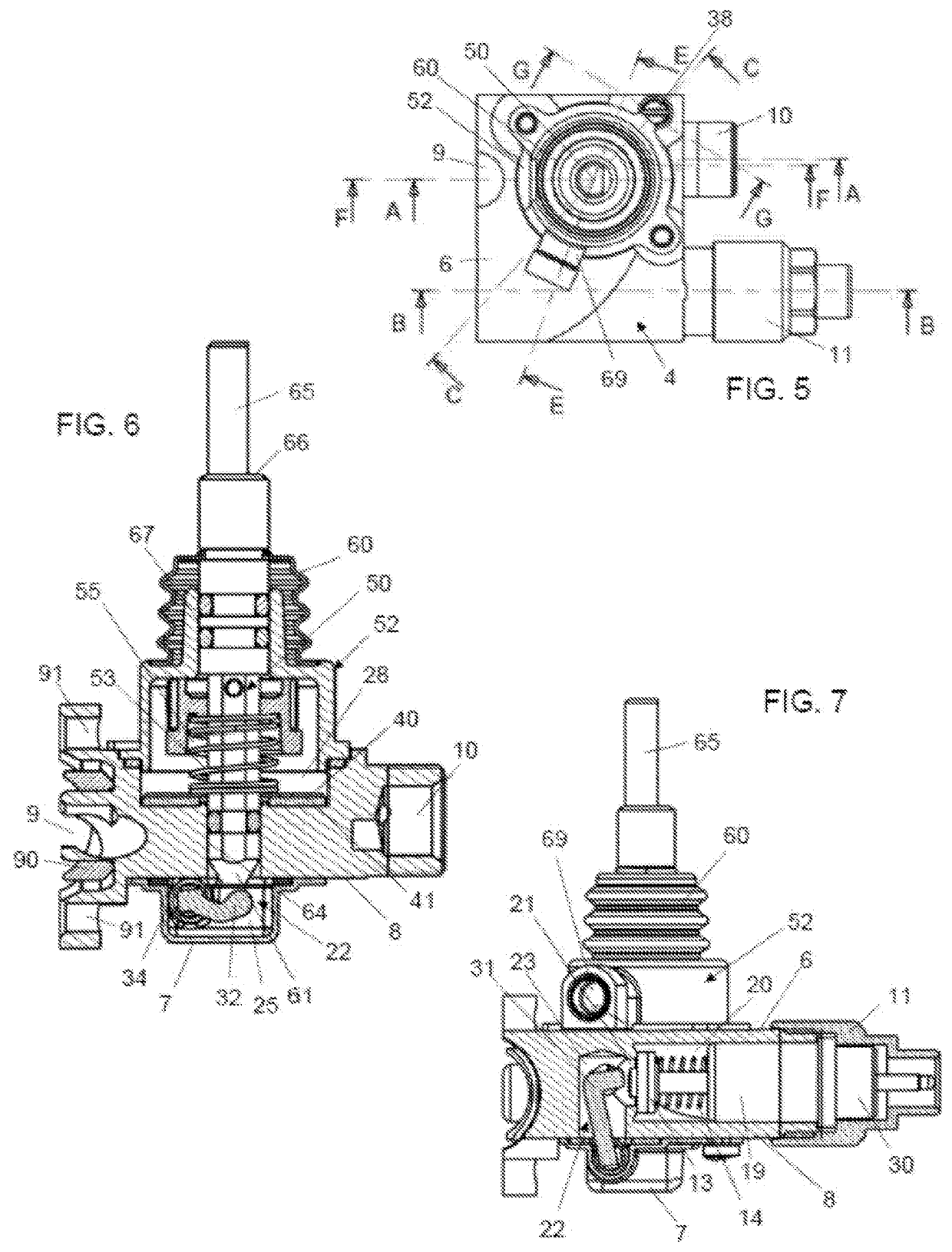

An improved gas valve unit

ActiveUS20200103108A1High and easy customizationIncrease the number of cyclesFuel supply regulationGaseous fuel feeder/distributionControl cellEngineering

A gas valve unit to be connected to a gas source includes a body having an inlet, a main chamber in the body communicating with the inlet and having a main outlet communicating with the outlet of the gas valve unit, a disc-shaped element in the main chamber with one or more openings putting the main chamber in communication with the main outlet hole and rotatable between a closing position, where the main outlet hole is entirely covered by the disc-shaped element, and at least two opening positions in which the one or more openings face, at least in part, the main outlet hole to enable gas passage from the main chamber to the main outlet hole via the through opening, and a control unit associated causing the snapping rotation of the disc-shaped element between the closing position and an opening position, and between the at least two opening positions.

Owner:E G O ELEKTRO GERAETEBAU GMBH

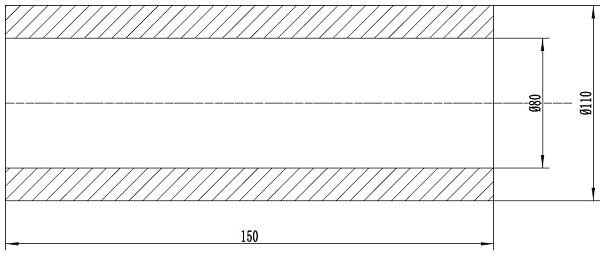

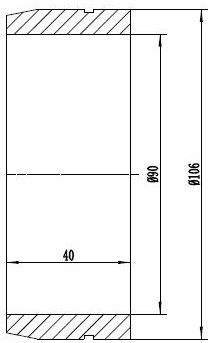

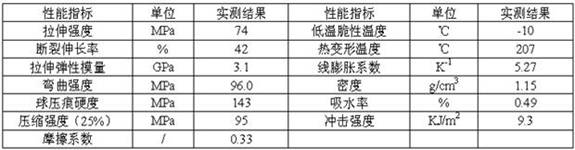

Preparation method of self-lubricating MC nylon elastic band material

ActiveCN111825974AHigh mechanical strengthImprove the lubrication effectPolymer chemistryThermal treatment

