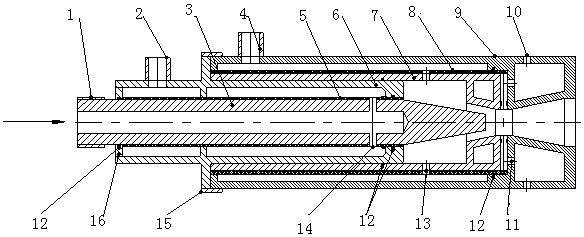

Double-cathode double-medium gas plasma burner

A plasma and burner technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of large power consumption of secondary energy, reduce power consumption, wide operating conditions, and increase the flame temperature adjustment range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The operating voltage is 80V, the current is 150A, the gas uses air and natural gas as the medium gas, and the designed power of the burner is 10kw. Test results: The thermal power provided by plasma is 6.3kw, the thermal power provided by combustion is 4.6kw, the actual operating power is 9.9kw, which is basically the same as the design power, the temperature after combustion is about 2550°C, and the ignition can be stabilized after repeated ignition experiments Combustion, the air-fuel ratio is controlled between 1:1.1~1.3, the gas flow rate is 20L / min, the cooling water volume is 15L / min, and the cooling water level difference is about 1°C.

Embodiment 2

[0052] When the operating voltage is 80V and the current is 200A, air and natural gas are used as the medium gas respectively, and the designed power of the burner is 10kw. Test results: The thermal power provided by plasma is 7.2kw, the thermal power provided by combustion is 2.7kw, the actual operating power is 9.9kw, which is basically the same as the design power, the temperature after combustion is about 2850°C, and the ignition can be stabilized after repeated ignition experiments Combustion, the air-fuel ratio is controlled between 1:1.1~1.3, the gas flow rate is 20L / min, the cooling water volume is 15L / min, and the cooling water level difference is about 1.5°C.

Embodiment 3

[0054] The operating voltage is 80V, the current is 100A, the gas uses air and natural gas as the medium gas, and the designed power of the burner is 10kw. Test results: The thermal power provided by plasma is 5.2kw, the thermal power provided by combustion is 4.2kw, the actual operating power is 10kw, which is basically the same as the design power, the temperature after combustion is about 2250 ℃, repeated ignition experiment ignition, all can burn stably , the air-fuel ratio is controlled between 1:1.1~1.3, the gas flow rate is 20L / min, the cooling water volume is 15L / min, and the cooling water level difference is about 0.8°C.

[0055] In summary, the double-cathode double-medium gas plasma burner of the present invention adopts a double-cathode double-medium plasma burner, which can cancel the traditional ion rod electric spark ignition and the traditional gas burning lamp ignition, making the ignition method more convenient; When the flame temperature is high, part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com