Patents

Literature

82results about How to "Raise the gas temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

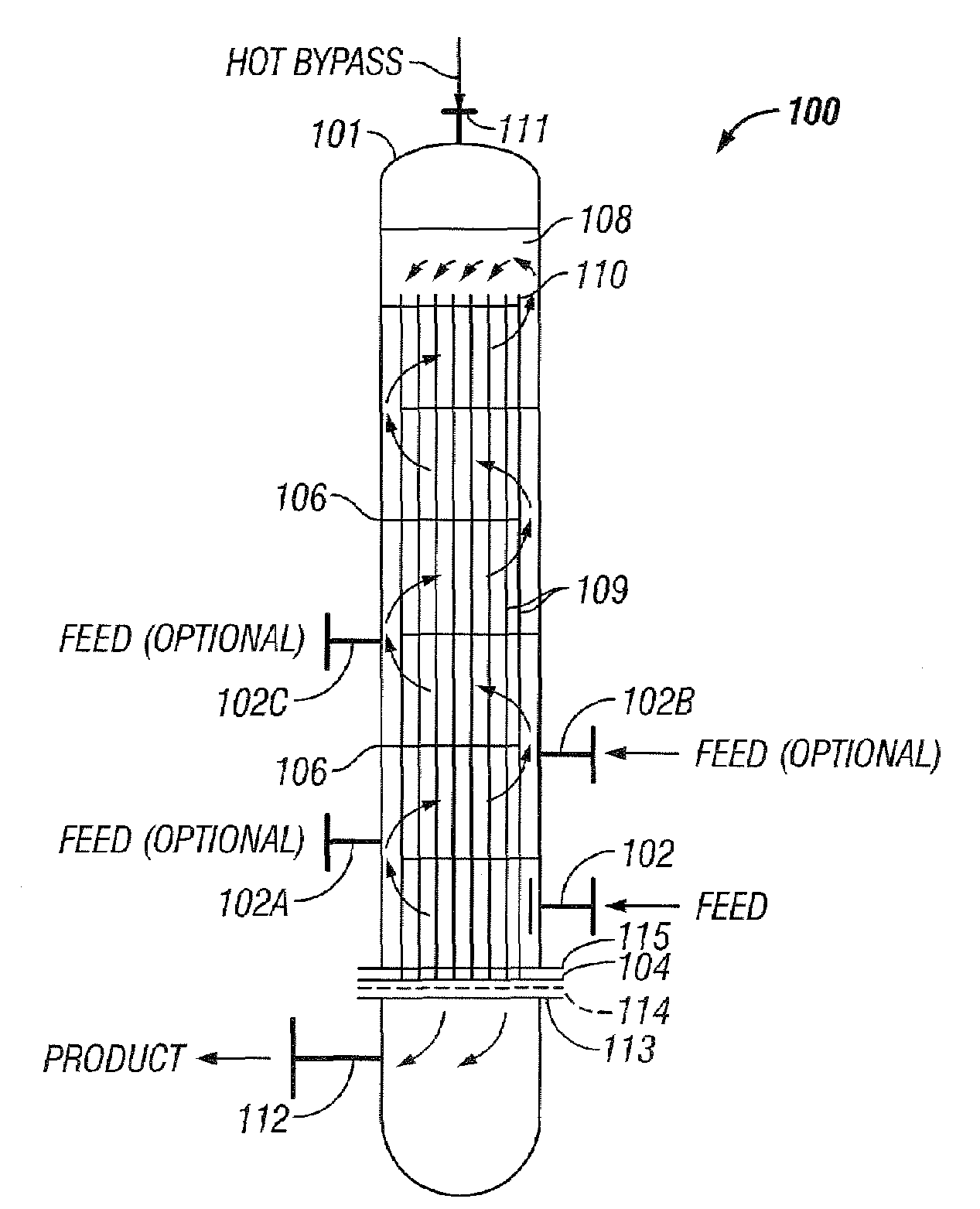

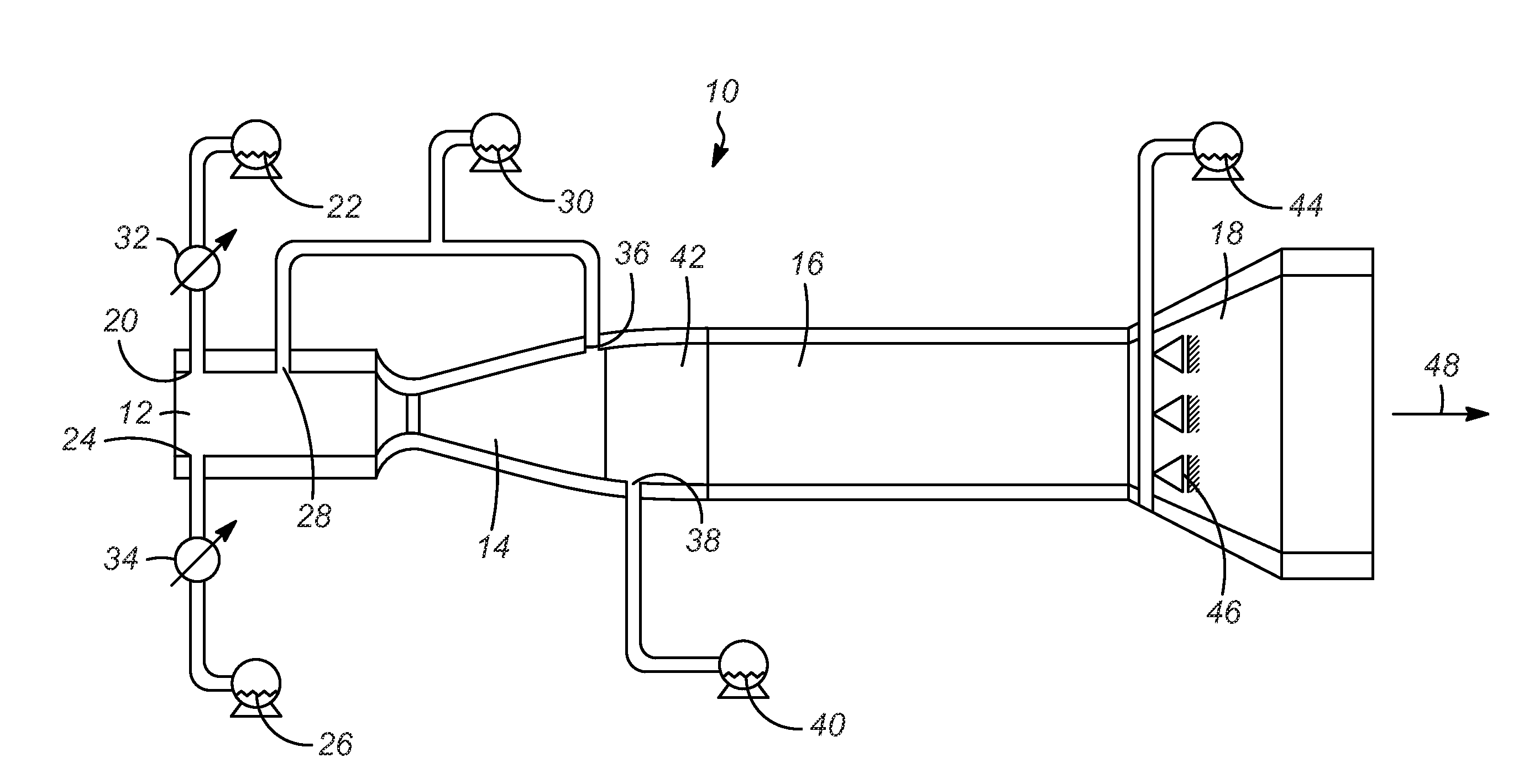

Maximum reaction rate converter system for exothermic reactions

ActiveUS20060099131A1Reduction in catalyst volumeSpeed up the conversion processMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionReaction temperatureEquilibrium curve

