Patents

Literature

39results about How to "Increase initial velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

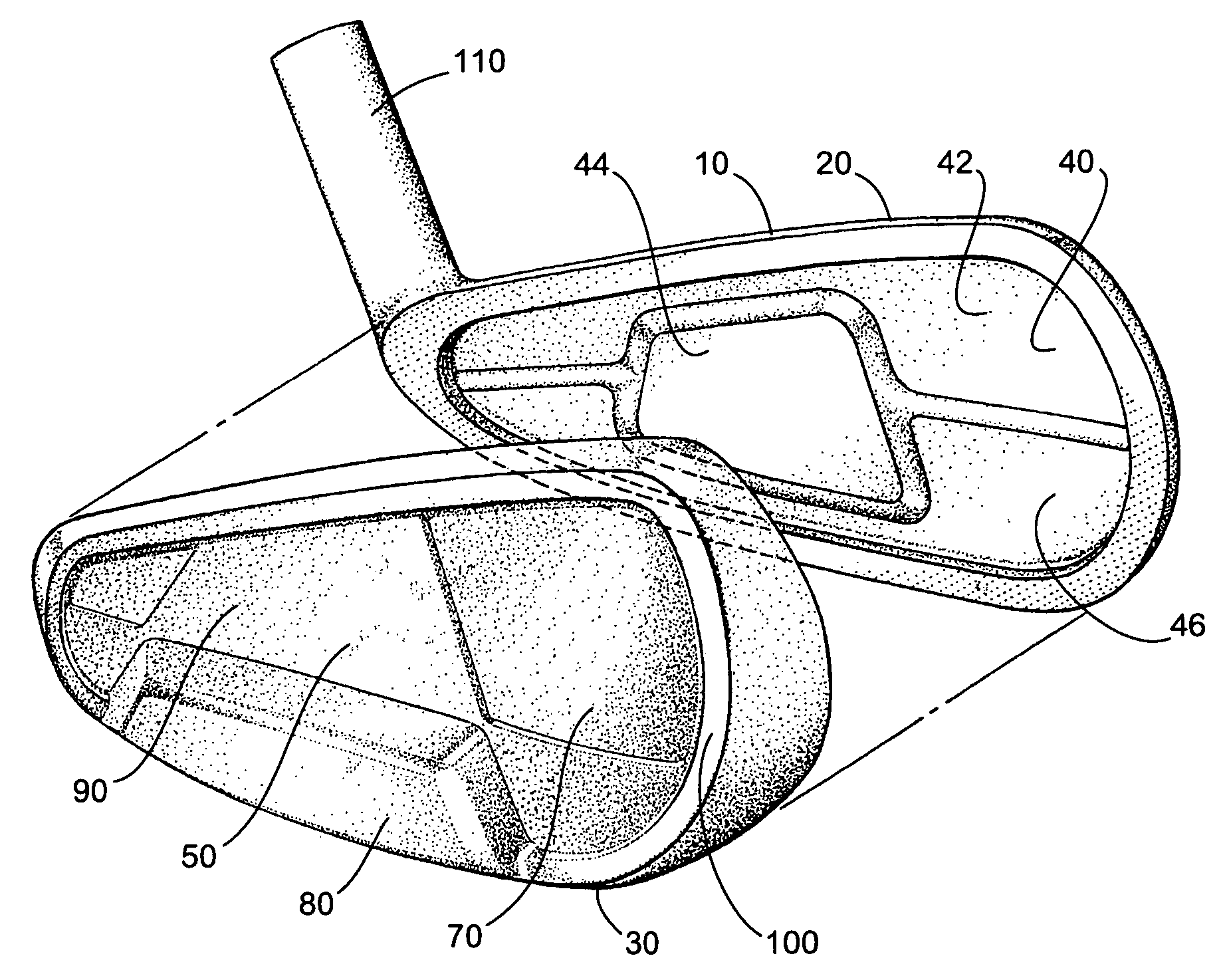

Utility iron golf club with weighting element

InactiveUS7126339B2Increase initial velocityIncrease velocityGolf clubsElectric/magnetic detectionEngineeringGolf club

A golf club head comprising of a front plate integral with a primary body having a top, a sole, a rear portion, and a general periphery wherein the primary body and the front plate define a hollow interior and where the rear portion carries a weighting element that protrudes behind the general periphery.

Owner:MIZUNO CORPORATION

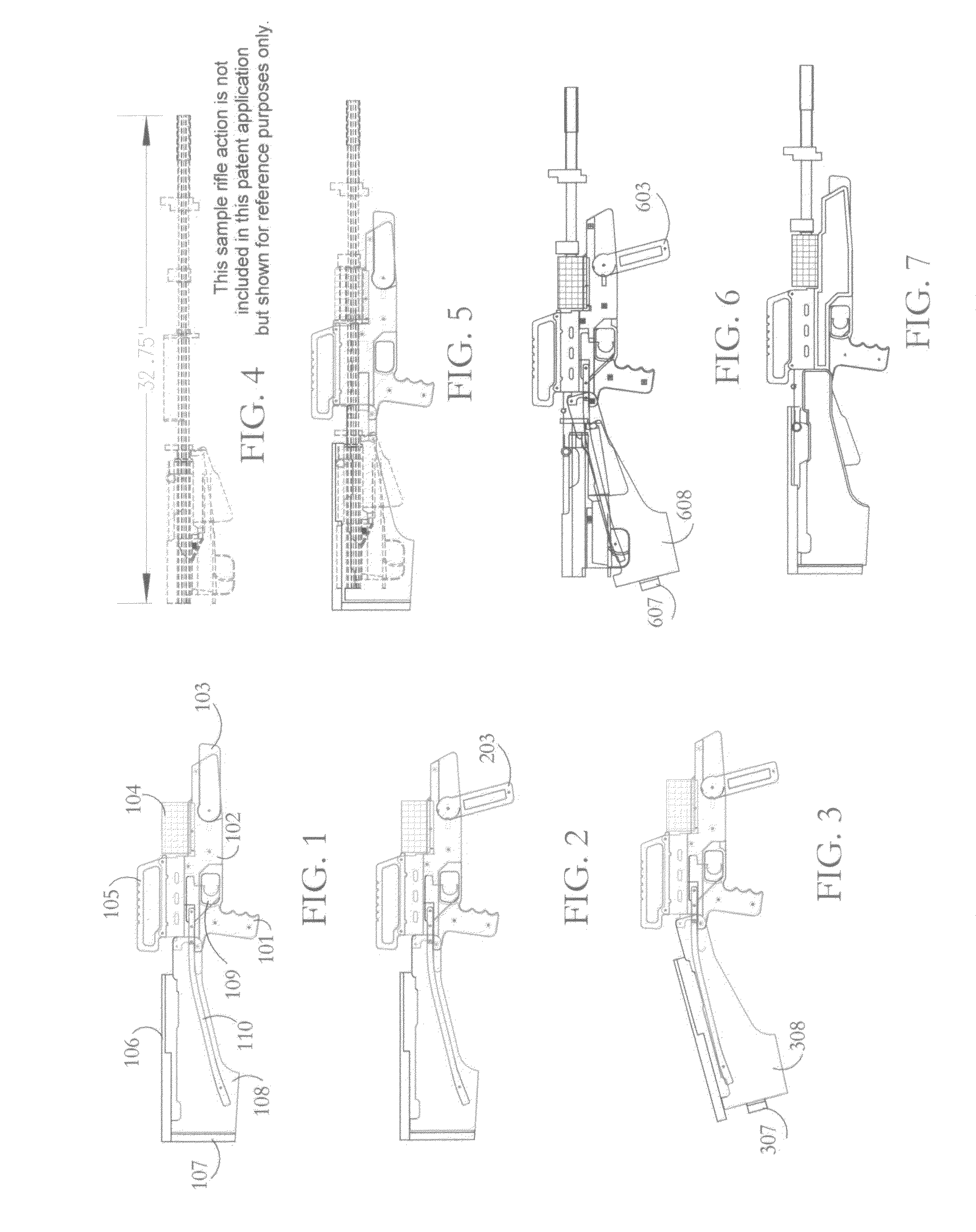

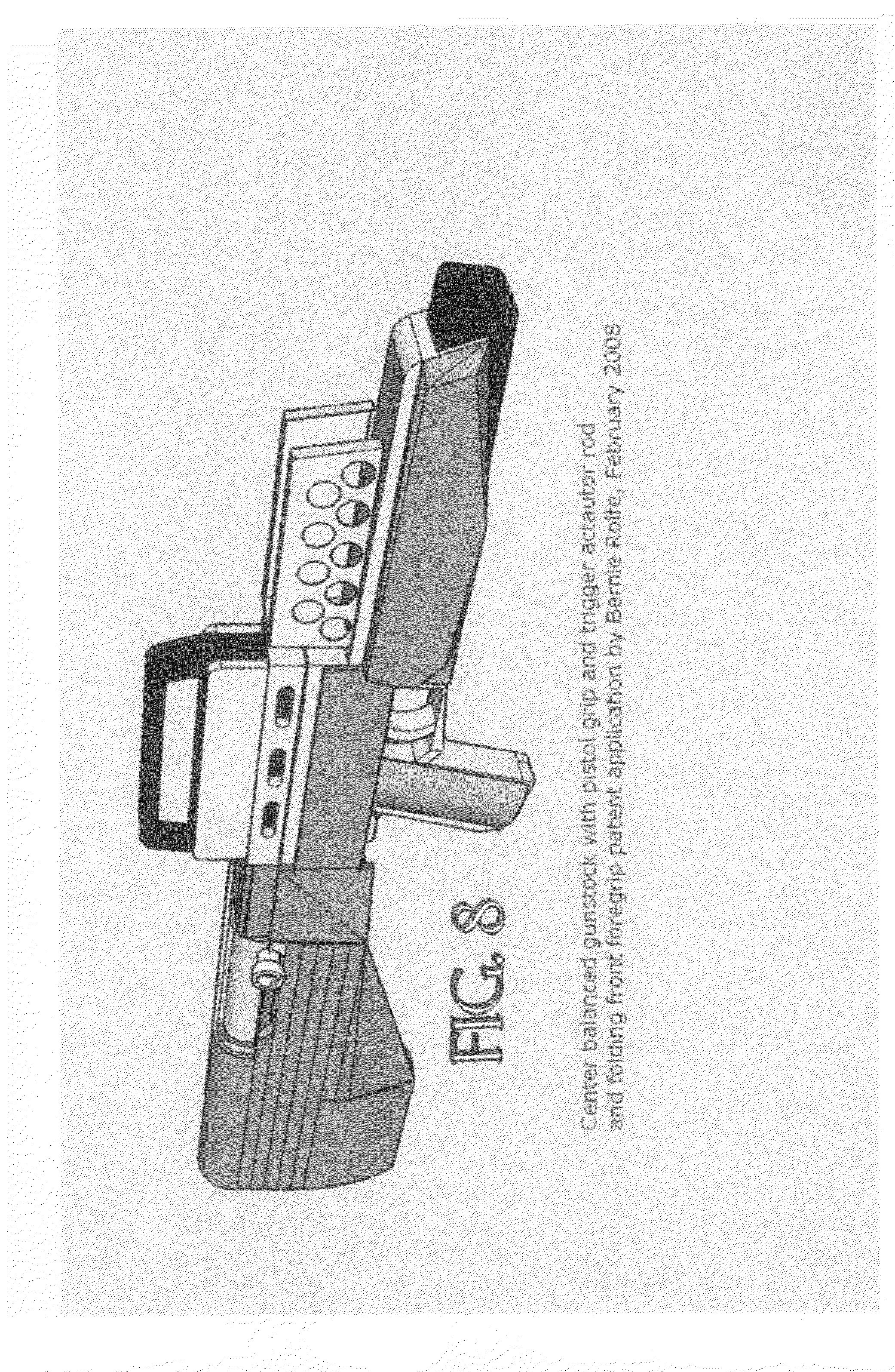

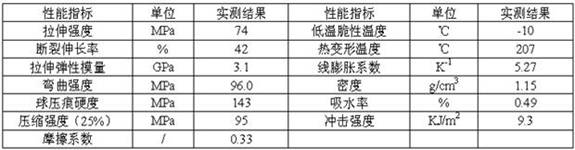

Center balanced gunstock with pistol grip and trigger actuator rod and folding front foregrip

InactiveUS20090211140A1Improve shooting experienceRemarkable rifle balanceButtsActuatorControl theory

A center balanced gunstock with pistol grip and trigger actuator rod and folding front foregrip is an after market gunstock suited for use on well designed, mechanically sound, unaltered rifle actions that would benefit from current production of an ergonomically designed alternate rifle stock system.

