Charging structure for high chamber pressure artillery

A charge and chamber pressure technology, applied to ammunition, weapon accessories, offensive equipment, etc., can solve problems such as difficulty in reaching the initial velocity, achieve the effects of improving ignition, increasing the initial velocity of projectiles, and improving ballistic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in conjunction with accompanying drawing.

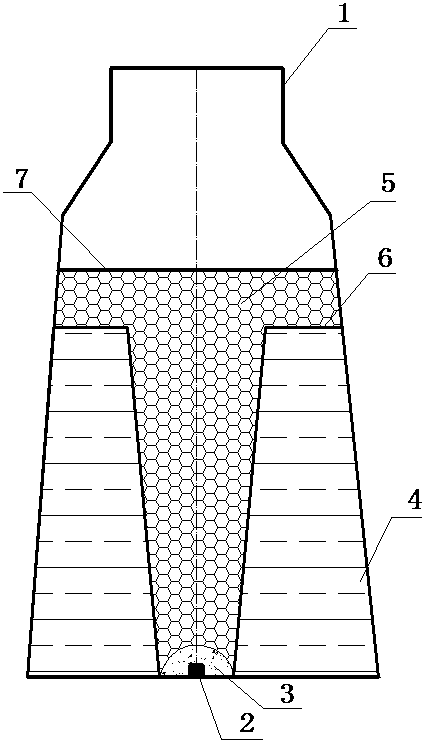

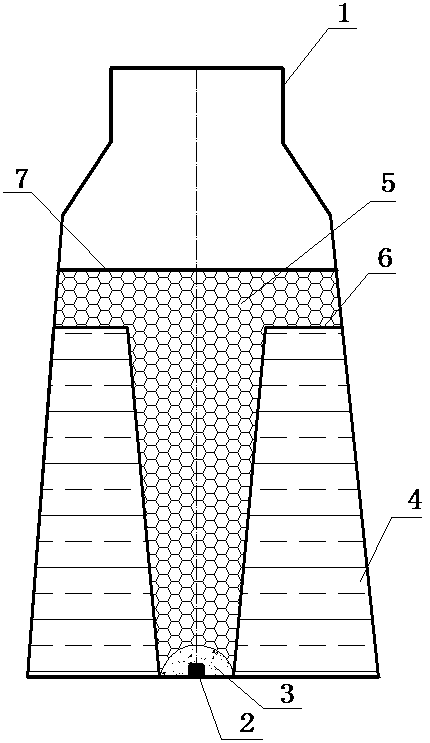

[0016] Such as figure 1 Shown is a charge structure for high-pressure guns, including cartridge 1, primer 2, black powder bag 3, single-11A-8 / 1 propellant 4, single-base 5 / 7 propellant 5, and nitrocellulose Cardboard 6 and cardboard cover 7, the cartridge 1 is a truncated conical shell with an open upper part, the primer 2 is fixed on the bottom of the cartridge 1, and the black powder pack 3 is fixed on the upper part of the primer 2, single camphor-11A- The 8 / 1 propellant 4 is arranged around the inside of the cartridge 1, the single-base 5 / 7 propellant 5 is arranged in the center of the cartridge 1, and the nitrocellulose cardboard 6 is arranged between the single-11A-8 / 1 propellant 4 and the Between the 5 single-base 5 / 7 propellants and in close contact with the two, the cardboard cover plate 7 is arranged on the top of the single-base 5 / 7 propellant 5; the cartridge 1 is brass with a th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Top diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com