Demoulding device and demoulding method of magnetic material

A magnetic material and demoulding device technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of low demoulding efficiency and achieve the effect of easy installation and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

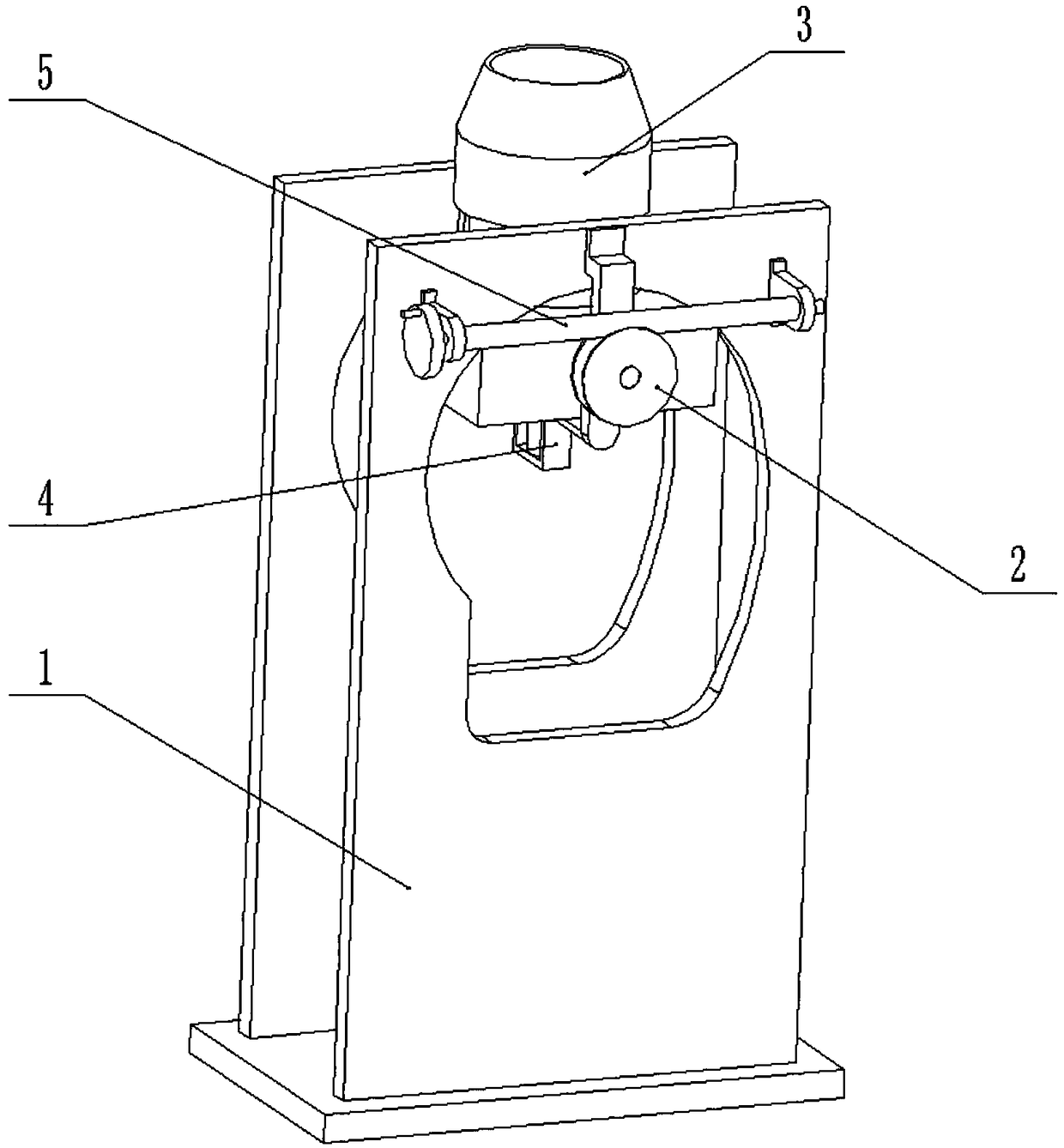

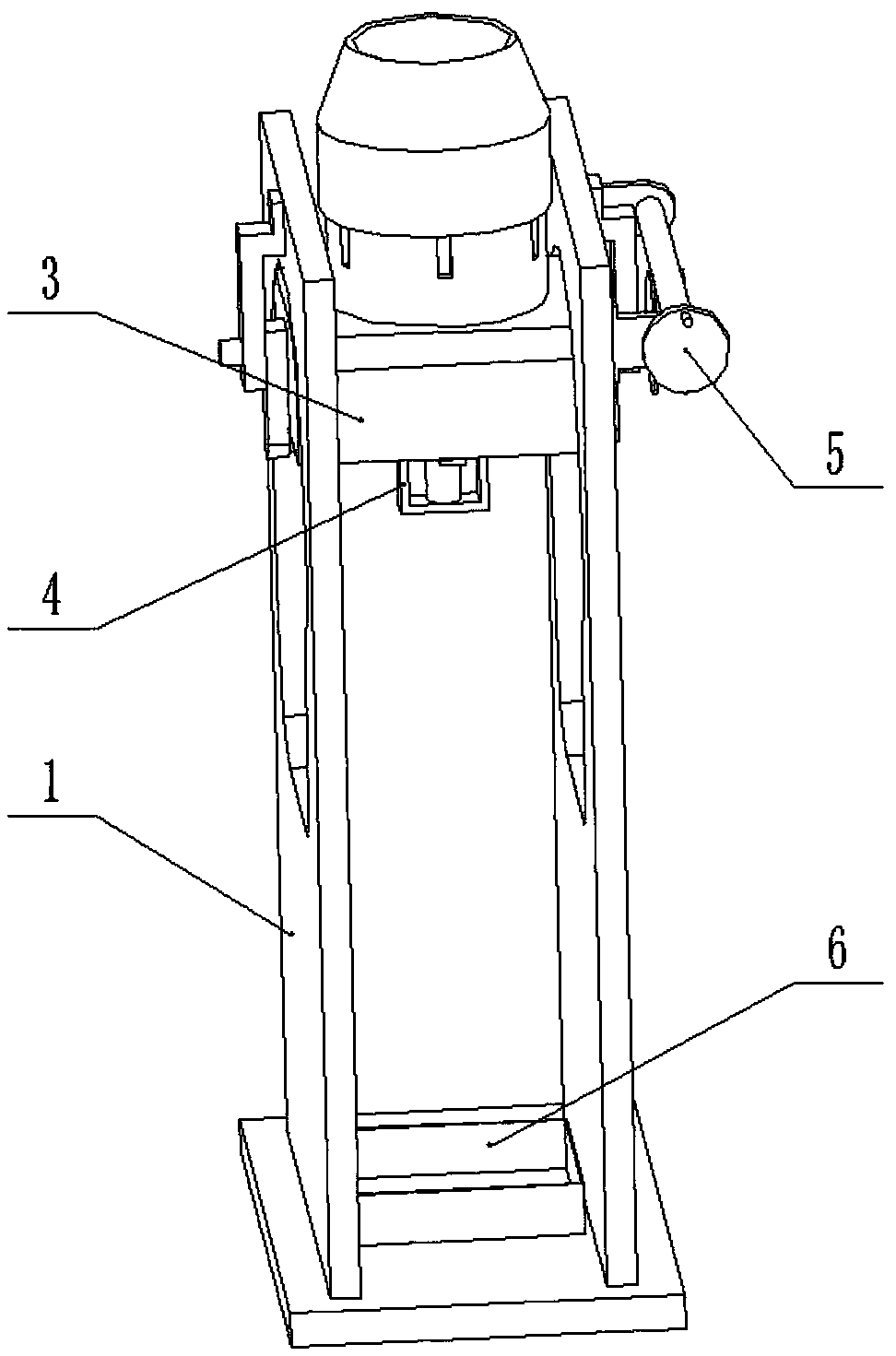

[0031] Combine below Figure 1-11 Describe this embodiment, a magnetic material demoulding device, including a frame 1, a worm gear assembly 2, a mold fixture 3, a pushing device 4 and a worm assembly 5, the worm gear assembly 2 is rotatably connected to the frame 1, the The mold fixing part 3 is arranged at the middle end of the worm gear assembly 2, the pushing device 4 is fixedly connected to the worm gear assembly 2, the pushing device 4 elastically squeezes the mold fixing part 3, and the mold fixing part 3 is slidably connected On the frame 1, the worm assembly 5 is rotatably connected to the frame 1, and the worm assembly 5 and the worm assembly 2 are engaged and connected through the worm gear; when in use, the mold is fixed in the mold fixture 3, and the worm is manually operated The component 5 drives the worm gear component 2 to rotate, and the rotation of the worm gear component 2 drives the mold fixing part 3 to turn over. When the opening of the mold fixing part ...