The invention relates to a preparation method of a self-lubricating MC nylon elastic band material. The method comprises the following steps: (1) heating a centrifugal mold in a centrifugal machine; (2) putting the monomer into a reaction container, heating to completely melt the monomer, and vacuumizing; (3), adding a catalyst, and vacuumizing; (4) sequentially adding a lubricating agent, a reinforcing agent and a toughening agent, and vacuumizing; (5) adding an activating agent, quickly dissolving, quickly stirring, casting into the centrifugal mold obtained in the step (1), centrifuging, naturally cooling to room temperature, and taking out a pipe fitting in the mold; (6) putting the prepared pipe fitting into a silicone oil tank for heating treatment; and (7) heating the pipe fitting subjected to oil bath in a water bath to obtain the self-lubricating MC nylon elastic band material. The self-lubricating MC nylon cartridge belt material prepared by the method has good dimensional stability, low water absorption, excellent self-lubricating property and mechanical strength, can improve the sealing and air-tight performance at the moment of bore launching when being applied to a sliding cartridge belt, and plays an important role in the flight attitude stability of a cartridge body.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

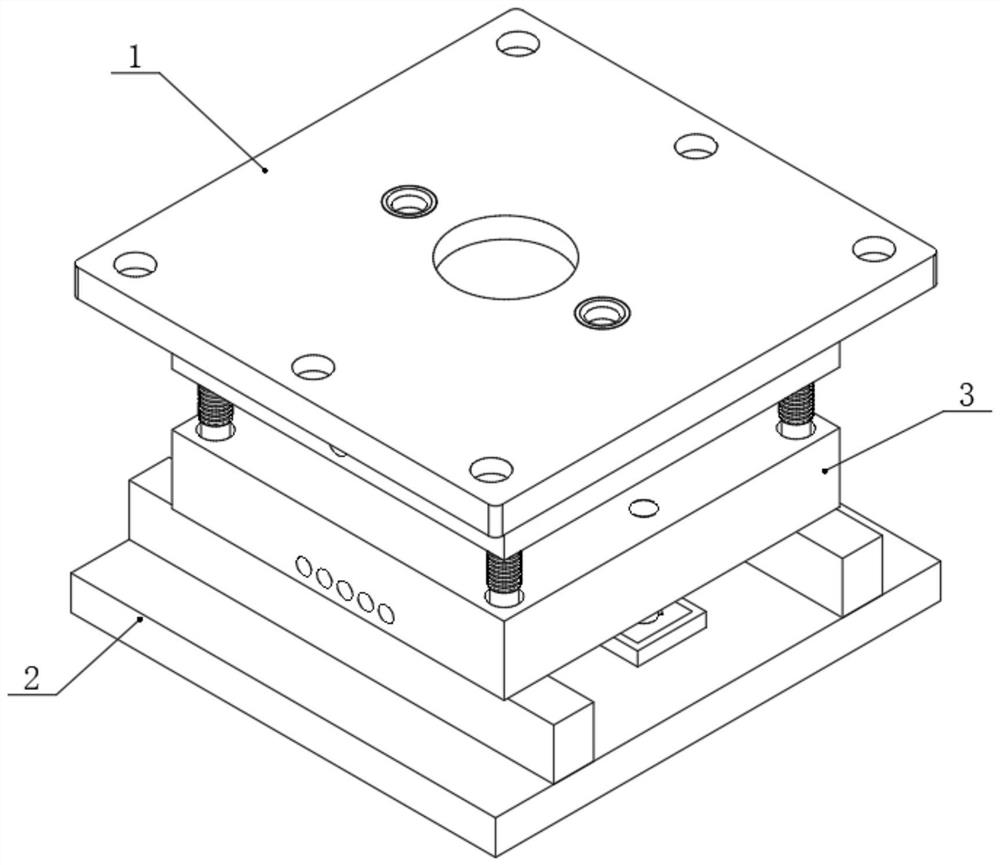

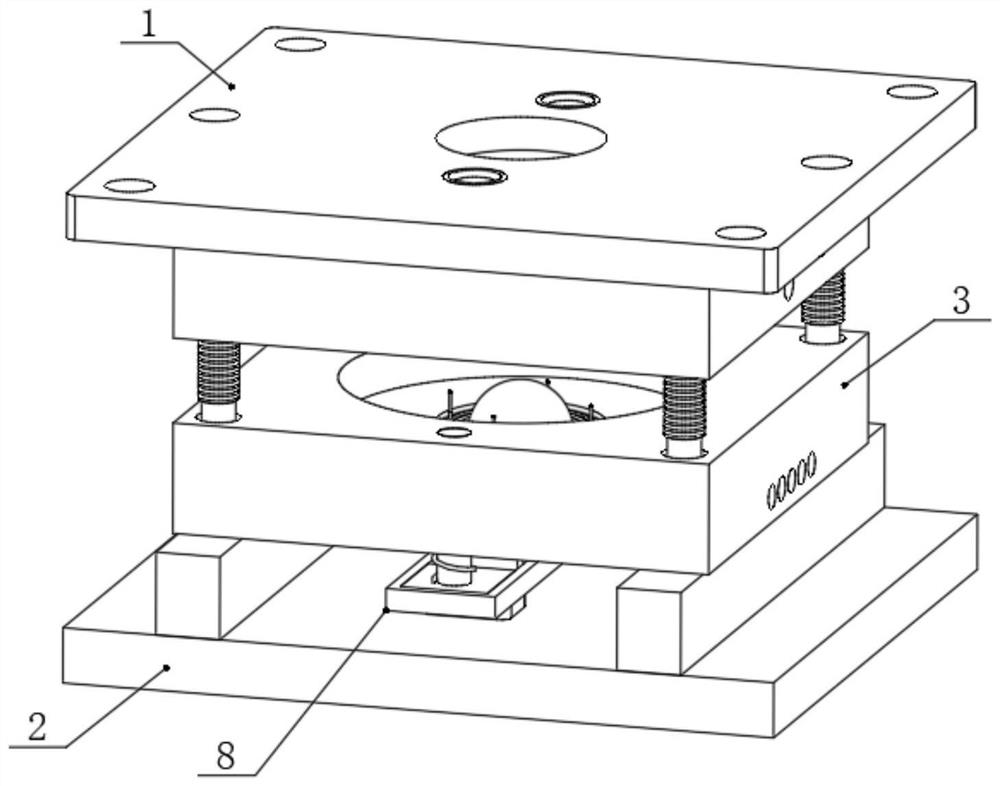

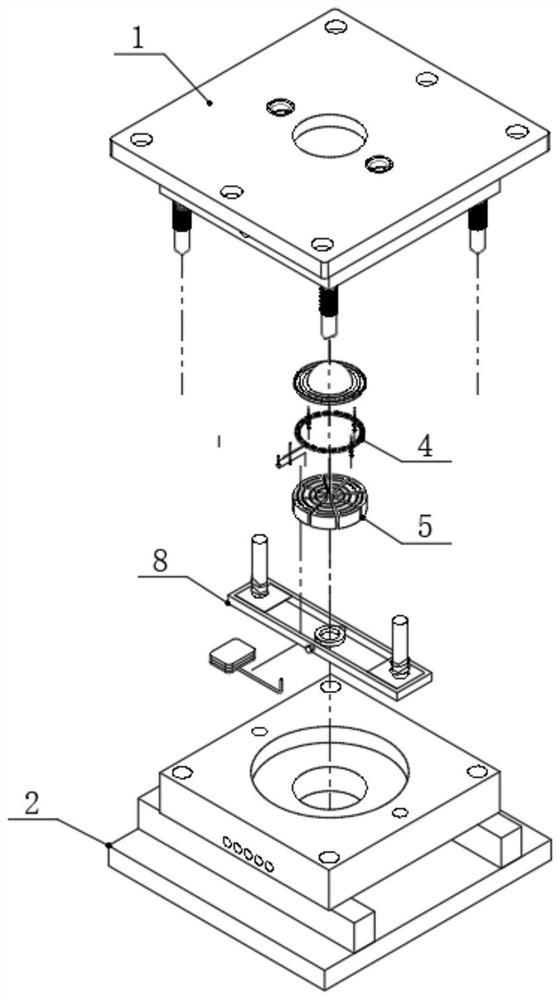

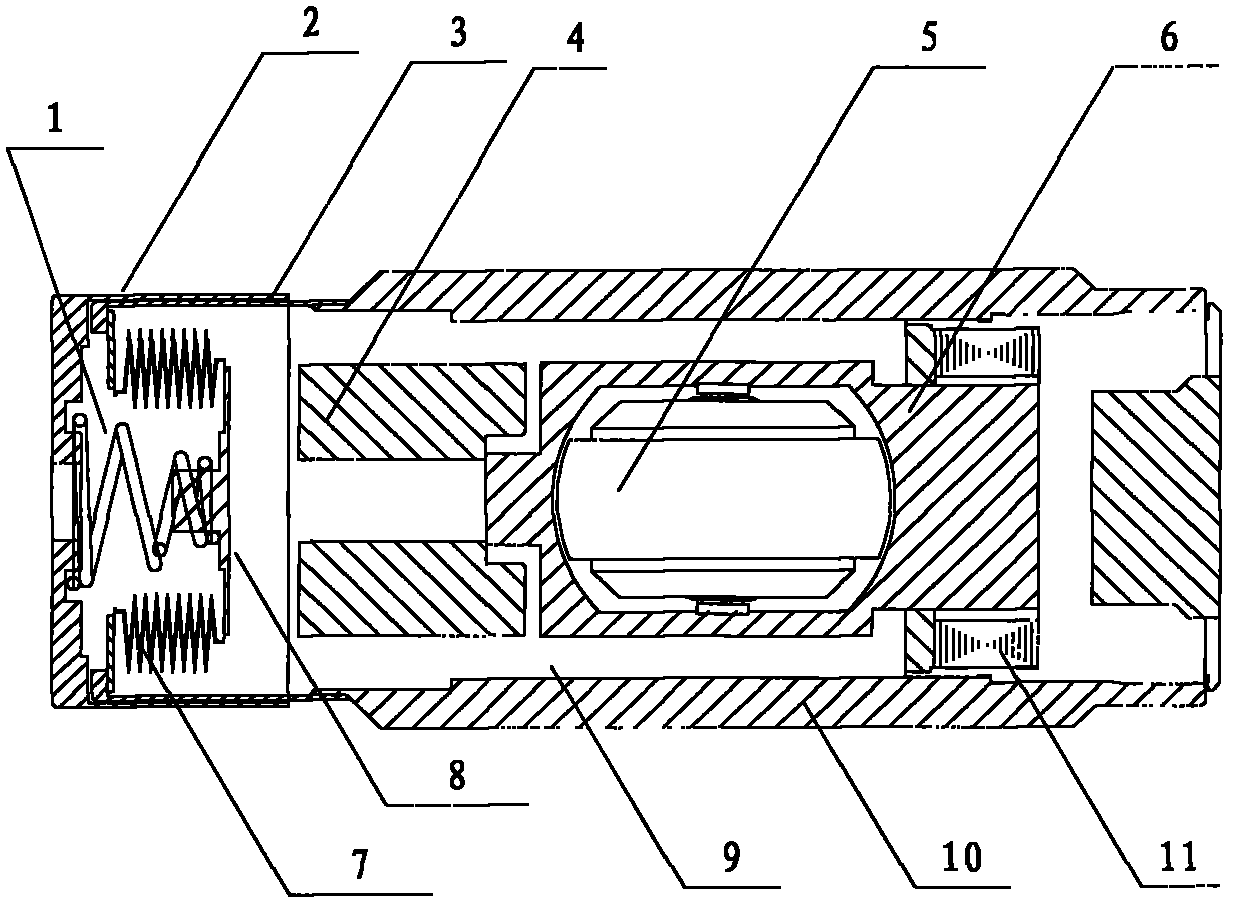

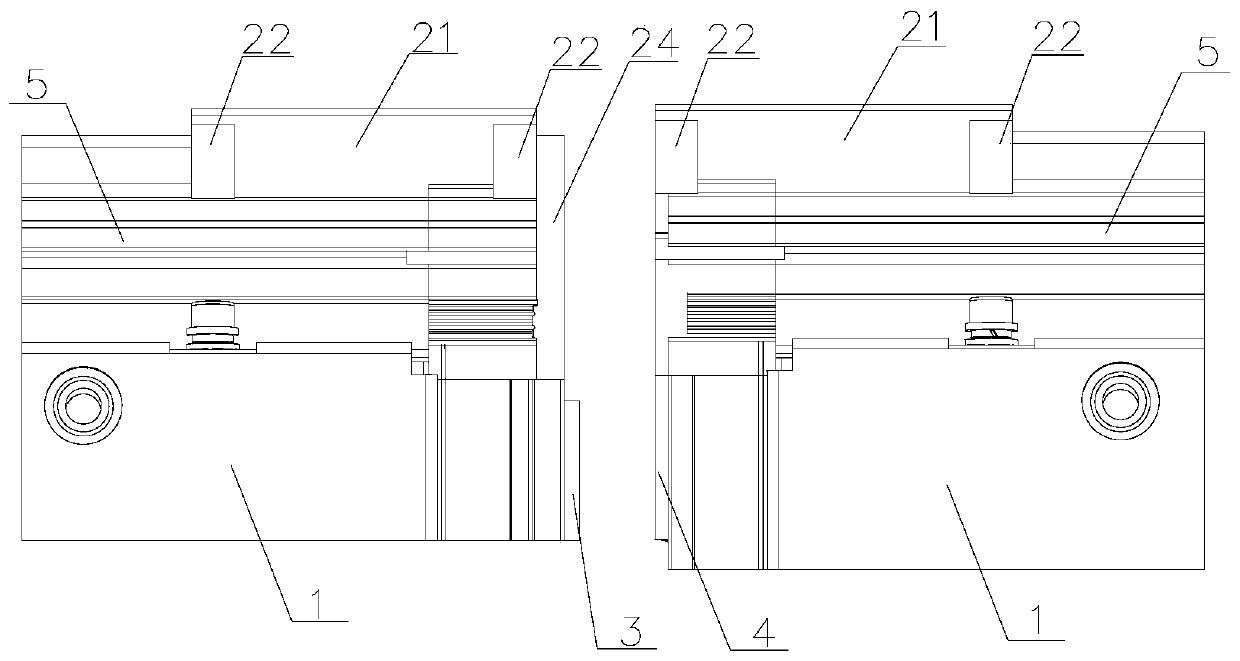

Injection mold and manufacturing method thereof

InactiveCN114434738AReduce the difficulty of adjustmentReduce maintenance difficultyMechanical engineeringIndustrial engineering

The invention discloses an injection mold and a manufacturing method of the injection mold, and belongs to the technical field of injection molds, the injection mold comprises an upper mold base and a lower mold base, the upper mold base and the lower mold base are oppositely arranged, a base is fixedly mounted at the bottom of the lower mold base, and an ejector pin assembly mechanism is movably mounted in an inner cavity of the lower mold base; and a filling mechanism is movably mounted at the top of the ejector pin assembling mechanism. According to the invention, the outer side abutting block of the second assembly block can support the inner cavity of the second assembly groove after abutting against the inner cavity of the second assembly groove by means of the elastic force of the second assembly block, modular assembly of the ejector pin main body is realized through the ejector pin seat, and meanwhile, the ejector pin main body can be quickly adjusted at the relative axial position at the top of the ejector pin seat by cooperating with the second assembly block on the bottom side; adjustment and adaptation of ejection positions of injection mold cores in different shapes are met, injection molding discharging of products of different specifications is facilitated, the injection mold ejector pin replacement adjustment and maintenance difficulty can be effectively reduced, and the use requirement is met.

