Preparation method of self-lubricating MC nylon elastic band material

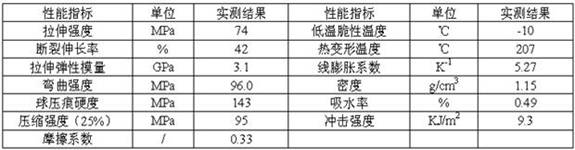

A self-lubricating, nylon technology, applied in the field of preparation of self-lubricating MC nylon elastic belt materials, can solve the problems affecting the physical and mechanical strength of sliding elastic belts and product stability, product performance decline, easy to absorb water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 A kind of preparation method of self-lubricating MC nylon elastic band material comprises the following steps:

[0030] (1) Heat the centrifugal mold to 175±3°C in a centrifuge and keep the temperature constant.

[0031] (2) Put 1600g of caprolactam (CL) and 200g of laurolactam (LL) solid powder into a 3000mL reaction vessel, melt them completely at 90°C, and evacuate to below -0.08MPa, turn on the magnetic stirrer, and keep 25 minutes.

[0032] (3) Release the vacuum, add 6.4g of sodium methoxide to the reaction vessel, continue vacuuming to below -0.08MPa, keep the temperature at 125°C, and keep magnetic stirring and vacuum state for 25 minutes.

[0033] (4) Release the vacuum, add 54g of toughening agent (PEA) and 80g of lubricant (graphite: PTFE = 1:2) into the reaction vessel at the same time, continue to vacuumize to below -0.08MPa, keep the temperature at 126°C, and Maintain magnetic stirring and vacuum for 20 min. Release the vacuum, add 36g of t...

Embodiment 2

[0040] Embodiment 2 A kind of preparation method of self-lubricating MC nylon elastic band material comprises the following steps:

[0041] (1) Heat the centrifugal mold to 175±3°C in a centrifuge and keep the temperature constant.

[0042] (2) Put 1000g of caprolactam (CL) and 800g of laurolactam (LL) solid powder into a 3000mL reaction vessel, melt them completely at 130°C, and evacuate to below -0.08MPa, turn on the magnetic stirrer, and keep 20 minutes.

[0043] (3) Release the vacuum, add 3.6g sodium caprolactam into the reaction vessel, continue vacuuming to below -0.08MPa, keep the temperature at 125°C, and keep magnetic stirring and vacuum state for 25 minutes.

[0044] (4) Release the vacuum, add 100g toughening agent (PEA) and 18g lubricant (graphite: polytetrafluoroethylene = 1:1) into the reaction vessel at the same time, continue to vacuumize to below -0.08MPa, keep the temperature at 126°C, and Maintain magnetic stirring and vacuum for 23 min. Release the vacuum...

Embodiment 3

[0051] Embodiment 3 A kind of preparation method of self-lubricating MC nylon elastic band material comprises the following steps:

[0052] (1) Heat the centrifugal mold to 175±3°C in a centrifuge and keep the temperature constant.

[0053] (2) Put 900g of caprolactam (CL) and 900g of laurolactam (LL) solid powder into a 3000mL reaction vessel, melt them completely at 90°C, and evacuate to below -0.08MPa, turn on the magnetic stirrer, and keep 30 minutes.

[0054] (3) Release the vacuum, add 3.6g sodium caprolactam into the reaction vessel, continue vacuuming to below -0.08MPa, keep the temperature at 130°C, and keep magnetic stirring and vacuum state for 20 minutes.

[0055] (4) Release the vacuum, add 270g of toughening agent (PEA) and 90g of lubricant (graphite: PTFE = 1:5) into the reaction vessel at the same time, continue vacuuming to below -0.08MPa, keep the temperature at 126°C, and Maintain magnetic stirring and vacuum for 22 min. Release the vacuum, add 90g of rei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com