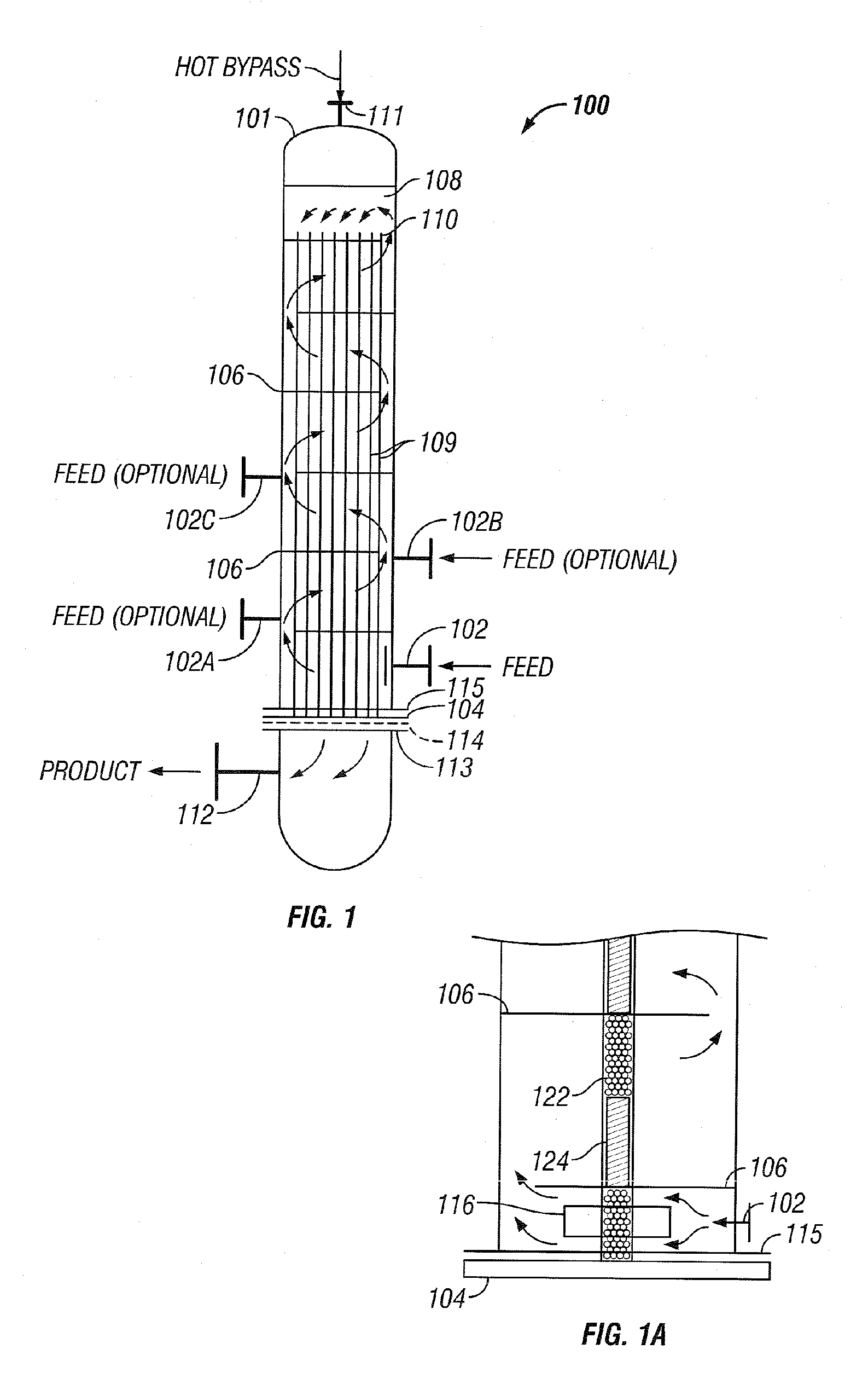

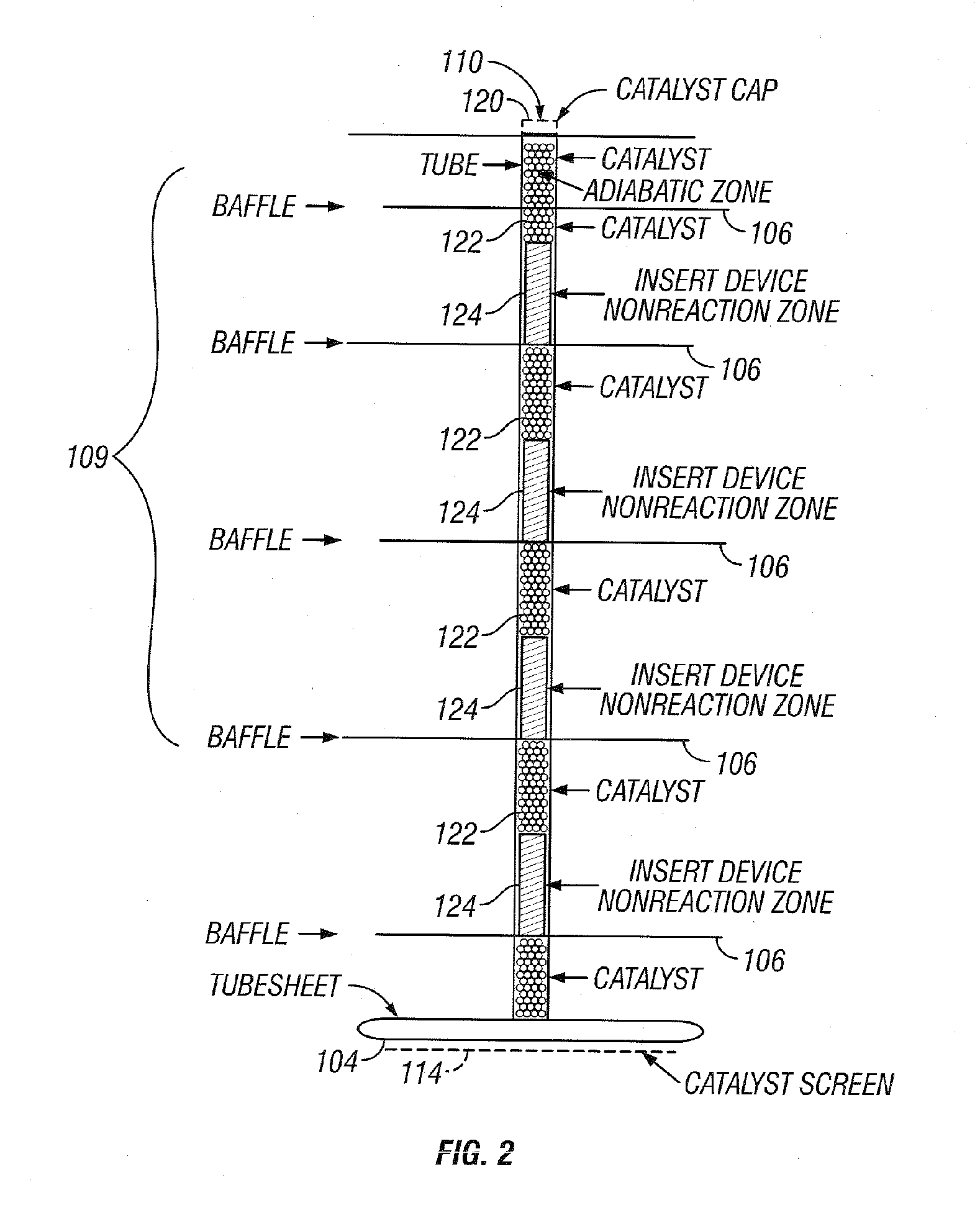

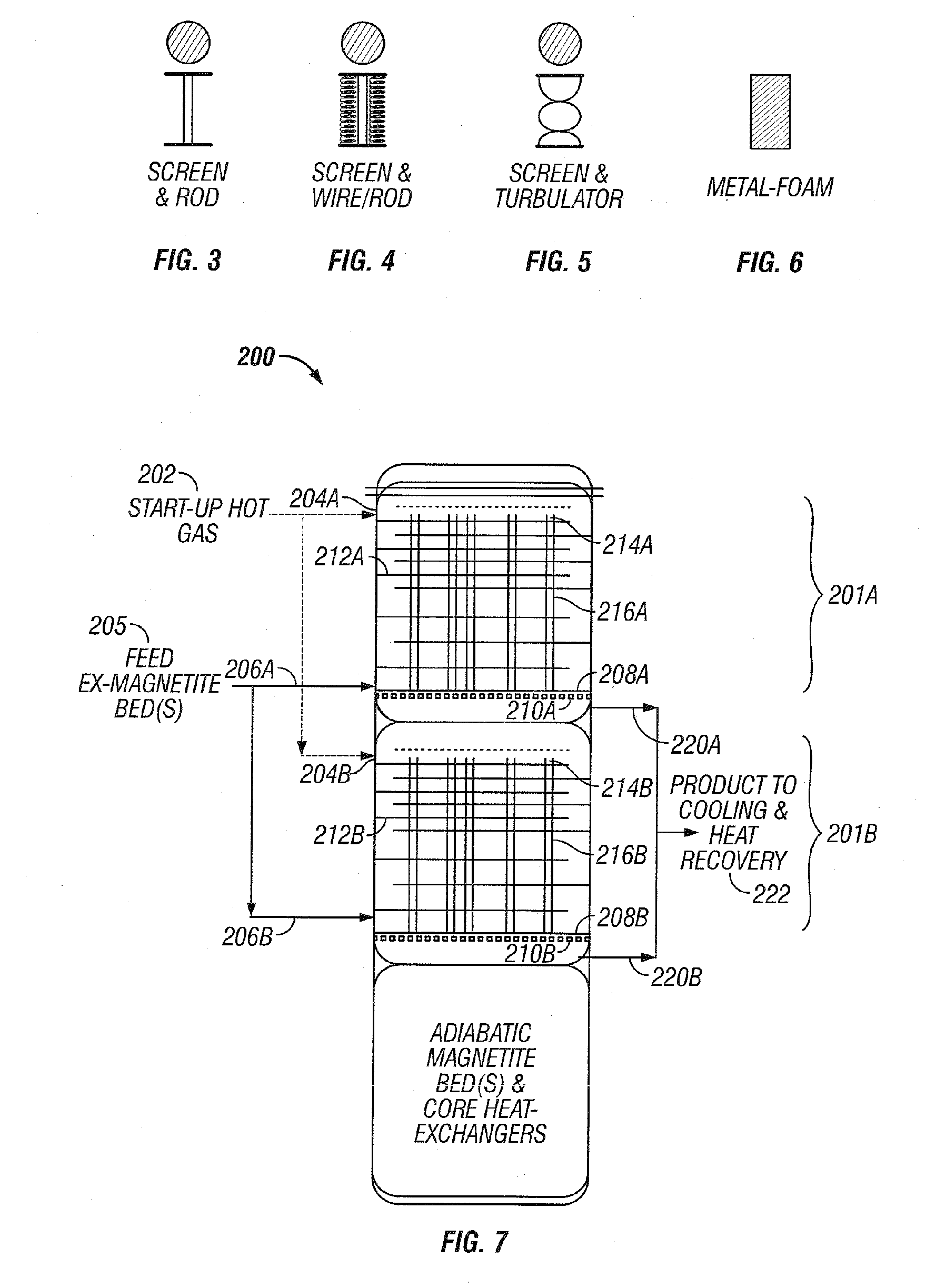

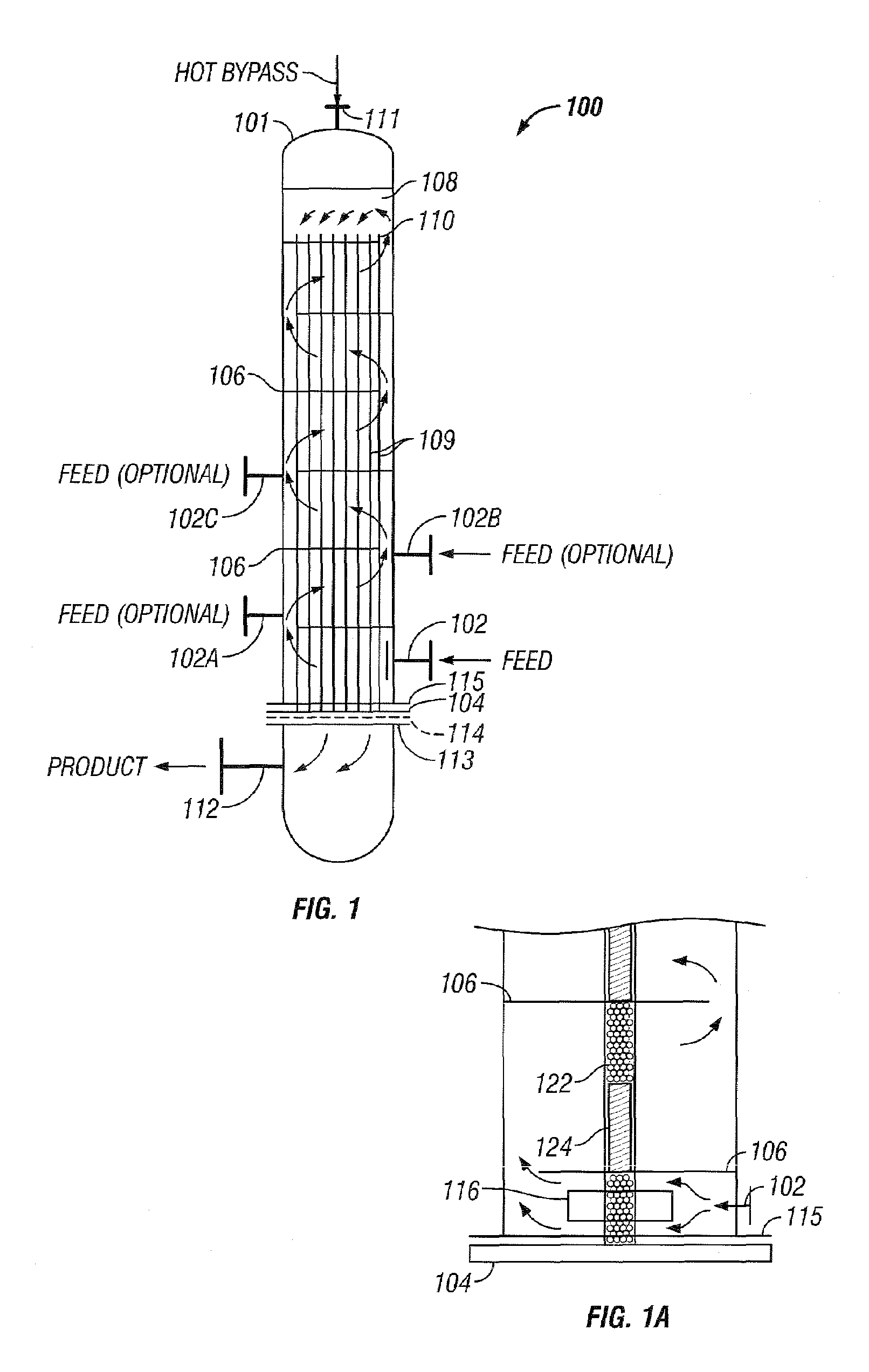

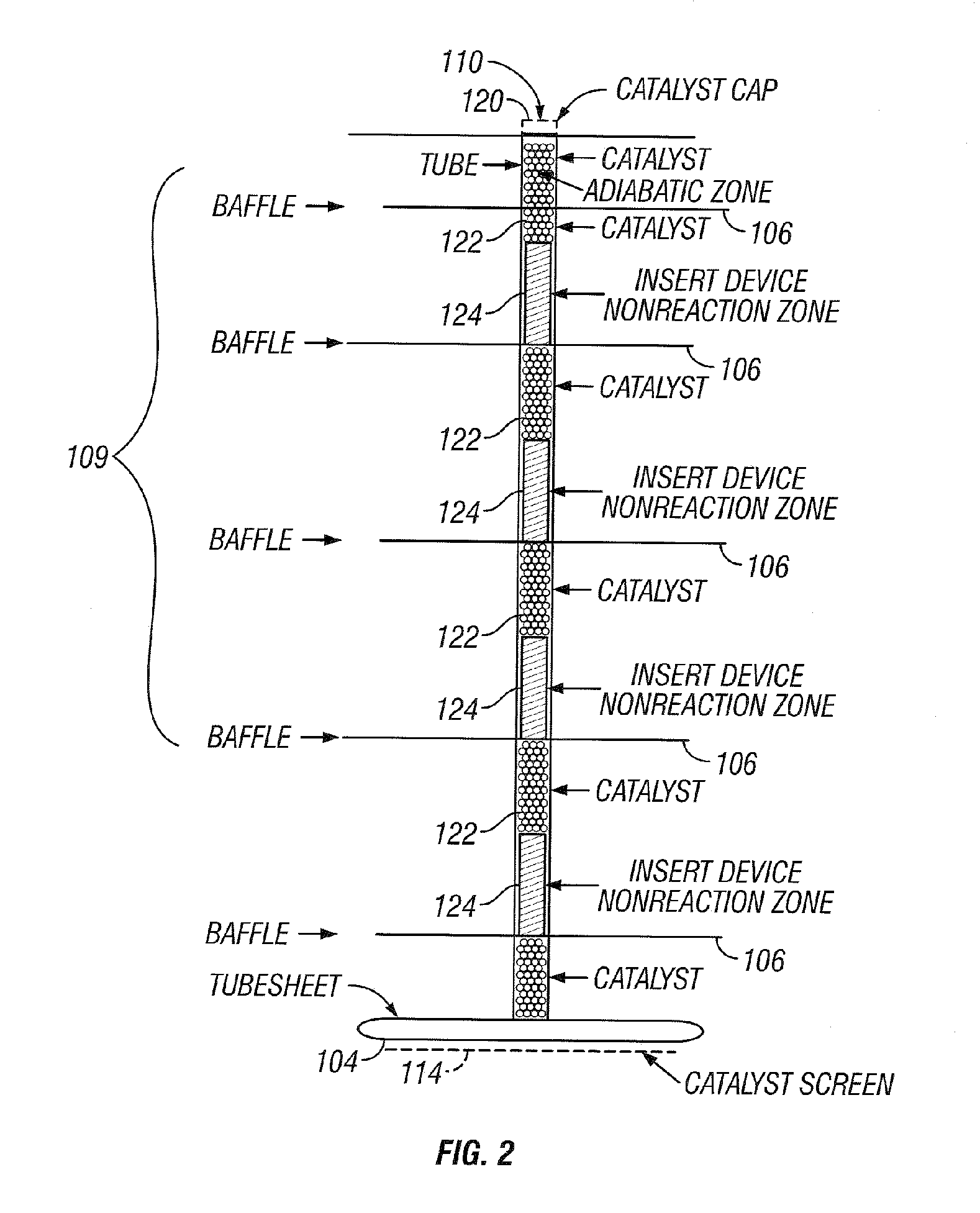

An ammonia converter system and method are disclosed. The reactor can alter the conversion of ammonia by controlling the reaction temperature of the exothermic reaction along the length of the reactor to parallel the equilibrium curve for the desired product. The reactor 100 can comprise a shell 101 and internal catalyst tubes 109. The feed gas stream enters the reactor, flows through the shell 101, and is heated by indirect heat exchange with the catalyst tubes 109. The catalyst tubes 109 comprise reactive zones 122 having catalyst and reaction limited zones 124 that can comprise inert devices that function to both separate the reactive zones, increase heat transfer area, and reduce the temperature of the reaction mixture as the effluent passes through the catalyst tube 109.