Owner:任丹

Liquid floated gyroscope

InactiveCN102889886ASimple structureMake up for the problem of low stiffnessRotary gyroscopesGyroscopeHermetic seal

The invention discloses a liquid floated gyroscope which comprises a shell, a rear shade, a corrugated pipe and a gasket, wherein the corrugated pipe and the gasket are fixedly connected into a whole. The liquid floated gyroscope is characterized in that the rear shade of the shell is externally provided with a rear cover, and the rear cover is glued with the rear shade; and the big end of a conical spring is sleeved in the rear cover, and the small end of the conical spring is sleeved on the gasket. Compared with the prior art, the liquid floated gyroscope provided by the invention has the advantages and beneficial effects that the conical spring is adopted, the small rigidity problem of the existing corrugated pipe is overcome, the rigidity is improved, the rear cover is glued with the rear shade, the occurrence of a gas leakage phenomenon is avoided, and the hermetic seal property of the gyroscope is improved.

Owner:SHANGHAI XINYUE METER FACTORY

An electrode lead-out device for a capacitive liquid level sensor used in a high-pressure storage tank

ActiveCN104006864BExtend your lifeImprove airtight performanceLarge containersLevel indicators by physical variable measurementElectricityCapacitance

The invention discloses an electrode lead-out device for a capacitive liquid level sensor of a high-pressure storage tank. communicated to allow the first electrode to enter the first lead-out tube from this end and pass through the other end, and the first lead-out tube is electrically connected to the tank electrically connected to the second electrode of the probe, and the first lead-out tube is electrically connected to the second electrode of the probe. An insulating sealing body is provided between the inner wall of the first drawing pipe and the first electrode, and the insulating sealing body is poured between the inner wall of the first drawing pipe and the first electrode and is connected with the first drawing pipe. The inner wall and the first electrode are integrated into one body. The technical problem solved by the present invention is to overcome the shortcoming that the electrode lead-out device of the existing high-pressure storage tank is prone to seal failure under the action of high pressure, and to provide a capacitive liquid level for high-pressure storage tanks with higher sealing performance and more reliable sealing. The electrode lead-out device of the sensor.

Owner:北京鼎力华业测控仪表有限公司

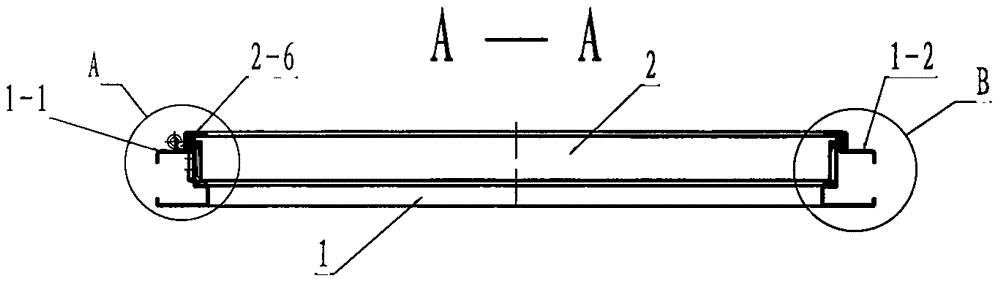

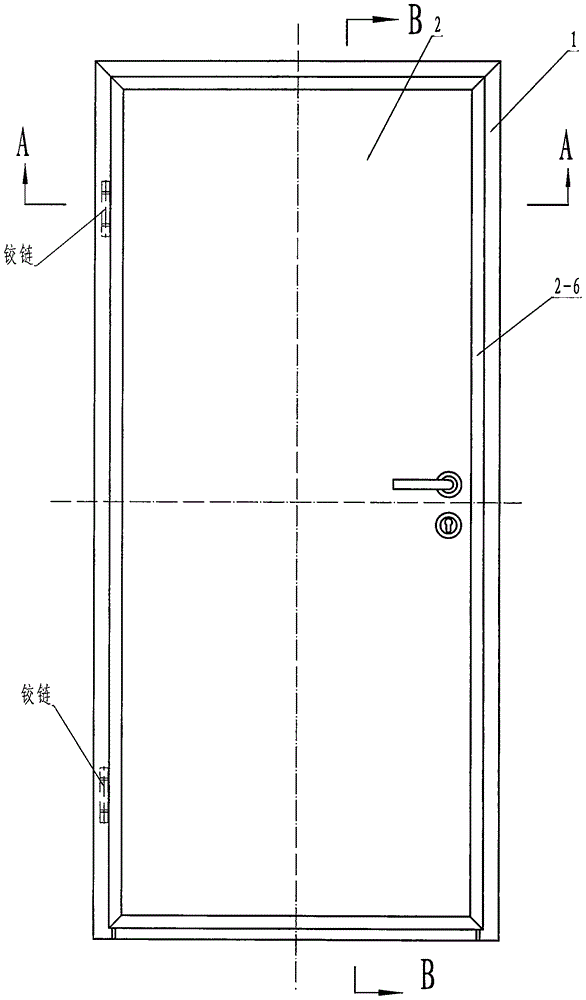

T-shaped door with groove-shaped cover port

PendingCN106761251AImprove airtight performanceImprove sealing performanceBurglary protectionSealing arrangementsEngineeringMechanical engineering

