gas delayed recoil method

A technology with barrel and technical characteristics, applied in the field of gas delayed recoil, can solve the problem of impulse balance barrel, etc., to achieve the effect of improving mobility, easy assembly, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

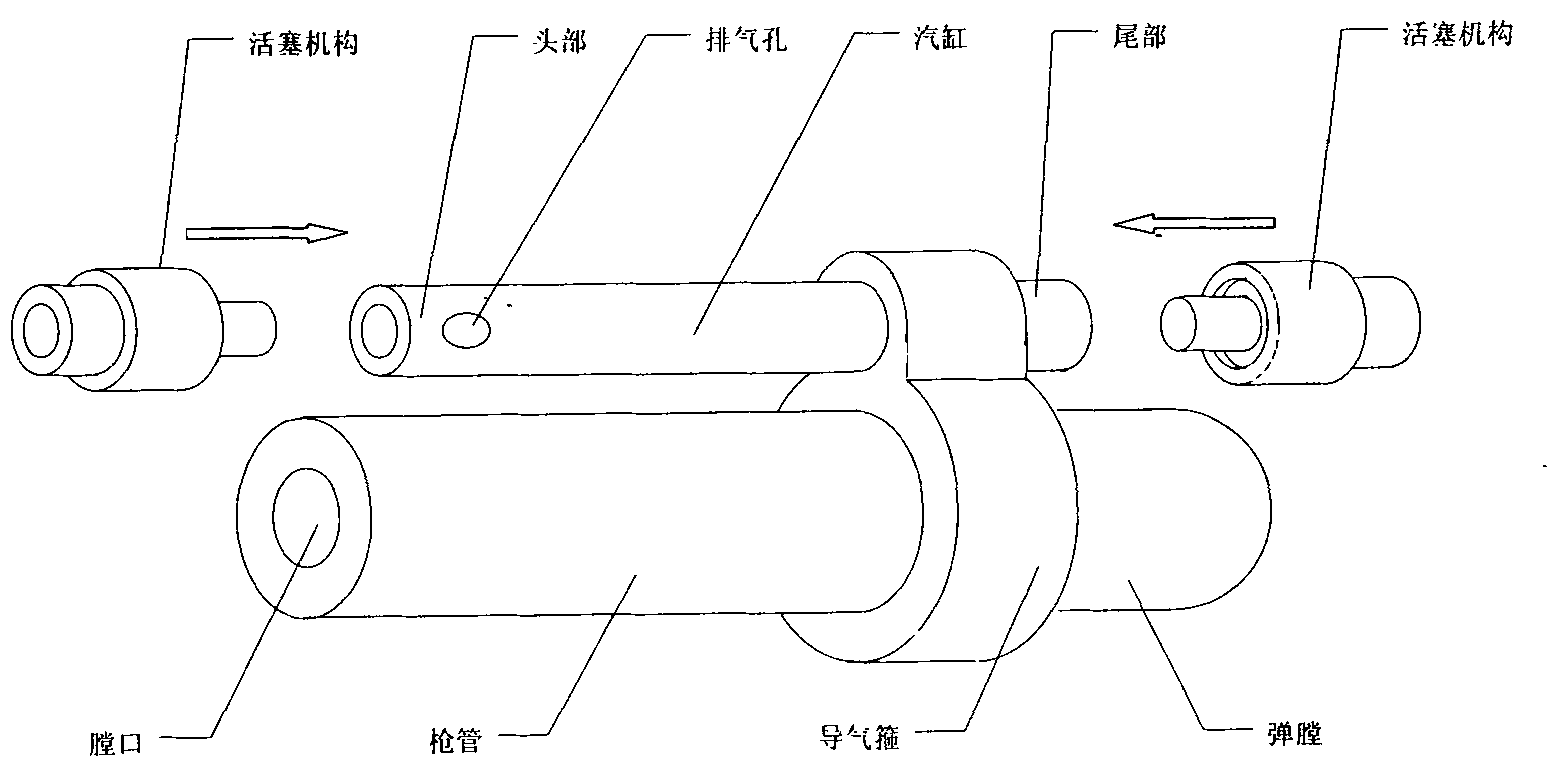

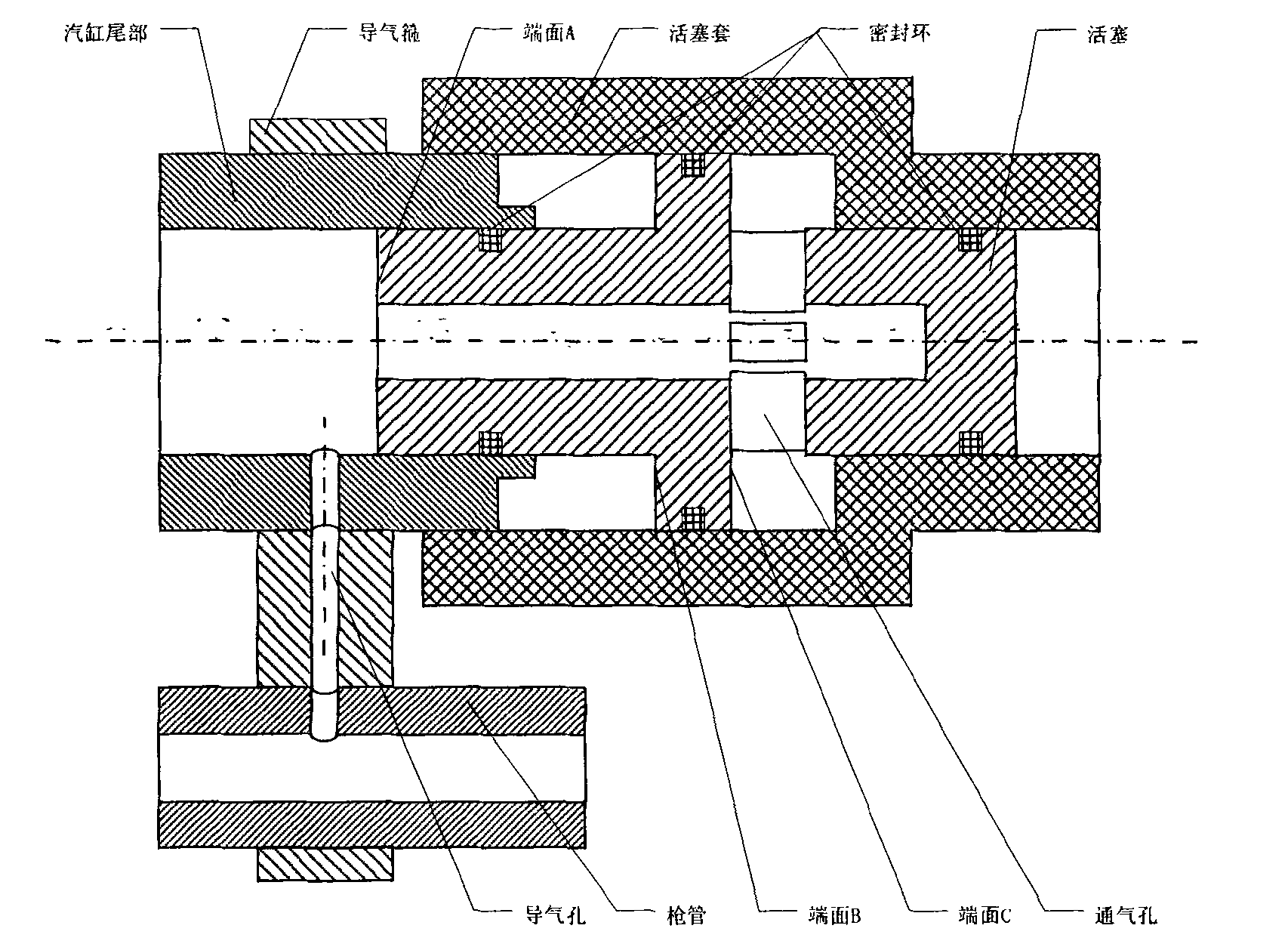

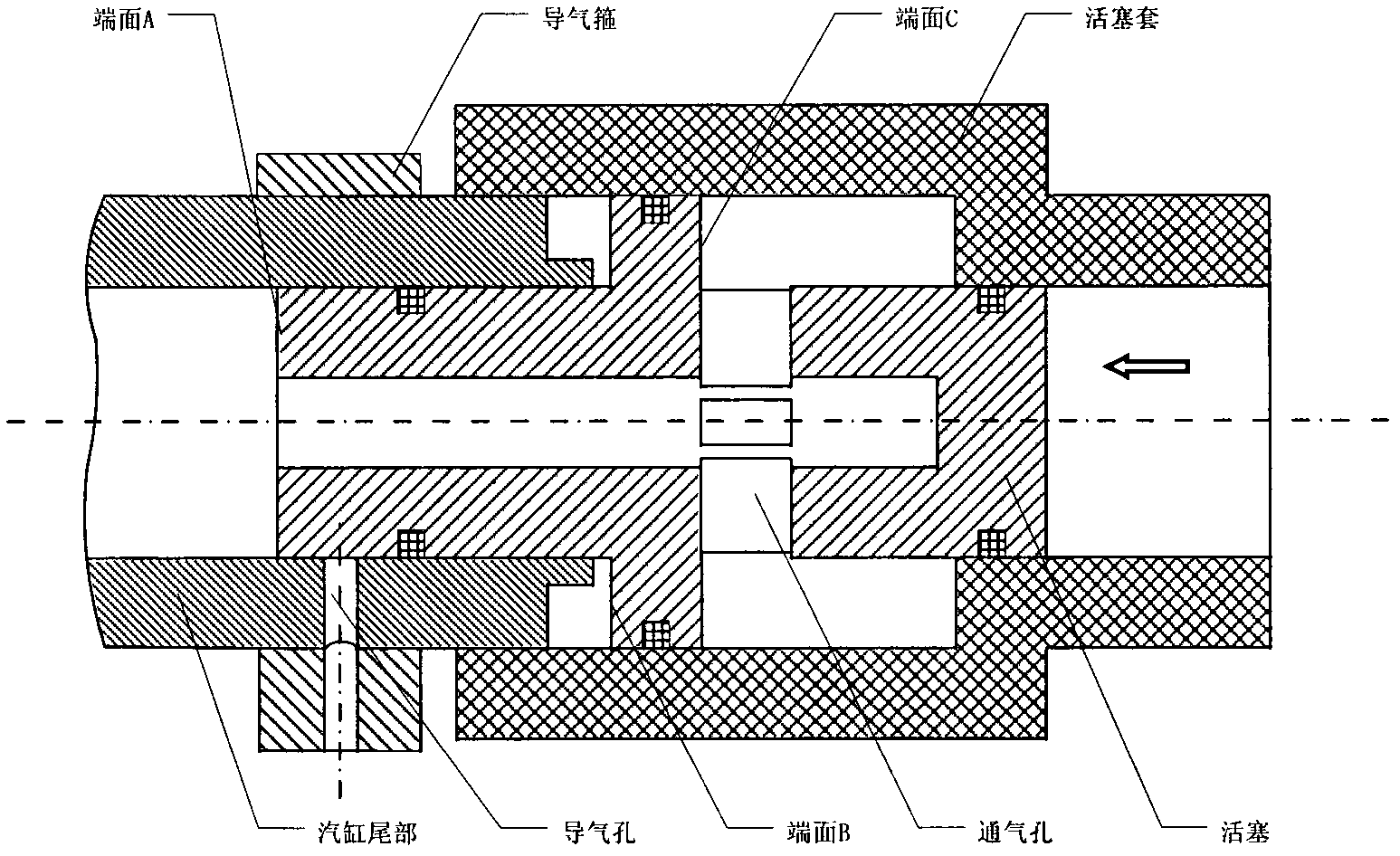

[0059] Applied to weapon systems and using cylinders.

[0060] (Note: In this part, simplified calculations and estimates are used to illustrate design ideas, design methods and calculation methods, not to obtain accurate design data.)

[0061] For example, referring to the 25mm cannon and the 25mm high-speed grenade launchers under development in various countries (such as the "Ideal Individual Combat Weapon"-OICW and "Ideal Team Support Weapon"-OCSW in the United States), the weapon design index is set as: caliber 25mm , The projectile mass is 100g, the initial velocity is 500m / s, the maximum chamber pressure is over 200MPa, and the total length of the rifling part and the slope part of the barrel is 300mm; the recoil impulse is required to be equivalent to that of the ordinary 7.62mm rifle (about 14N·s) to achieve shoulder and shoulder resistance. Motorized launch, the length of the cylinder (excluding the piston mechanism) does not exceed 400mm; the known conditions are:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com