Owner:ROLFE BERNARD HOPE

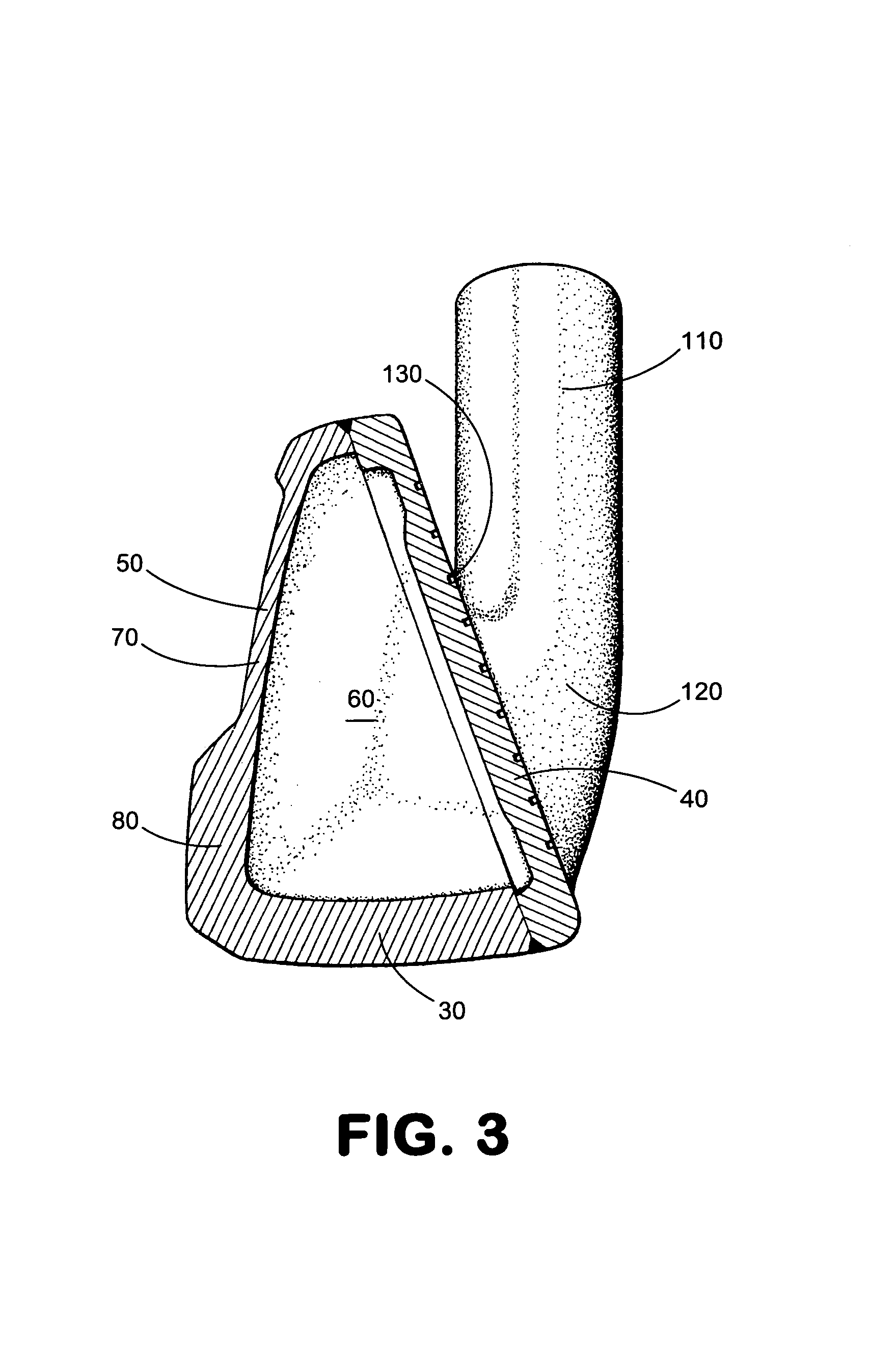

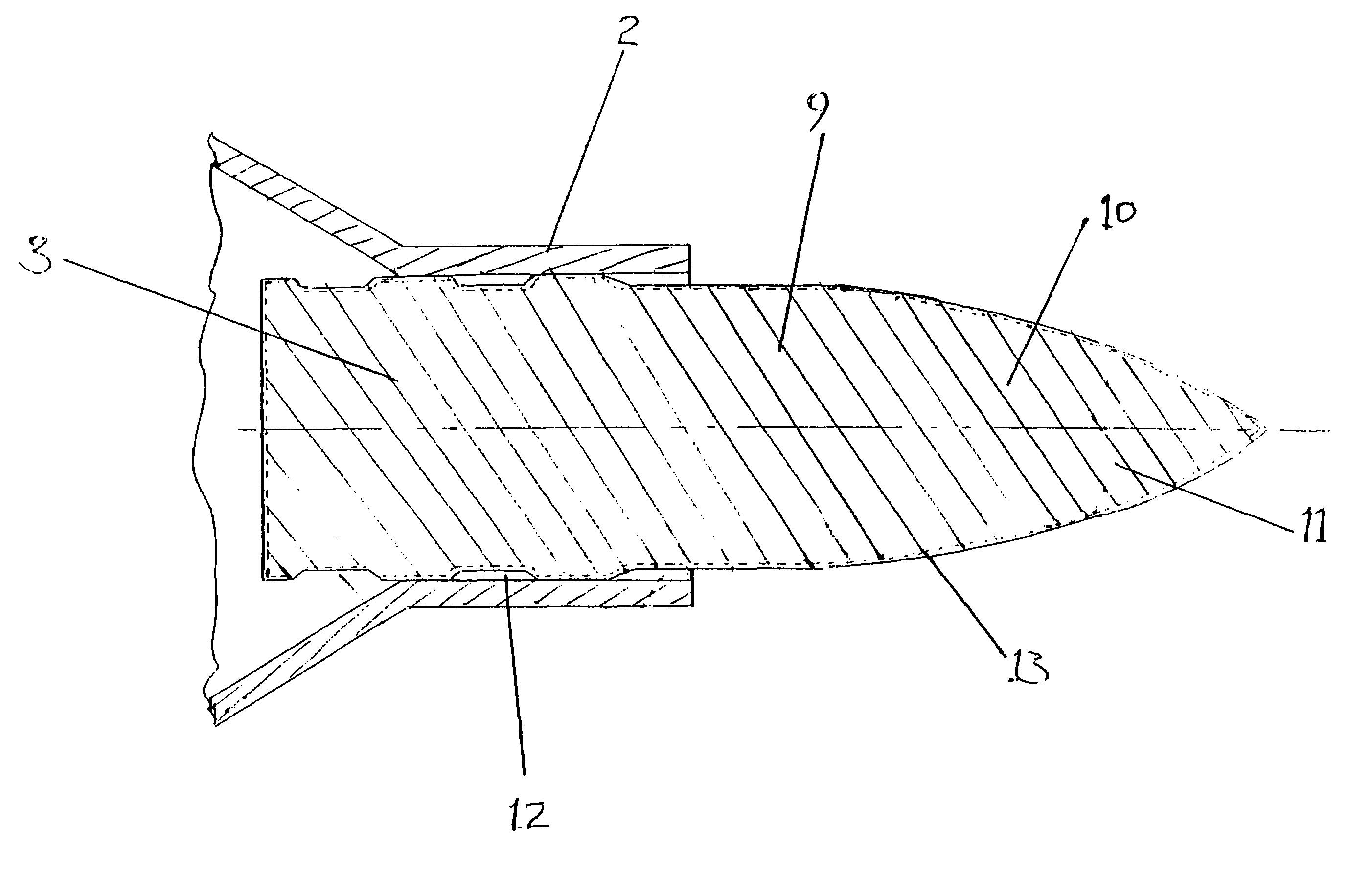

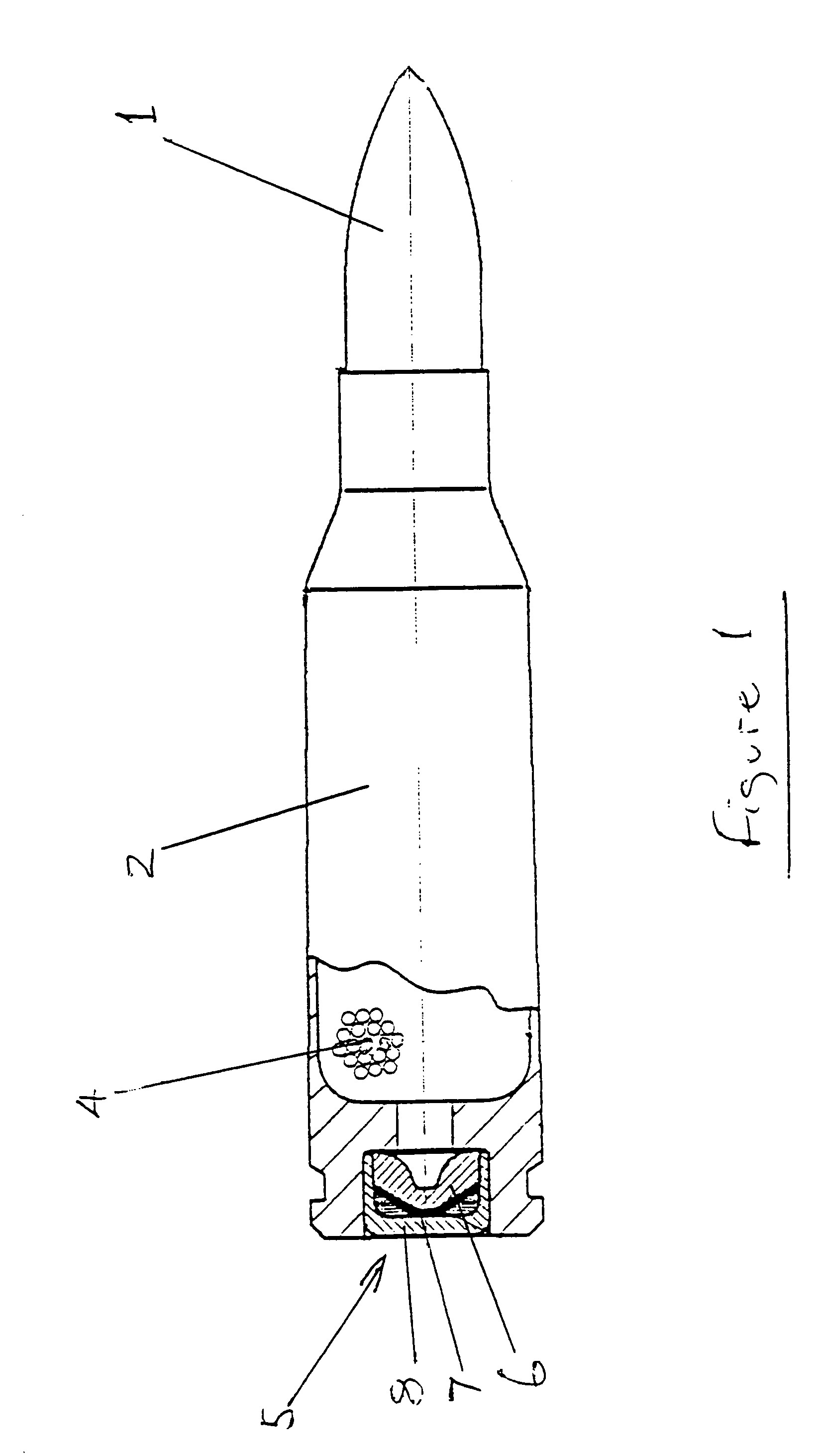

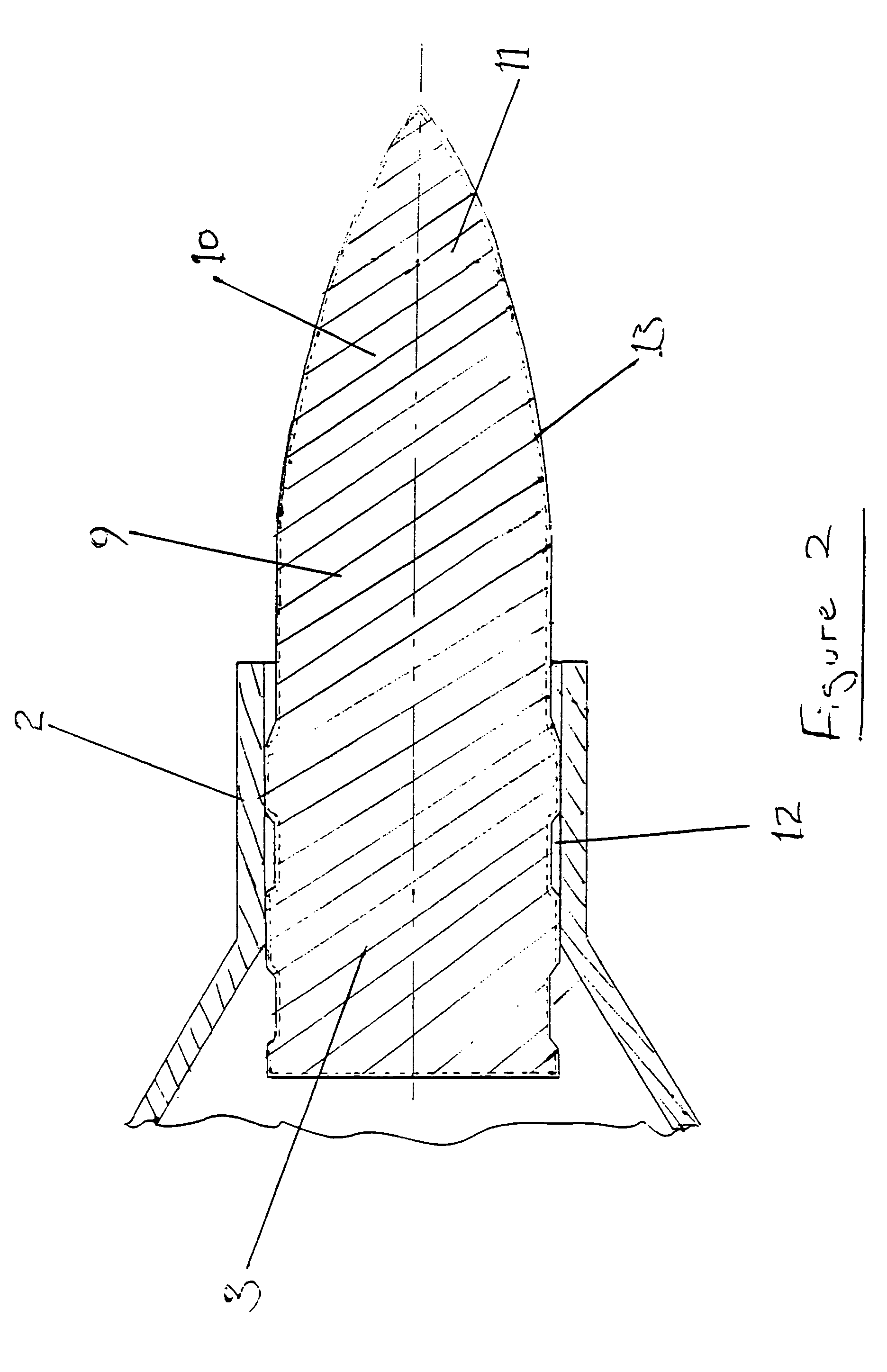

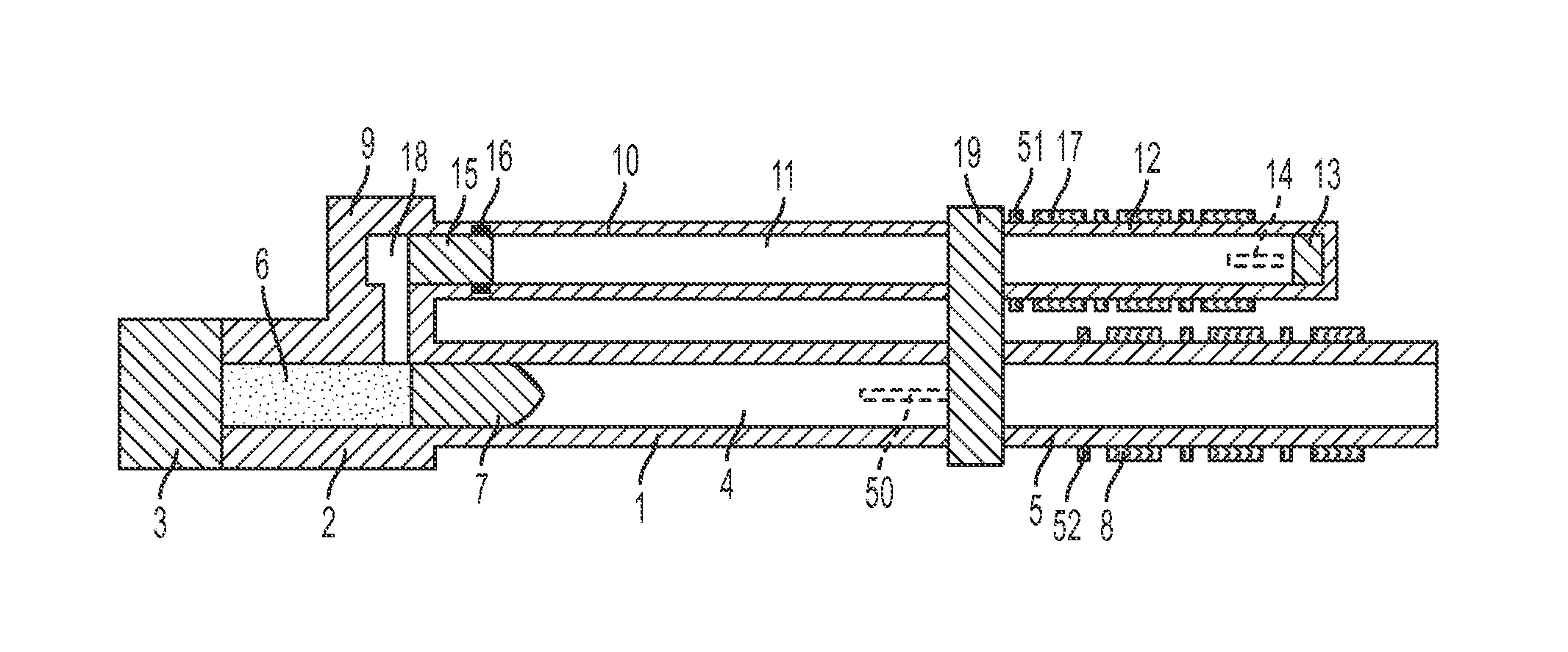

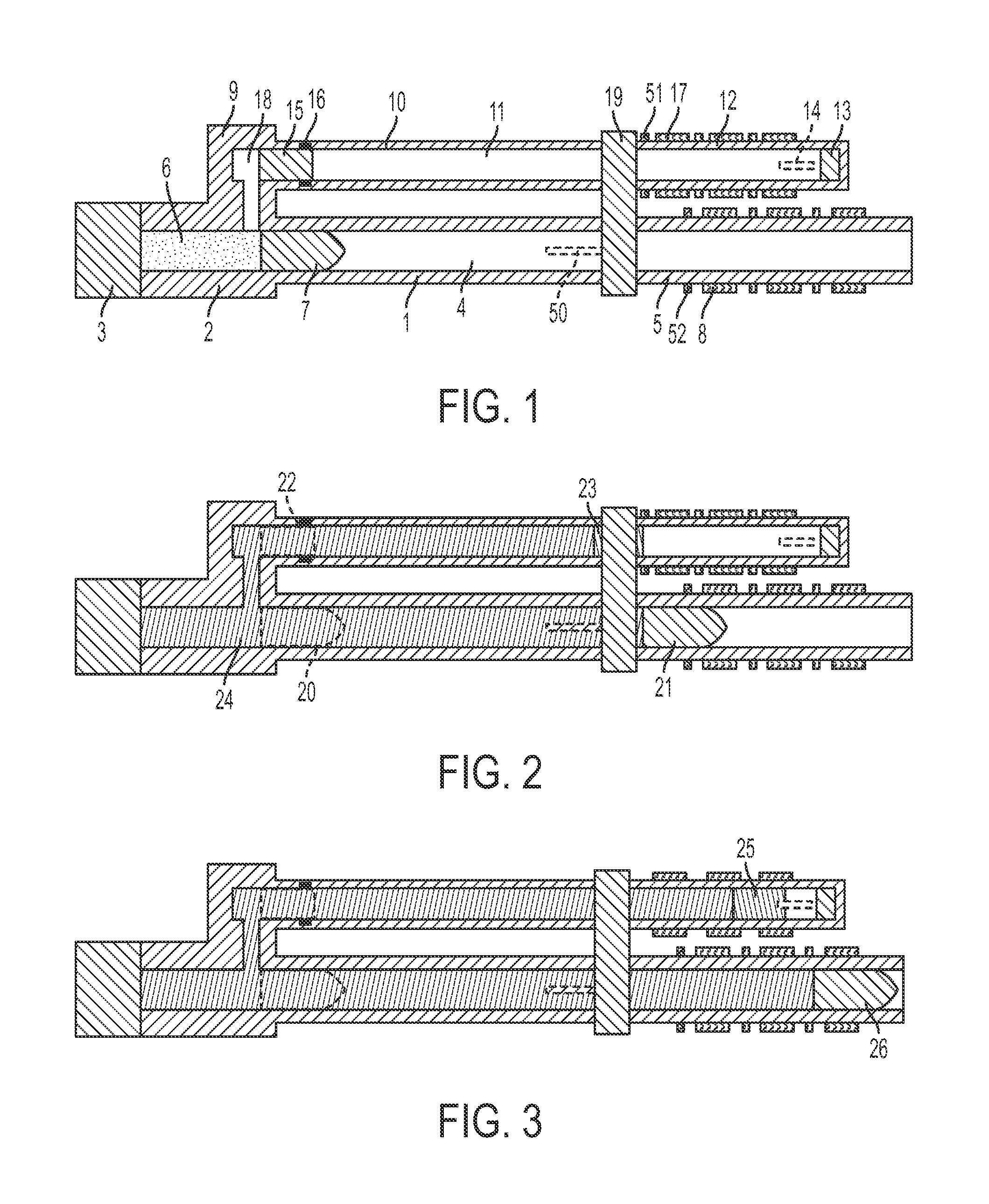

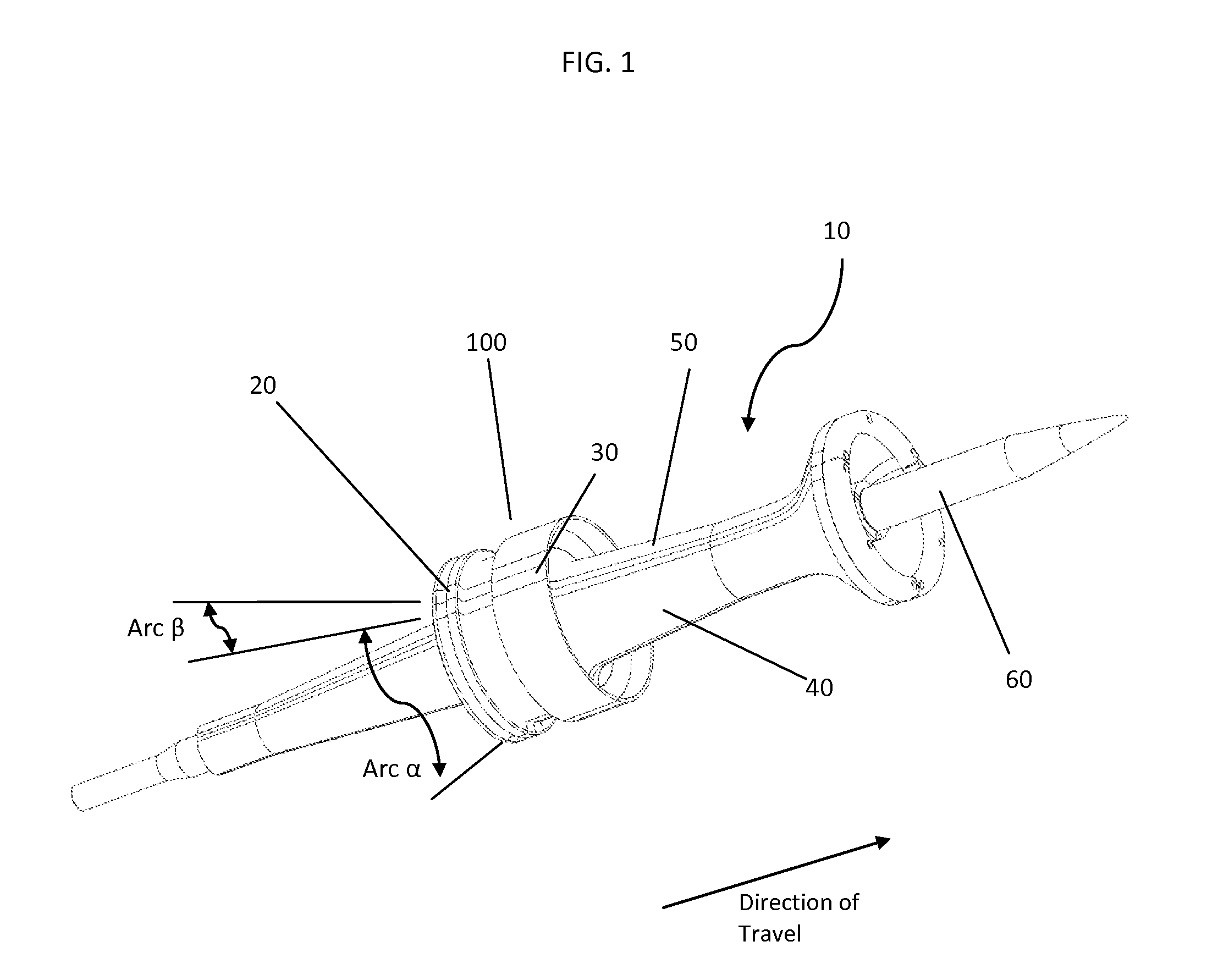

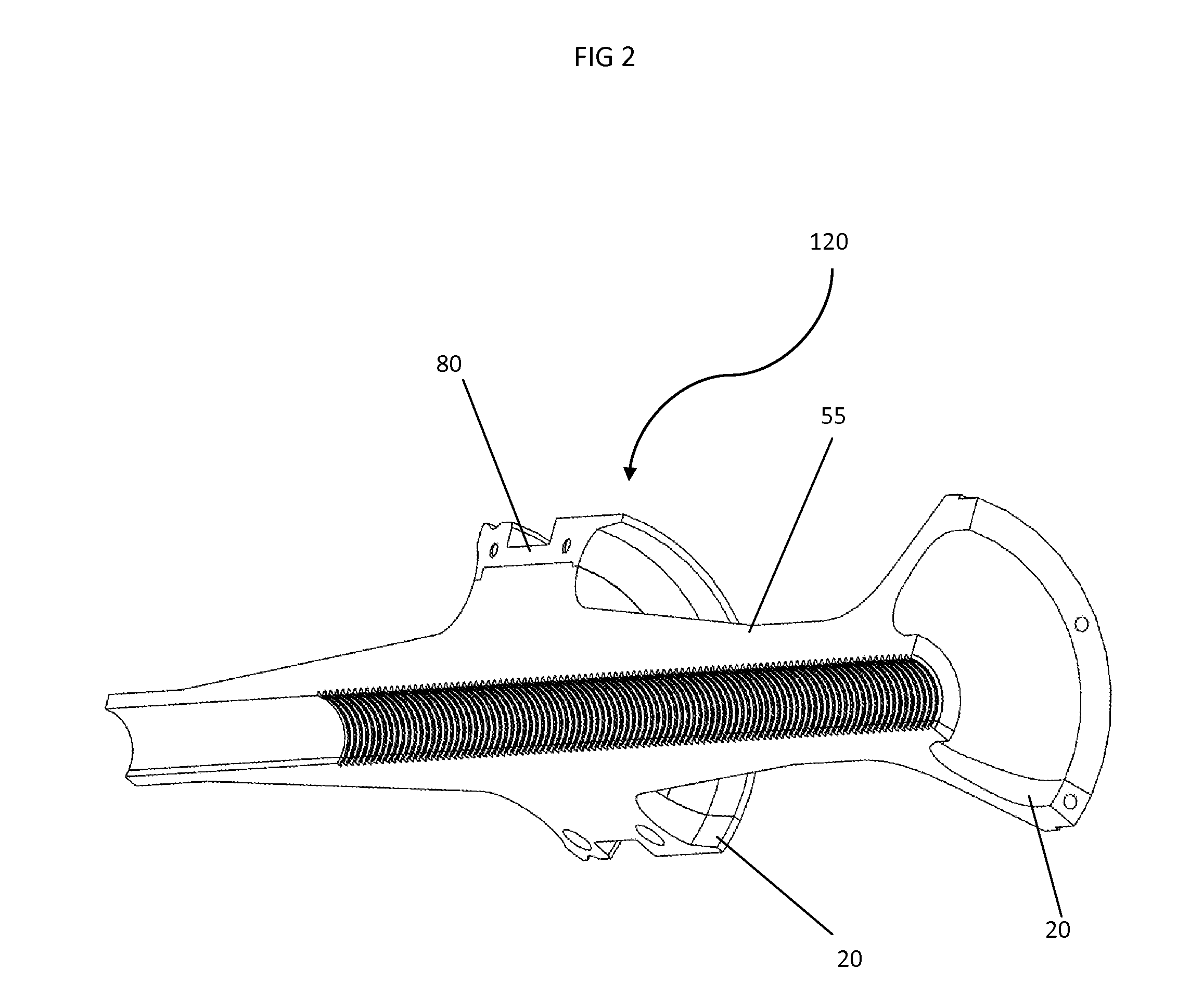

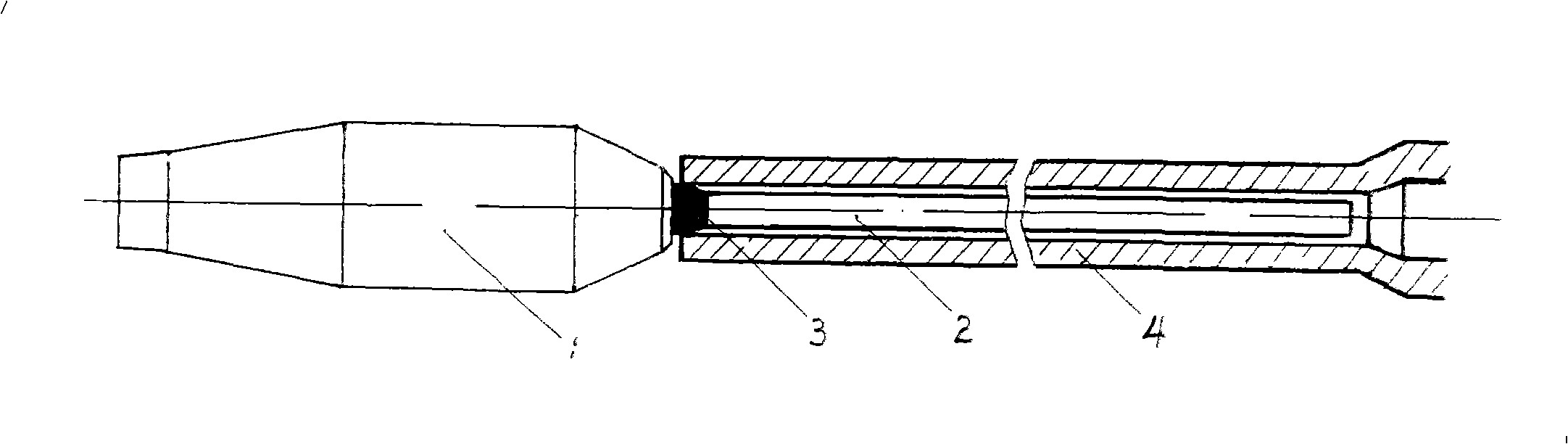

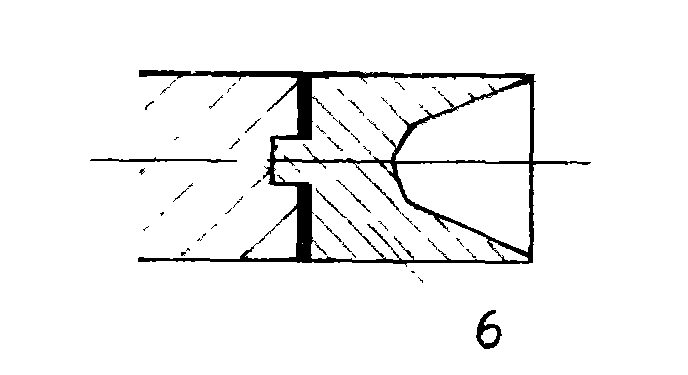

4.6 mm small arms ammunition

ActiveUS7210411B2Well formedReduce coefficient of frictionAmmunition projectilesProjectilesHardnessRifling

A round of ammunition for firing from a gun having a rifled barrel, especially a small arms weapon. The projectile (1) forming a part of the round is of steel or other material having a Vickers Hardness value not less than 550, and has a coating (13) of copper or copper alloy. The projectile has a forward body portion (9) which has a diameter similar to that of the lands of the rifling, and a rearward body portion (3) having a diameter which is similar to the diameter defined by the roots of the rifling grooves. The coating (13) is of a thickness not less than the depth of the said rifling grooves, so that the rifling engraves the coating but does not significantly engrave the underlying steel or other hard material. The advantages associated with a hard projectile material are thus obtained without substantially increasing barrel wear.

Owner:RUAG AMMOTECH

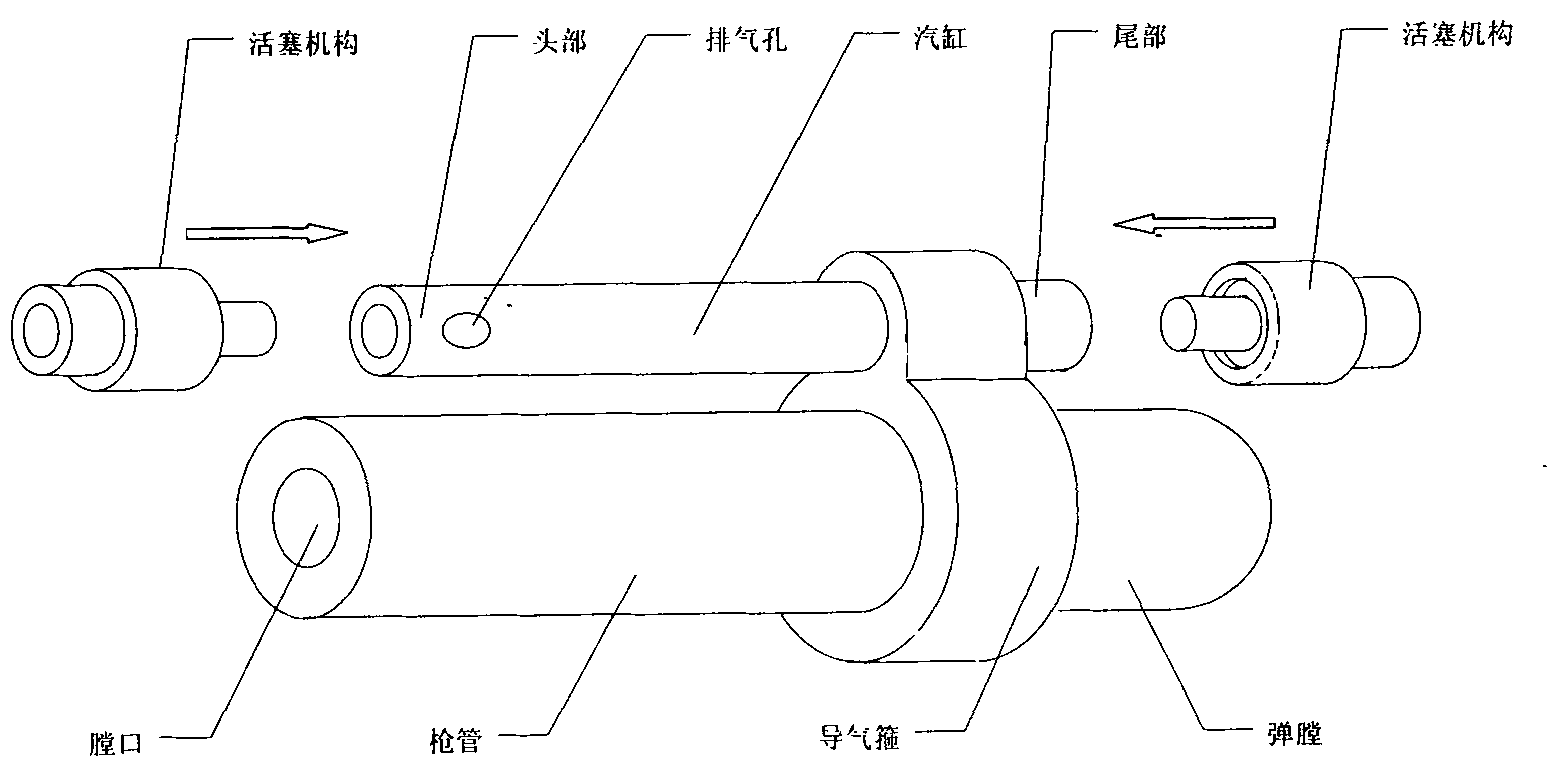

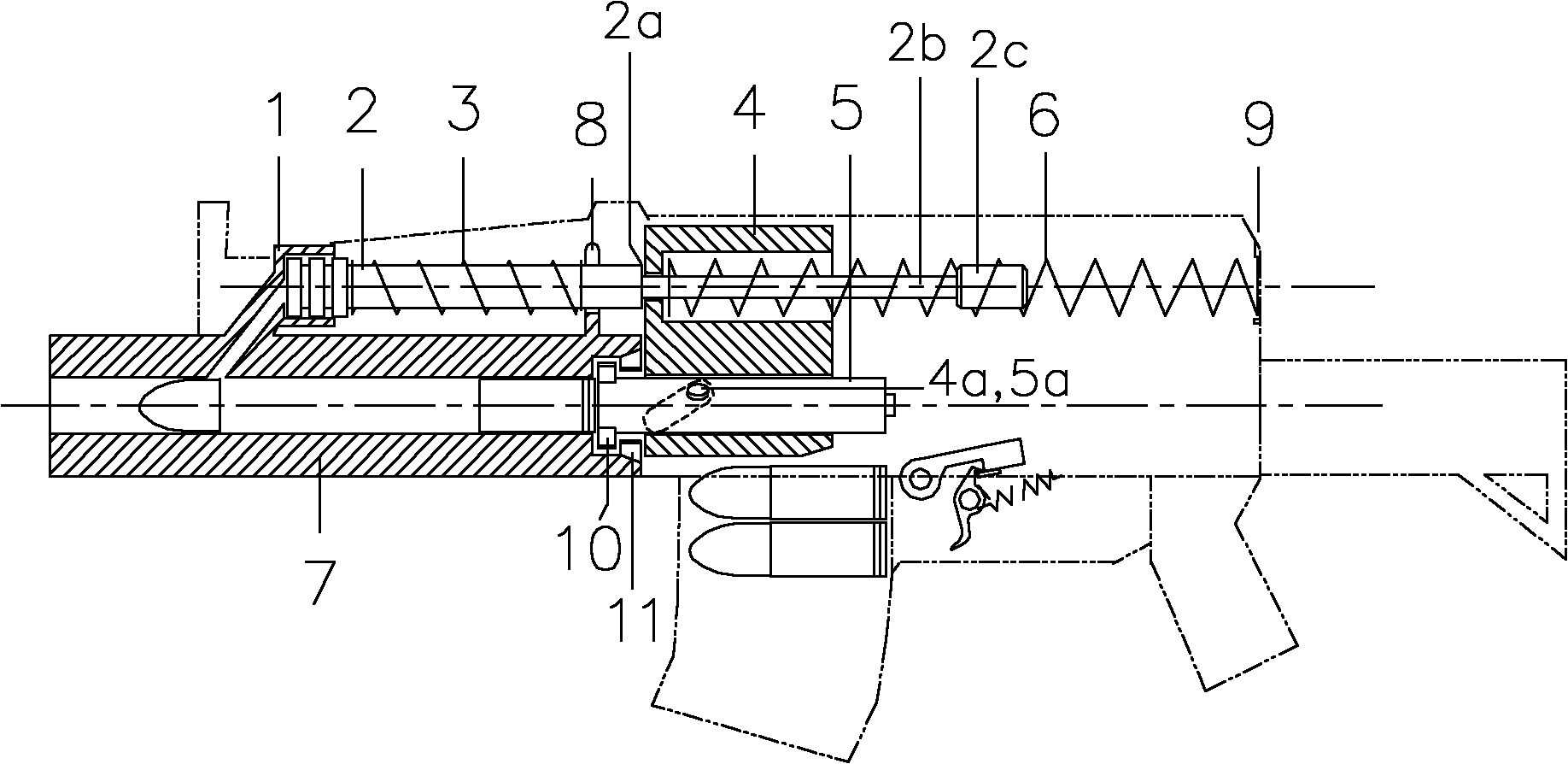

gas delayed recoil method

InactiveCN102288070AEasy to assembleReduce recoilGas turbine plantsRocket engine plantsRamjetCombustion chamber

One involves a gas delayed recoil method. This method is applied to: 1. Weapons with any caliber, chamber pressure and muzzle velocity can be launched with low recoil or recoilless. 2. Gas turbine engines, ramjet engines and rocket engines. As a combustion chamber subsystem, the working medium is changed from a constant pressure combustion mode to a constant volume combustion mode with higher thermal cycle efficiency. A piston is assembled in the barrel of the weapon (that is, the gun barrel or gun barrel). When the gunpowder gas in the barrel burns and expands to do work and launch the projectile, the piston is simultaneously pushed to move along the axis; when the "bore pressure-time curve" of the barrel Certainly, the special structural design of the piston allows the piston to move to the position of the exhaust hole opened on the barrel at the moment when the projectile exits the chamber, so that part of the gunpowder gas is ejected forward with the projectile and part of it is released. The gunpowder gas is ejected backward through this exhaust hole to form a recoil force to counteract the recoil momentum of the barrel.