Owner:何振

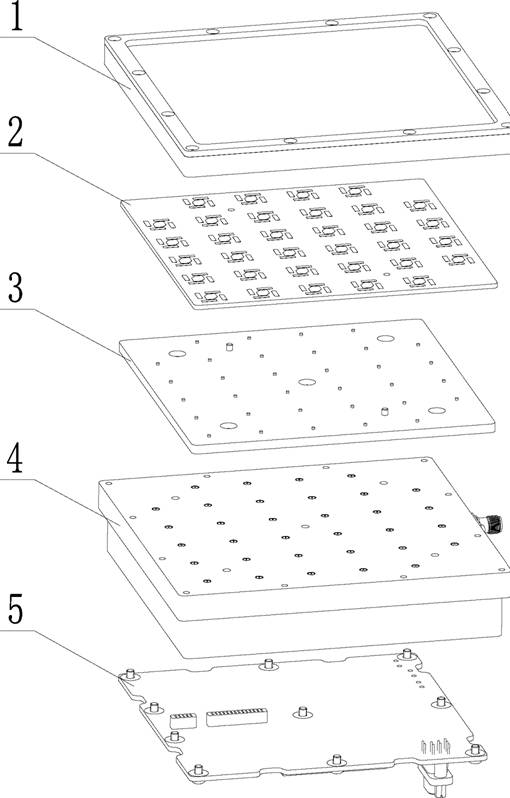

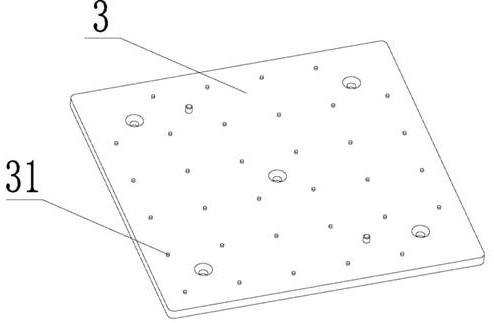

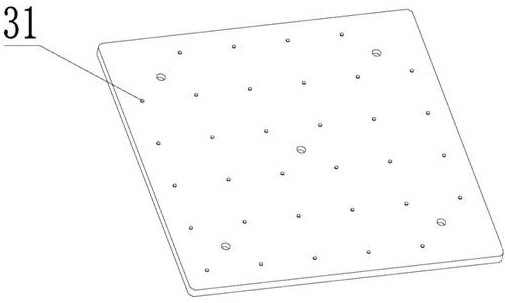

A thin phased array antenna structure

ActiveCN113839201BImprove operational reliabilityGuaranteed uptimeParticular array feeding systemsRadiating elements structural formsControl powerRadar

The invention relates to the technical field of satellite communication radar, and provides a thin phased array antenna structure, which includes a radome body, a patch antenna, a fur button integrated board, a thin radio frequency module and a control power supply board connected in sequence; the patch antenna includes an antenna Carrier board, one side of the antenna carrier board is provided with a number of antenna units evenly spaced in a rectangular array, and the other side of the antenna carrier board is provided with a radio frequency signal transmission pad corresponding to each antenna unit; the radio frequency signal transmission pad of the antenna unit passes through The fur button integrated board communicates with the thin radio frequency module; the lower cavity structure of the thin radio frequency module fits the fur button integrated board and the lower cavity structure is provided with a radio frequency signal link, a self-calibration signal link and a radio frequency power supply board; the control power supply board It is arranged in the upper cavity of the thin radio frequency module and electrically connected with the radio frequency power supply board. The invention processes the overall structure according to flattening, which not only meets the requirements of small size and light weight, but also improves the operating reliability of the antenna.

Owner:成都雷电微力科技股份有限公司

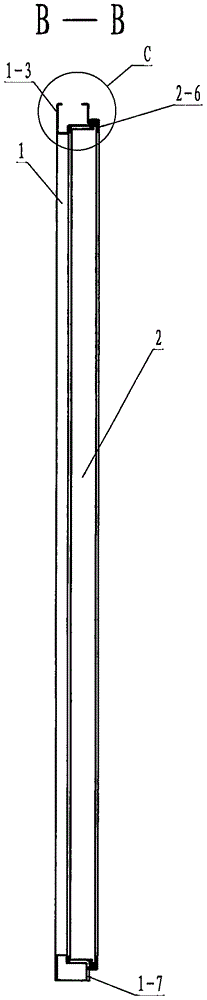

A rail vehicle double-opening plug-and-pull door system

ActiveCN108179966BImprove airtight performanceImprove waterproof performanceCondensed water drain-offDoor arrangementMechanical engineeringSteel structures

The invention relates to a double sliding-plug door system of a rail vehicle. The double sliding-plug door system comprises two side-by-side door leaves and a door frame, the door frame is fixed to avehicle body steel structure, and centering sealing rubber strips are symmetrically arranged on the butt-joint faces of the two door leaves; and the connecting face where each door leaf is connected with the door frame is provided with a circumferential sealing rubber strip, at least one of the centering sealing rubber strips comprises a first mounting part and a first sealing part, the first mounting parts are fixedly connected with the door leaves, and an outer side sealing lip edge flanging towards the outside of the vehicle is at least arranged on the vehicle outer side of one first sealing part. The double sliding-plug door system of the rail vehicle plays a good air sealing effect, meanwhile, watertightness is more facilitated, and the good water sealing effect is achieved.

