A sorting device for cutting potatoes into strips

A classification device and a technology for cutting strips, which are applied in the fields of classification, solid separation, chemical instruments and methods, etc., can solve the problems of irregular shape of french fries, affecting the quality of french fries, low accuracy, etc., achieving high accuracy and easy promotion. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

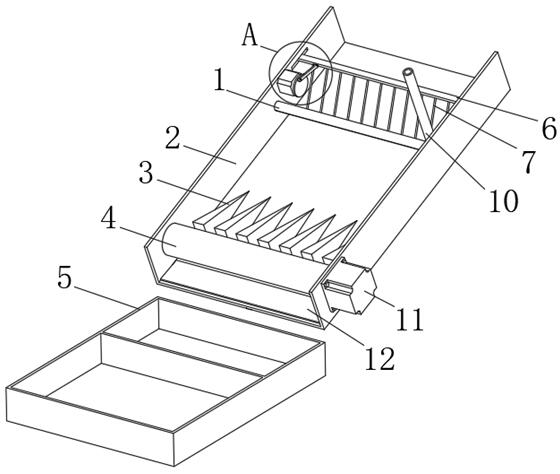

[0033] Example 1: Please refer to Figure 1-4 , the present embodiment discloses a sorting device for sliced potatoes, including an adjustment unit, a sorting unit and a support member 2. The support member 2 includes a substrate arranged obliquely along its length direction, and baffles extend upwards at both ends of the substrate width direction.

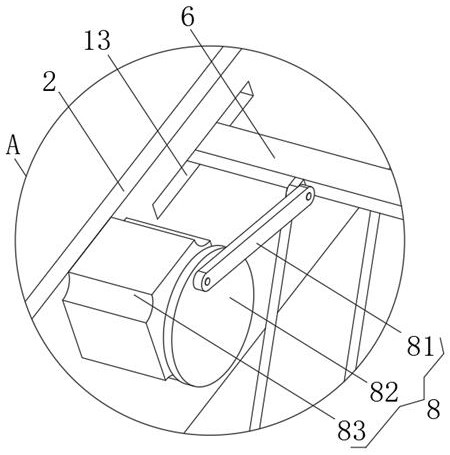

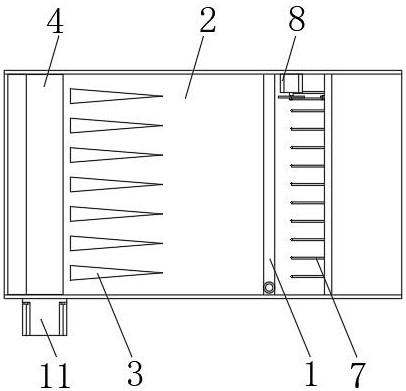

[0034] The adjustment part is located on the upper part of the inner side of the two baffles. The adjustment part includes a moving rod 6 parallel to the base plate. One end of the moving rod 6 is connected to the inner side of the baffle through a guide 13, and the moving rod 6 is supported by the guide 13. The length direction of the substrate moves, and the lower side of the moving rod 6 is provided with several shaking rods 7 along its length direction, and the driving member 8 for driving the moving rod 6 to reciprocate is installed on the support member 2 .

[0035] The sorting part includes a rotating roller 4, which is i...

Embodiment 2

[0044] Embodiment two: if figure 1 and Figure 4As shown, this embodiment discloses a sorting device for cutting potatoes into strips. Its structure is roughly the same as that of Embodiment 1. The difference is that this embodiment also includes a water pipe 1 located between the two baffles, and the water pipe 1 Located on the obliquely lower side of the adjustment part, the water pipe 1 is provided with an obliquely downward water outlet hole, and the water pipe 1 is provided with a water inlet hole connected to one end of the water inlet pipe 10 .

[0045] The working process and principle of this embodiment are:

[0046] The external water pump injects water into the water pipe 1 through the water inlet pipe 10, and the water in the water pipe 1 is sprayed out through the water outlet hole. The water ejected from the water pipe 1 accelerates the potato slices. On the one hand, the distance between the potato slices is opened to avoid Potato slices are piled up at the tu...

Embodiment 3

[0047] Embodiment three: as figure 1 , image 3 and Figure 4 As shown, this embodiment discloses a sorting device for cutting potatoes into strips. Its structure is roughly the same as that of Embodiment 2. The plate 3 and the tapered plate 3 are located on the oblique upper side of the rotating roller 4, the tip of the tapered plate 3 is attached to the upper side of the baffle plate, and the tip of the tapered plate 3 faces the adjustment part.

[0048] The working process and principle of the present embodiment are: the conical plate 3 adjusts the direction of potato cutting, so that the rotation axis of the potato cutting and the turning roller 4 is vertical, so that the turning roller 4 accelerates the potato cutting. The acceleration time obtained by potato strips is different, and the potato strips can be separated according to the length; the water sprayed from the water pipe 1 accelerates the potato strips, and the distance between the potato strips is opened to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com