Owner:王志彬

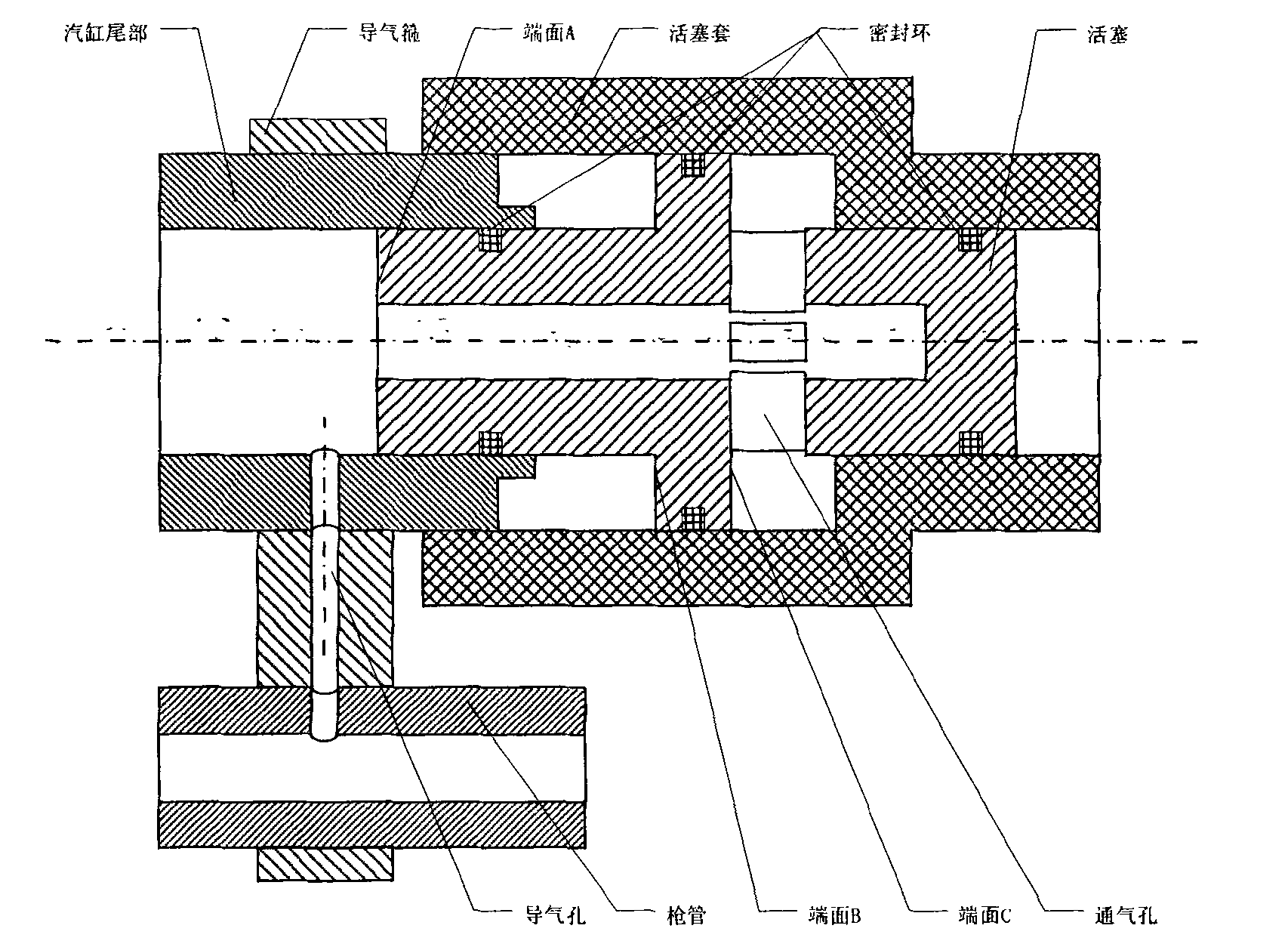

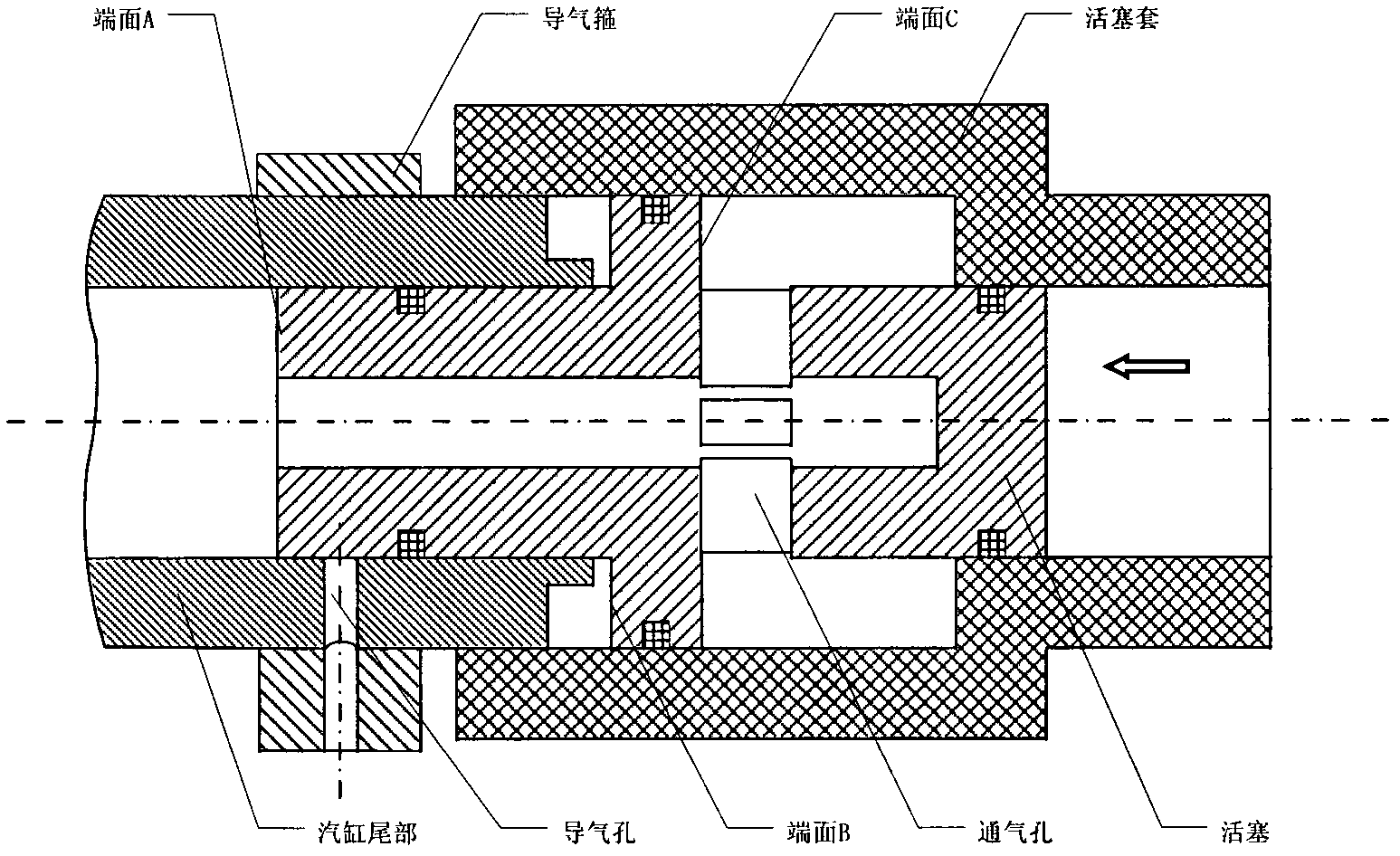

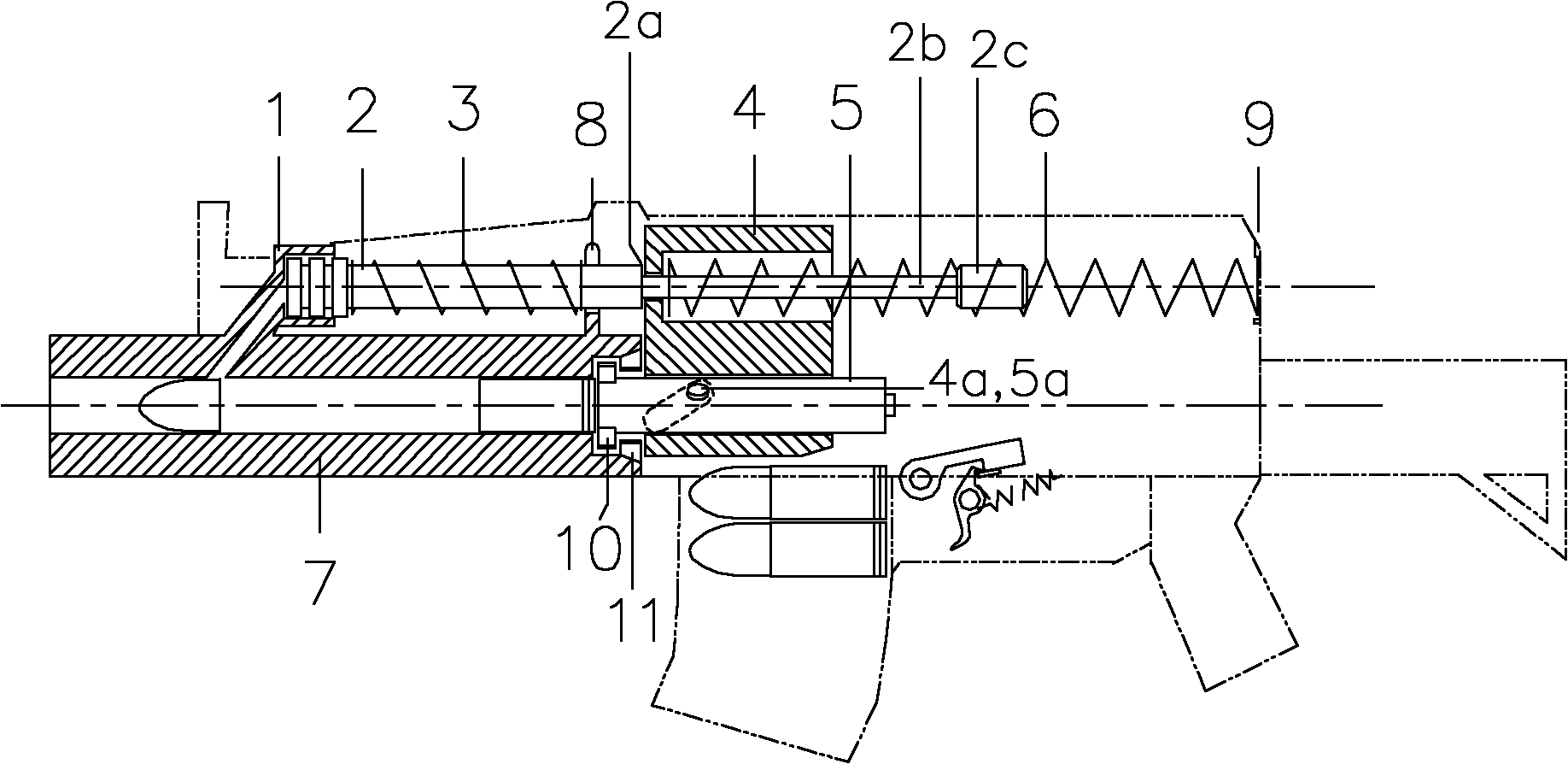

03 type rifle automat

InactiveCN102062559AReduced total recoil travelShorten design lengthBreech mechanismsShoulder-fired smallarmsShootEngineering

The present invention discloses a 03 type rifle automat, comprising a piston sleeve, a piston rod, a piston spring, a gunlock frame, a gunlock and a return spring, wherein the piston sleeve is connected to an extract opening above a gun barrel; the piston rod is disposed in the piston sleeve; the piston spring is disposed on the piston rod between a piston disc at a front end of the piston rod and a spring seat disposed on the gun barrel; the return spring of the piston rod is disposed in a spring hole of the gunlock frame; the other end of the return spring is disposed on a spring seat at aninner wall of a rifle cartridge receiver; a step through hole is disposed at the bottom centre of the spring hole of the gunlock frame; an extension rod connected to a pushing face of the piston rod passes through the through hole; and a tail end of the extension rod is provided with a limit weight for limiting the recoil stroke of the gunlock frame. A locking lug radially projected at the front end of the gunlock is switched and paired with a locking tooth at the tail end of the gun barrel. The automat uses a recoil force of a piston assembly to neutralize the redundant recoil after a gunlock assembly is recoiled in place, and the recoil stroke is compressed. Under a condition that the gun length is determined, the length of the cartridge receiver can be shortened, so that the gunlock iscompact and the weight is reduced; or the length of the gun barrel is increased, so that the initial speed of bullets is increased; a gun body is stable during shoot, and the shooting average of a running fire is improved.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP +1

Hybrid propellant electromagnetic gun system

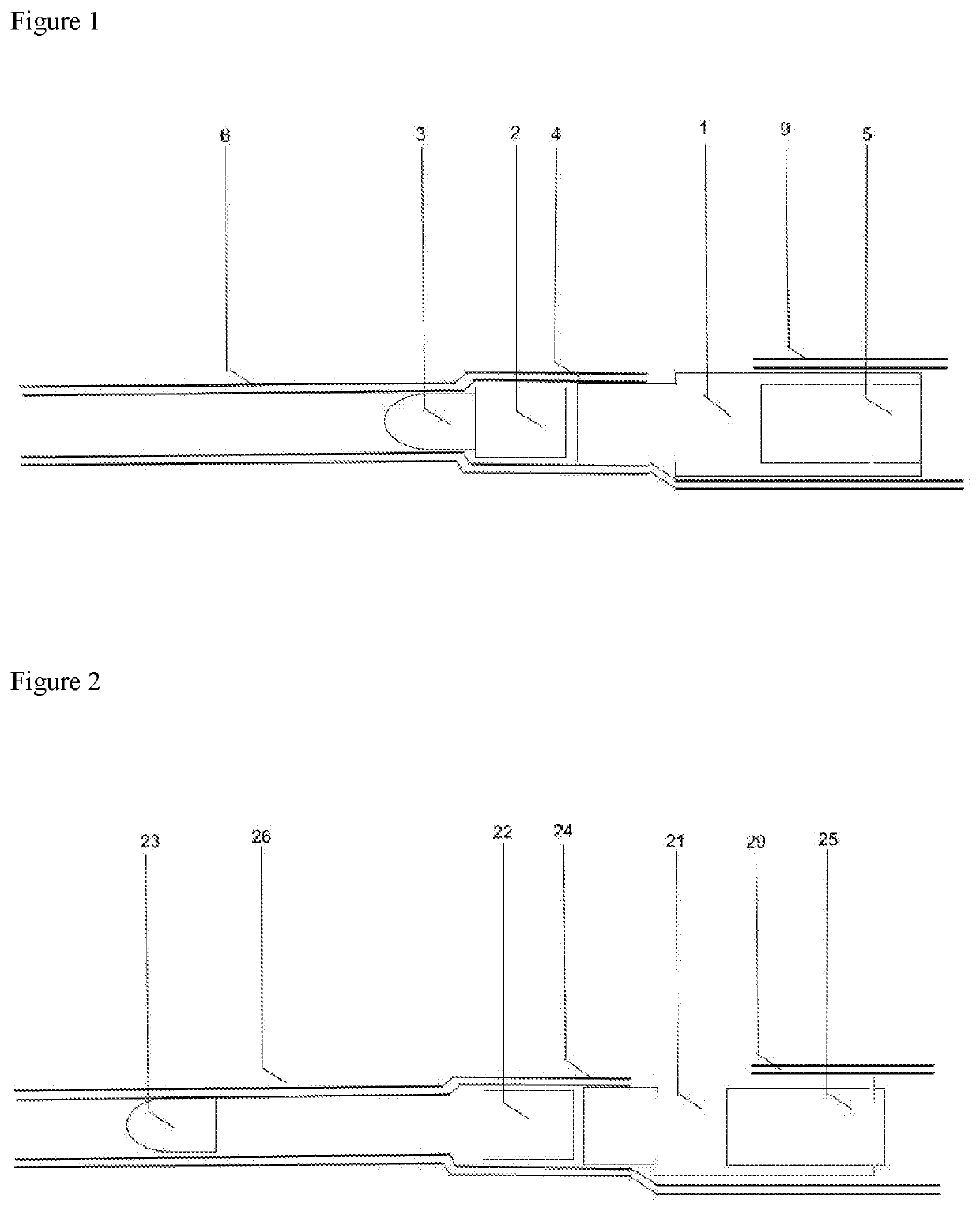

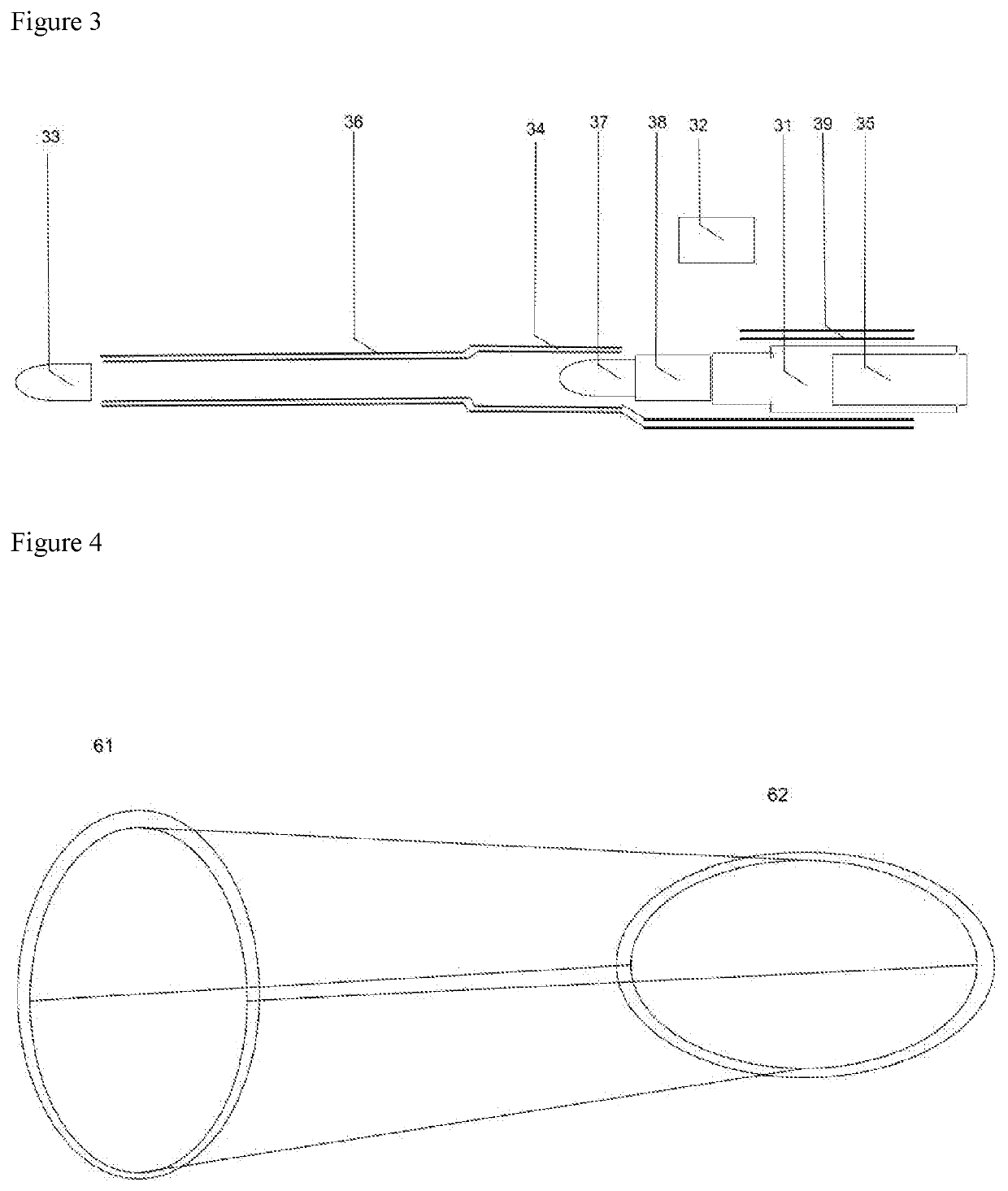

ActiveUS20160341514A1Improve the level ofIncrease projectile velocityElectromagnetic launchersMissile propulsionElectricityCombustion