Owner:CRRC QINGDAO SIFANG CO LTD

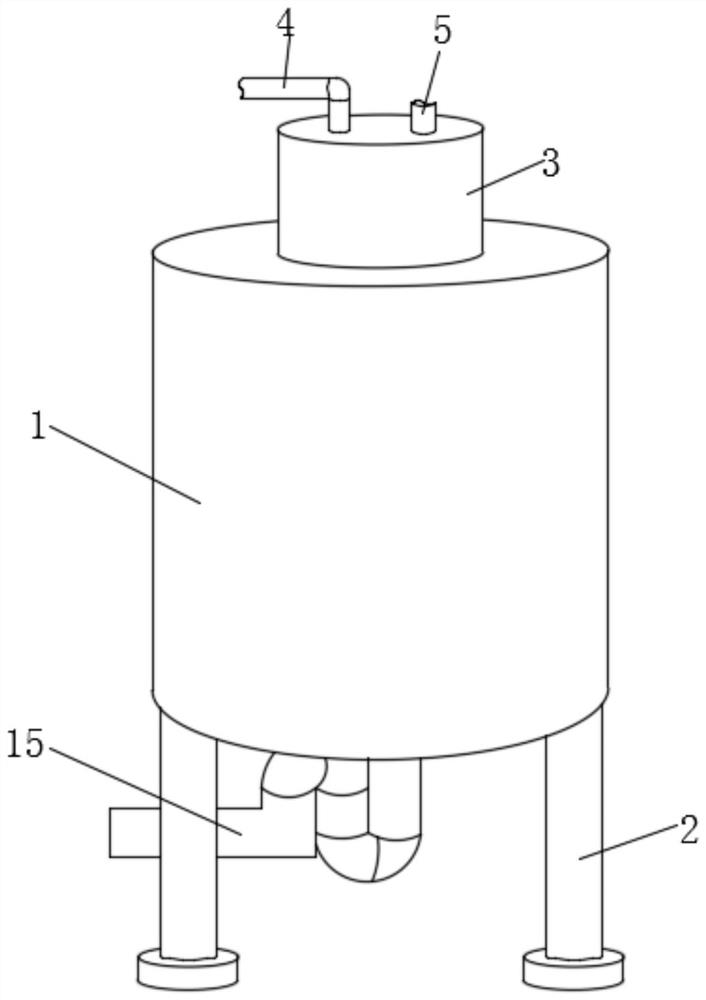

Industrial flue gas denitrification equipment

PendingCN111888931AEfficient removalAdequate responseGas treatmentDispersed particle separationNitrogen oxidesFlue gas

The invention discloses industrial flue gas denitrification equipment, and belongs to the technical field of denitrification. The equipment comprises a reaction box, wherein supporting legs are fixedly connected to four corners of the bottom of the reaction box, a fan is fixedly connected to the top of the reaction box, and a butt joint pipe is welded to the left side of the top of the fan. According to the invention, a butt joint pipe is in butt joint with equipment for generating flue gas, and a fan is powered on, so that external air and flue gas are respectively sucked into a reaction boxby the fan through the butt joint pipe and a gas inlet pipe via a gas outlet pipe; nitric oxide can be subjected to cylinder denitration through a cylinder denitration device, so that nitrogen oxidesin the flue gas react more sufficiently; and auxiliary denitration can be effectively carried out through a secondary reaction cavity, so that residual nitric oxide is effectively removed, and the problem that in the using process of existing denitration equipment, nitric oxide is not completely removed, so that residual nitric oxide still exists in treated flue gas, and the removal effect is pooris solved.

Owner:霍普斯特科技(深圳)有限公司

Oil-gas well gas-seal stage collar and assembly method thereof

InactiveCN104653149ASimple structureEasy to assembleAssembly machinesSealing/packingRelative displacementLocking mechanism

The invention discloses an oil-gas well gas-seal stage collar and an assembly method thereof. The stage collar comprises a body, a closing sleeve, a circumferential anti-rotation mechanism, a first clamping lock mechanism, a second clamping lock mechanism, an unlocking mechanism, a stage mechanism and a lower connector, wherein an outer stage hole is radially formed in a tube wall; the closing sleeve is arranged in the body, the closing sleeve is in sliding seal with the body, and an inner stage hole is radially formed in the tube wall of the closing sleeve; the circumferential anti-rotation mechanism is used for limiting circumferential relative displacement between the closing sleeve and the body; the first clamping lock mechanism is used for fixing the closing sleeve in a first position of the body; the second clamping lock mechanism is used for fixing the closing sleeve in a second position of the body; the unlocking mechanism is used for unlocking the first clamping lock mechanism; the stage mechanism is arranged in the closing sleeve; the lower connector is in sealing connection with the lower connecting end of the body, and outer connecting threads are formed on the lower end of the lower connector. Before staging, the closing sleeve is fixed in the first position, the inner and outer stage holes are opposite, and the inner stage hole is sealed by the stage mechanism; during staging, the inner stage hole is opened; after staging, the first clamping lock mechanism is unlocked, the closing sleeve moves downward to the second position, so as to be fixed, and the inner and outer stage holes are staggered. The oil-gas well gas-seal stage collar is convenient to assemble.