Owner:KELLOGG BROWN & ROOT LLC

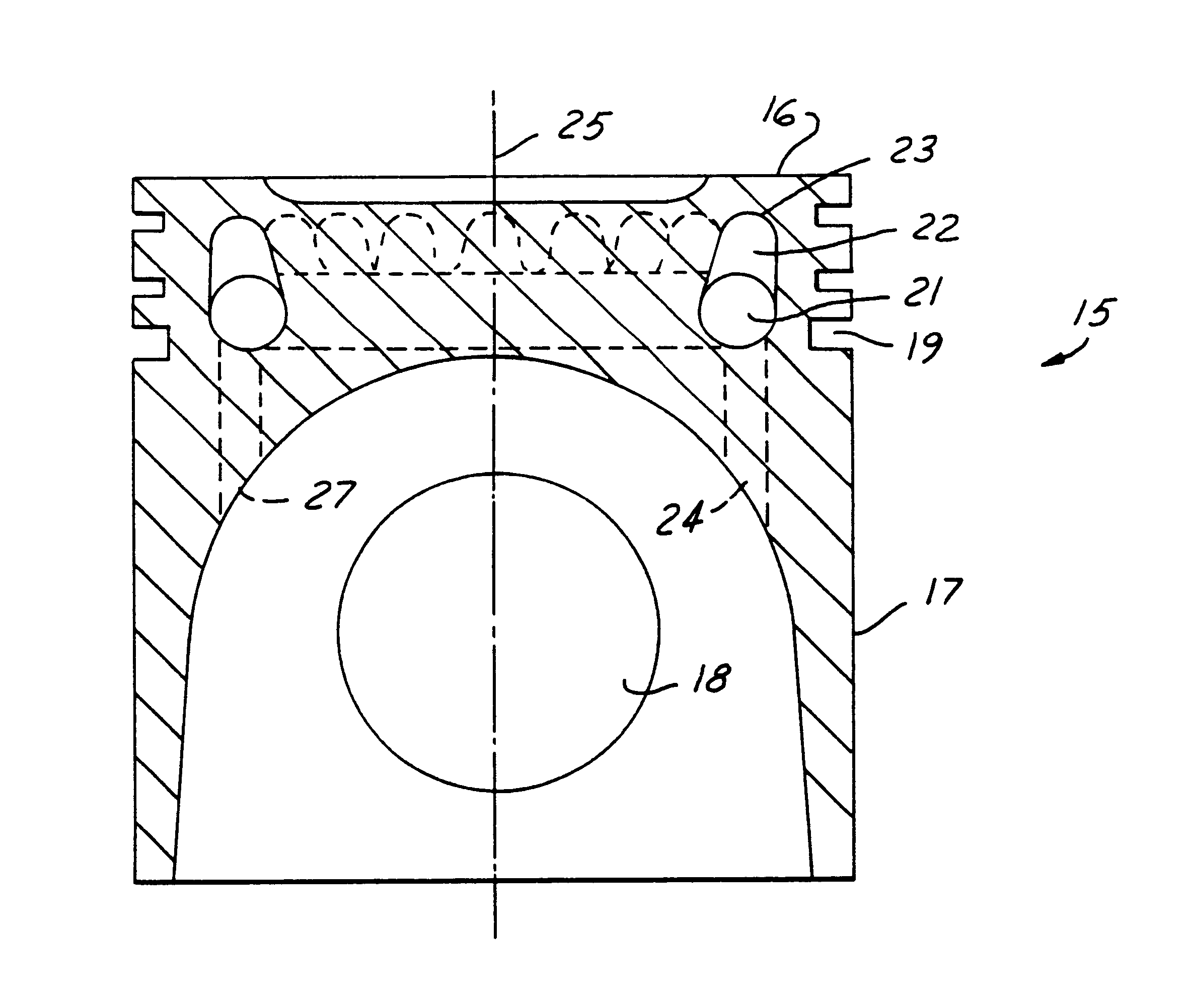

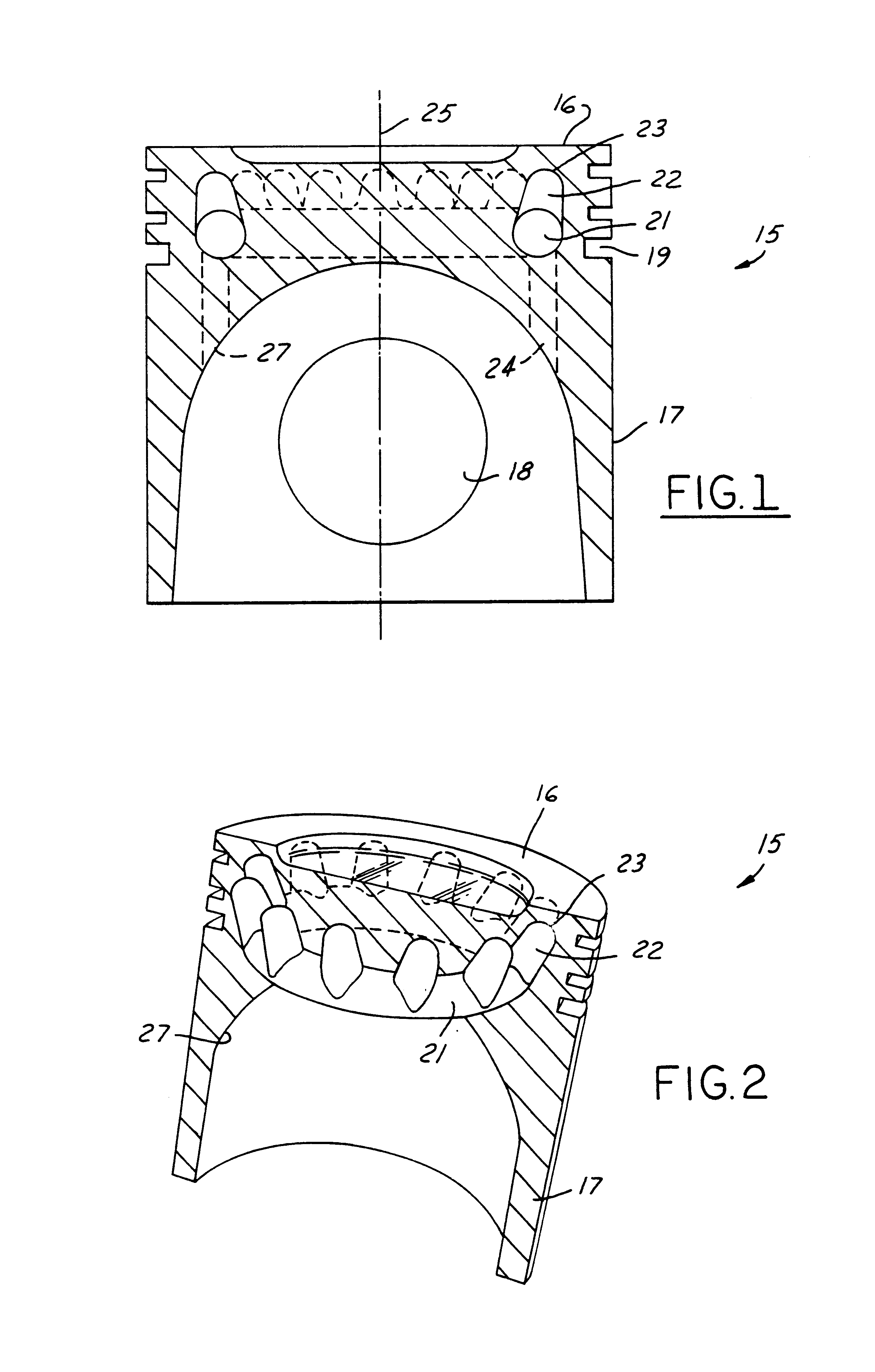

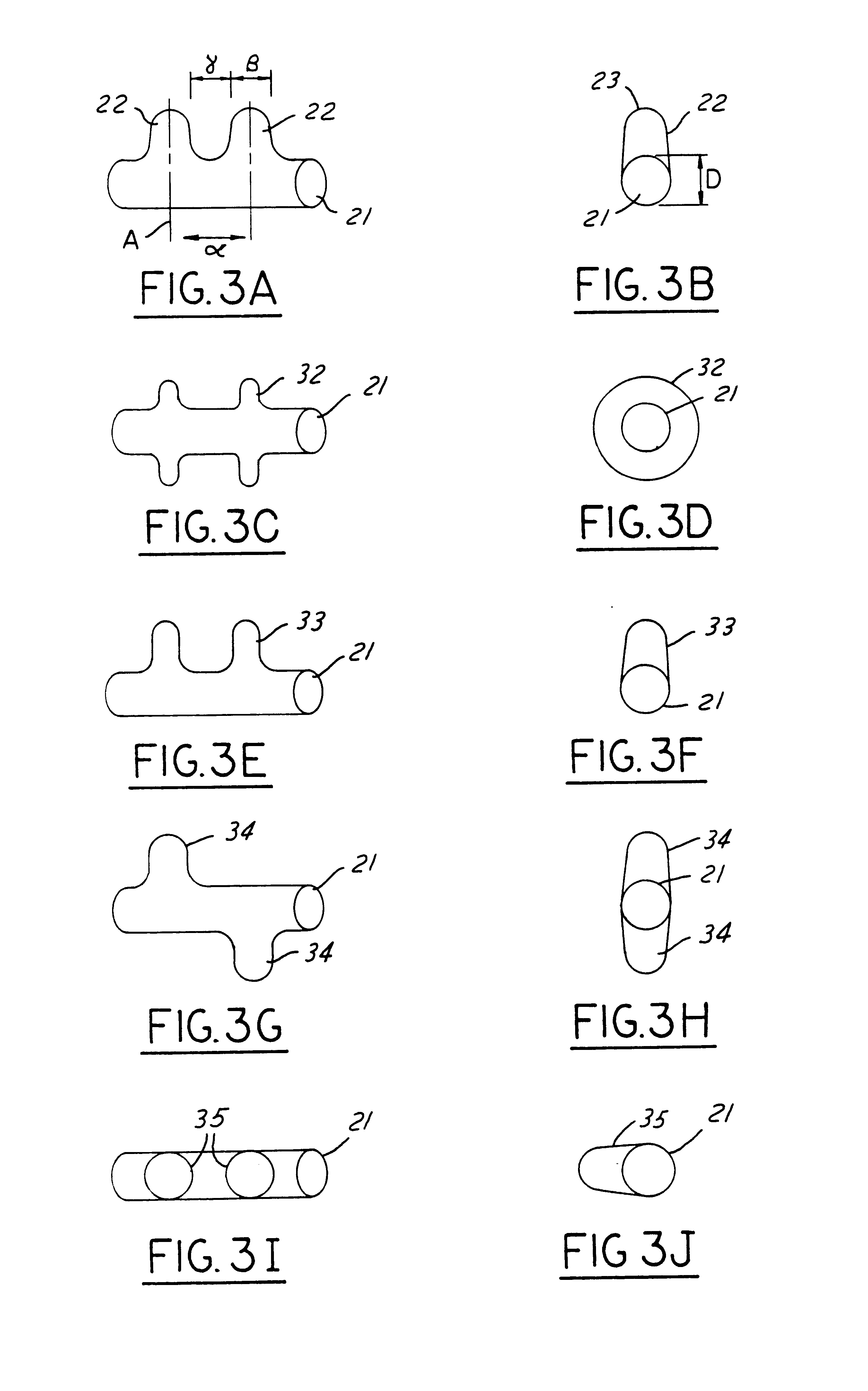

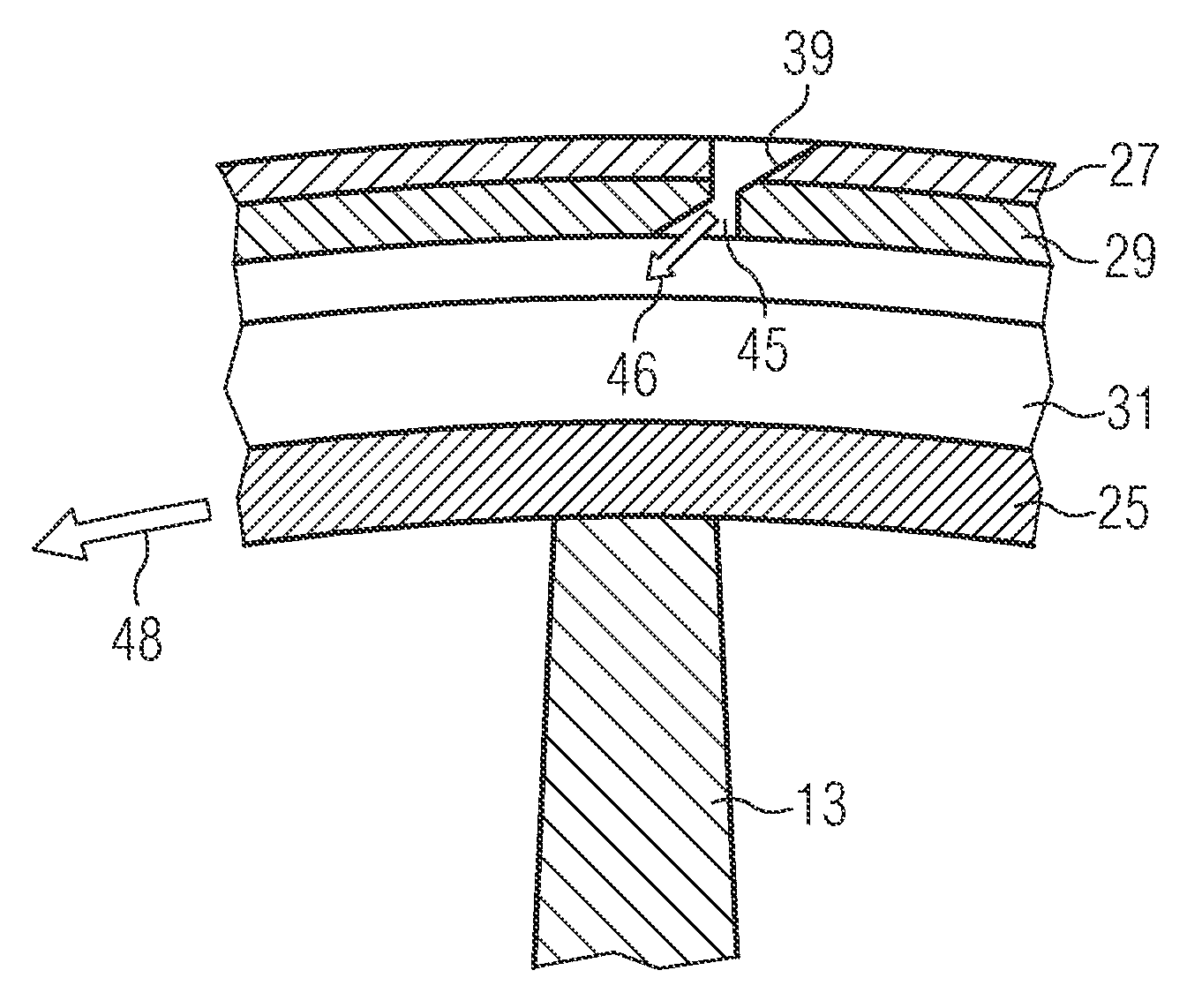

Piston coolant gallery

InactiveUS7281466B1Low sectionAvoid many problemsFoundry mouldsMachines/enginesWorking fluidHeat flow

A cast piston, for an internal combustion engine or pump has an integral coolant ring gallery, with localized extensions, to achieve a coolant interchange with the gallery upon piston reciprocation. At least a portion of an extension lies generally parallel to the longitudinal piston axis and towards an upper end of the piston adjacent the working fluid. This provides an attendant increase in surface area exposed to coolant allowing either a decrease in operational piston temperature or an increase in allowable heat flow into the piston from a working fluid.