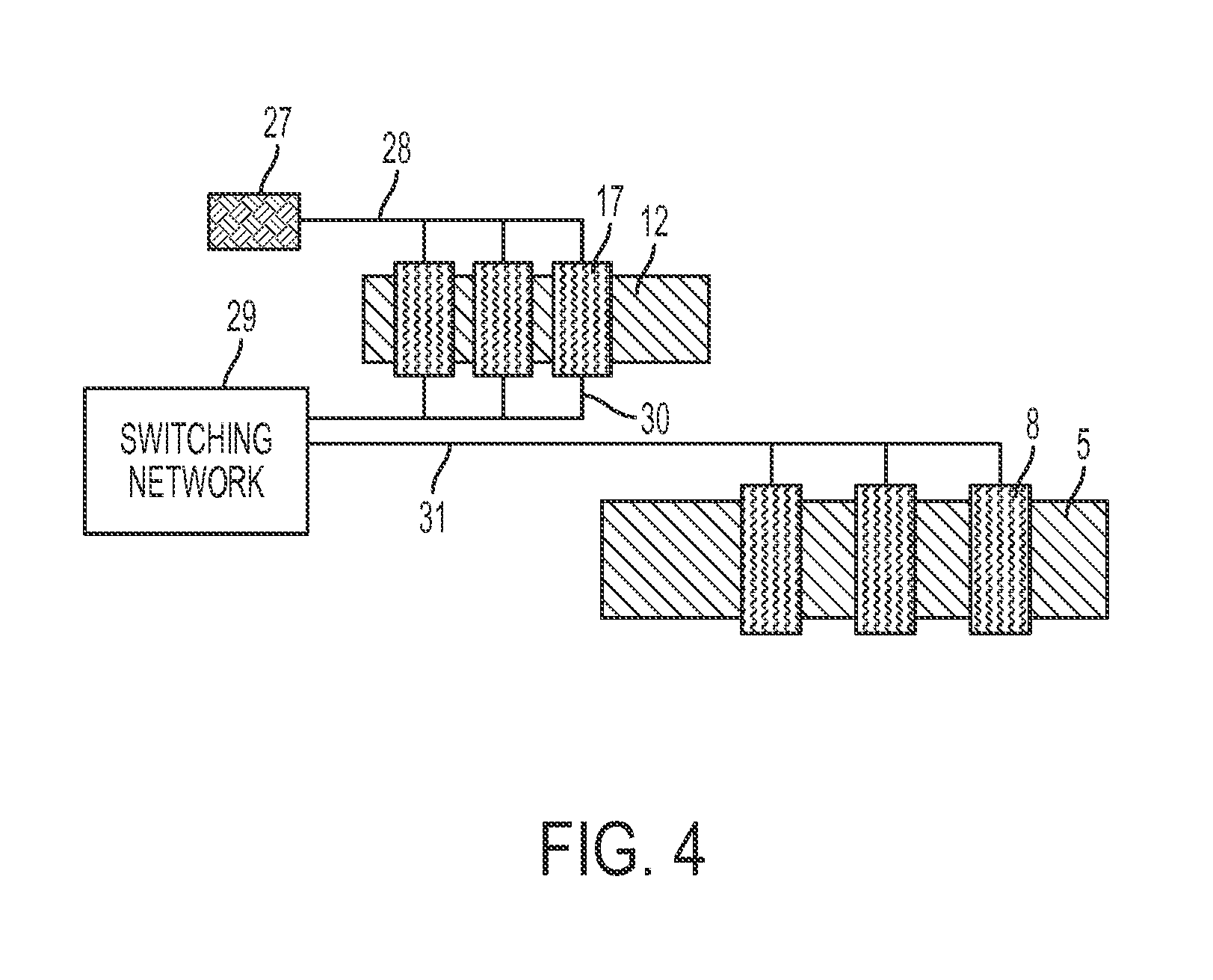

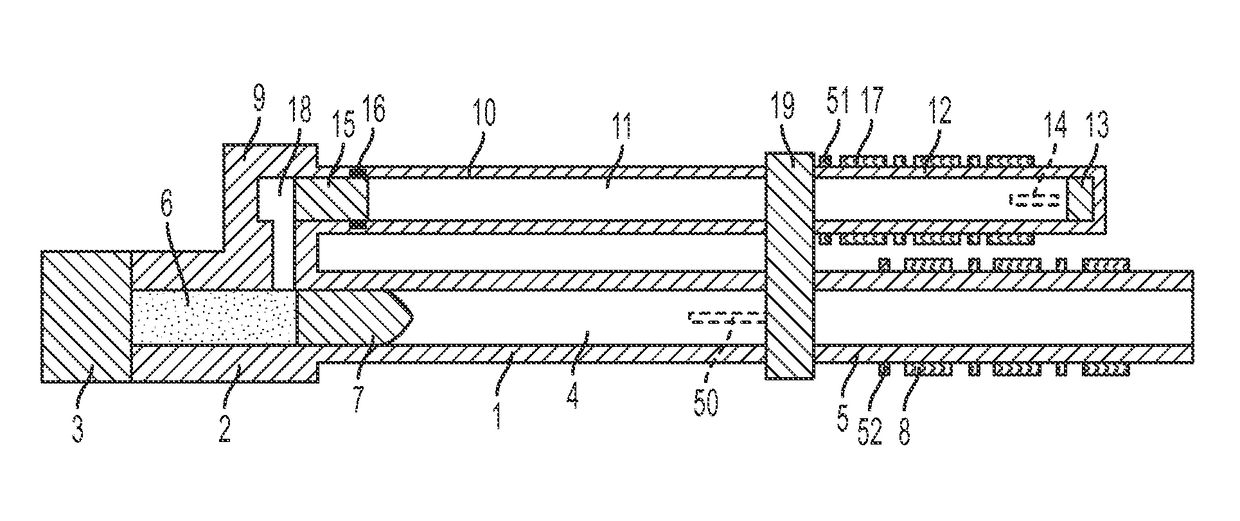

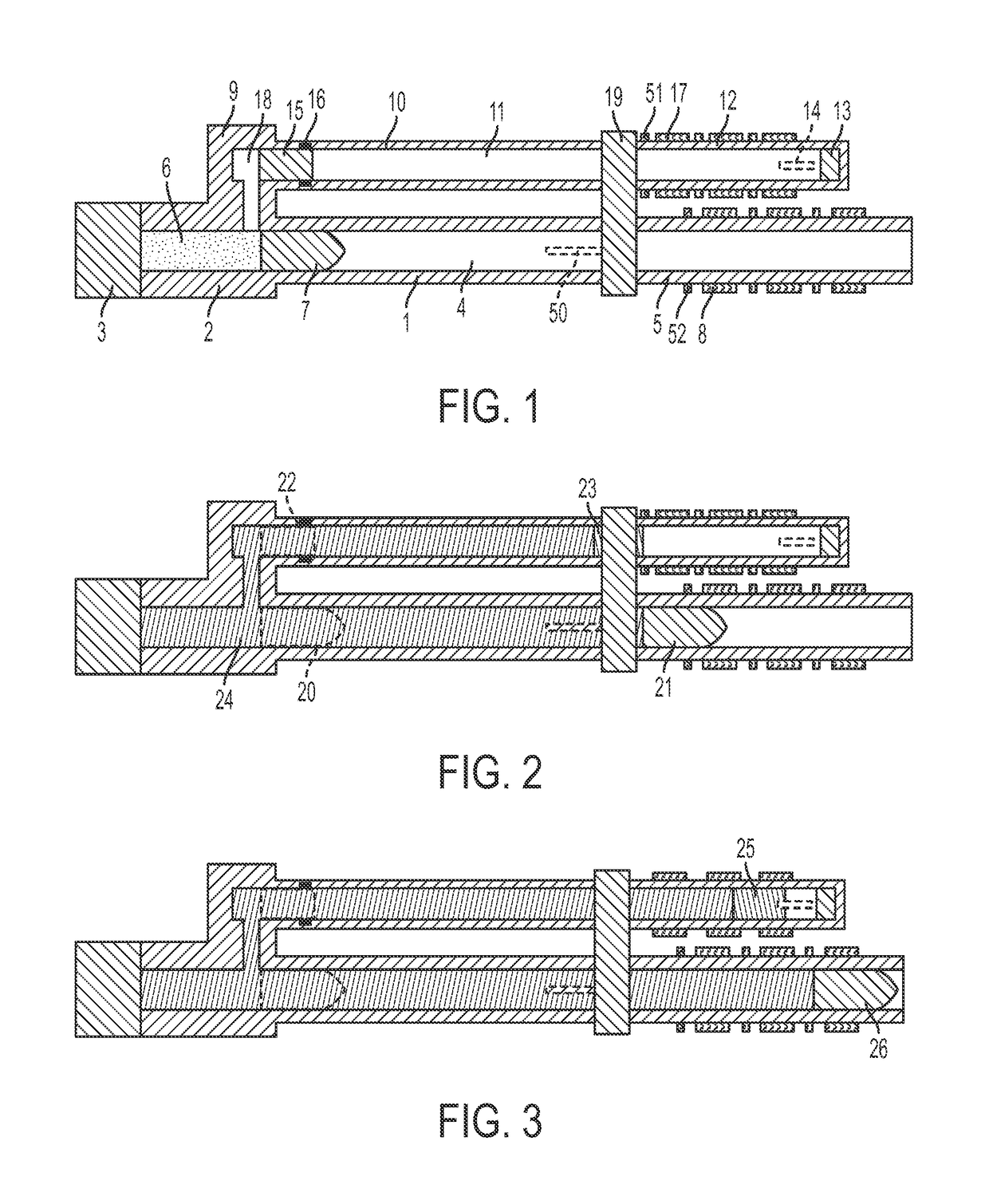

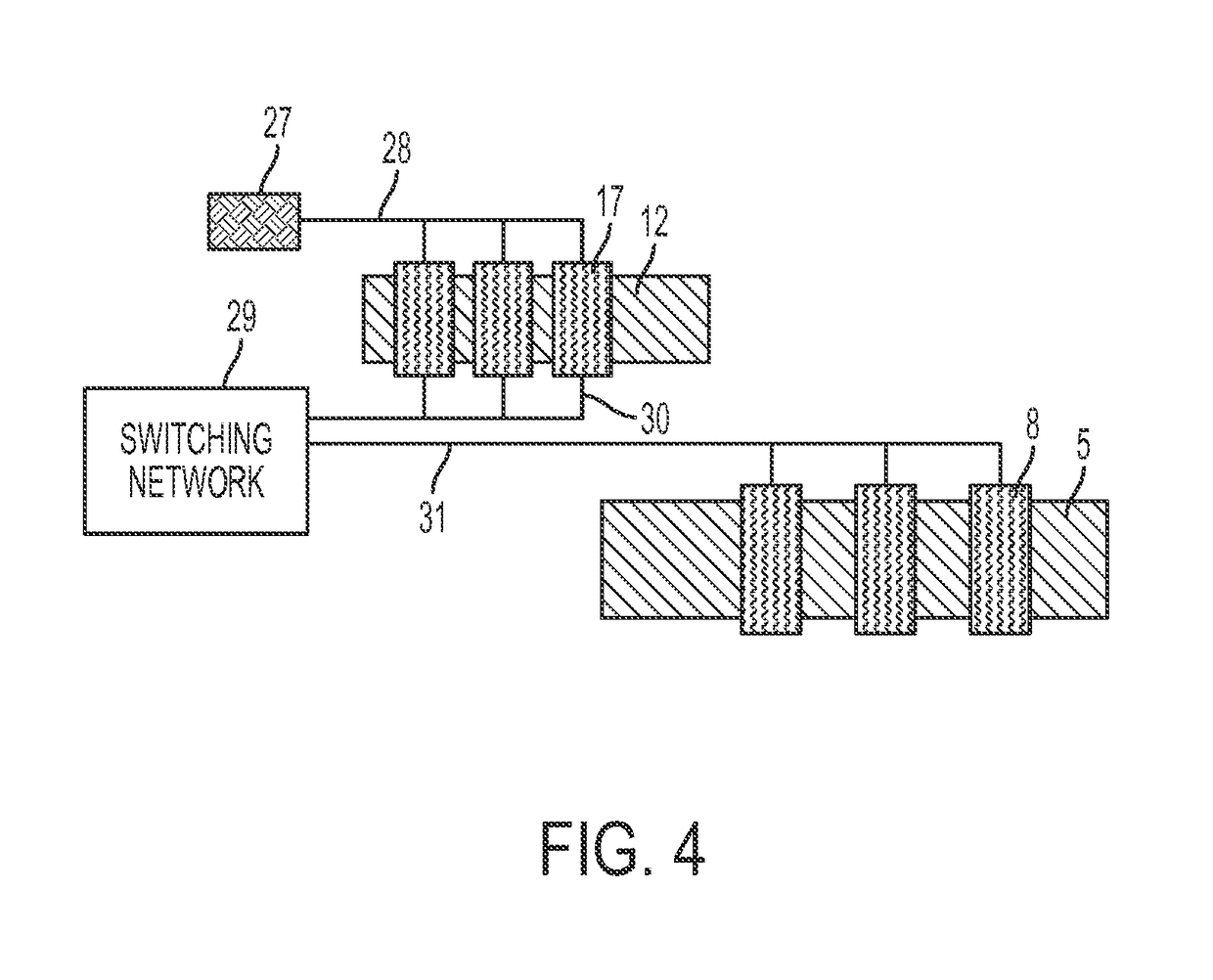

A hybrid gun device composed of two barrels (1,10) that accept energy from combustion of standard propellant (6), one barrel (10) being operative to produce a high intensity electric current to add accelerating energy to a projectile (7) in the second barrel (1) and at least one coil (8) stage to convert energy between electrical and kinetic to cause the projectile (7) to be launched at hypervelocity.

Owner:ENIG ASSOCS

Hybrid propellant electromagnetic gun system

ActiveUS9784523B2Great intensity and durationHigh blast overpressureElectromagnetic launchersMissile propulsionElectricityCombustion

A hybrid gun device composed of two barrels (1,10) that accept energy from combustion of standard propellant (6), one barrel (10) being operative to produce a high intensity electric current to add accelerating energy to a projectile (7) in the second barrel (1) and at least one coil (8) stage to convert energy between electrical and kinetic to cause the projectile (7) to be launched at hypervelocity.

Owner:ENIG ASSOCS

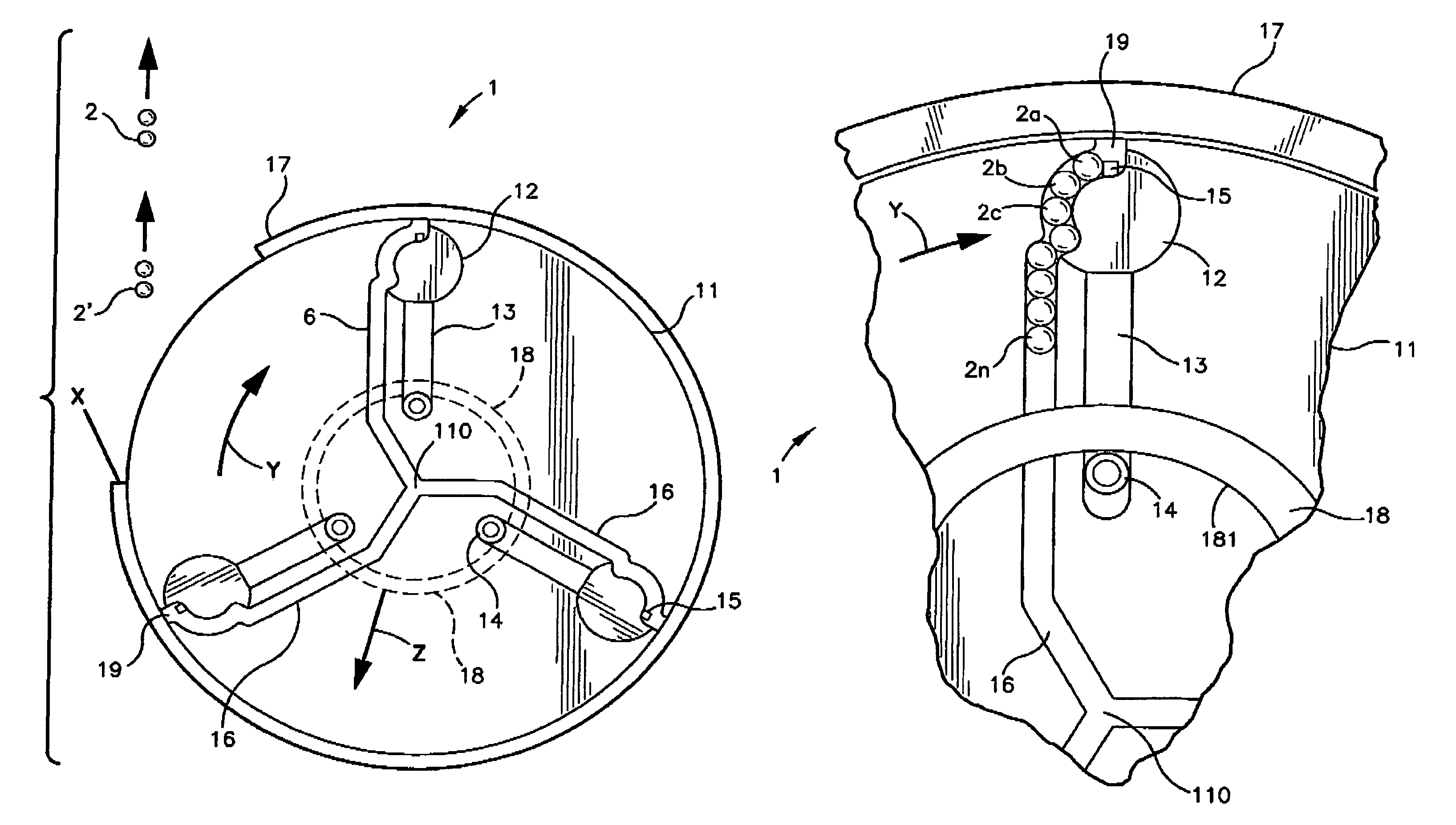

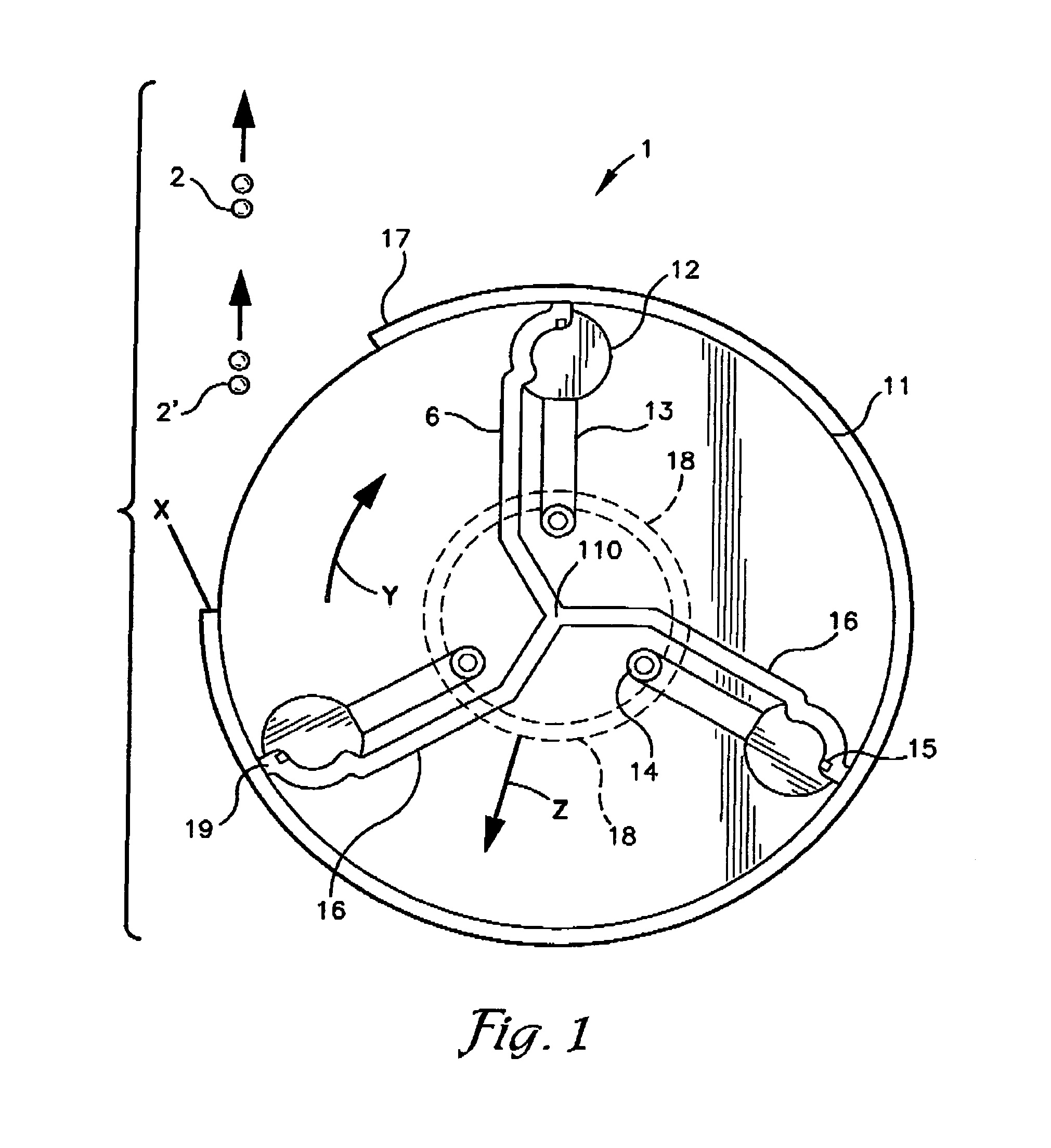

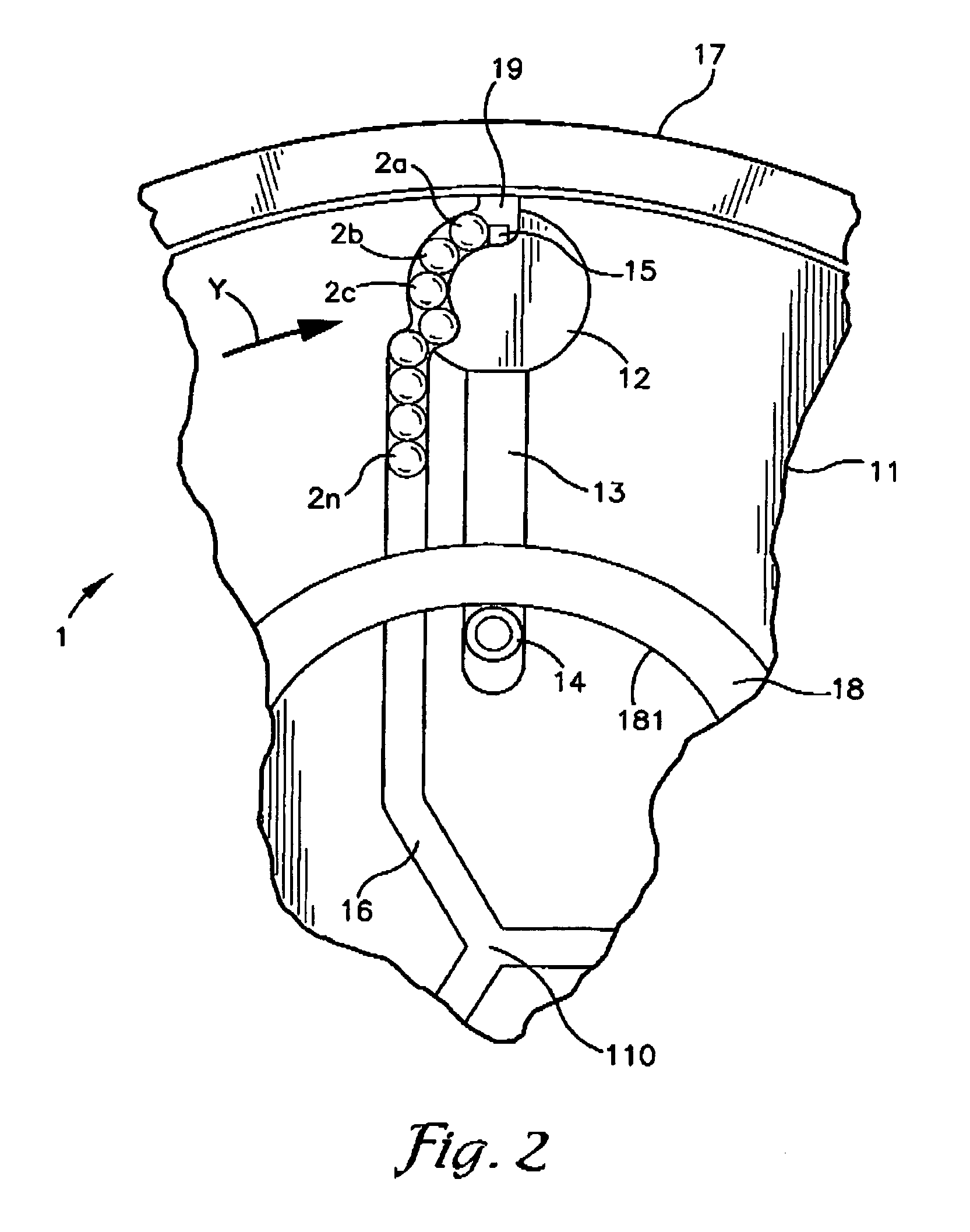

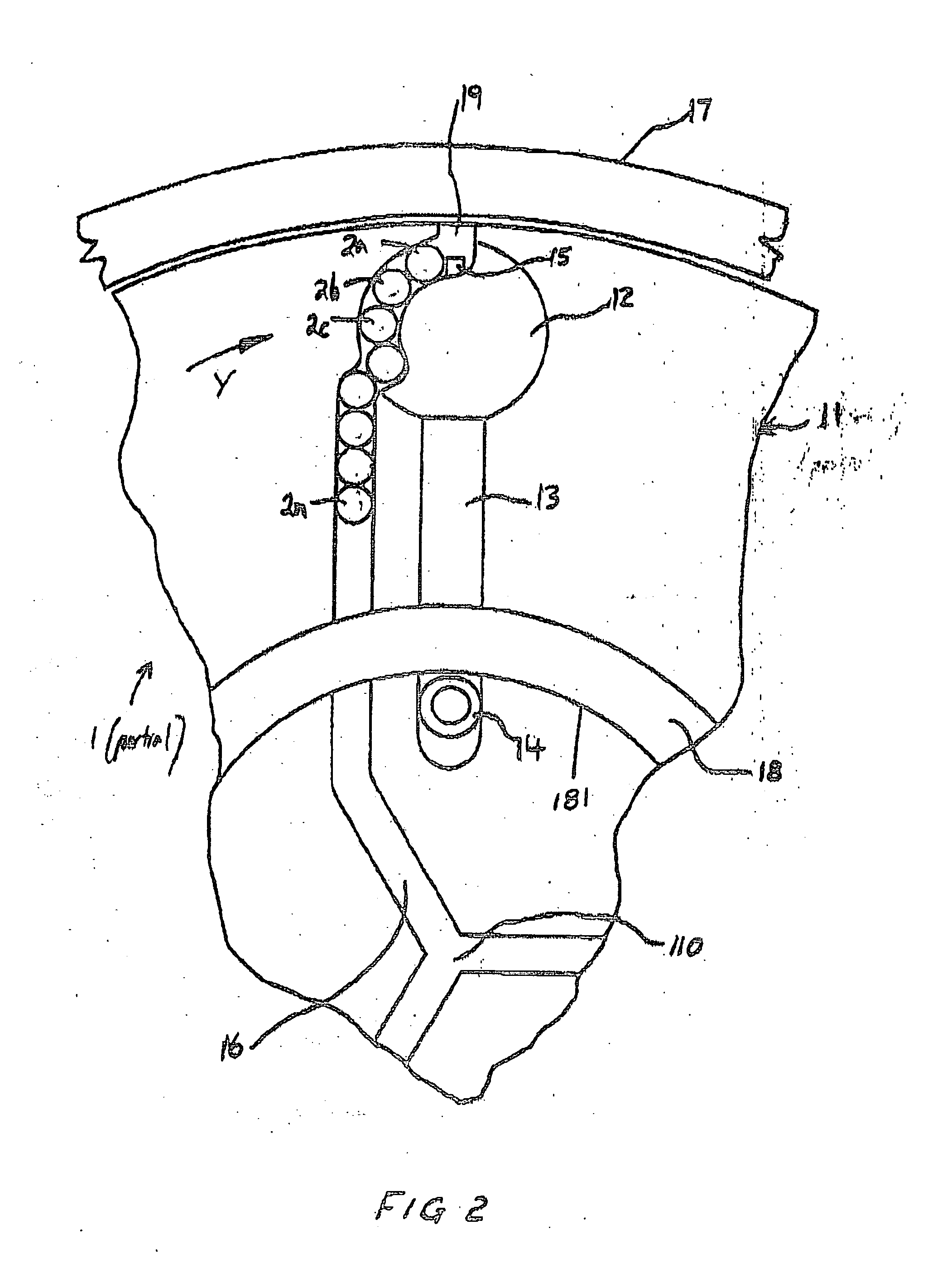

Trigger controlled release of controlled numbers of projectiles at each of controlled number of instances per revolution in a centrifugal propulsion weapon

InactiveUS7497211B2High rateIncrease initial velocitySling weaponsLaunching weaponsControlled releaseRotational axis

Owner:ST GEORGE CHARLES

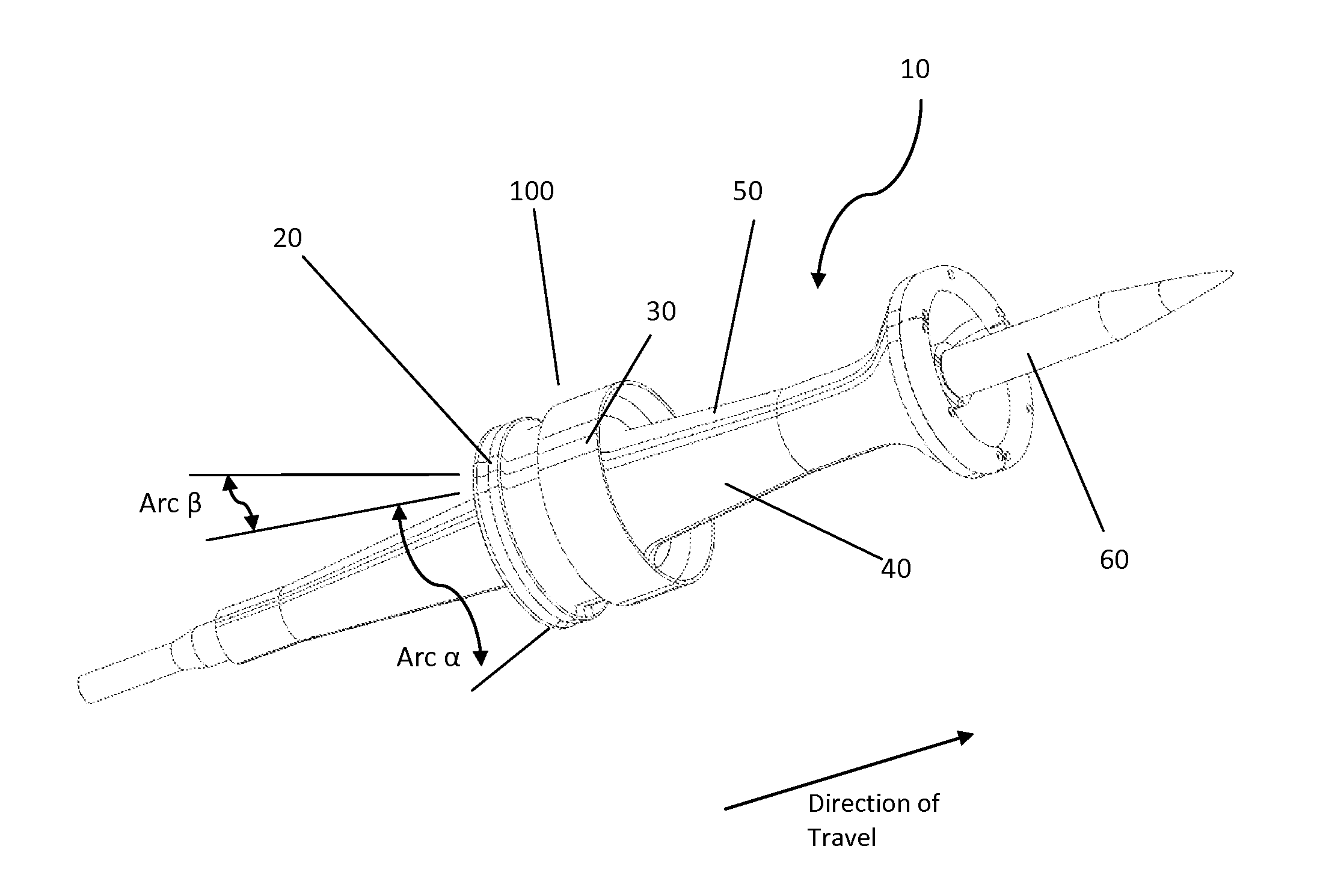

Composite sabot

InactiveUS8695507B1Improve rendering capabilitiesEnhanced armor defeatAmmunition projectilesProjectilesTorsional strengthSmall caliber

