mortar launcher

A technology for launching devices and mortars, which is applied to the field of mortar launching devices, can solve the problems of reduced shooting accuracy, insufficient firing energy, and insufficient sliding speed of shells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are described in detail below:

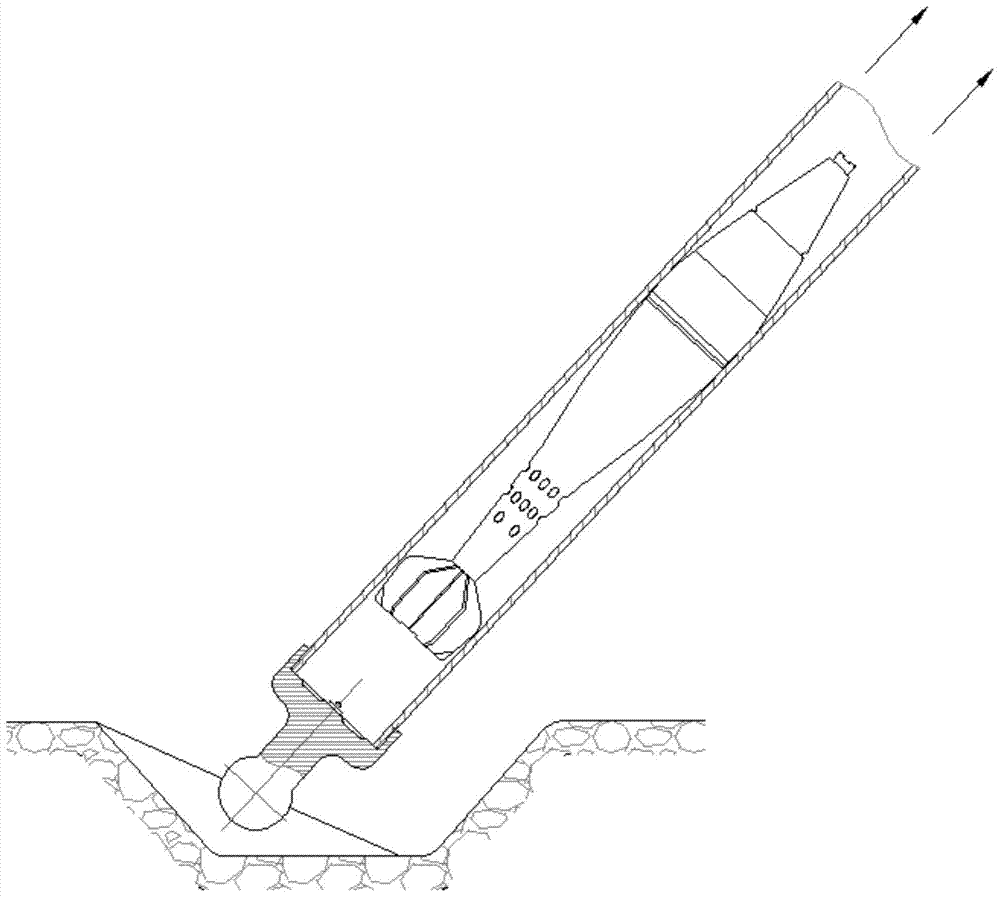

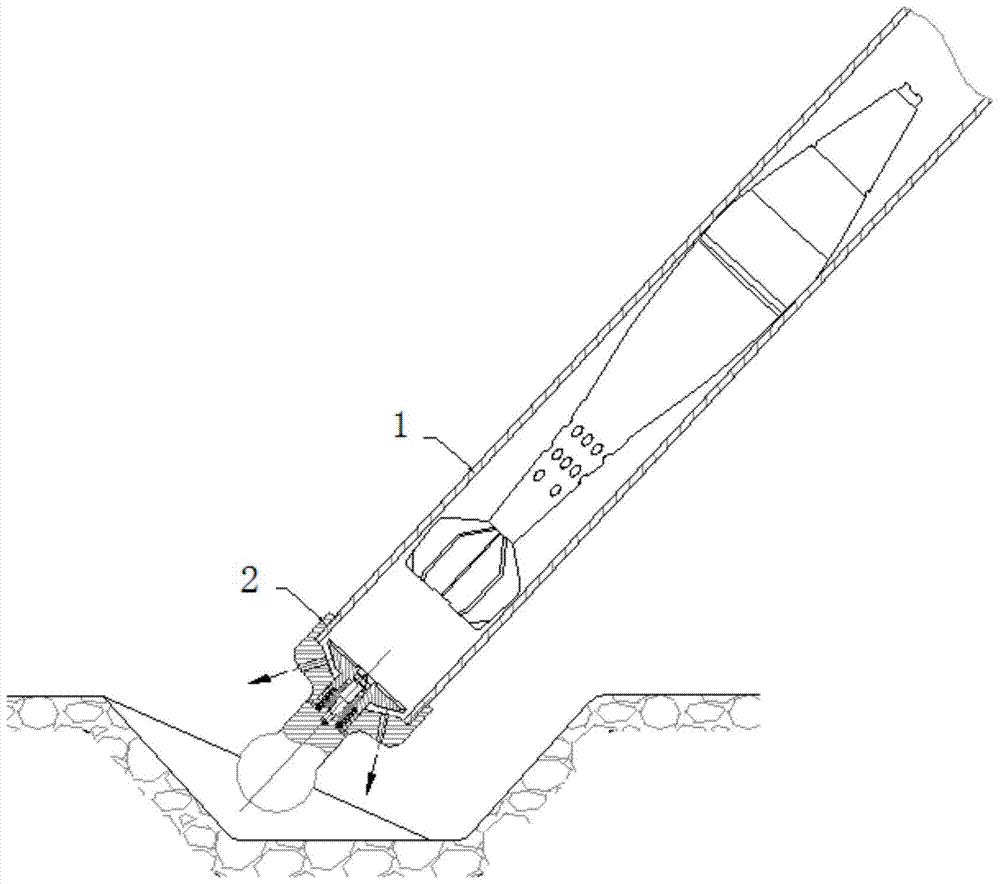

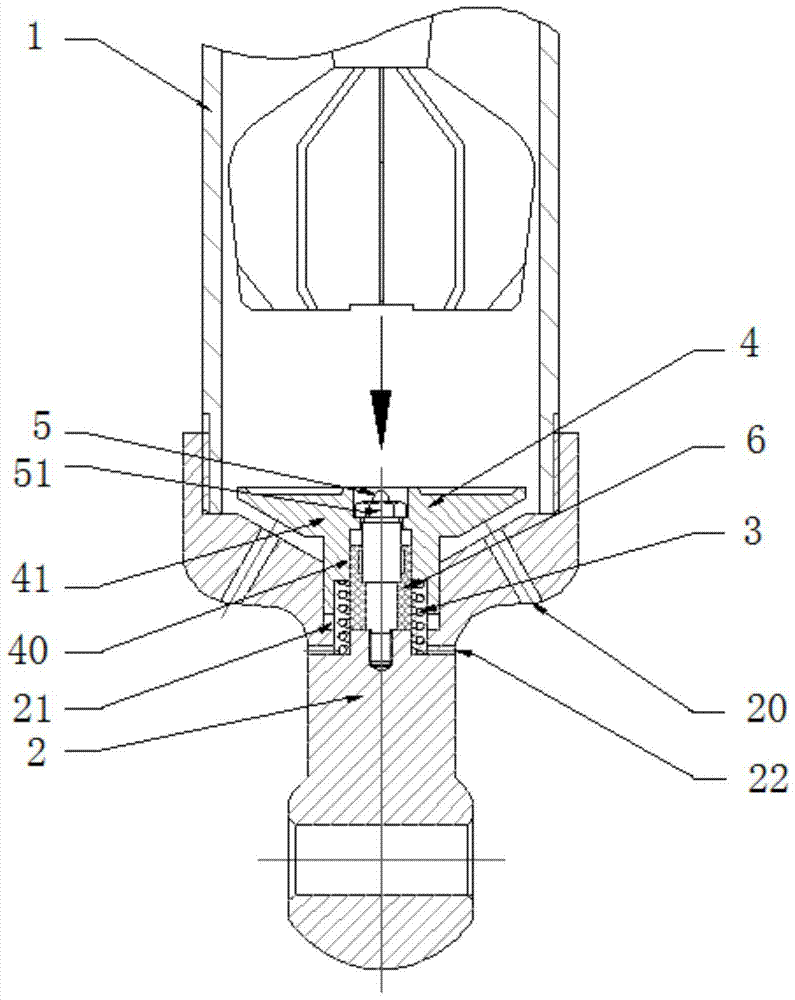

[0029] Such as figure 2 , 3 As shown (the direction of the arrow is the gas discharge direction), the mortar launching device described in the present embodiment includes a breech 2, an elastic member 3, a blocking member 4 and a cylindrical barrel 1 with a bore, and the breech 2 is installed at one end of the barrel 1, and the breech 2 is provided with a firing pin 5 located in the bore, and the blocking member 4 includes a bushing 40 and a shoulder 41 arranged outside the bushing 40. The sleeve 40 is set outside the firing pin 5, the first end of the elastic member 3 abuts on the blocking member 4, and the second end abuts on the breech 2, and the breech 2 is provided with at least one The first exhaust hole 20 (there are two first exhaust holes 20 in this embodiment, and the two first exhaust holes 20 are arranged at the position close to the shoulder), when the elastic member 3 is in the origin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com