Owner:SENECA TECH

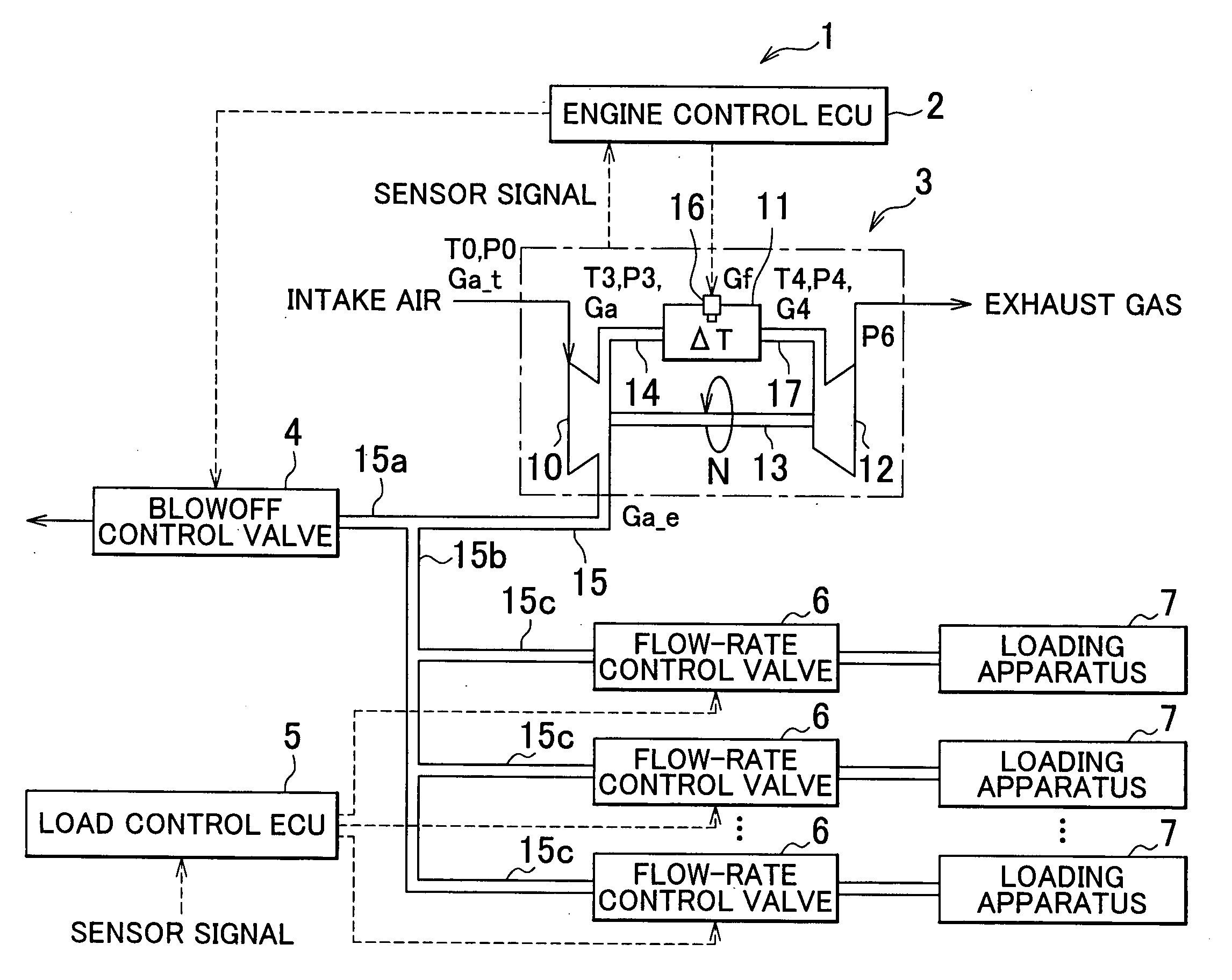

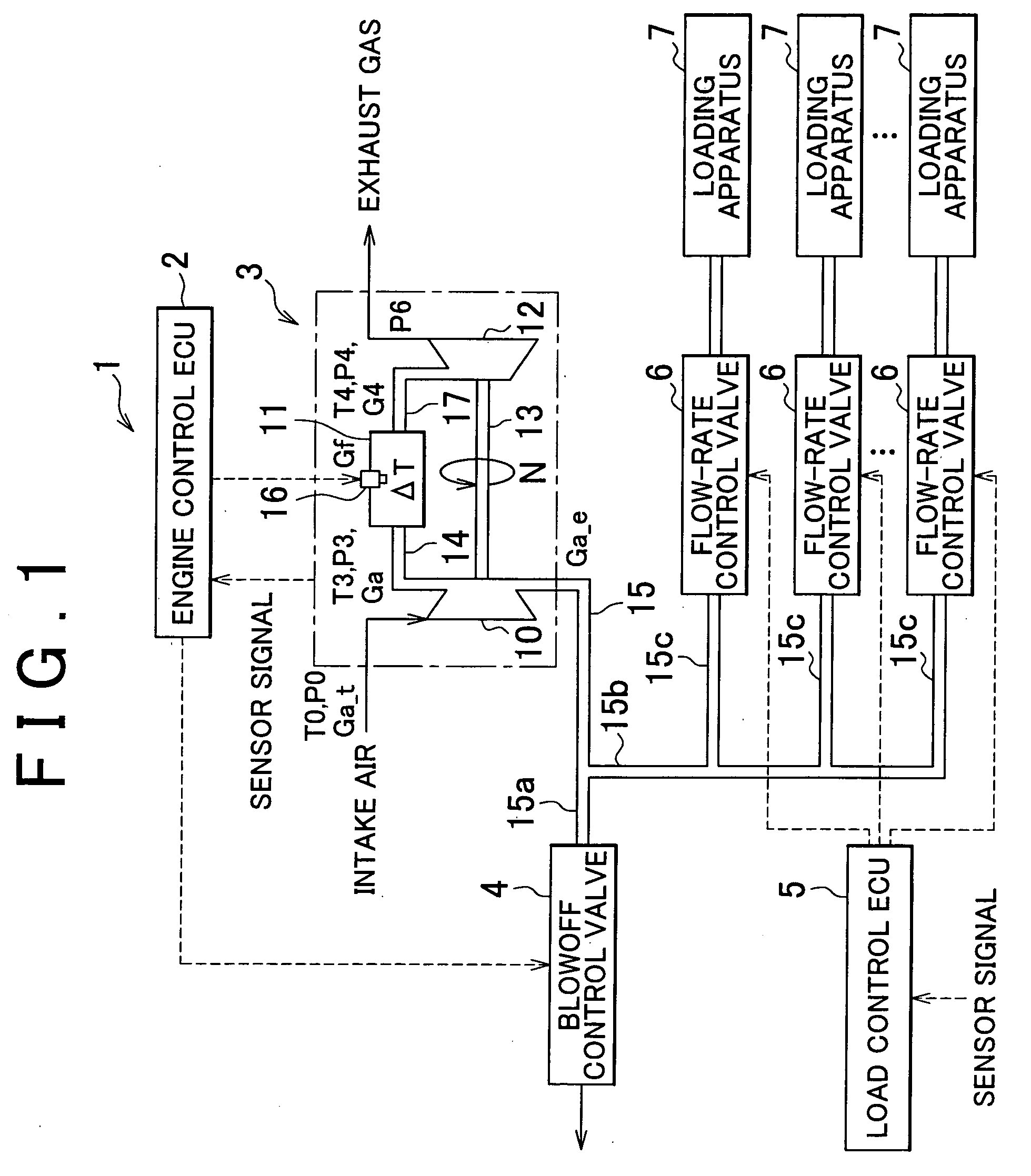

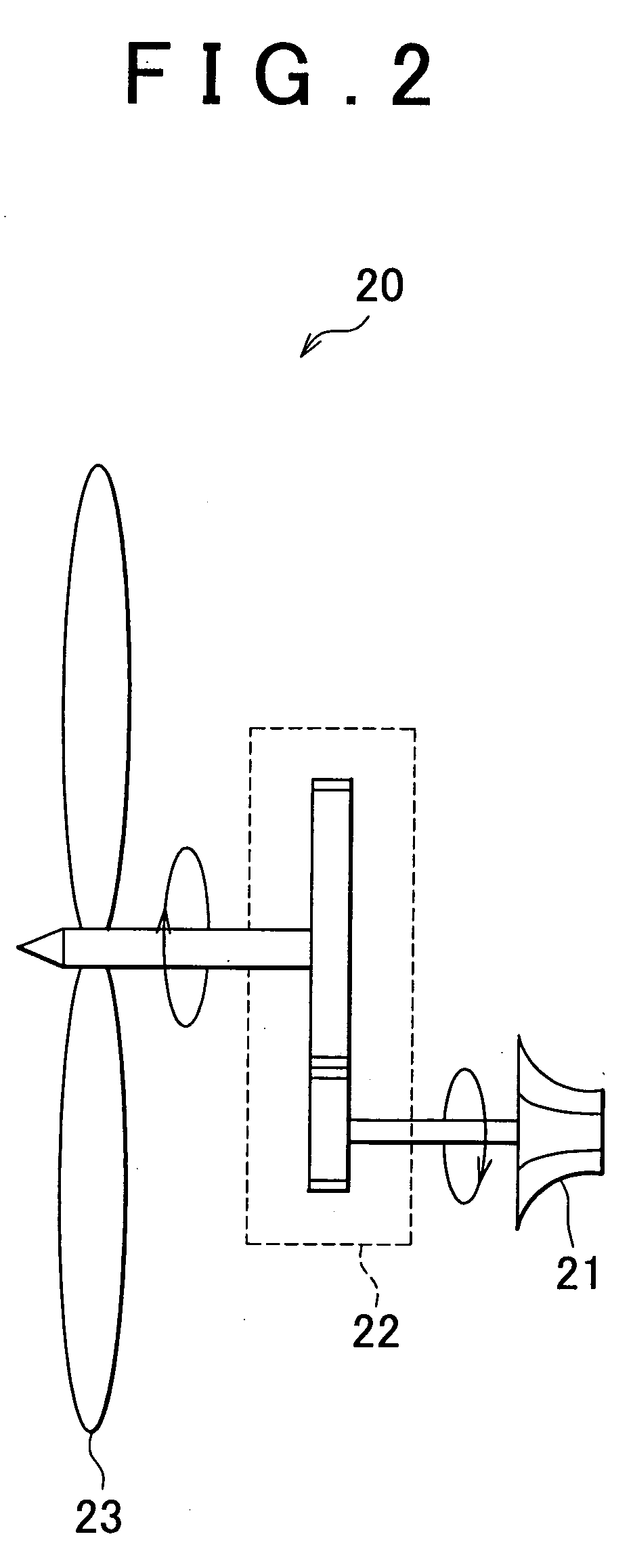

Control apparatus and method for gas-turbine engine

InactiveUS20090113896A1Avoid it happening againImprove engine performanceAnalogue computers for vehiclesGas turbine plantsCombustion chamberTurbine

There is provided a control apparatus for a gas-turbine engine which is configured in such a manner that a portion of compressed air from a compressor is supplied to a combustion chamber and the other portion of the compressed air is sent to the outside of the engine to be used as source of energy, and a turbine is rotated by combustion gas produced in the combustion chamber. The control apparatus executes the optimum combustion control in an extraction engine. The control apparatus calculates the physical quantity related to the air in the gas-turbine engine using the turbine flow-rate coefficient in the range in which the turbine chokes.