A lightweight composite sabot useful in large, medium and small caliber rifled gun systems, wherein each of the sabot segments are reinforced with thin aluminum, or other, metal wedges to increase the torsional strength of the sabot body to survive the torsional forces created when fired from a rifled gun tube. And, which composite sabot also has a metal bulkhead about the periphery thereof, to reduce the spin and resulting hoop stresses, and to help protect the composite material during firing.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

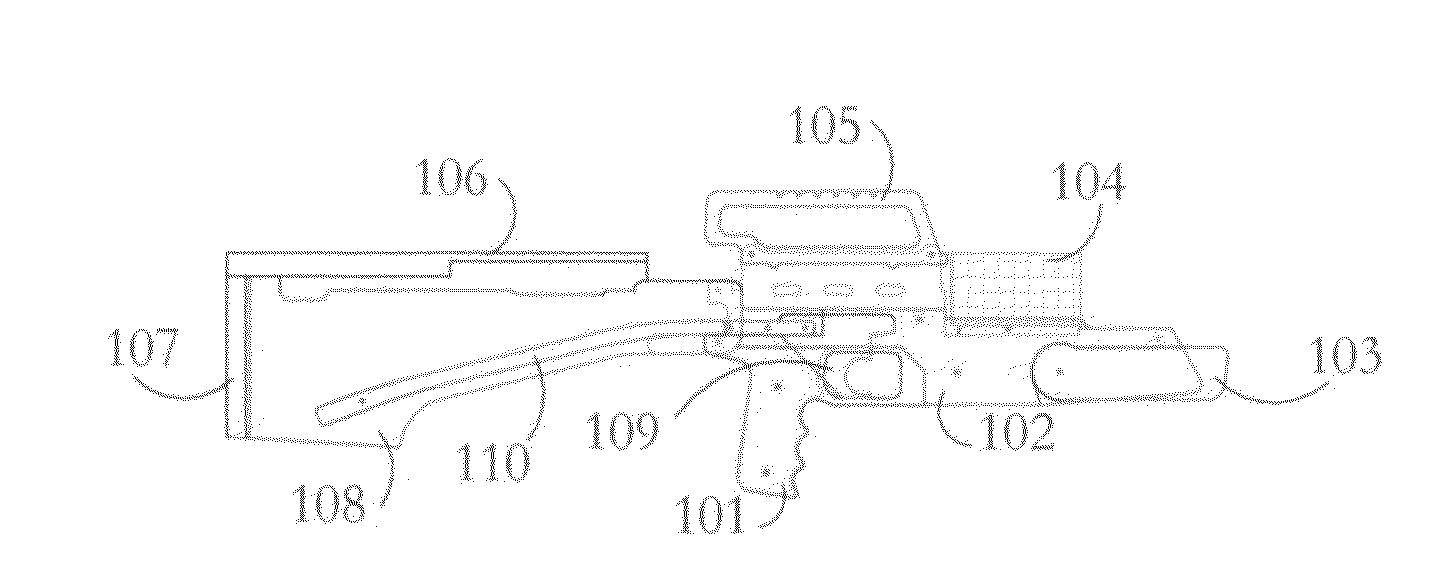

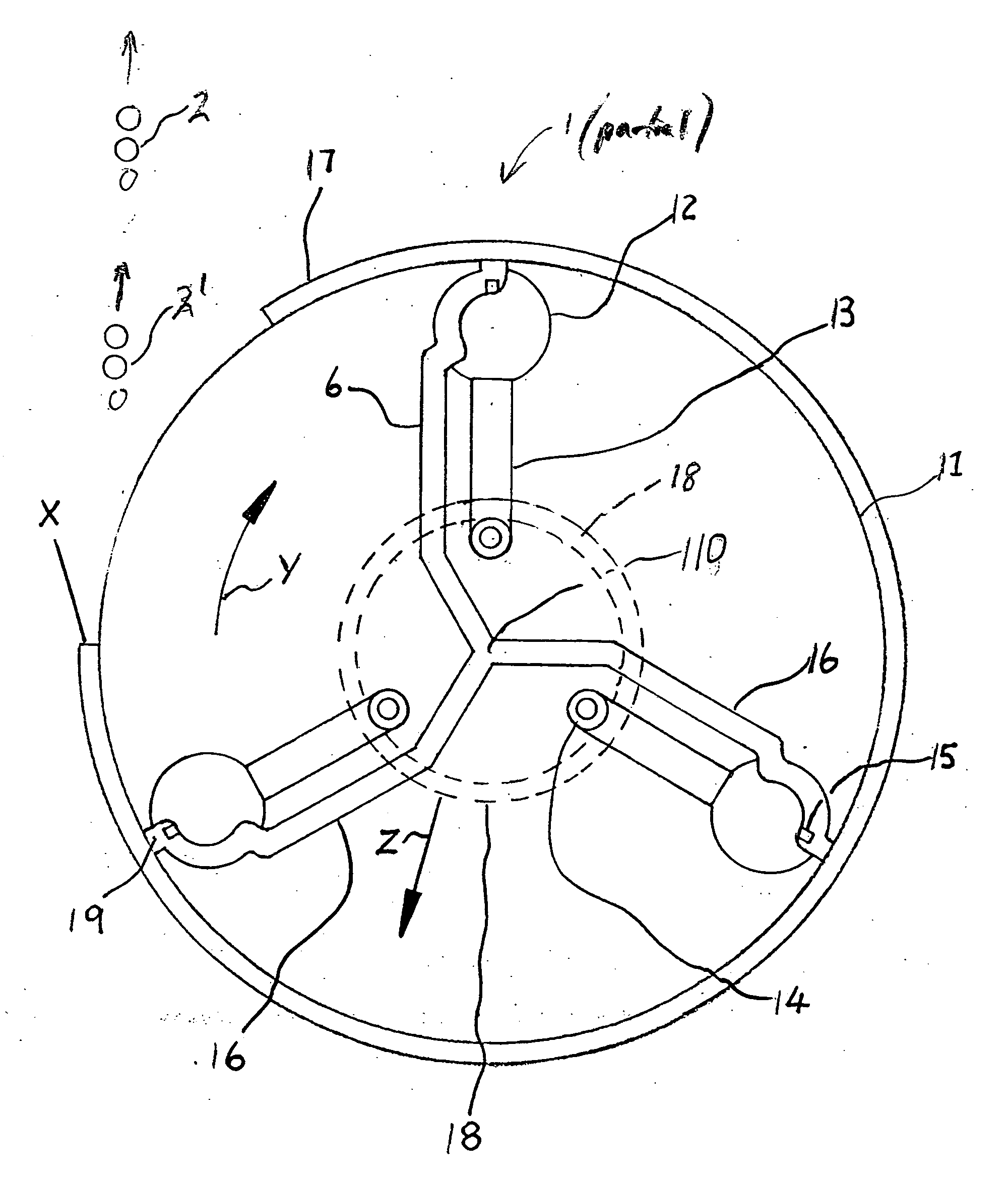

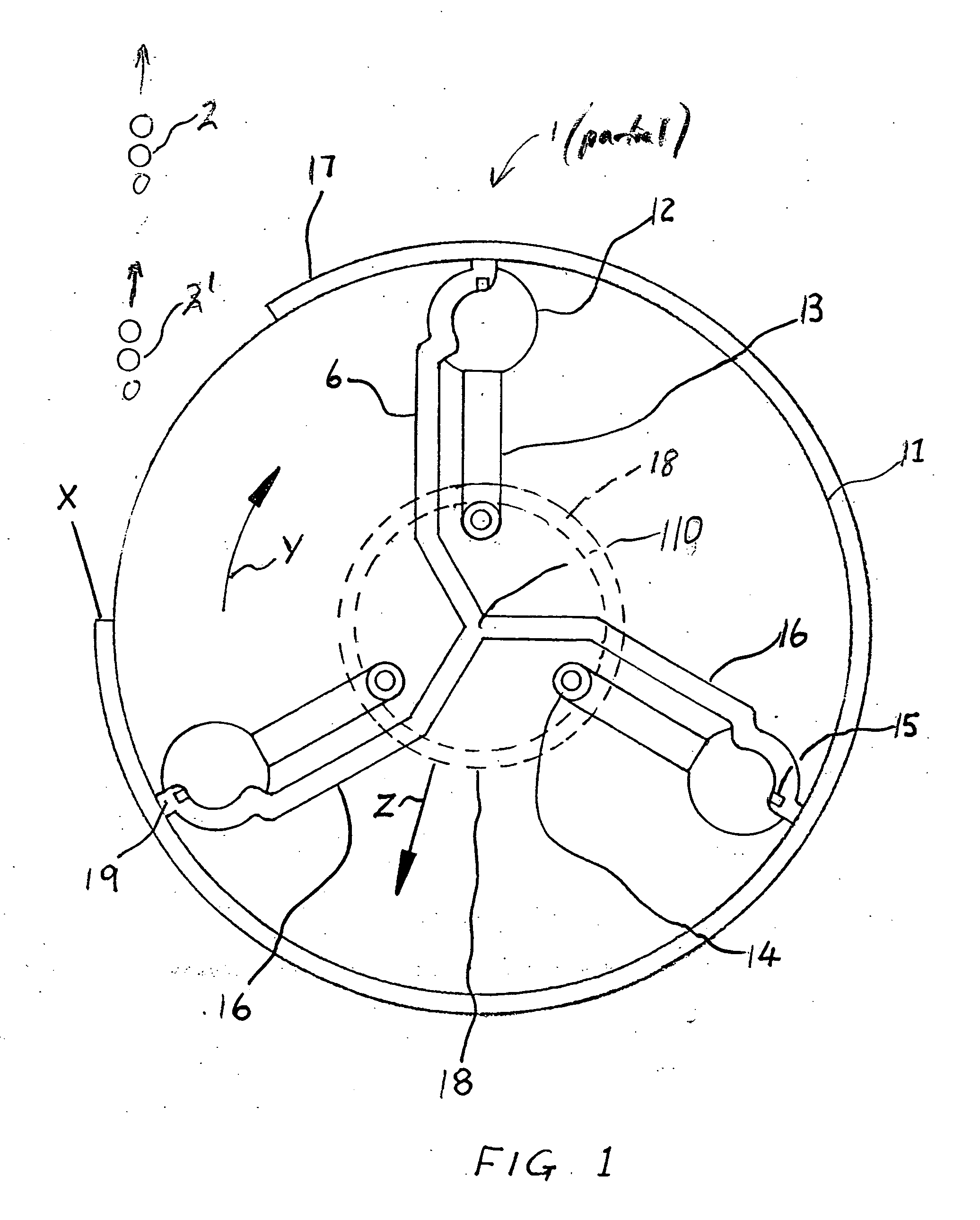

Low-mass-trigger controlled release of projectiles having variable energies and numbers in a centrifugal propulsion weapon, and methods of weapon use

InactiveUS20080257326A1Increase chanceHigh rateSling weaponsLaunching weaponsControlled releaseRotational axis

A weapon 1 peripherally discharging projectiles 2a-2n, normally ball bearings, at sustained high rates under centrifugal force preferably has two opposed members 11 each rotating within a housing, or guide track, 10. Each rotating member 11 preferably has at least two channels, or track, 16 with a radial component within which projectiles 2a-2n received near the center of rotation progress radially outwards until first escaping at 19, and then being ejected at X, under centrifugal force at the periphery of the at least one rotating member 11. A projectile release mechanism controls the timing, locations, and numbers of projectiles released per rotation of the at least one rotating member. This mechanism uses (1) opposed connected elongate members 13, substantially positioned along a radius line and within the at least one member 11 with its distal end protruding within the at least one channel 16 and with a proximal end cam follower 13 contacting the interior circumference 181 of (2) a ring cam 18, non-rotating to the housing 10 and movable between positions both coaxial, and displaced, to the rotational axis of the at least one rotating member 11. The elongate members 13 move (1) radially outward under centrifugal force of the rotation of the at least one rotating member 11 until its distal end protrudes within the at least one channel 16, therein obstructing passage of projectiles 2a-2n along the channel 16 and any ejection of these projectiles 2a-2n from the periphery of the at least one rotating member 11, until (2) the cam follower 14 of the elongate arm 13 contacts during rotation the cam 181 surface of the ring cam 18, pulling the elongate member 13 against centrifugal force radially inwards until its distal end ceases to protrude within the channel 16, losing passage of projectiles 2a-2n along the channel 16 for subsequent escape at 19 and for ejection at X.

Owner:ST GEORGE CHARLES

Long-tail type rifle grenade

InactiveCN101929826AIncrease profitIncrease muzzle velocity and rangeAmmunition projectilesProjectilesProduct gasRifle

The invention relates to a rifle grenade which can increase the initial speed and the range by one time, has quite simple structure and is provided with a slender rod (a grenade tail) which is connected with a fighting part, provided with a sealing device at the tail end and used as a part for simultaneously bearing the powder gas thrust and providing flight stability.