Owner:TIANJIN ANTON PETROLEUM MACHINERY MFG

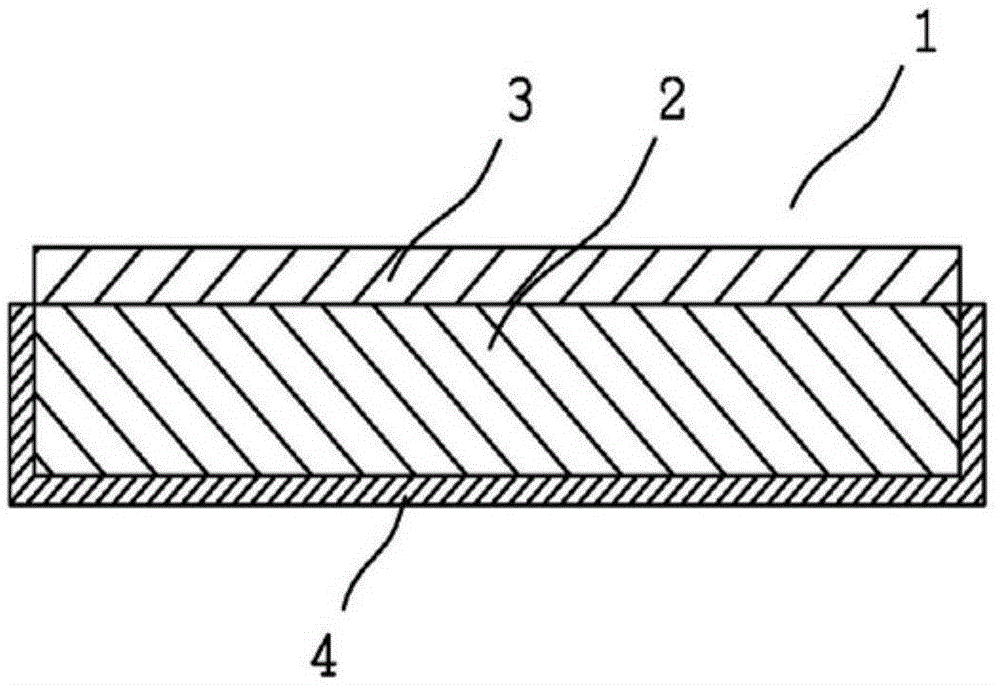

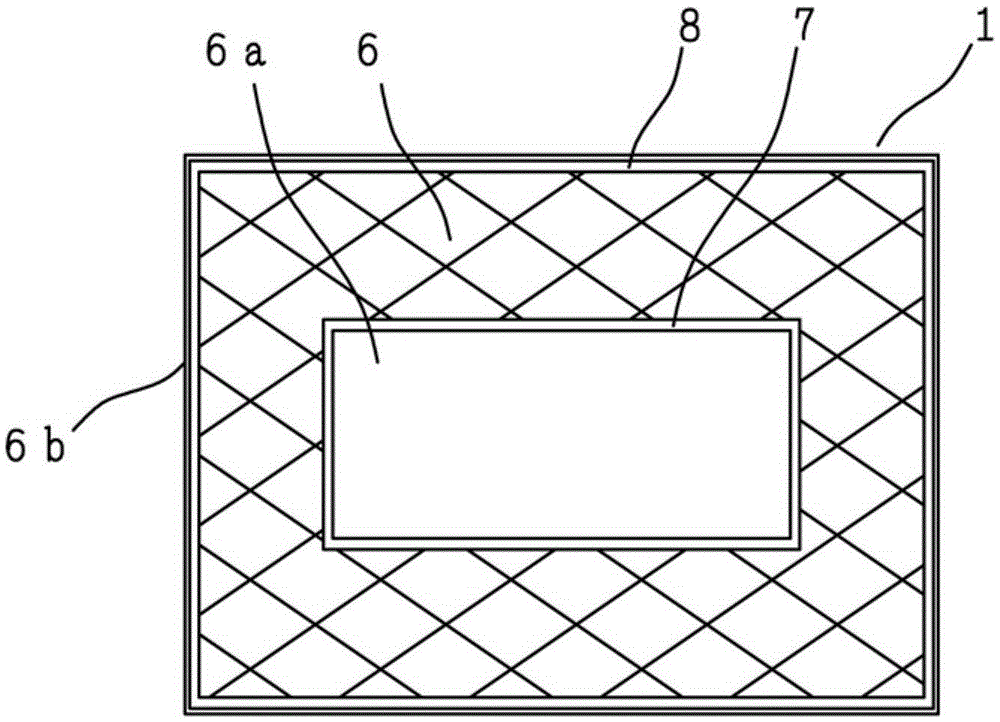

Lid for gas-tight seal and manufacturing method of the same, electronic component receiving package using the same

ActiveCN105575912AImprove airtight performanceSemiconductor/solid-state device detailsSolid-state devicesHermetic sealThinning

The invention provides a lid for gas-tight seal, a manufacturing method of the lid, and an electronic part storage package. The lid is provided with a flat first metal layer; a second metal layer which is disposed on one surface of the first metal layer; and an oxidation skin film layer which is disposed on the other surface of the first metal layer. The section of the first metal layer is detected to contain 2 mass% to 8 mass% of Cr through SEM-EDX, and the section of the second metal layer is detected to contain less than 10 mass% of Cr through SEM-EDX. The section of the oxidation skin film layer is detected to contain more than 10 mass% of Cr through SEM-EDX. Moreover, the package is used for combining the lid and a ceramic frame body storing an electronic part through a glass combination layer. The package can achieve the reading of a laser mark and the recognition of information, improves the gas-tight reliability, and can achieve the thinning.

Owner:HITACHI METALS LTD

Piston type double-stroke engine with fuel choosable

InactiveCN103277190AIncreased number of ignitionsIncrease the number of injectionsMachines/enginesCombustionFour-stroke engine

The invention discloses a piston type double-stroke engine with fuel choosable. According to the piston type double-stroke engine with the fuel choosable, the technical characteristics of a combustion gas turbine, the good airtightness of the piston set and the cylinder of a four-stroke piston type engine and the advantages of the double-stage piston type pressurizing device and the electric pressurizing device of an exhaust-driven gas turbine are integrated, a piston type double-stroke acting method with two sixths of the piston stroke for air inflow and four sixths of the piston stroke for acting and waste gas exhausting is utilized, the problems of uneven operation of the four-stroke piston type engine and the like are solved, and the range of the usable fuel of the piston type double-stroke engine with the fuel choosable is widened. Compared with the four-stroke cylinder piston type engine, the piston type double-stroke engine with the fuel choosable has the advantages that the power of the piston type double-stroke engine with the fuel choosable is more than twice of that of the four-stroke engine on the premise that the size and the weight of the piston type double-stroke engine with the fuel choosable are the same as those of the four-stroke engine, and the piston type double-stroke engine with the fuel choosable is more powerful.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com