Owner:TOYOTA JIDOSHA KK

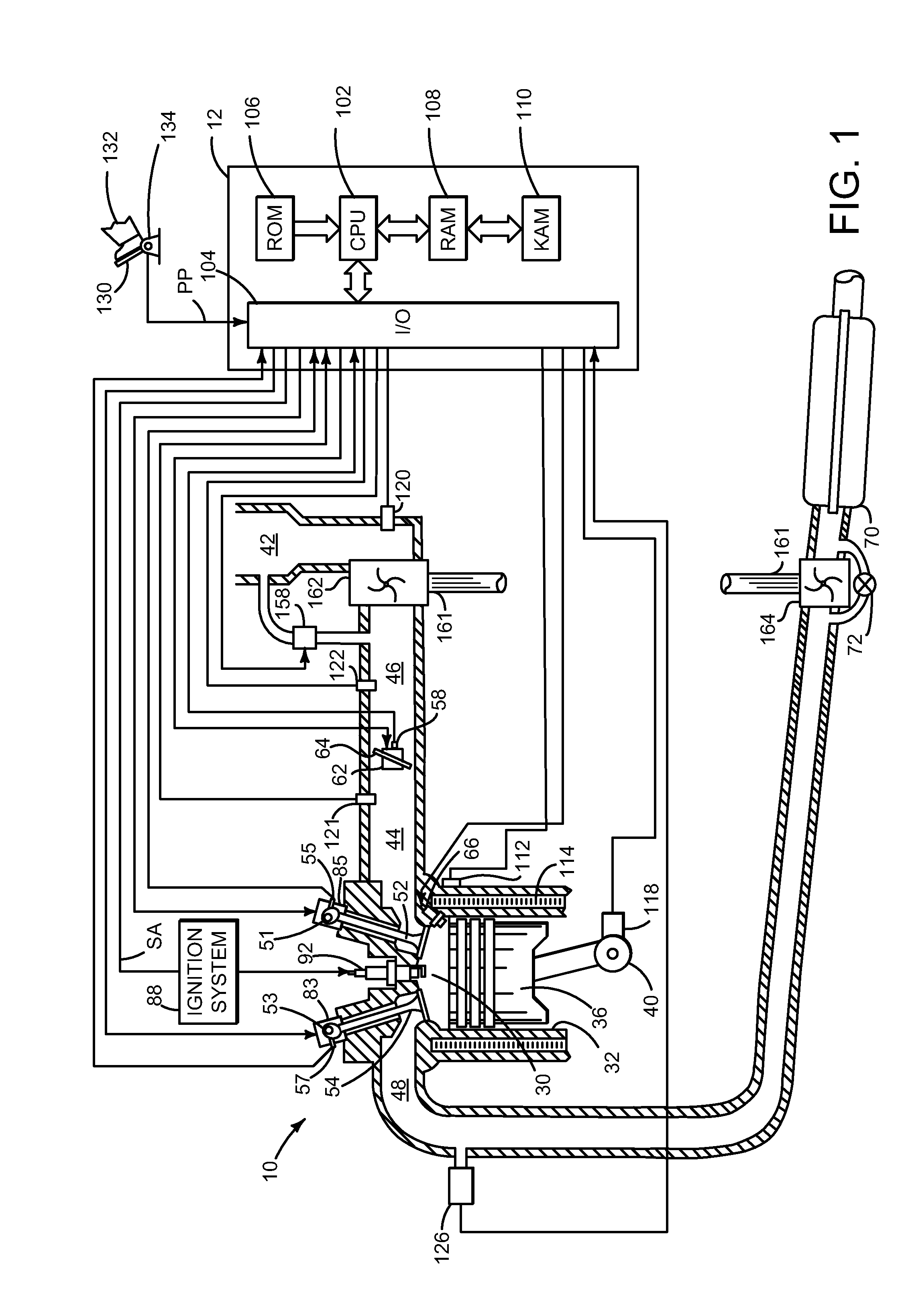

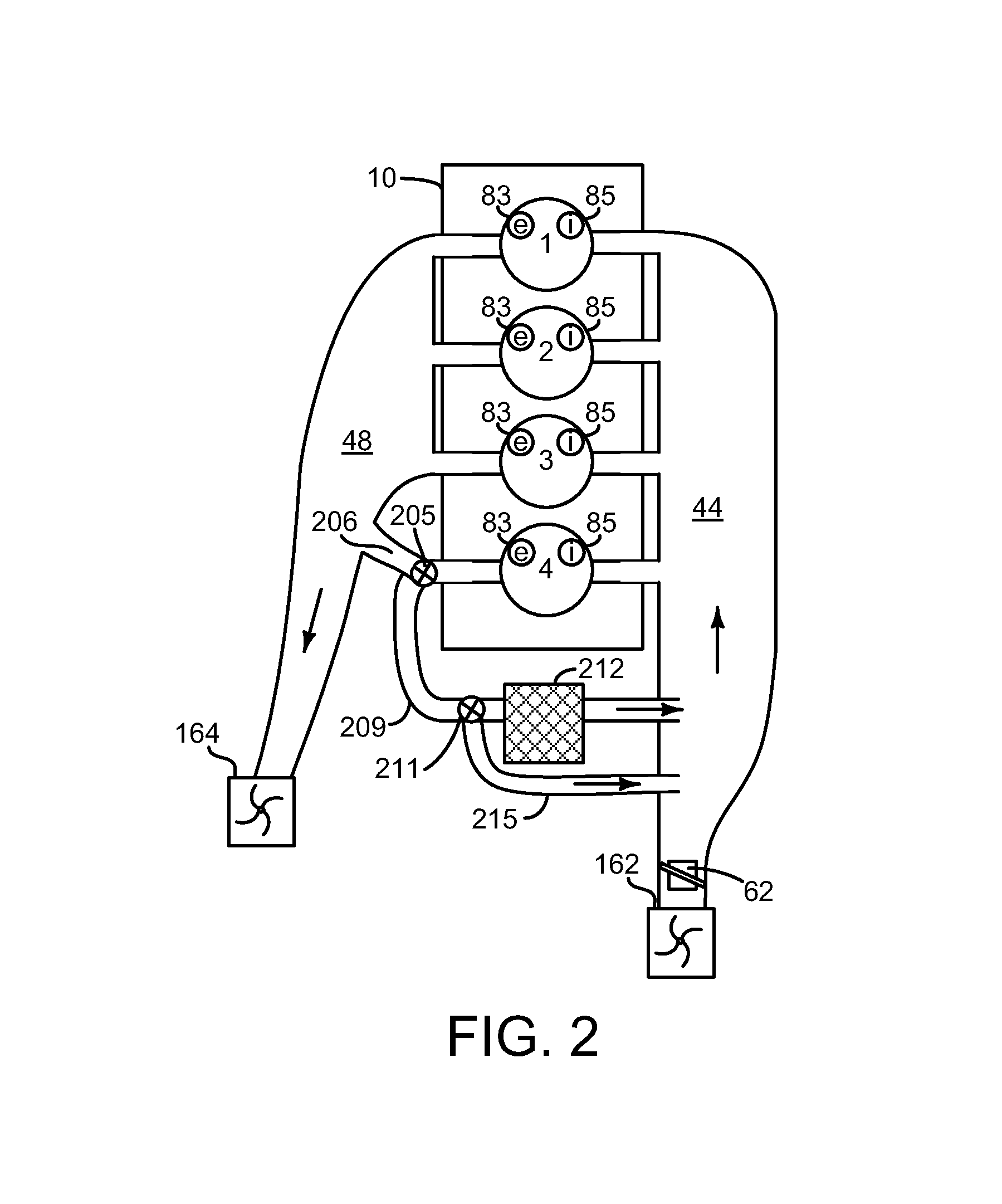

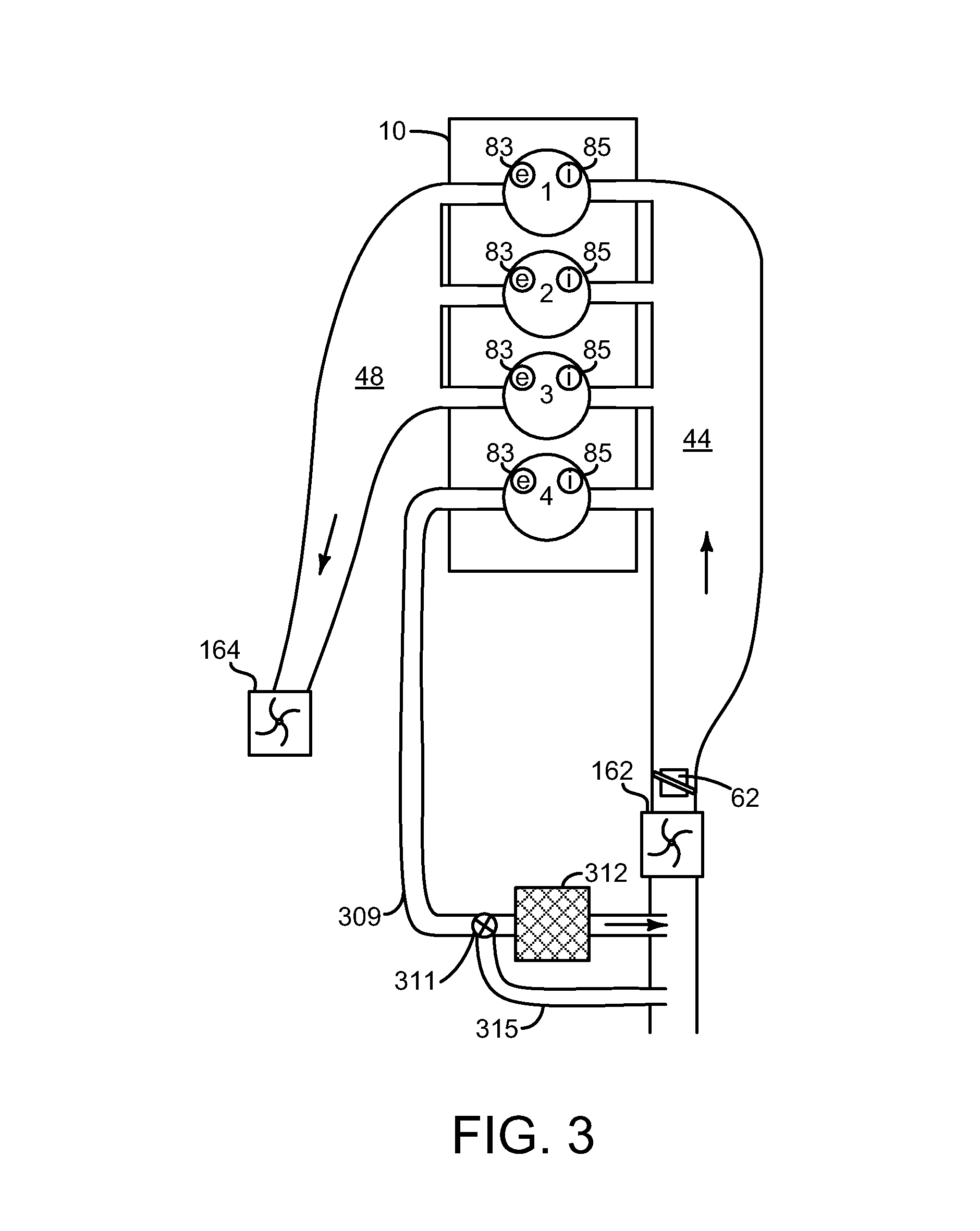

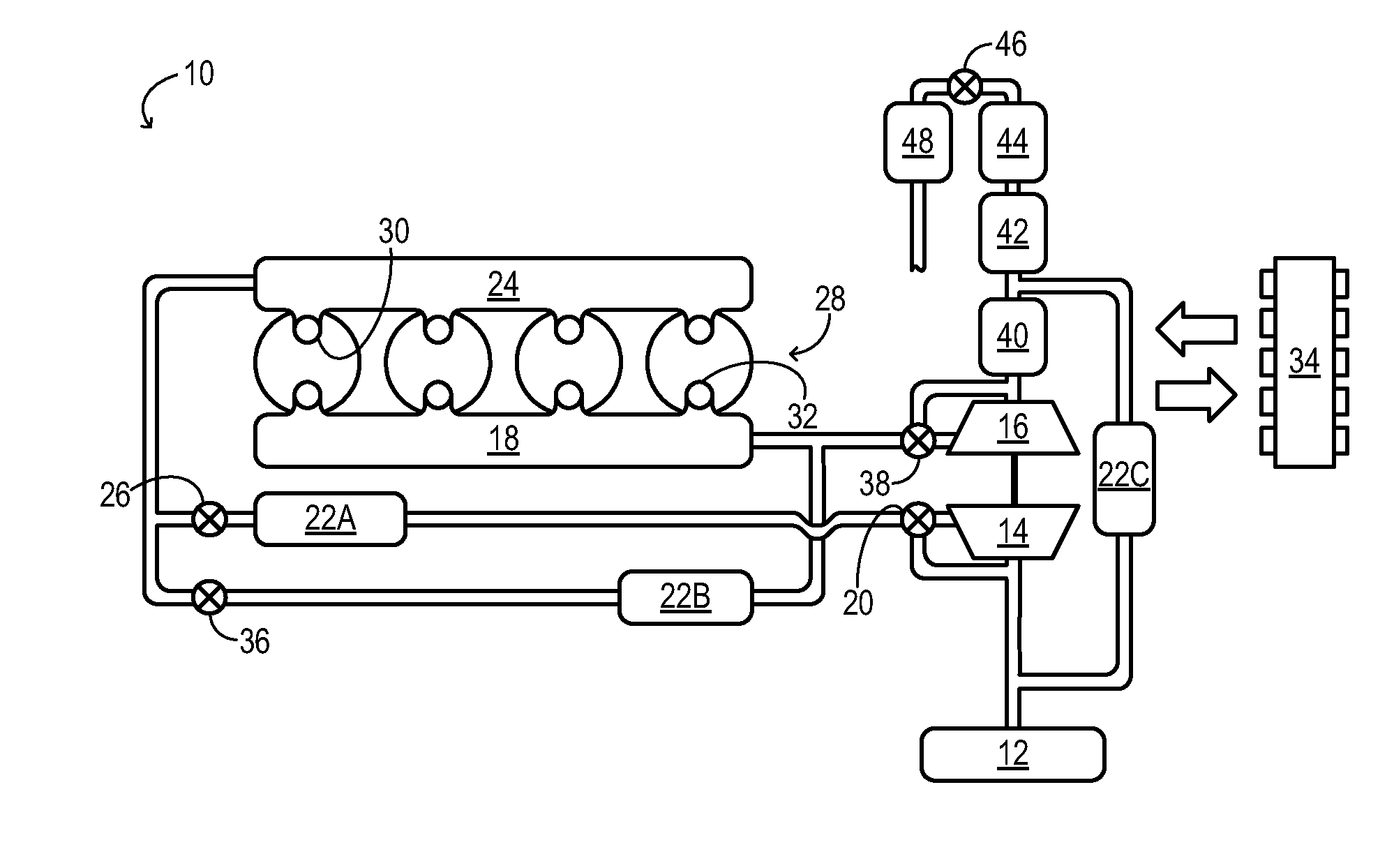

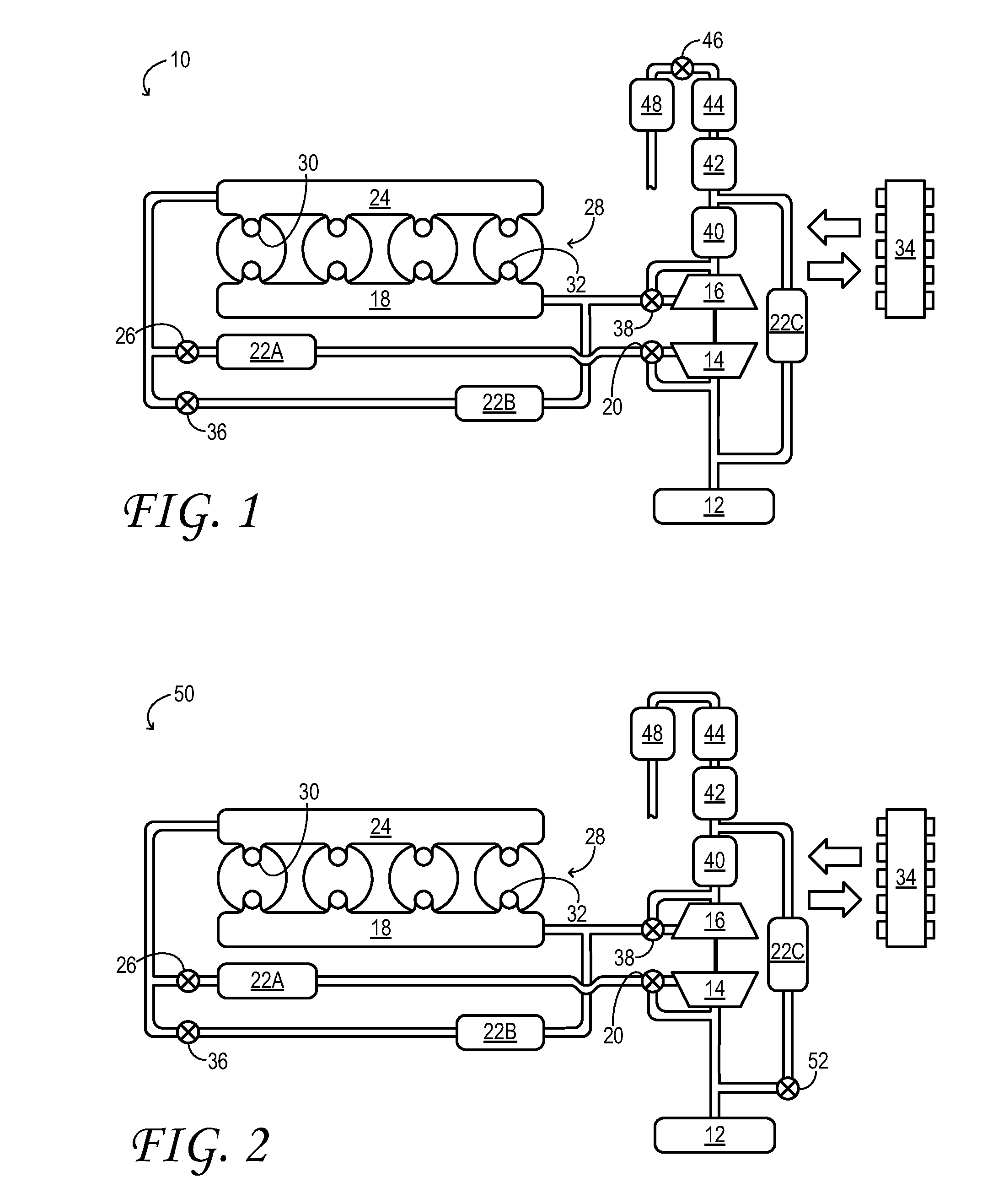

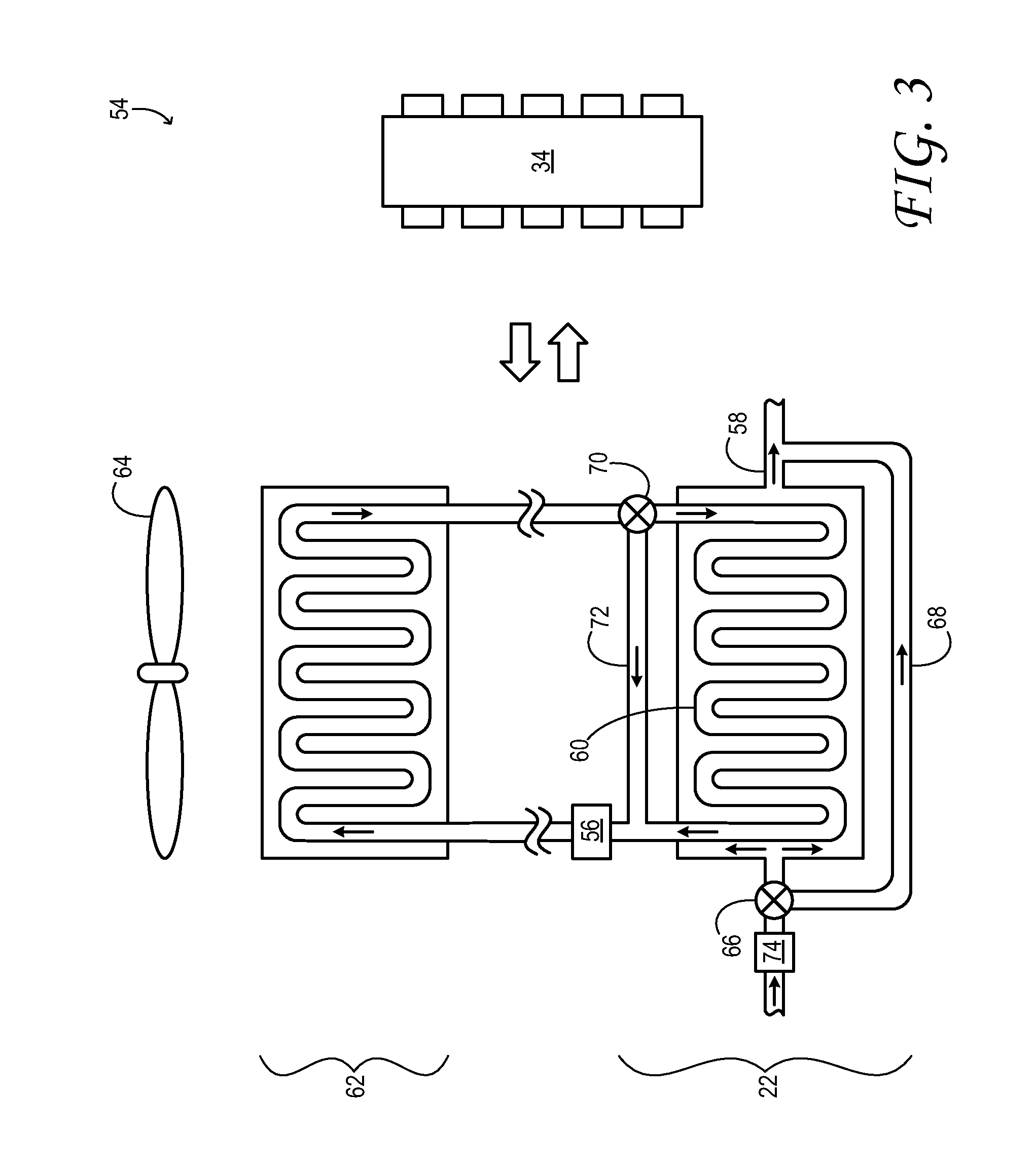

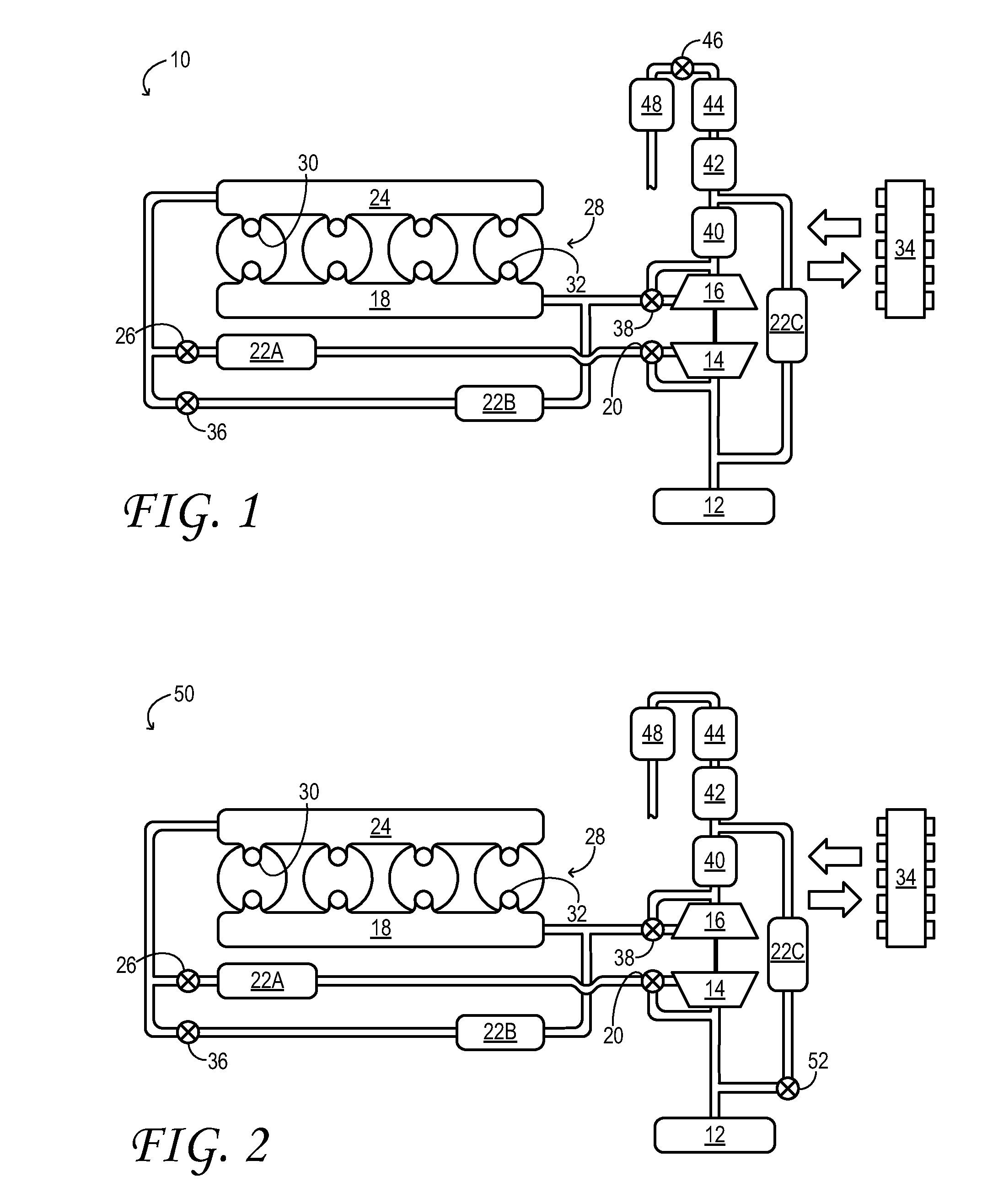

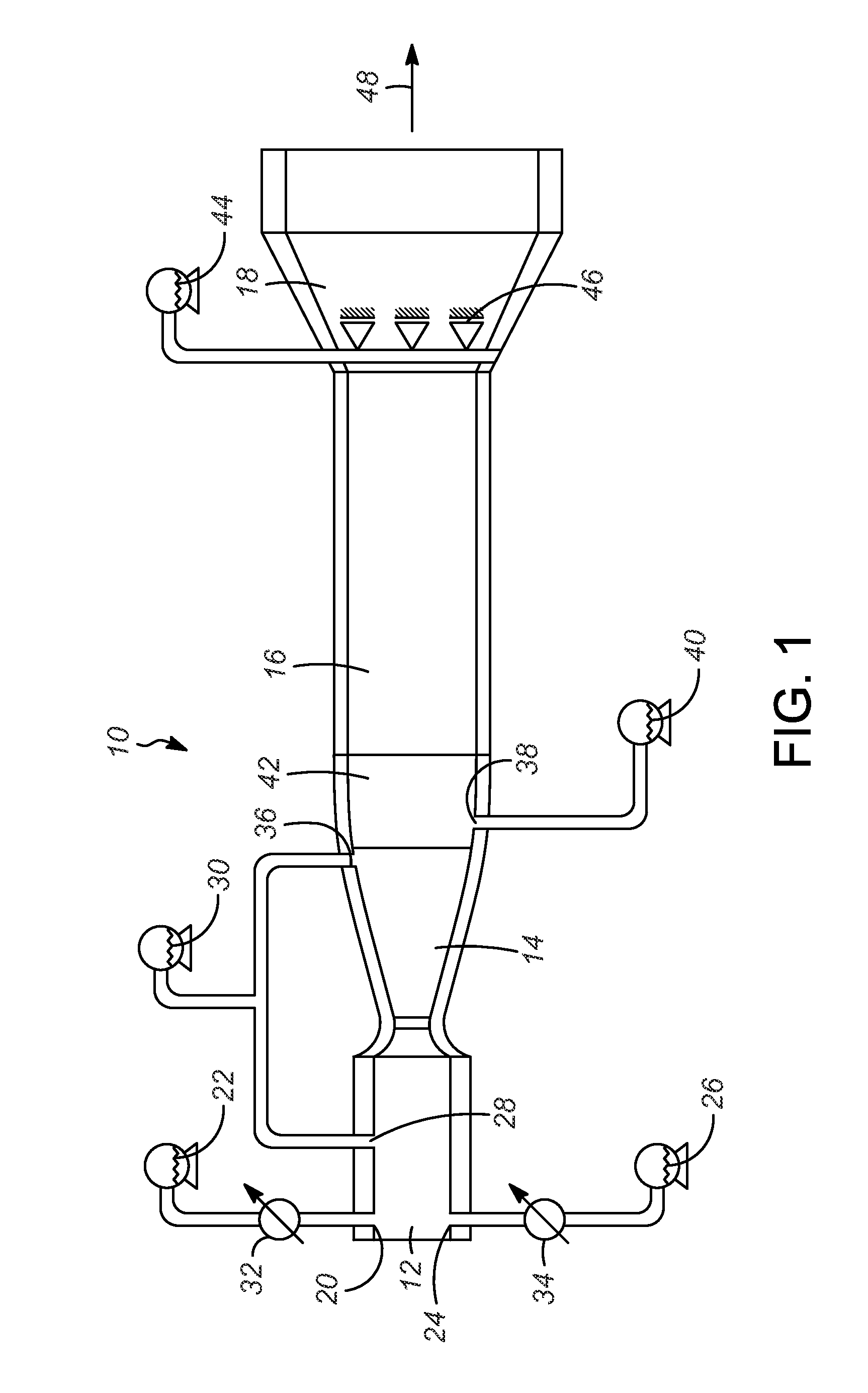