Owner:强晓明

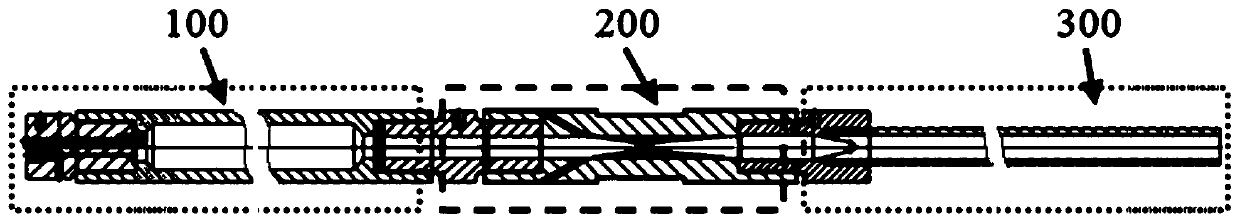

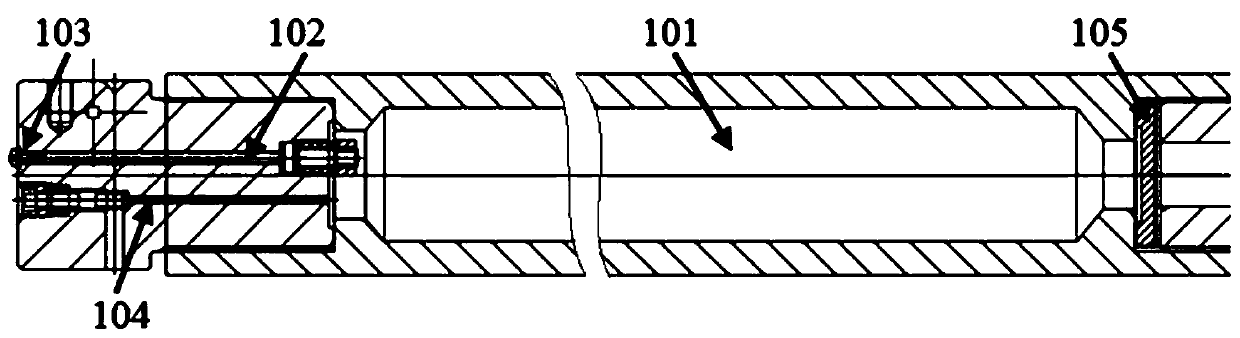

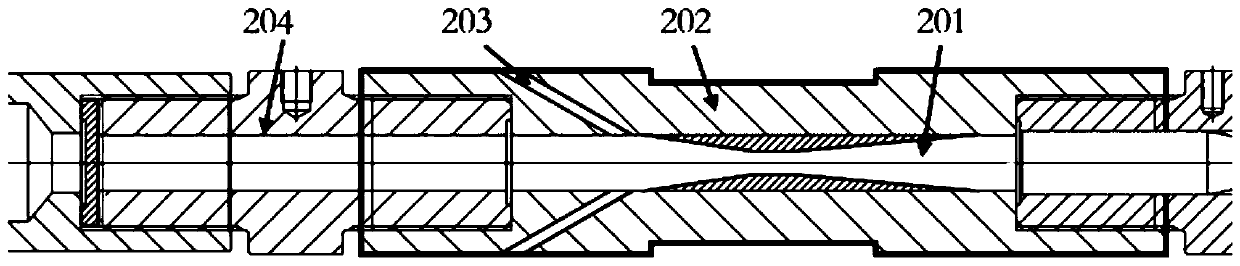

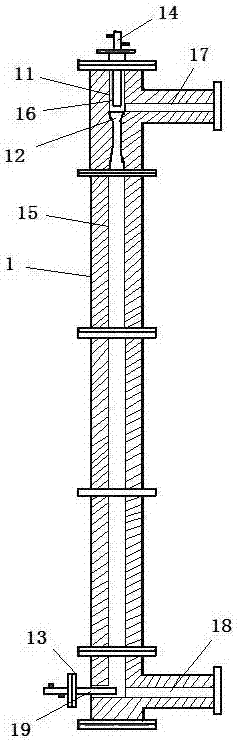

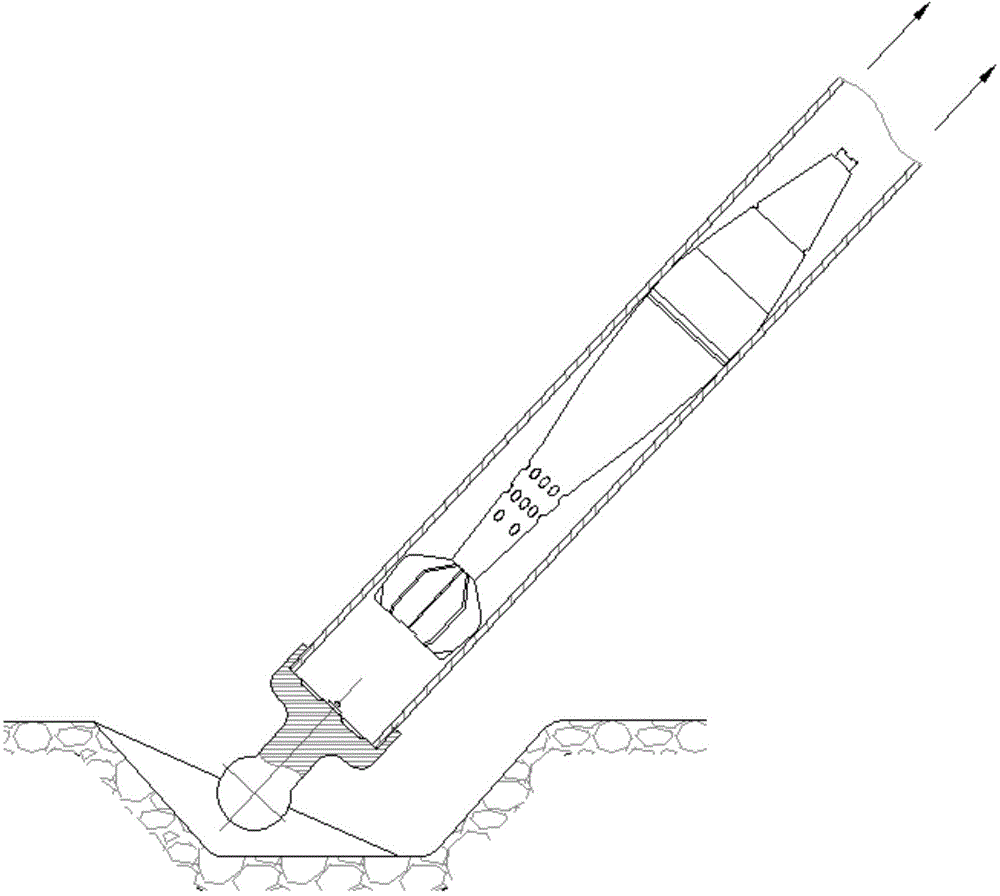

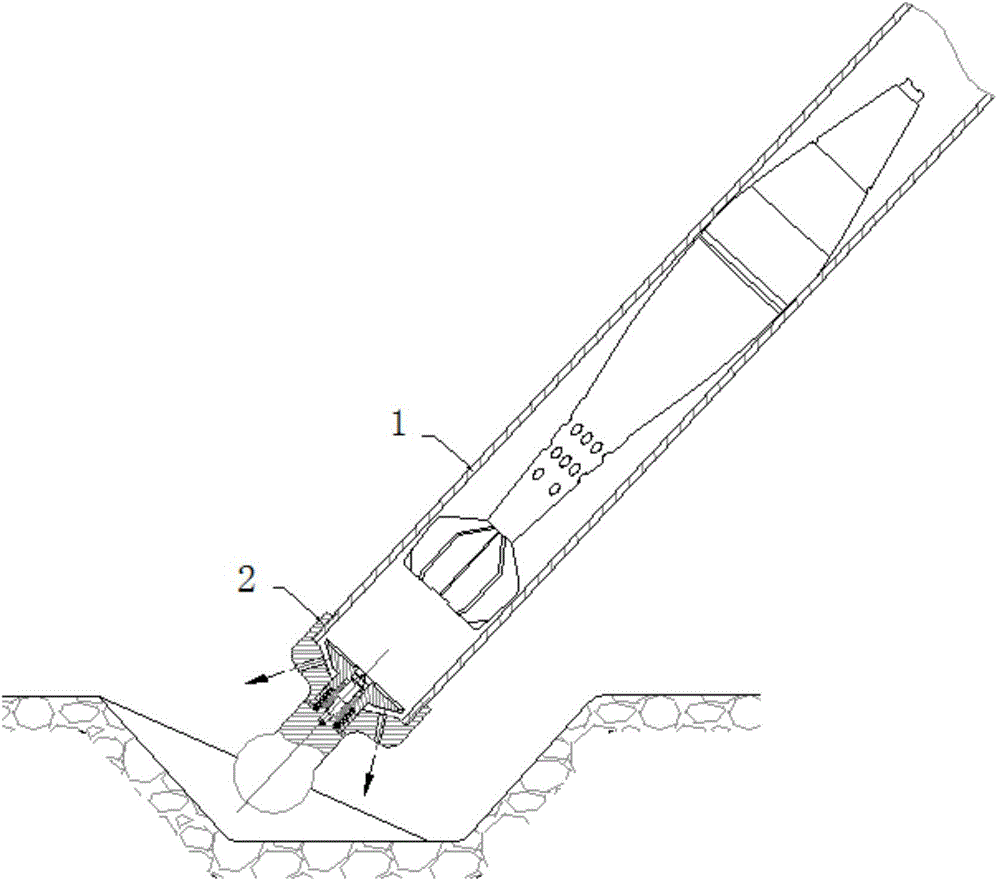

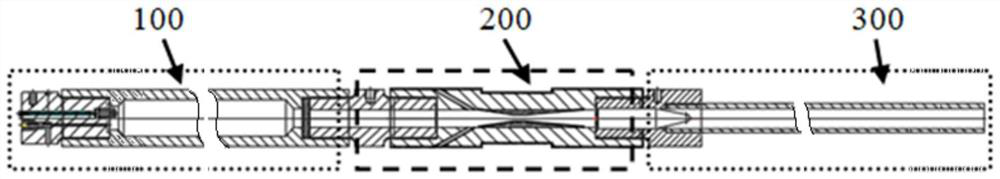

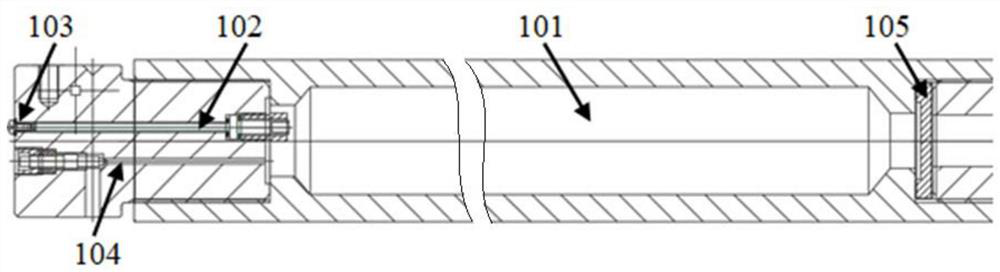

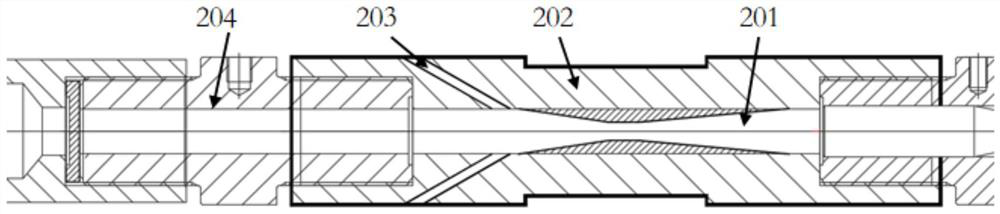

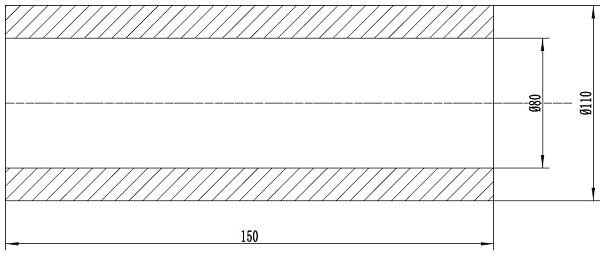

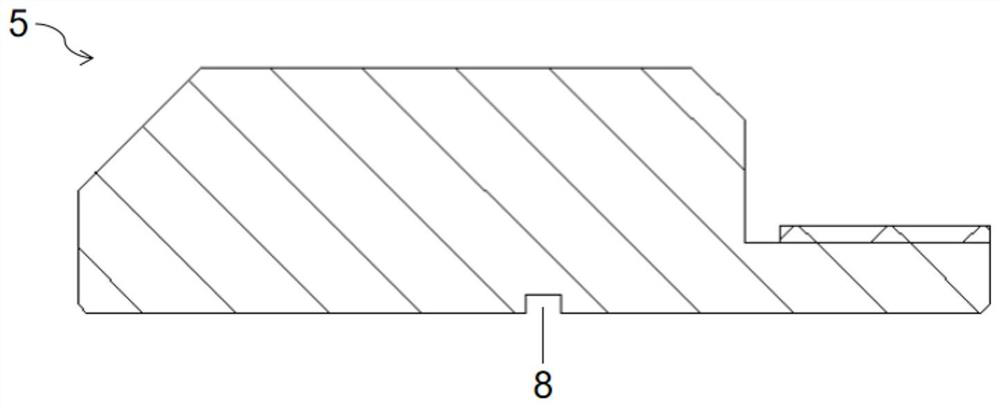

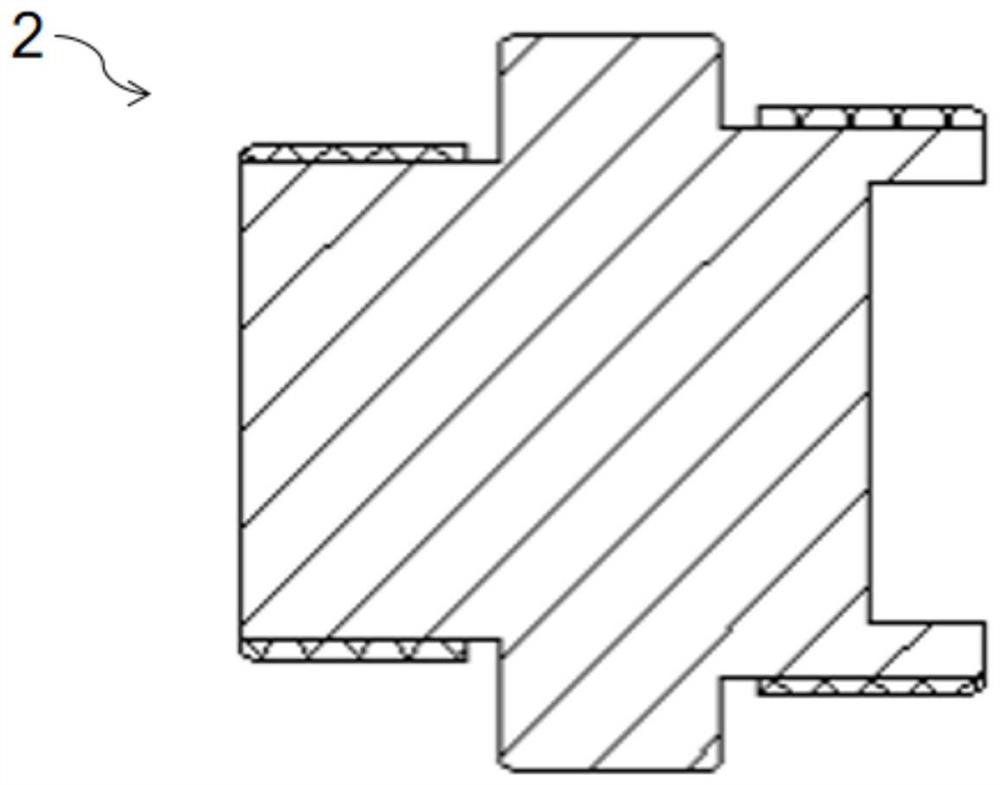

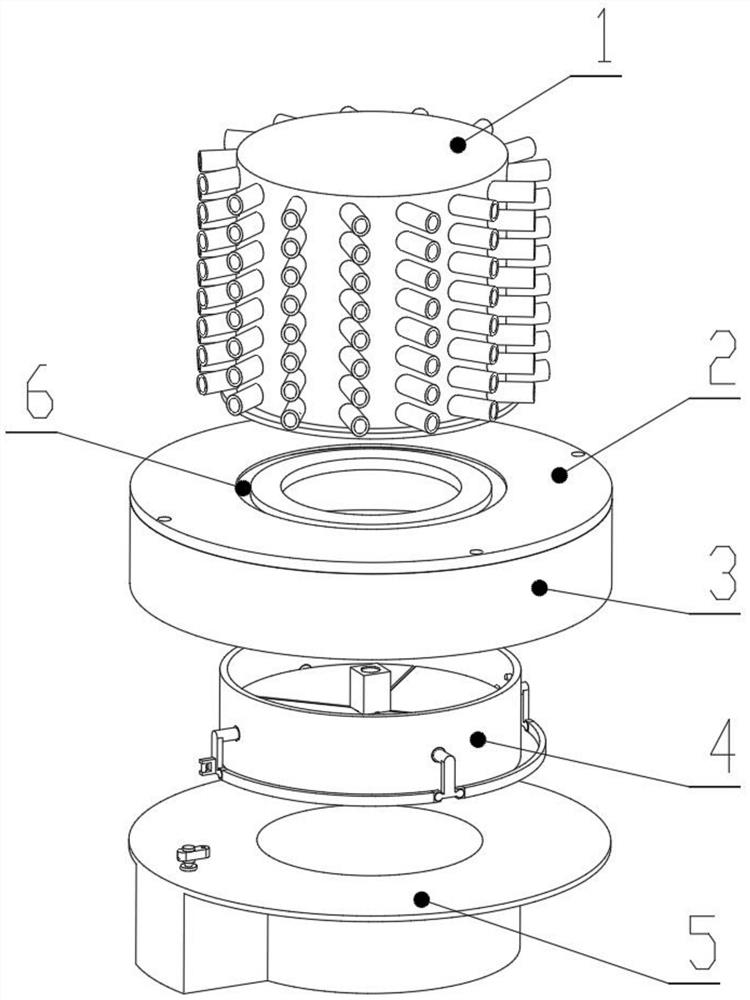

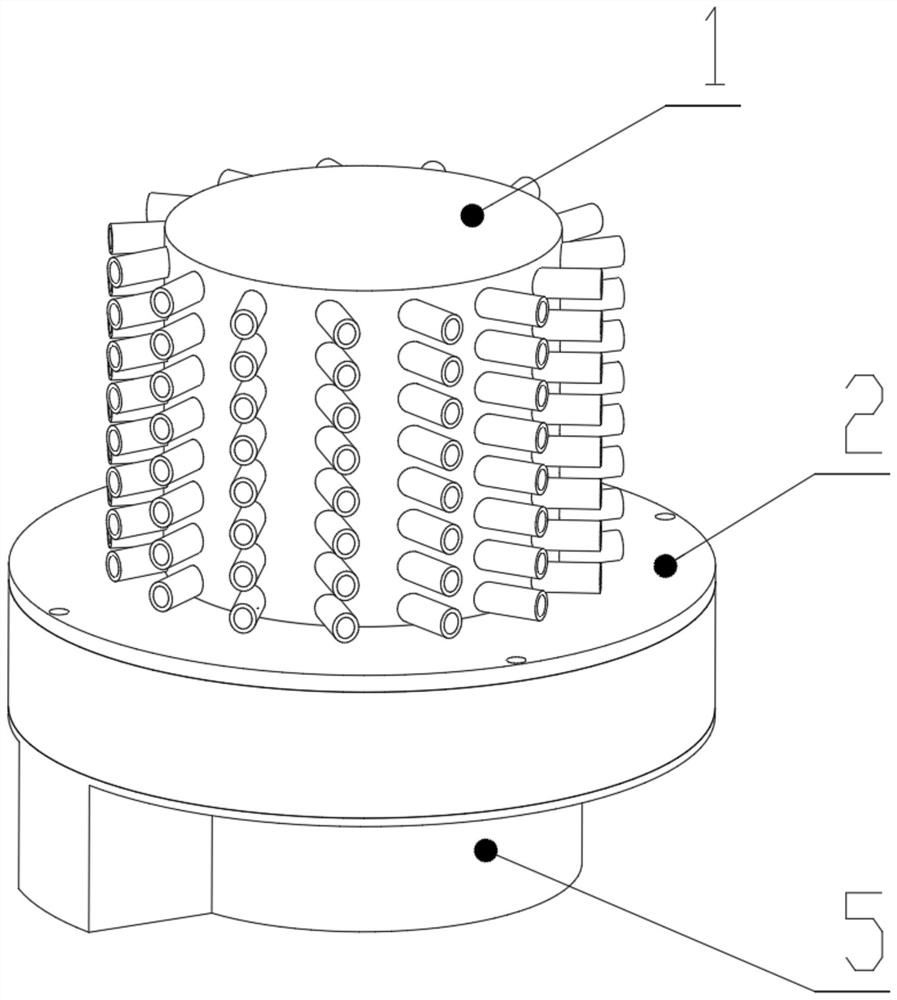

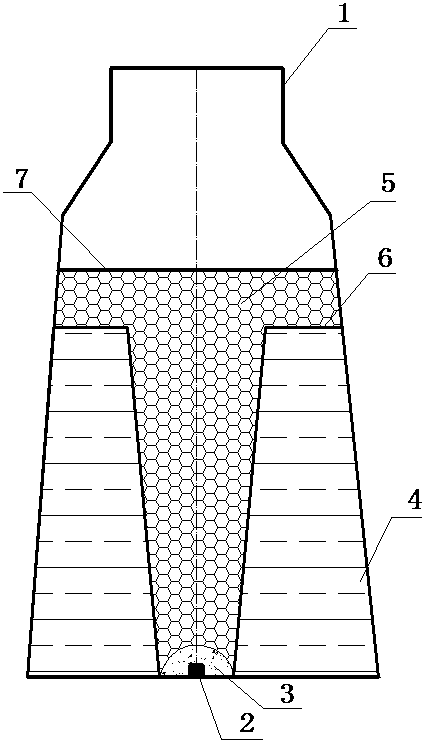

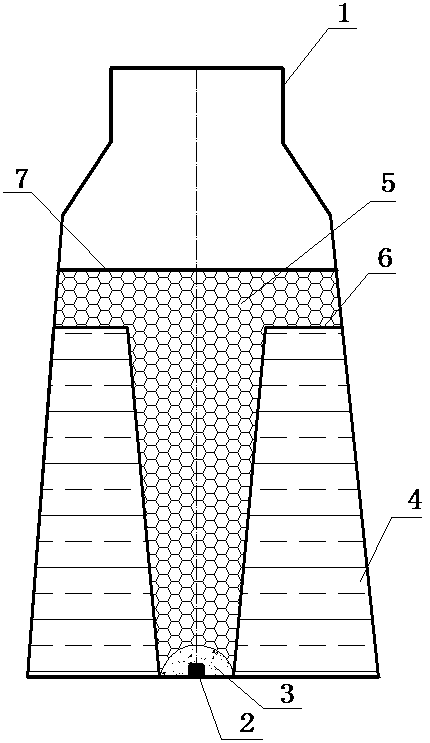

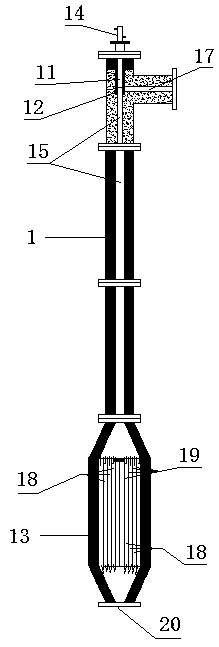

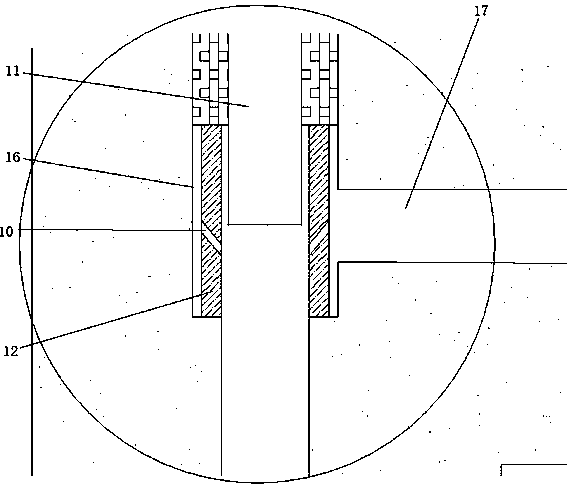

Cannon body structure of supercritical carbon dioxide gas cannon

ActiveCN111256531ASmall recoilReduce aerodynamic lossesCompressed gas gunsEmergency rescueMechanical engineering

The invention provides a cannon body structure of a supercritical carbon dioxide gas cannon. The cannon body structure is used for emergency rescue in earthquake relief work, emergency relief and other occasions, and is composed of three parts, namely a carbon dioxide liquid filling assembly, an accelerating section assembly and a cannon barrel assembly. According to the cannon body structure, magnesium powder in a heating pipe releases a large amount of heat after being ignited through an electric spark, so that the temperature and the pressure of carbon dioxide in the liquid filling pipe aresharply increased, and the supercritical state is quickly achieved; when the pressure exceeds the damage limit of a rupture disk, the carbon dioxide is rapidly jetted to push a cannonball; and an acceleration connecting section is composed of an acceleration section and a recoil section, so that the outlet speed of the cannonball is remarkably increased, and meanwhile the length of a cannon barrel is remarkably reduced. The cannon body structure has the advantages of simple structure, safety, reliability, rapidness in filling, portability and high efficiency, and is suitable for emergency rescue.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

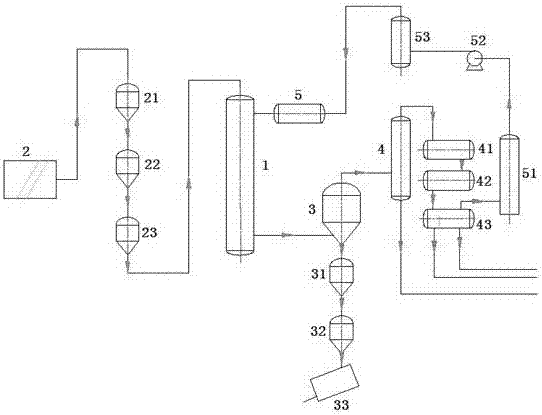

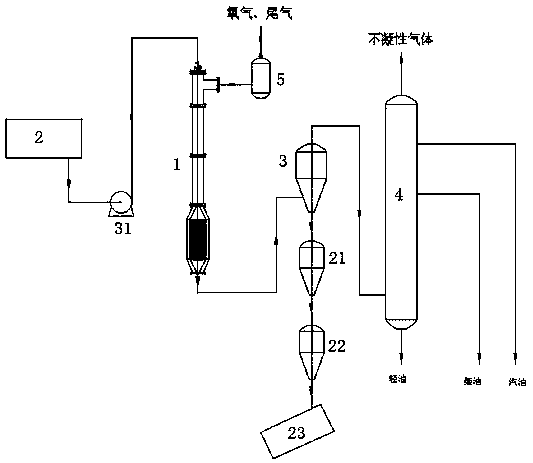

High-temperature pyrolysis reactor and system and method for producing oil and carbon black by waste tire pyrolysis

ActiveCN107384458ARaise the gas temperatureFast pyrolysisProductsReagentsCooling towerProcess engineering

The invention discloses a high-temperature pyrolysis reactor which comprises a reactor body, a rubber powder spray pipe, a nozzle, a mixer, a cooling device, a chilling air nozzle and the like. The invention further discloses a system for producing oil and carbon black by waste tire pyrolysis. The system applies the high-temperature pyrolysis reactor and further comprises a waste tire crushing system, a conveying system, a flying ash filter, an absorption cooling tower, a carbon black collecting system, an oil and gas cooling separation system and a tail gas recovery system. The invention further discloses a method for producing oil and carbon black by waste tire pyrolysis, and the method applies the system for producing oil and carbon black by waste tire pyrolysis. Waste tire powder is sufficiently mixed and pyrolyzed by the aid of rapid high-temperature injection and mixing pyrolysis, and the high-temperature pyrolysis reactor has the advantages of simple technological process, compact device structure, less investment, good oil quality and the like.

Owner:柳州淦源环保科技有限公司

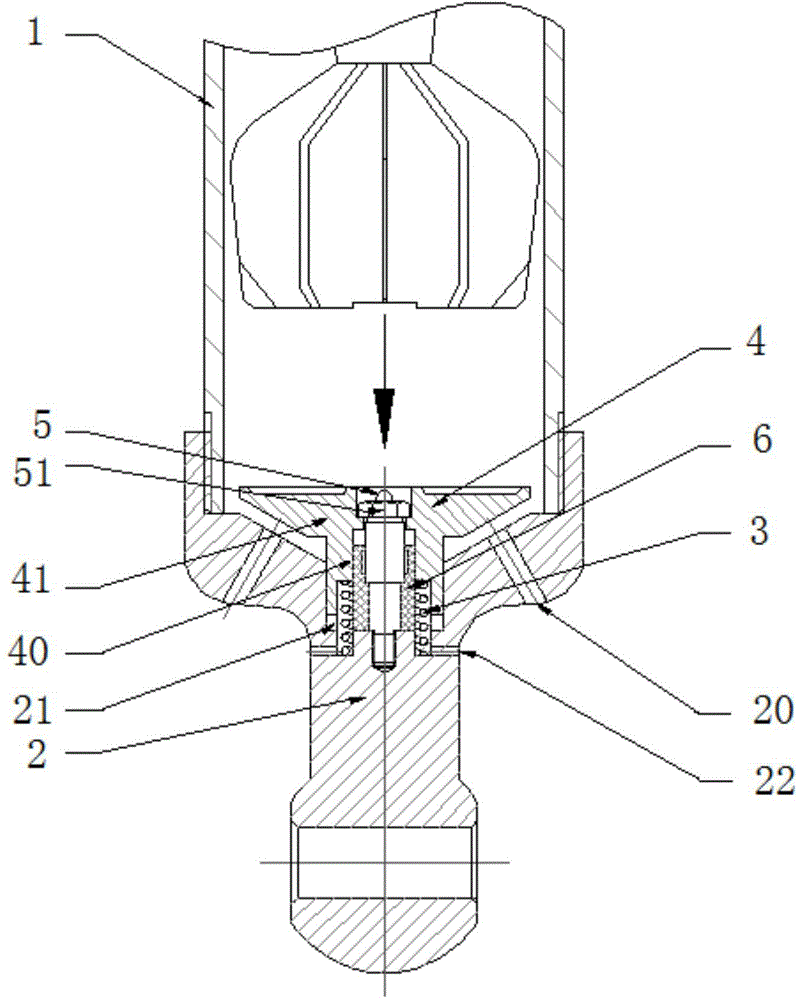

Mortar launching device

The invention discloses a mortar launching device. The device comprises a mortar breech, an elastic part, a blocking part, and a barrel shaped tube with a bore, wherein the breech is mounted at one end of the tube; a firing pin positioned in the bore is arranged on the breech; the blocking part comprises a shaft sleeve, and a heading which is arranged at the outer side of the shaft sleeve; the shaft sleeve sleeves the firing pin; the first end of the elastic part is arranged against the blocking part, and while the second end of the elastic part is arranged against the breech; at least one first exhaust hole is formed in the breech; when the elastic part is in the original state, the first exhaust hole is communicated with the bore; when the elastic part is compressed, the first exhaust hole is blocked through the beading. With the adoption of the device, a mortar can reliably downwards slide; the inside diameter of the tube under small gaps is adopted on the premise that the air can be exhausted through the first exhaust hole in the breech; therefore, the initial speed of the mortar can be increased, the firing range can be expanded, and meanwhile, the launching precision can be efficiently improved.

Owner:GUANGZHOU INST OF RAILWAY TECH

Cannon body structure of a supercritical carbon dioxide gas cannon

The invention provides a cannon body structure of a supercritical carbon dioxide gas cannon, which is used for emergency rescue in earthquake relief, emergency rescue and other occasions. The magnesium powder in the heating tube is ignited by electric sparks and releases a large amount of heat, which makes the temperature and pressure of the carbon dioxide in the liquid filling tube rise sharply and quickly reach a supercritical state. When the pressure exceeds the rupture limit of the rupture disc, a rapid jet of carbon dioxide pushes the projectile. Wherein the acceleration connection section in the present invention is composed of an acceleration section and a recoil section, which significantly improves the exit velocity of the projectile, and at the same time significantly reduces the barrel length. The invention has the advantages of simple structure, safety and reliability, fast filling, portability and high efficiency, and is suitable for emergency rescue.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

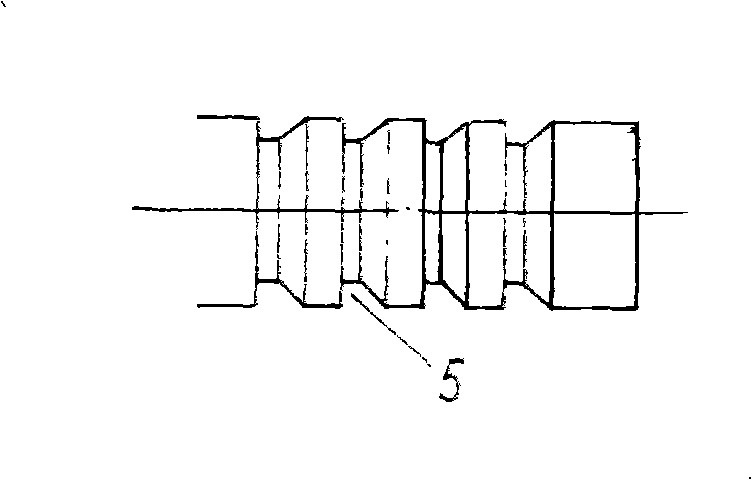

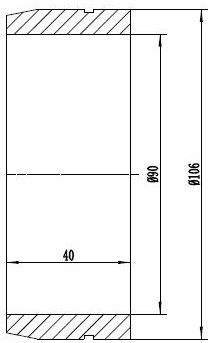

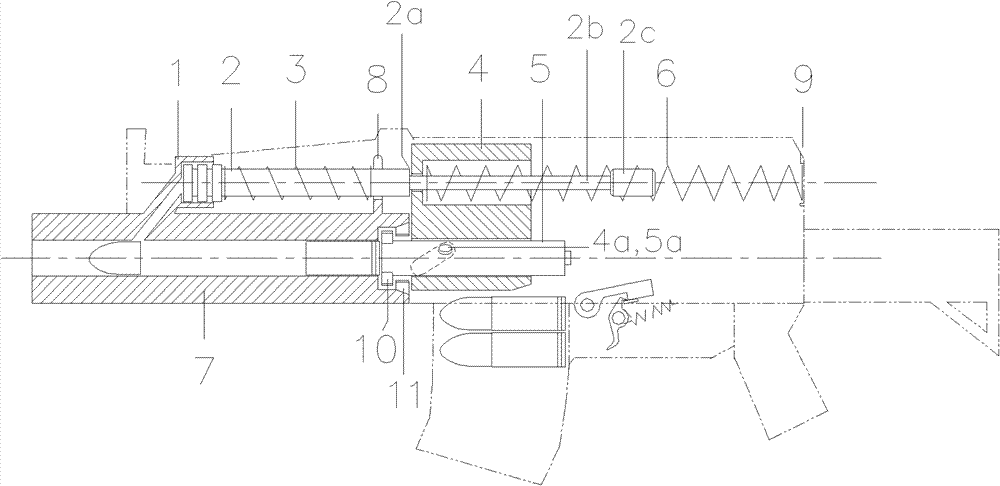

Preparation method of self-lubricating MC nylon elastic band material

ActiveCN111825974AHigh mechanical strengthImprove the lubrication effectPolymer chemistryThermal treatment

The invention relates to a preparation method of a self-lubricating MC nylon elastic band material. The method comprises the following steps: (1) heating a centrifugal mold in a centrifugal machine; (2) putting the monomer into a reaction container, heating to completely melt the monomer, and vacuumizing; (3), adding a catalyst, and vacuumizing; (4) sequentially adding a lubricating agent, a reinforcing agent and a toughening agent, and vacuumizing; (5) adding an activating agent, quickly dissolving, quickly stirring, casting into the centrifugal mold obtained in the step (1), centrifuging, naturally cooling to room temperature, and taking out a pipe fitting in the mold; (6) putting the prepared pipe fitting into a silicone oil tank for heating treatment; and (7) heating the pipe fitting subjected to oil bath in a water bath to obtain the self-lubricating MC nylon elastic band material. The self-lubricating MC nylon cartridge belt material prepared by the method has good dimensional stability, low water absorption, excellent self-lubricating property and mechanical strength, can improve the sealing and air-tight performance at the moment of bore launching when being applied to a sliding cartridge belt, and plays an important role in the flight attitude stability of a cartridge body.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

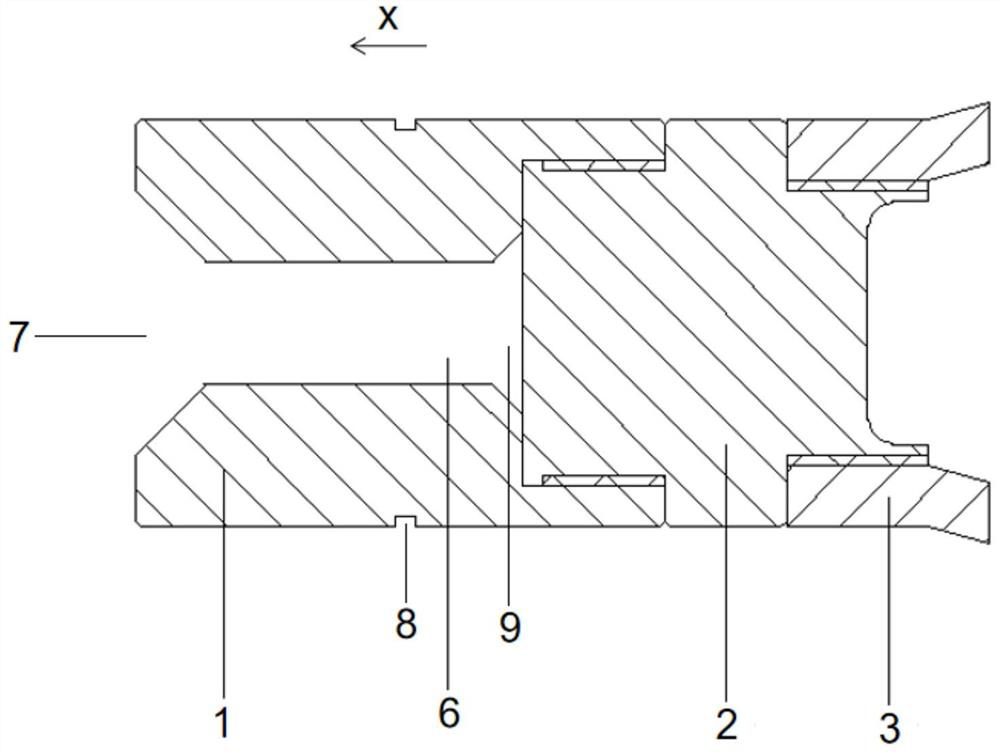

03 type rifle automat

InactiveCN102062559BReduced total recoil travelShorten design lengthBreech mechanismsShoulder-fired smallarmsShootGun barrel