specific Embodiment approach 2

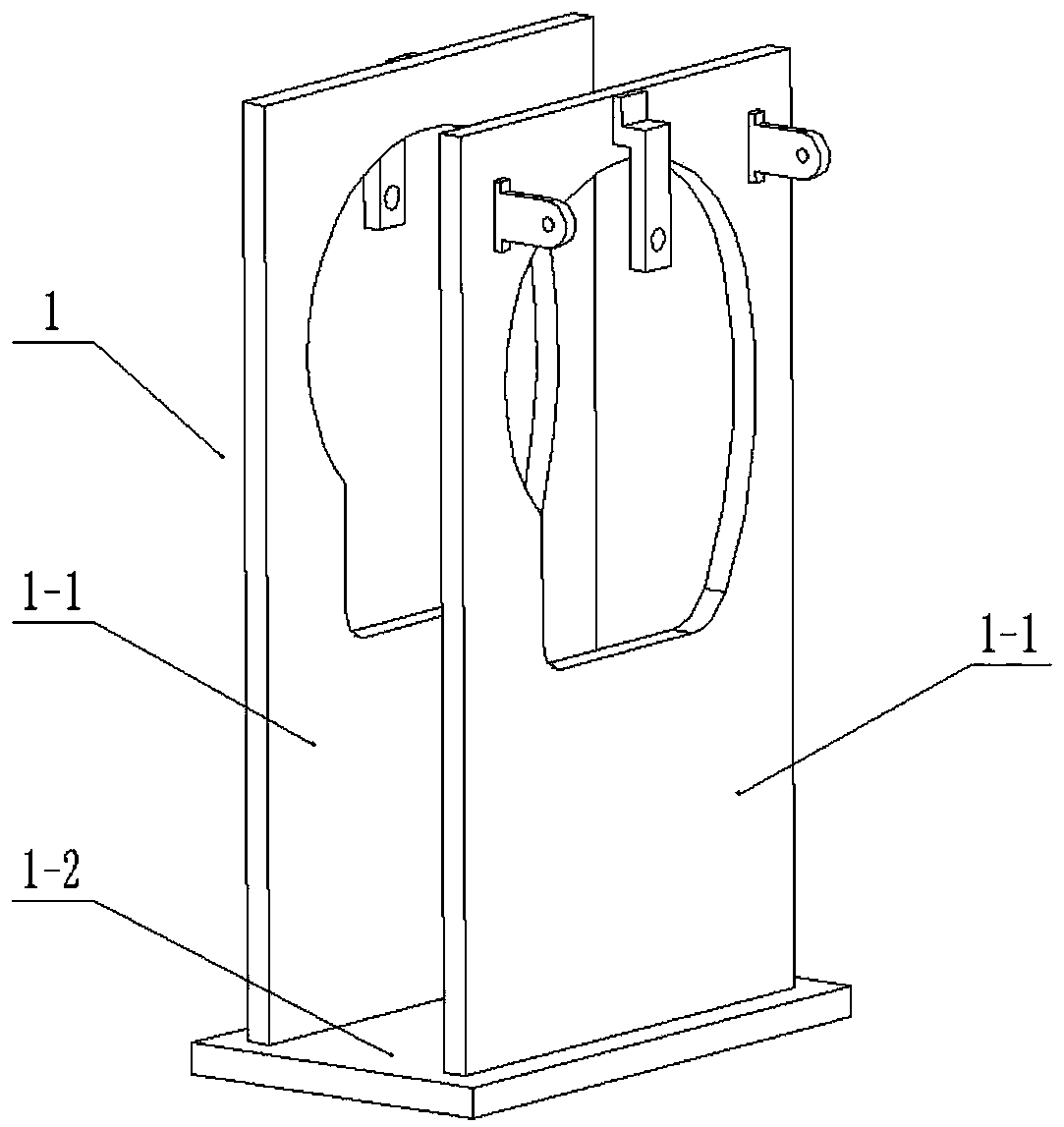

[0032] Combine below Figure 1-11 This embodiment will be described, and this embodiment will further describe Embodiment 1. The frame 1 includes a side plate 1-1 and a bottom plate 1-2, and the bottom plate 1-2 is fixedly connected with two opposite side plates 1 -1, the side plate 1-1 is provided with a semicircular groove 1-1-1, a rectangular groove 1-1-2 and a transition arc edge 1-1-3, and the rectangular groove 1-1-2 is located in the semicircular groove The lower end of 1-1-1, the semicircular groove 1-1-1 communicates with the rectangular groove 1-1-2, and the right end of the rectangular groove 1-1-2 and the semicircular groove 1-1-1 is provided with a transition arc Side 1-1-3; when the opening of the mold fixing part 3 faces upwards, the taper sleeve base 3-1 is against the inner side of the semicircular groove 1-1-1, and the spring 4-5 is compressed to the shortest state; the opening of the mold fixing part 3 faces When it is down, the taper sleeve base 3-1 slides...

specific Embodiment approach 3

[0033] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the second embodiment, the worm gear assembly 2 includes a rectangular shaft 2-1, a circular shaft end 2-2 and a worm wheel 2-3, the two sides of the rectangular shaft 2-1 Both ends are fixedly connected with a circular shaft end 2-2, the worm gear 2-3 is fixedly connected to the right-hand circular shaft end 2-2, and the two circular shaft ends 2-2 are respectively connected to the side plate 1- 1, the rectangular shaft 2-1 is located in the semicircular groove 1-1-1, and the rectangular shaft 2-1 is used to drive the taper sleeve base 3-1 and.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com