The present invention discloses a 03 type rifle automat, comprising a piston sleeve, a piston rod, a piston spring, a gunlock frame, a gunlock and a return spring, wherein the piston sleeve is connected to an extract opening above a gun barrel; the piston rod is disposed in the piston sleeve; the piston spring is disposed on the piston rod between a piston disc at a front end of the piston rod and a spring seat disposed on the gun barrel; the return spring of the piston rod is disposed in a spring hole of the gunlock frame; the other end of the return spring is disposed on a spring seat at aninner wall of a rifle cartridge receiver; a step through hole is disposed at the bottom centre of the spring hole of the gunlock frame; an extension rod connected to a pushing face of the piston rod passes through the through hole; and a tail end of the extension rod is provided with a limit weight for limiting the recoil stroke of the gunlock frame. A locking lug radially projected at the front end of the gunlock is switched and paired with a locking tooth at the tail end of the gun barrel. The automat uses a recoil force of a piston assembly to neutralize the redundant recoil after a gunlock assembly is recoiled in place, and the recoil stroke is compressed. Under a condition that the gun length is determined, the length of the cartridge receiver can be shortened, so that the gunlock iscompact and the weight is reduced; or the length of the gun barrel is increased, so that the initial speed of bullets is increased; a gun body is stable during shoot, and the shooting average of a running fire is improved.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP +1

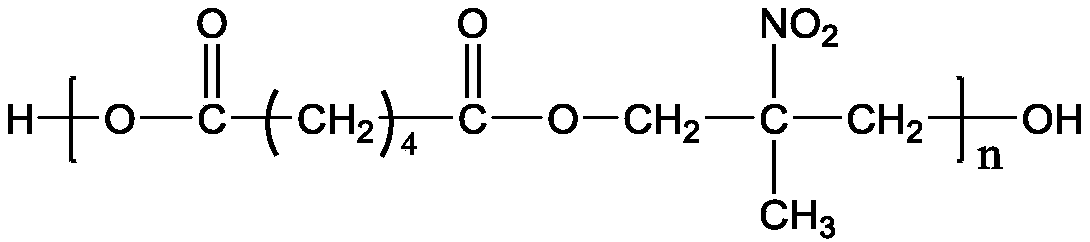

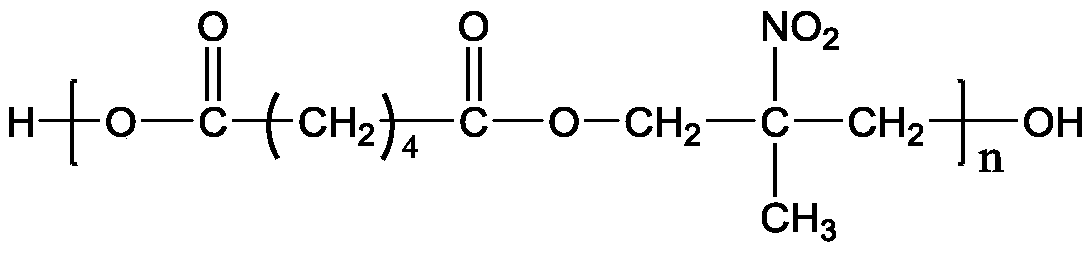

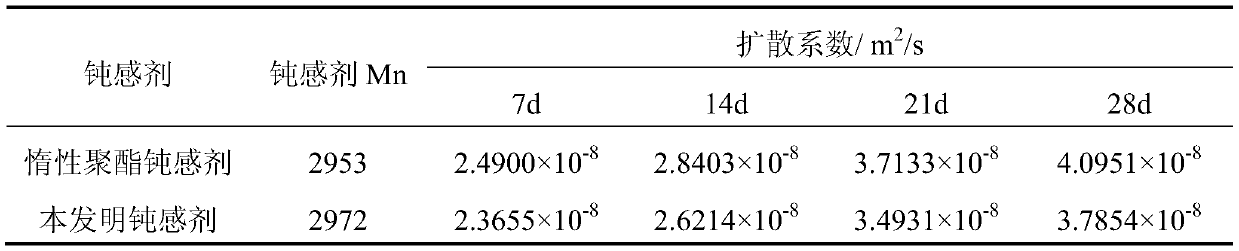

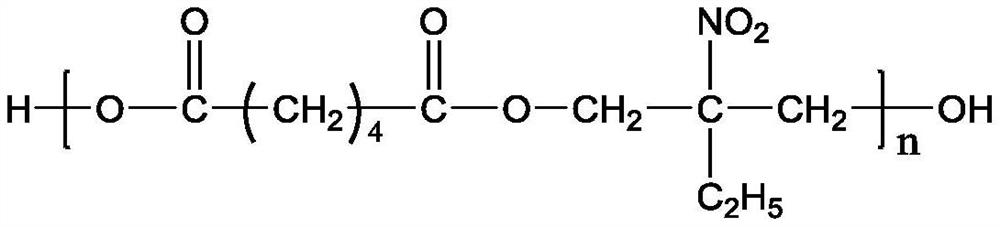

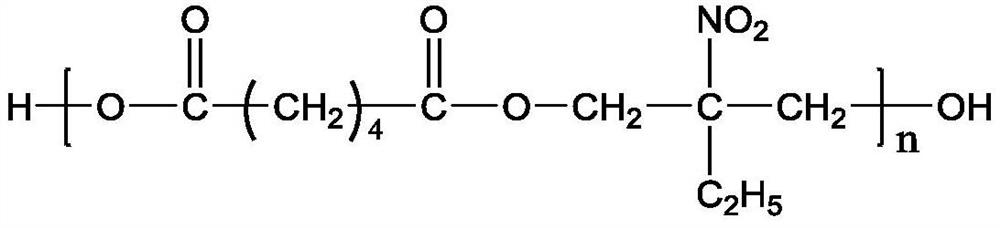

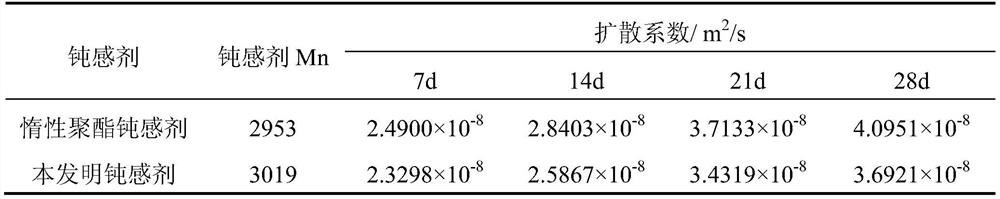

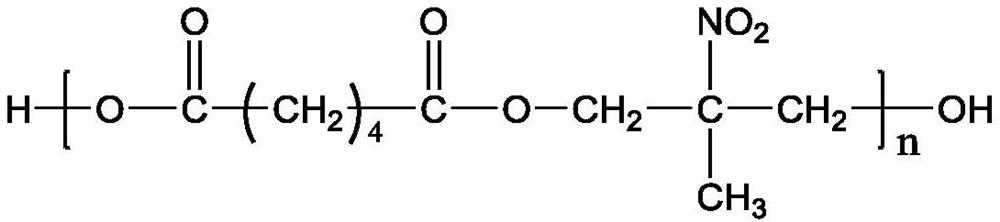

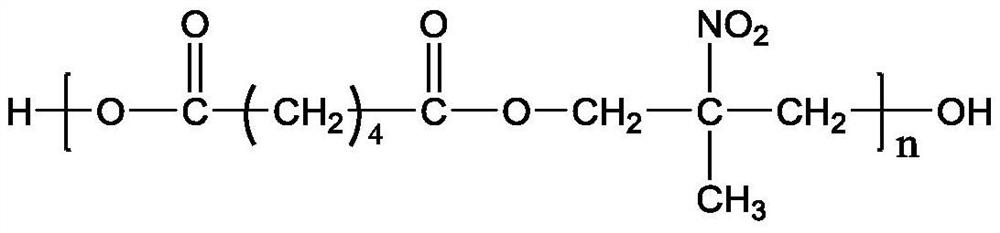

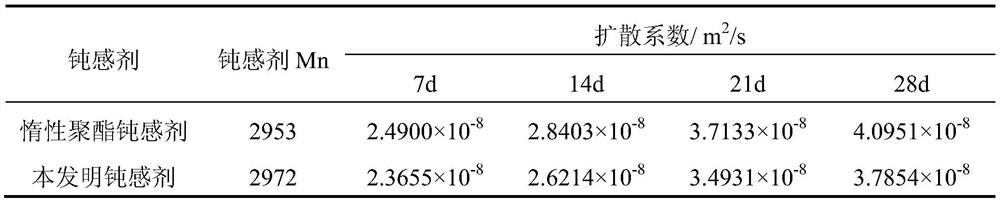

Poly (2-methyl-2-nitropropylene glycol adipate) as well as preparation method and application thereof

ActiveCN110483752AImprove migration resistanceSmall anti-migration performanceOrganic chemistryOrganic compound preparationDistillationAdipic acid

The invention discloses an energetic insensitive agent-containing poly (2-methyl-2-nitropropanediol adipate) for emission medicine as well as a preparation method and application of the energetic insensitive agent-containing poly (2-methyl-2-nitropropanediol adipate). The structural formula of the poly (2-methyl-2-nitropropanediol adipate) is shown in the specification, wherein n is greater than or equal to 2 and less than or equal to 20 and is an integer. The preparation method takes adipic acid and 2-methyl-2-nitropropylene glycol as raw materials, and comprises the following steps: adding adipic acid and 2-methyl-2-nitropropylene glycol into toluene, then adding a catalyst, heating until toluene flows back, and carrying out an esterification condensation reaction, after the reaction isfinished, cooling to below 30 DEG C, washing the reaction solution with water, and carrying out reduced pressure distillation to remove toluene, thereby obtaining the poly (2-methyl-2-nitropropylene glycol adipate). The poly (2-methyl-2-nitropropanediol adipate) synthesized by the method is applied as a desensitizer in propellant powder, the migration resistance is better, and the explosion heat and the projectile initial velocity are higher than those of an inert desensitizer.

Owner:XIAN MODERN CHEM RES INST

Forest fire extinguishing bomb launching system with high-pressure cold air as launching source

The invention discloses a forest fire extinguishing bomb launching system with high-pressure cold air as a launching source, and belongs to the technical field of forest fire extinguishing. The fire extinguishing system comprises a plurality of fire extinguishing bombs, a launching cabin body, an electric explosion valve, an electric exploder, a second-stage pressure cabin and a rear cabin. According to the forest fire extinguishing bomb launching system, high-pressure inert gas is used as a transmitting driving source, rapid maneuvering is facilitated, and rapid response can be made; an universal interface is arranged at the bottom of a rear cabin, so that quick installation can be performed according to different vehicle-mounted interfaces, and quick deployment under various terrain conditions can be met; a launching tube in the launching cabin body can be repeatedly filled, so that the launching efficiency is improved; a launching gas source of the second-stage pressure cabin adoptsa high-pressure gas cylinder gas storage mode, quick replacement is implemented, the pressure needed by launching of the fire extinguishing bomb can be adjusted according to the fire scene requirement, the initial speed and the firing range of the fire extinguishing bomb are increased, firefighters are prevented from making close contact with a fire scene, and casualties are reduced. The system also has the advantages of simple operation, safety, reliability, high launching efficiency and the like.

Owner:HUAIHAI IND GRP

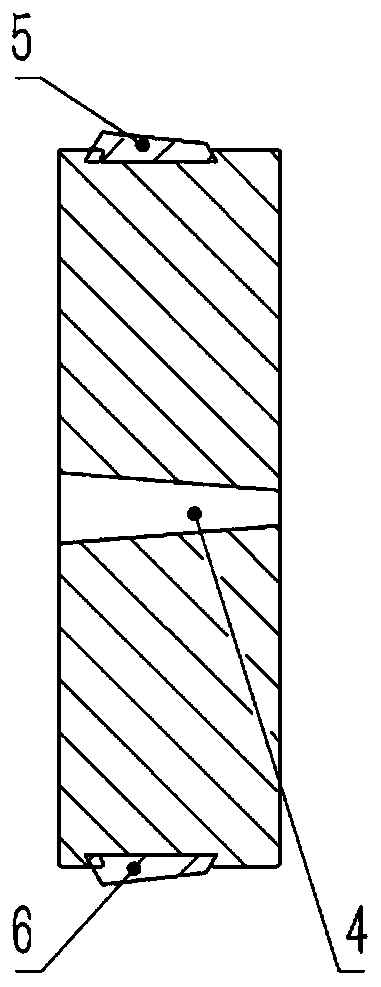

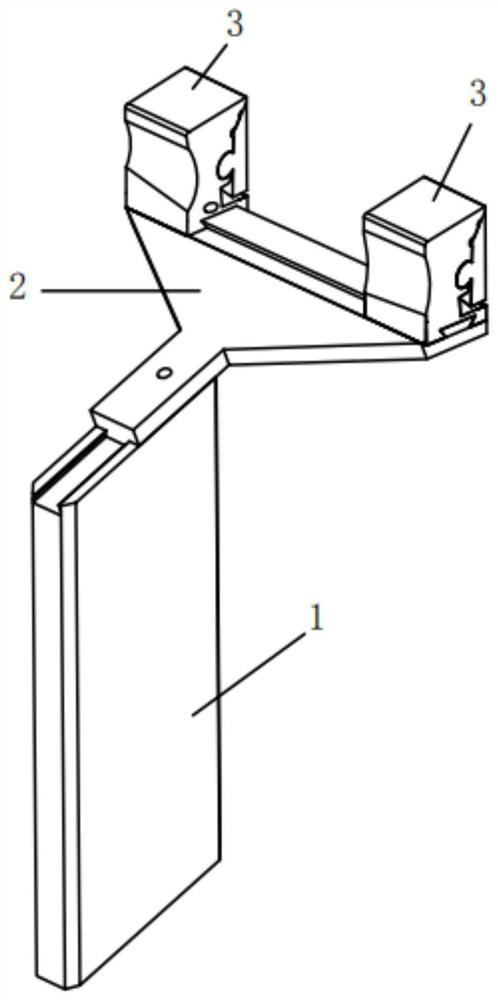

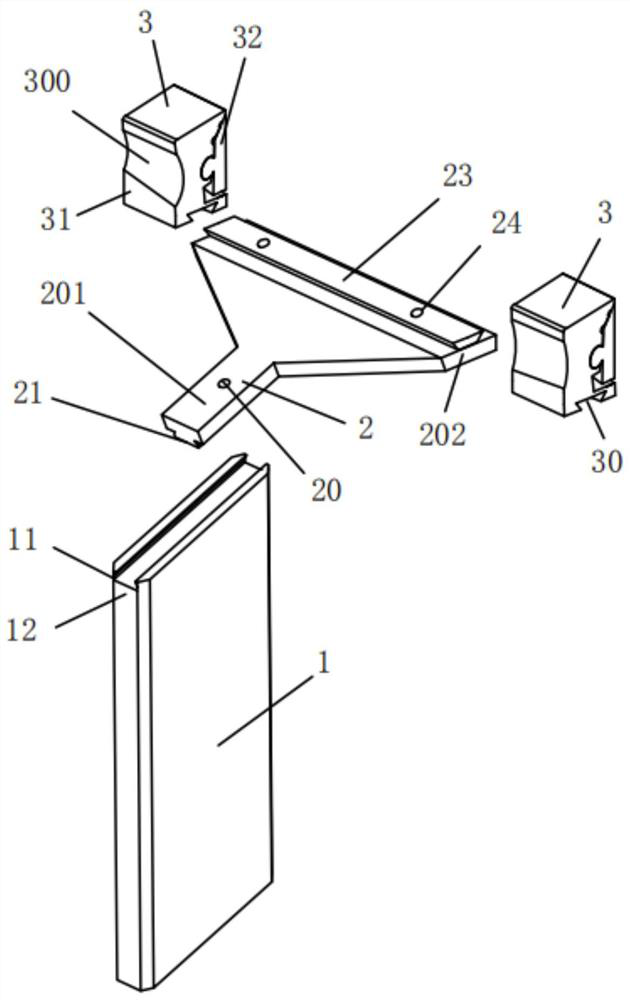

Target holder for cylindrical fragment simulation bomb and use method of target holder

PendingCN114087917AGuaranteed to fly outSimple structureWeapon componentsLaunching weaponsPetalMechanical engineering

The invention discloses a target holder for a cylindrical fragment simulation bomb. The target holder comprises a front holder main body, wherein the front holder main body is provided with a hollow inner cavity for placing the cylindrical fragment simulation bomb, the front holder main body is composed of 2-4 detachable petals with the same structure, the petals are uniformly distributed along the circumferential direction of the front holder main body, a first conical inner cavity is formed in an opening in the front end of the hollow inner cavity, the front end of the cylindrical fragment simulation bomb is located in the first conical inner cavity and grooves are formed in the sides, deviating from the hollow inner cavity, of the petals; a bottom pusher detachably connected with the front support main body; and an air closing ring detachably connected with one end, far away from the front support main body, of the bottom push. The strength of the target holder can be improved, and the accuracy of a high-speed fragment target test result is improved. The invention further provides a use method of the target holder for the cylindrical fragment simulation missile.

Owner:INNER MONGOLIA METAL MATERIAL RES INST

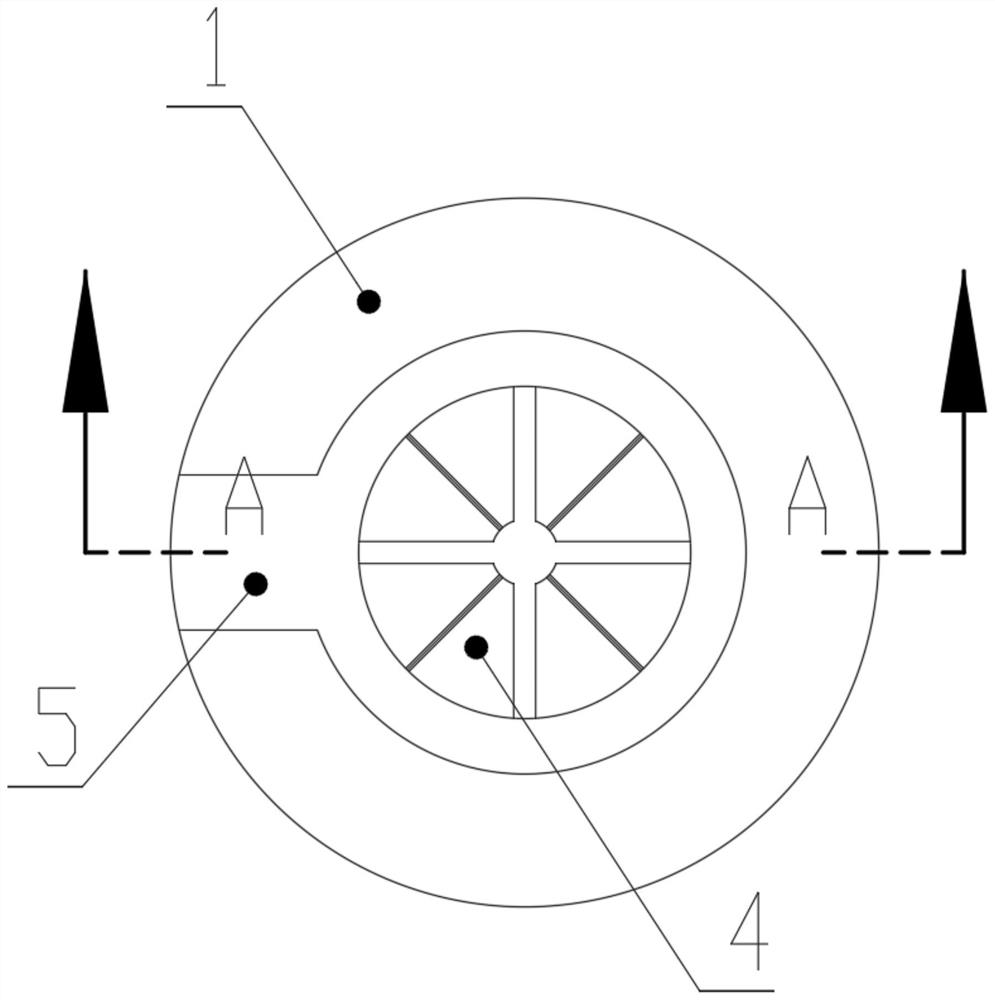

A High Efficiency Intermittent Aeration Mechanism for Industrial Sewage Treatment

ActiveCN111392880BEasy to replyImprove transmission efficiencyTreatment using aerobic processesWater aerationGear wheelSewage

The invention discloses a high-efficiency intermittent aeration mechanism for industrial sewage treatment, which includes an aeration cylinder, a sealing plate, an annular clamping plate, an adjustment mechanism, a transmission mechanism and a connecting groove, and the center of the upper end surface of the transmission mechanism is fixedly connected There is an adjustment mechanism for sealing, and the transmission mechanism includes a spring rod, a gear shaft, a limit rod, a connecting plate, a gear groove, a clamping block, a sealing baffle, a clamping groove, a connecting chute and an air storage pipe. The side wall of the inner end face of the trachea is provided with a connecting chute for positioning. The present invention can improve the dissolution rate of oxygen in the air in the industrial sewage by increasing the muzzle velocity of the gas when it is aerated and discharged by setting the transmission mechanism, the regulating mechanism and the aeration cylinder, and at the same time can carry out the intermittent aeration of the cycle operation, reducing the power consumption of aeration and reducing the cost of sewage treatment in the factory.

Owner:北京龙源惟德能源科技有限公司

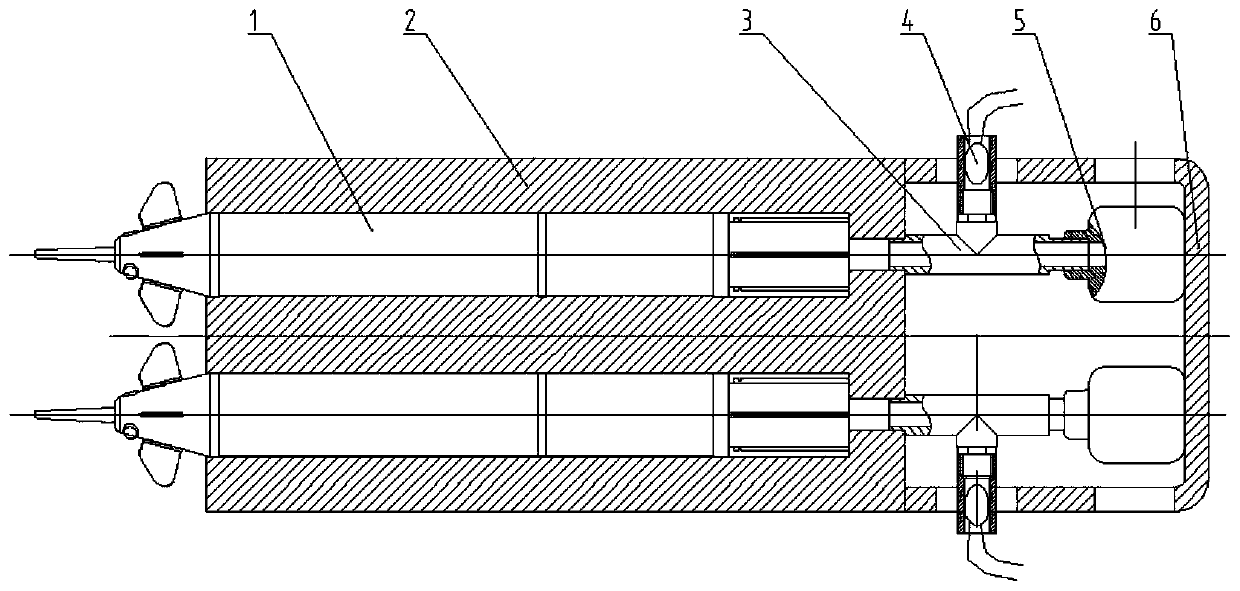

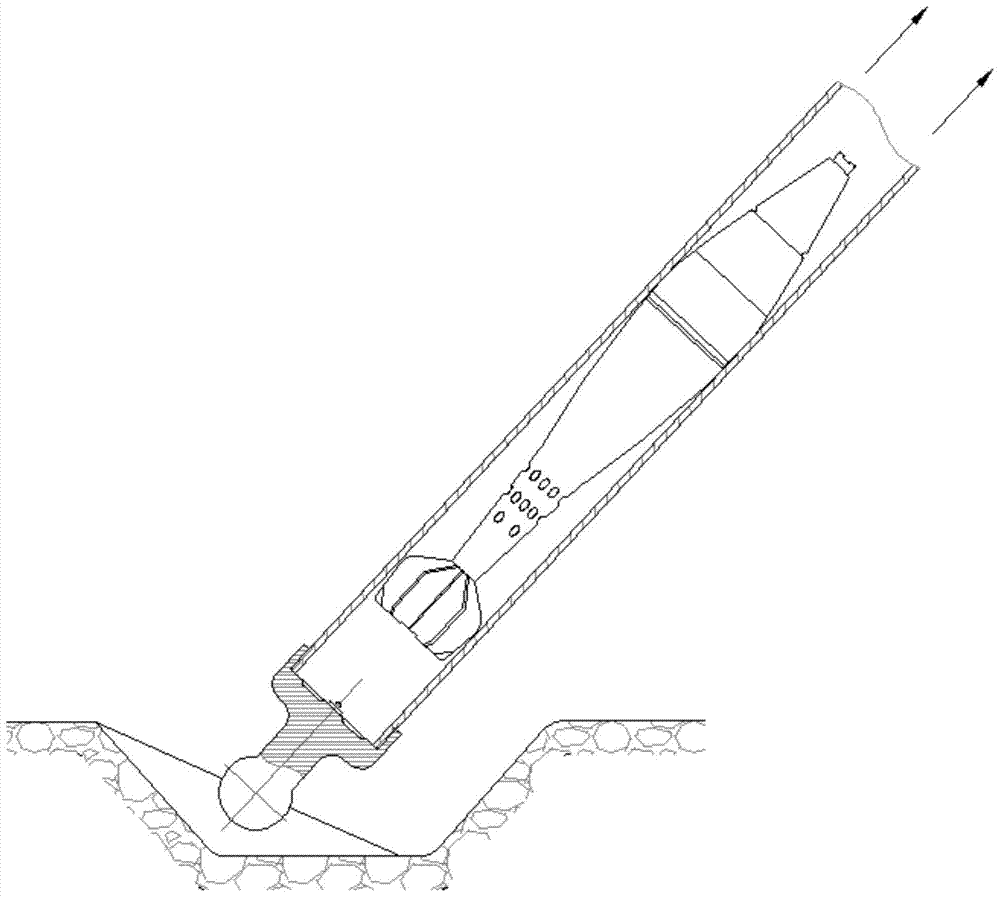

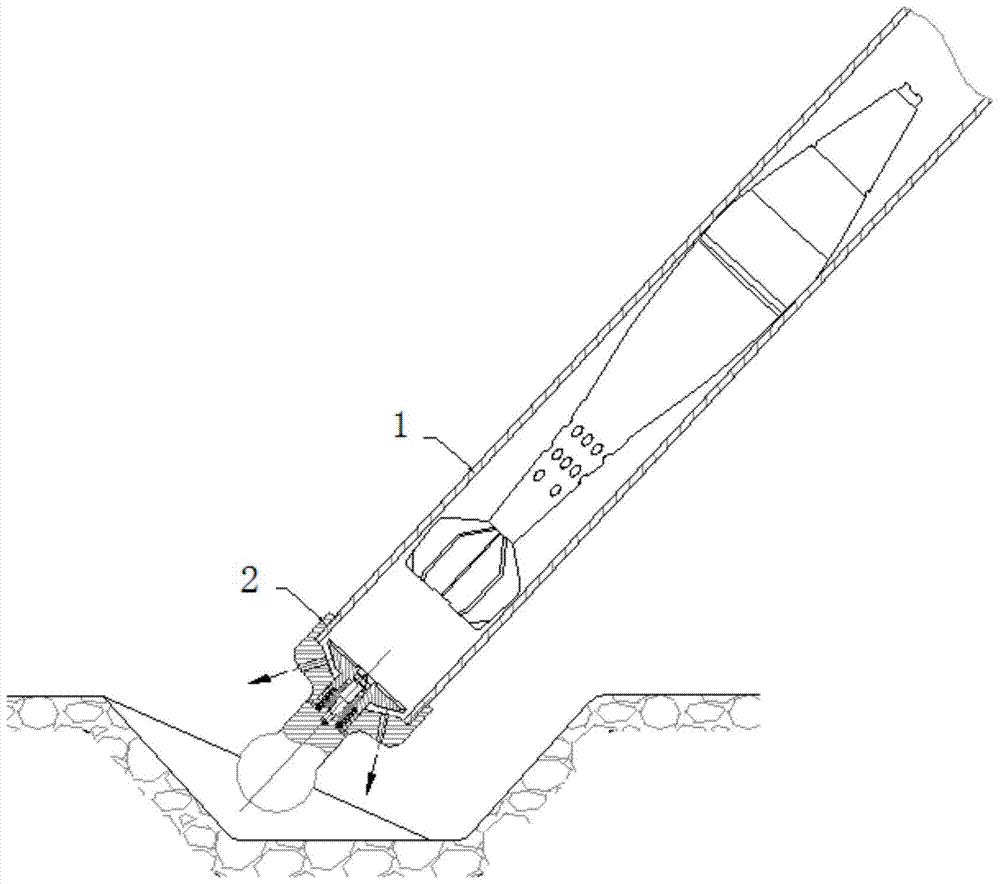

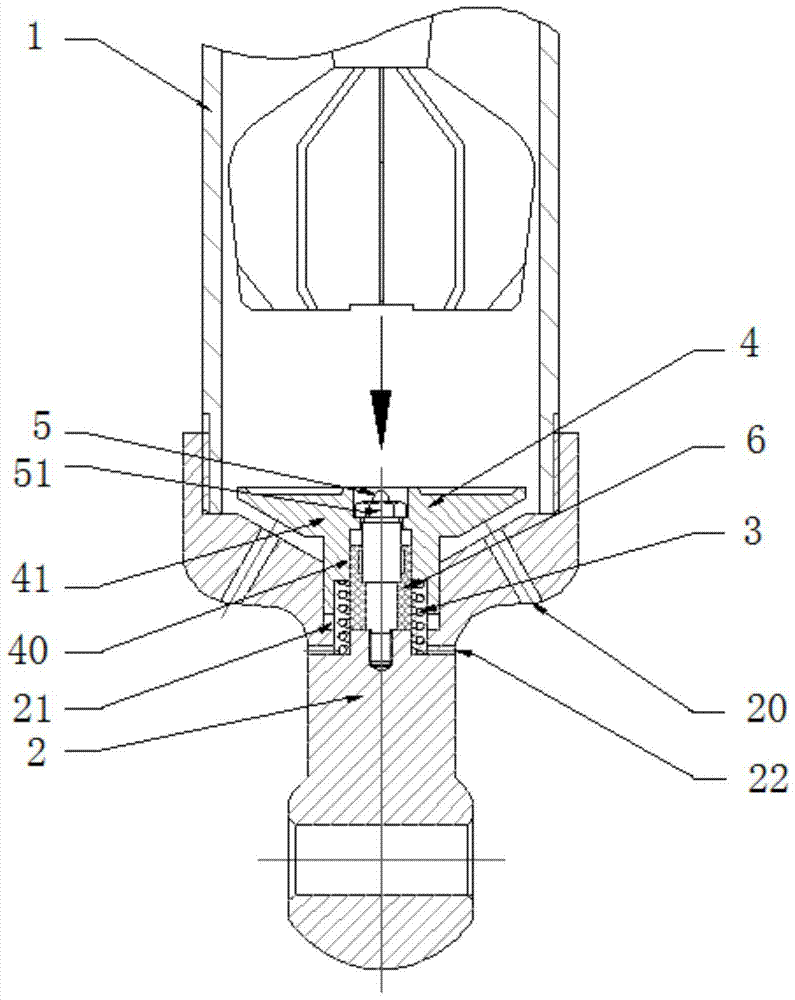

mortar launcher

InactiveCN104930916BRapid declineIncrease initial velocityLaunching weaponsEngineeringMuzzle velocity

The invention discloses a mortar launching device, which comprises a breech, an elastic member, a blocking member and a cylindrical barrel with a bore, the breech is installed at one end of the barrel, and the breech is provided with a The firing pin in the gun bore, the blocking member includes a bushing and a shoulder arranged outside the bushing, the bushing is set outside the firing pin, the first end of the elastic member abuts against the blocking member, The second end abuts on the breech, and the breech is provided with at least one first vent hole, and when the elastic member is in the original state, the first vent hole communicates with the gun bore; When compressed, the shoulder blocks the first vent hole. The mortar launching device can adopt a barrel inner diameter with a small gap under the premise of ensuring that the mortar shell can slide down reliably and the air is discharged from the first exhaust hole in the gun tail, so that the initial velocity of the shell can be increased and the shooting range can be increased. , while effectively improving shooting accuracy.

Owner:GUANGZHOU INST OF RAILWAY TECH

Charging structure for high chamber pressure artillery

The invention discloses a charging structure for a high chamber pressure artillery. The charging structure includes a cartridge case, artillery primer, a black fire cartridge bag, single camphor-11A-8 / 1 propellant powder, single base 5 / 7 propellant powder, a nitrocotton paper board and a hard paper cover board; the cartridge case is a conical bench-type shell body with upper part opened, the artillery primer is fixedly arranged on the bottom surface of the cartridge case, the black fire cartridge bag is fixedly arranged on upper part of the artillery primer, the single camphor-11-A-8 / 11 propellant powder is arranged on the periphery of the inner part of the cartridge case, the single base 5 / 7 propellant powder is arranged at the center part of the inner part of the cartridge case, the nitrocotton paper board is arranged between the single camphor-11A-8 / 1 propellant powder and the single base 5 / 7 propellant powder and is tightly contacts with the single camphor-11A-8 / 1 propellant powderand the single base 5 / 7 propellant powder, and the hard paper cover board is arranged on the upper part of the single base 5 / 7 propellant powder. The charging structure has the characteristics that the structure is simple, operation is convenient, and uniformity is good, the purposes that ignition, fire transmission and combustion performance are improved, thus the gas production rate of whole charged powder is improved are achieved, thus ballistic performance is greatly improved, and the initial speed of a pill is improved.

Owner:INST OF DEFENSE ENG ACADEMY OF MILITARY SCI PLA CHINA

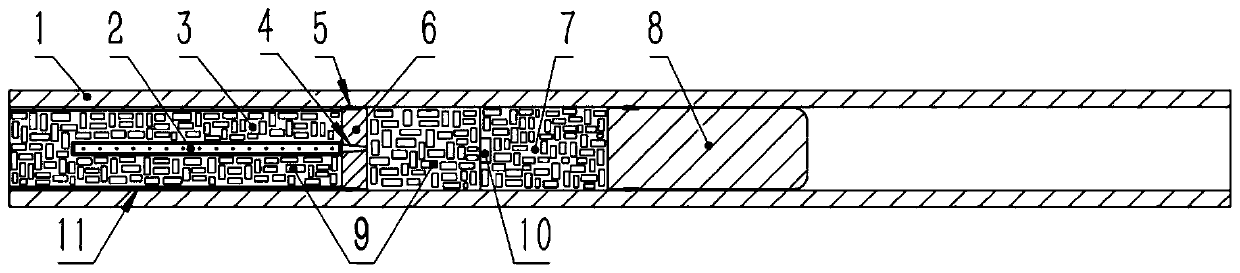

Graded propellant powder chamber pre-ignition launching device and method for fire extinguishing bullet launching

The invention discloses a graded propellant powder chamber pre-ignition launching device and method for fire extinguishing bullet launching. The device comprises a launching tube, propellant powder, apiston, an ignition device, a fire extinguishing bullet, a primary propellant powder chamber, a fire transferring device, a sealing ring, a support frame and a secondary propellant powder chamber. The method comprises the steps that the propellant powder is loaded in a serial split charging mode, the propellant powder in the front secondary propellant powder chamber is ignited through the ignition device to burn, generated propellant powder gas pushes the fire extinguishing bullet to move forwards, and the piston is kept still under the action of the support frame; when the pressure in the secondary propellant powder chamber reaches a set value, the propellant powder in the primary propellant powder chamber is ignited through the fire transferring device; then the piston moves forwards under the action of pressures in the two propellant powder chambers, the fire extinguishing bullet is pushed to move forwards until the fire extinguishing bullet is separatedfrom a launching tube outlet; and the piston and the fire transferring device are continuously pushed by the propellant powder gas in the primary propellant powder chamber to move forwards until the piston and thefire transferring deviceare separated from the launching tube outlet. A higher initial velocity of the bullet with a lower maximum chamber pressure can be reached under the premise of the same charge amount, and therange of the fire extinguishing bullet is enlarged.

Owner:NANJING UNIV OF SCI & TECH

A high-temperature pyrolysis reactor and a system and method for treating oil sludge or waste oil by hydropyrolysis

ActiveCN107686740BRaise the gas temperatureFast pyrolysisLiquid hydrocarbon mixture productionSpray nozzleFilter system

The invention discloses a high-temperature pyrolysis reactor. The high-temperature pyrolysis reactor comprises a reactor body, a slurry spraying pipe, a spray nozzle, a mixer, a heat exchanger and thelike. The invention further discloses a system for treating oil sludge or waste oil. The system uses the high-temperature pyrolysis reactor, and further comprises a slurrying and filtering system, afly ash filter, a fractionating tower, an ash collecting system. The invention further discloses a method for treating the waste oil sludge or the waste oil, in which the system for treating the oil sludge or the waste oil is used. According to the invention, through high-temperature jet mixing and rapid pyrolysis, sufficient mixing and pyrolysis of the oil sludge or the waste oil is achieved; thecharacteristics of simple technical process, compact equipment structure, low investment, good oil quality and the like are achieved.

Owner:柳州淦源环保科技有限公司

Poly 2-ethyl-2-nitropropanediol adipate and its preparation method and use

ActiveCN110452366BImprove migration resistanceSmall anti-migration performanceNon-explosive desensitisers/phlegmatisersPtru catalystEthyl group

Owner:XIAN MODERN CHEM RES INST

Novel slingshot

The invention discloses a novel slingshot which comprises a slingshot handle, a slingshot arm and a slingshot head, the slingshot handle and the slingshot arm are arranged at an angle of not less than 90 degrees, so that when a middle finger, a ring finger and a little finger of a player grasp the slingshot handle, the slingshot arm can be tightly attached to the middle finger to extend forwards and upwards, the second section of the index finger and the thumb can abut against the slingshot head connected with the front end of the slingshot arm, and a finger nest groove is formed in one side, facing the slingshot handle, of the slingshot head, so that fingers can support the slingshot head comfortably and stably. The installation position of each part of the slingshot can be adjusted to adapt to different hand shapes; the player can replace each part of the novel slingshot according to own use habits and hand shape conditions and select own favorite materials or shapes, so that different use requirements are met, and the applicability is high; and the novel slingshot is simple in overall structure, convenient to disassemble, assemble and store, and capable of meeting the experience requirements of players for the pushing mode of the frame-free slingshot.

Owner:卓良俊

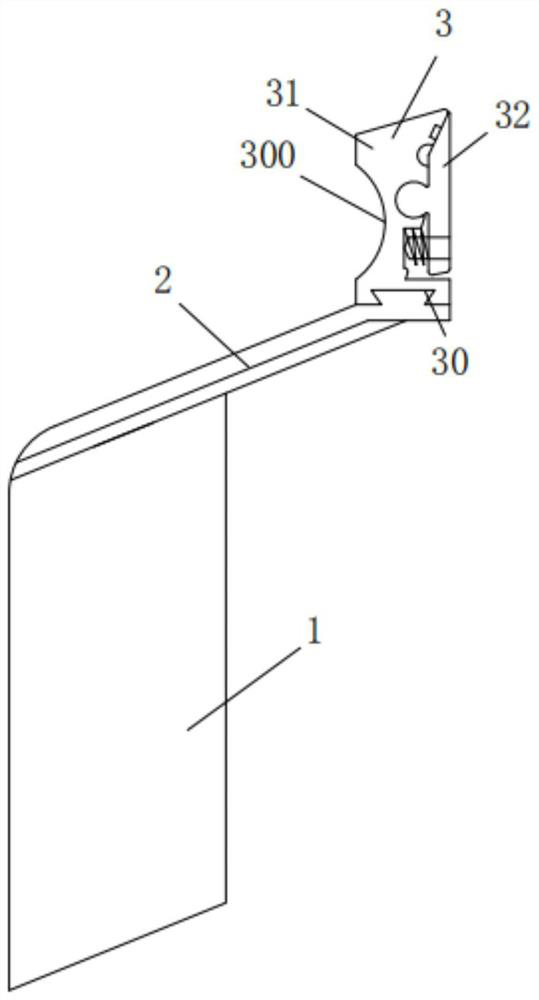

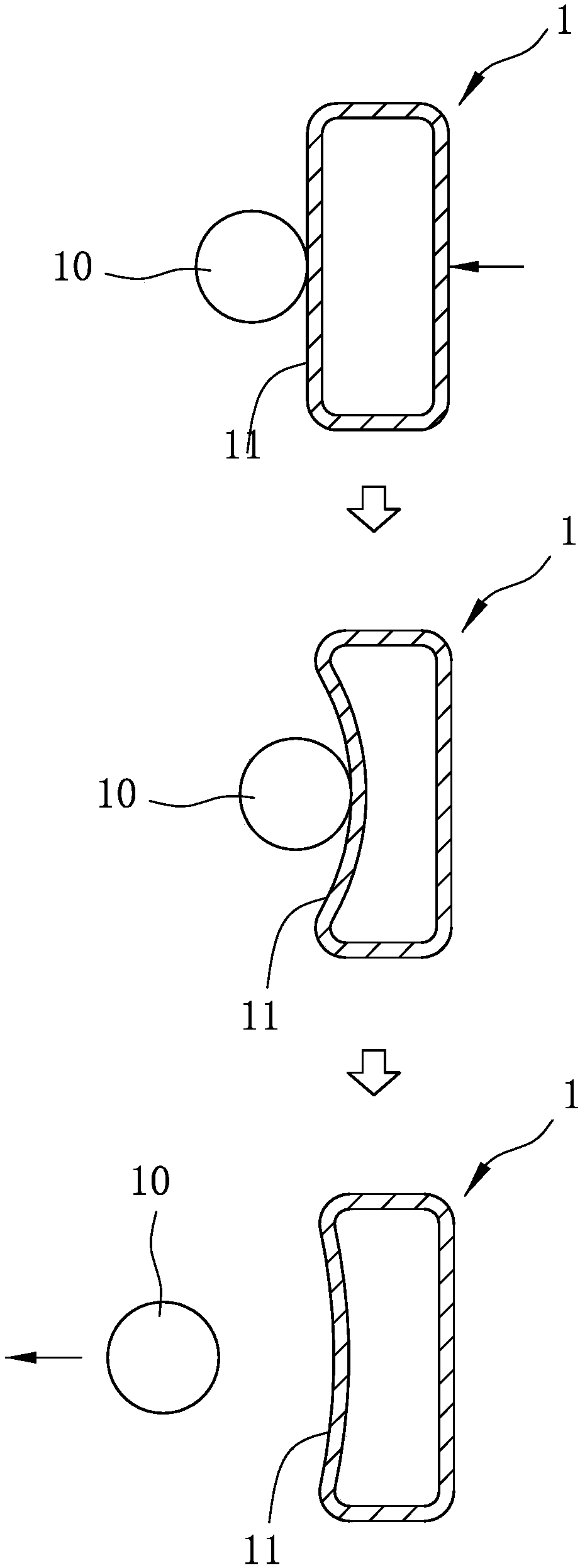

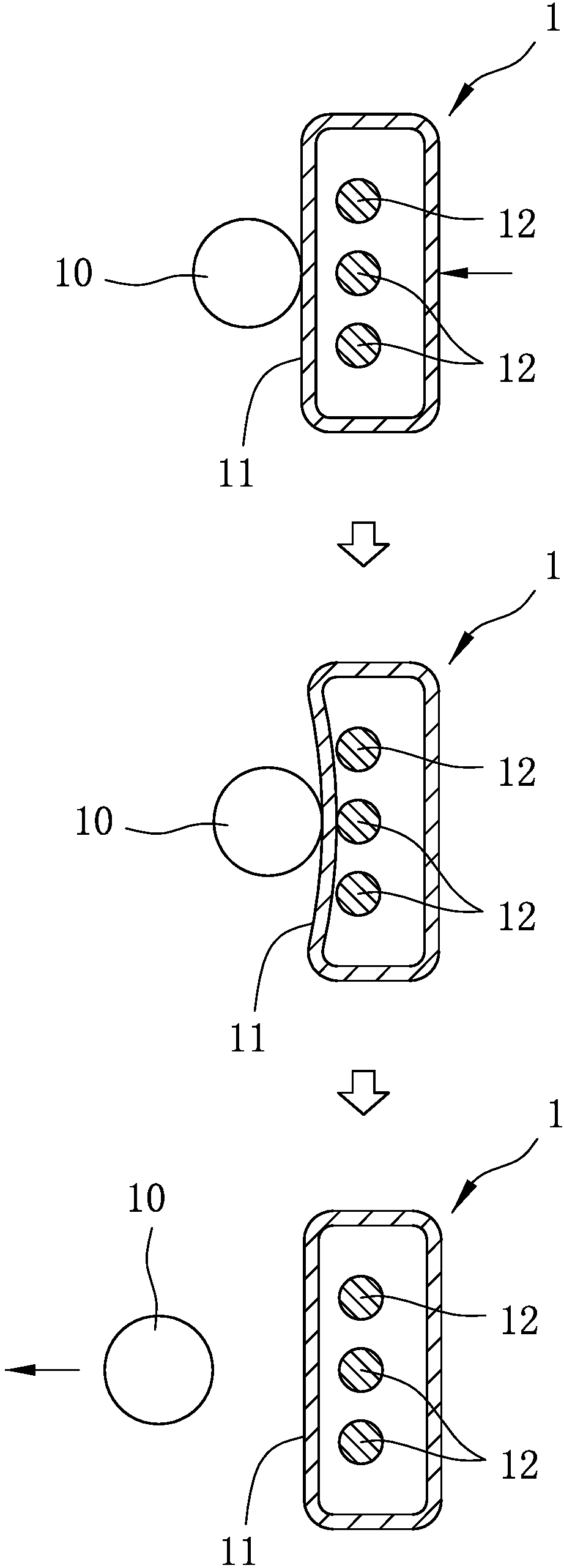

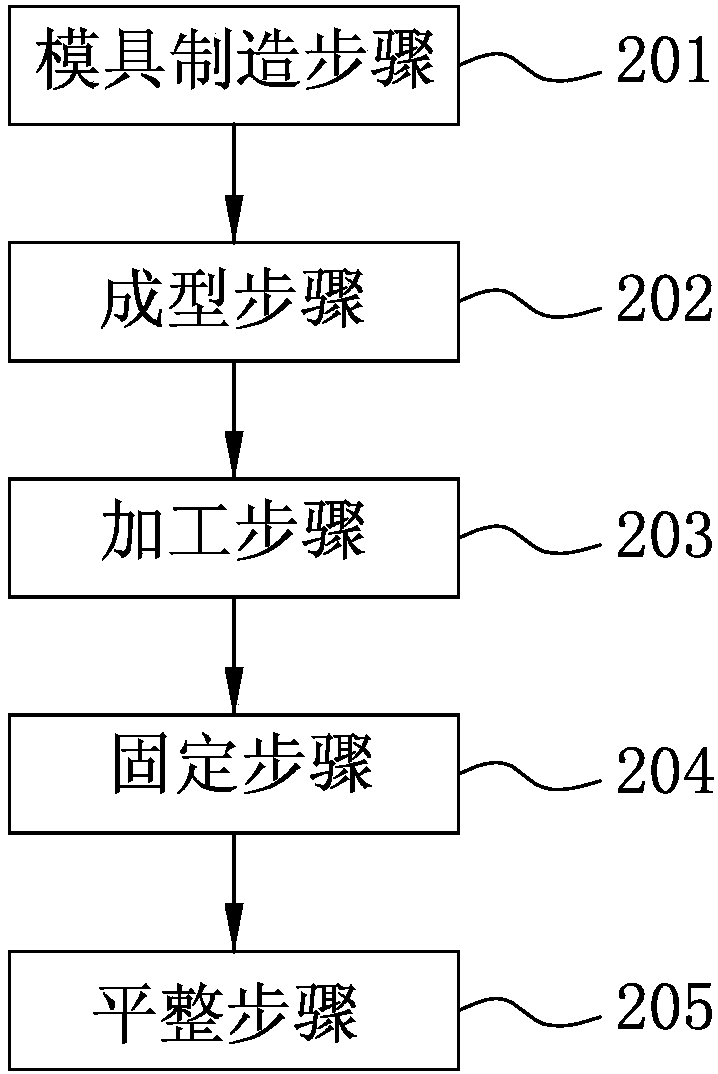

Method for manufacturing wax pattern for golf club head

InactiveCN108015222AReduce deformation timeIncrease initial velocityFoundry moulding apparatusGolf clubsWaxBonding strength

The invention discloses a method for manufacturing a wax pattern for a golf club head. The method comprises the steps of manufacturing a mold, carrying out forming, carrying out processing and carrying out fixing. According to the method, in the forming step, a primary blank is formed by using the mold, and the primary blank comprises a plate wall part, a shell part, a concave groove and at leastone inserting part, wherein the shell part is connected to the plate wall part, the concave groove is defined by the plate wall part and the shell part in a matched mode, and the at least one inserting part is formed on the shell part and faces the concave groove; in the processing step, at least one reinforcing part is arranged on the inserting parts, is arranged in the concave groove and is arranged parallel to the plate wall part at intervals so as to prepare the wax pattern. The wax pattern has the characteristics of the reinforcing parts and can be used for manufacturing the golf club head with the integrally-formed reinforcing parts, and therefore the bonding strength can be improved and the separation of the reinforcing parts can be avoided.

Owner:CALLAWAY GOLF CO

Chamber Nested Bolt and Oval Rifling

InactiveUS20200025489A1Gun to be simplerReduce maintenanceBreech mechanismsBarrelsEngineeringRifling

A means of keeping the cartridge in the chamber during the firing sequence until the peak pressure drops to a safe level by nesting the bolt into the chamber with the cartridge. The bolt and cartridge will form a gas seal and recoil backwards when the gun is fired, but the chamber walls will support the cartridge while it recoils backwards until it exits. The gun will be designed so that it does not exit until the pressure drops to a level where the cartridge can withstand the force. Doing this will allow the gun to utilize high pressure ammunition without requiring complicated locking and / or delay mechanisms currently used. This will decrease the initial cost of manufacturing the gun, improve accuracy and reliability, and reduce the peak recoil felt from the gun. Also spinning a projectile by using an oval cross section where the major and minor axis rotates around the center of the oval eliminates the need for groves and polygonal rifling. This will increase the efficiency and the precision of the gun.

Owner:AMBS JONATHAN

Poly 2-methyl-2-nitropropanediol adipate and its preparation method and use

ActiveCN110483752BImprove migration resistanceSmall anti-migration performanceOrganic chemistryOrganic compound preparationPtru catalystAdipic acid

The invention discloses an energetic insensitizer polyadipate 2-methyl-2-nitropropylene glycol ester for propellant and its preparation method and application, and polyadipate 2-methyl-2-nitropropylene glycol ester The structural formula is as follows: wherein 2≤n≤20, and n is an integer. Its preparation method takes adipic acid and 2-methyl-2-nitropropanediol as raw materials, comprising the steps of adding adipic acid and 2-methyl-2-nitropropanediol to toluene, then adding a catalyst, heating Reflux to toluene for esterification condensation reaction. After the reaction, the temperature was lowered to below 30°C, the reaction solution was washed with water, and the toluene was evaporated under reduced pressure to obtain poly-2-methyl-2-nitropropylene glycol adipate. The poly 2-methyl-2-nitropropylene glycol adipate synthesized by the invention is used as a desensitizing agent in propellants, and has better anti-migration performance, and higher detonation heat and projectile initial velocity than the inert desensitizing agent.

Owner:XIAN MODERN CHEM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com