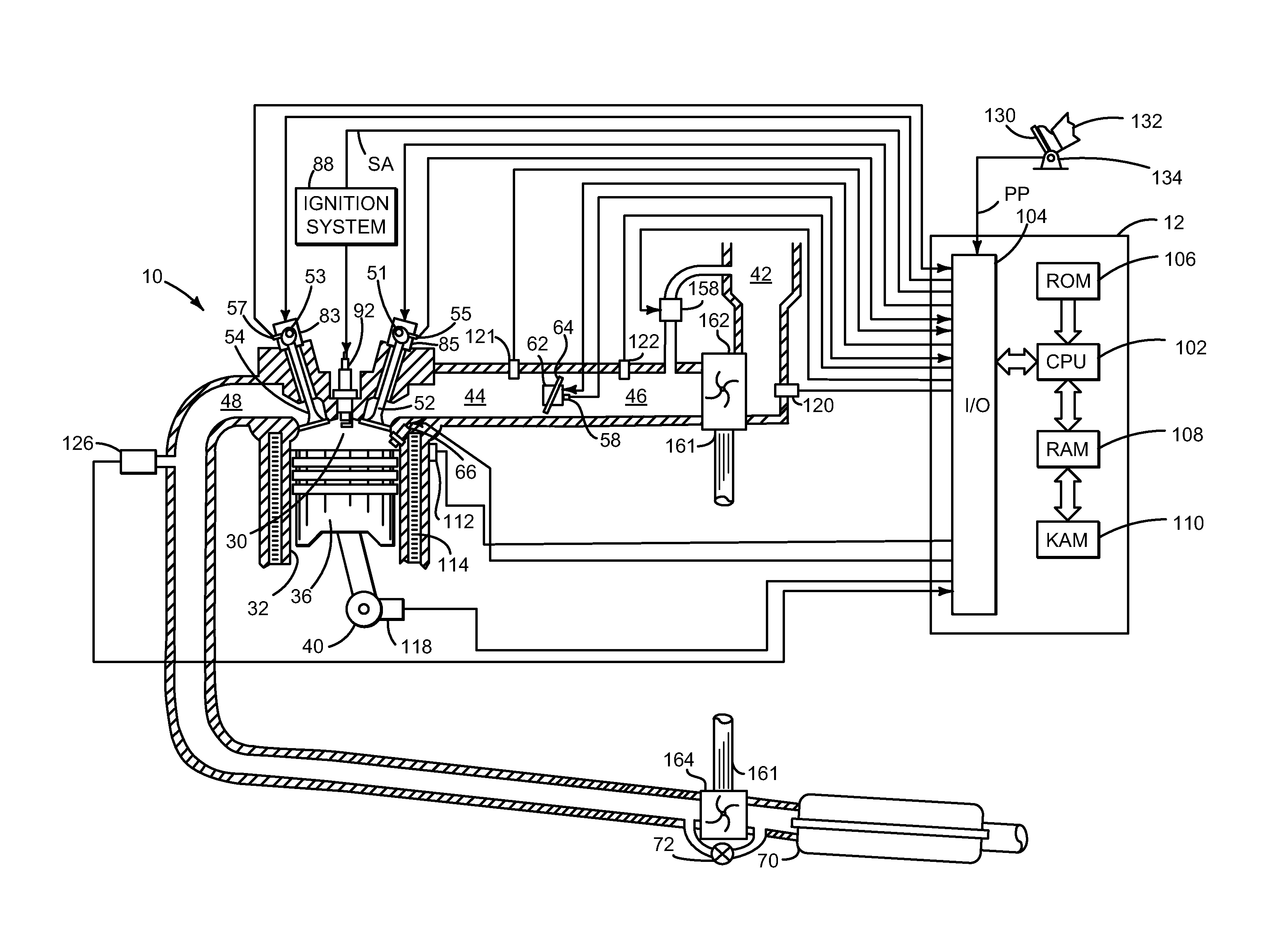

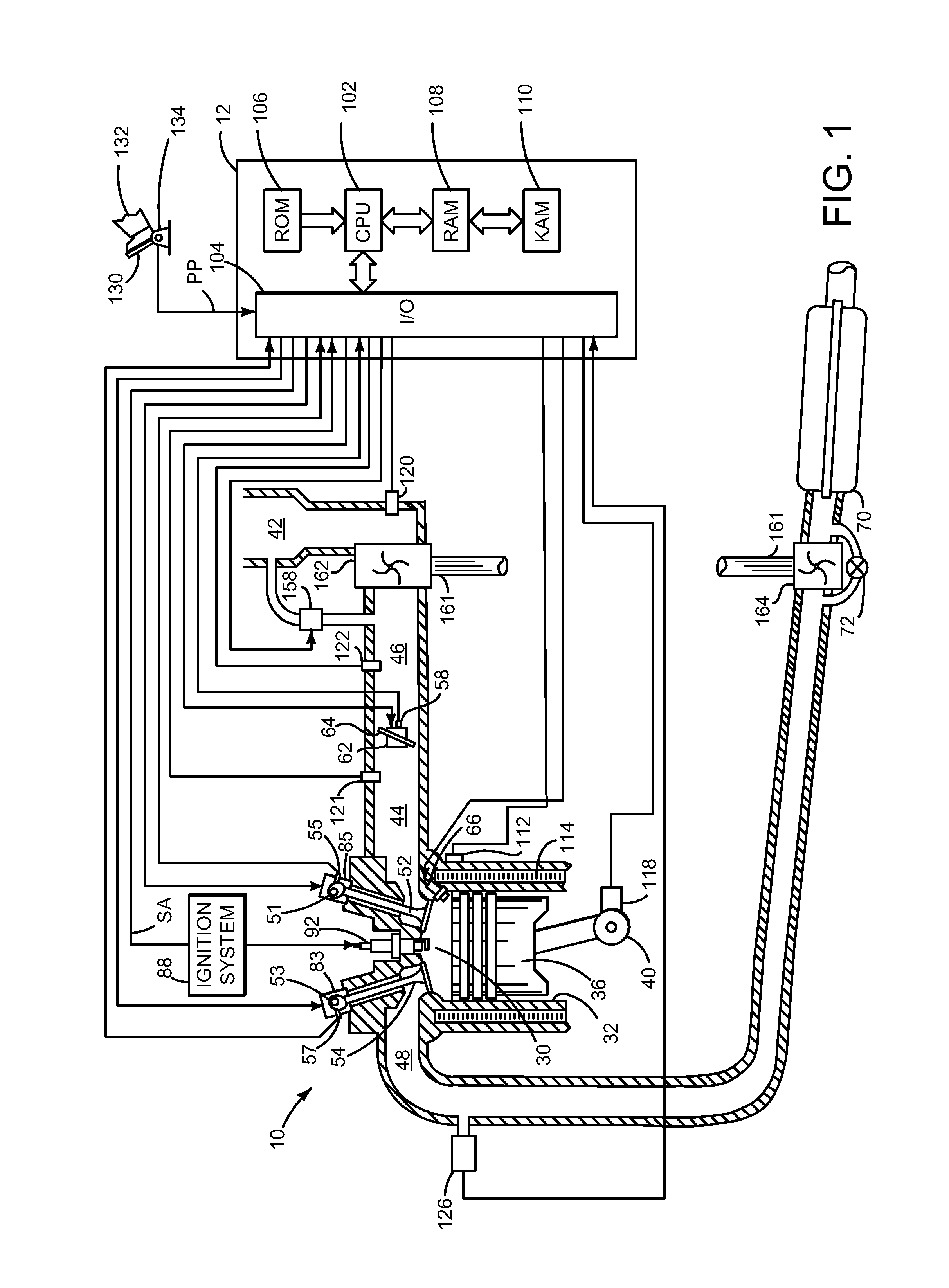

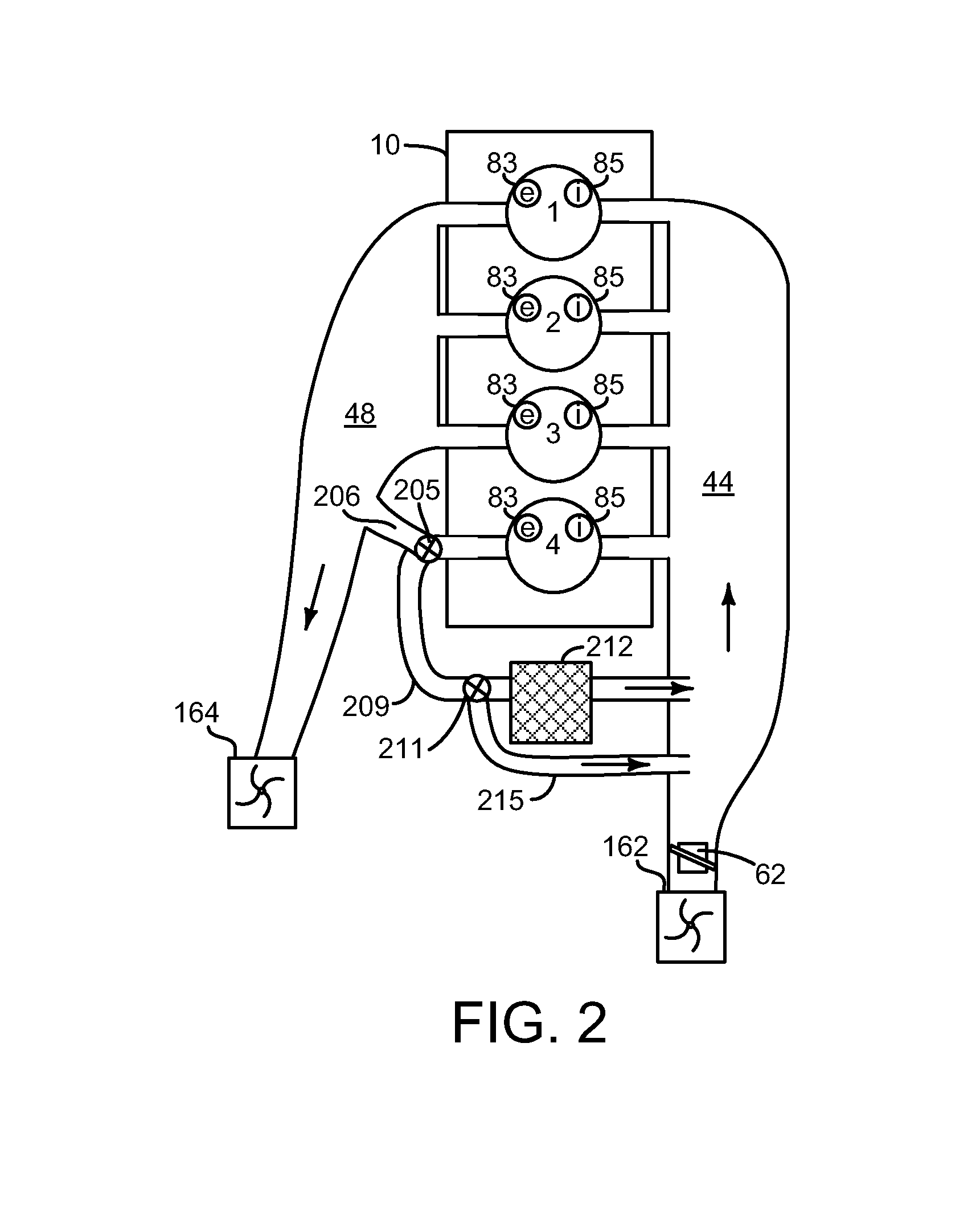

Systems and methods for dedicated egr cylinder exhaust gas temperature control

InactiveUS20160017847A1Improve the level ofWork lessElectrical controlNon-fuel substance addition to fuelTemperature controlExhaust gas

Systems and methods for increasing EGR gas temperature for an engine that includes at least one dedicated EGR cylinder. The dedicated EGR cylinder may provide exhaust gas to engine cylinders and the exhaust gas does not include exhaust gases from cylinders other than the dedicated EGR cylinder. The dedicated EGR cylinder may allow the engine to operate at higher EGR dilution levels.

Owner:FORD GLOBAL TECH LLC

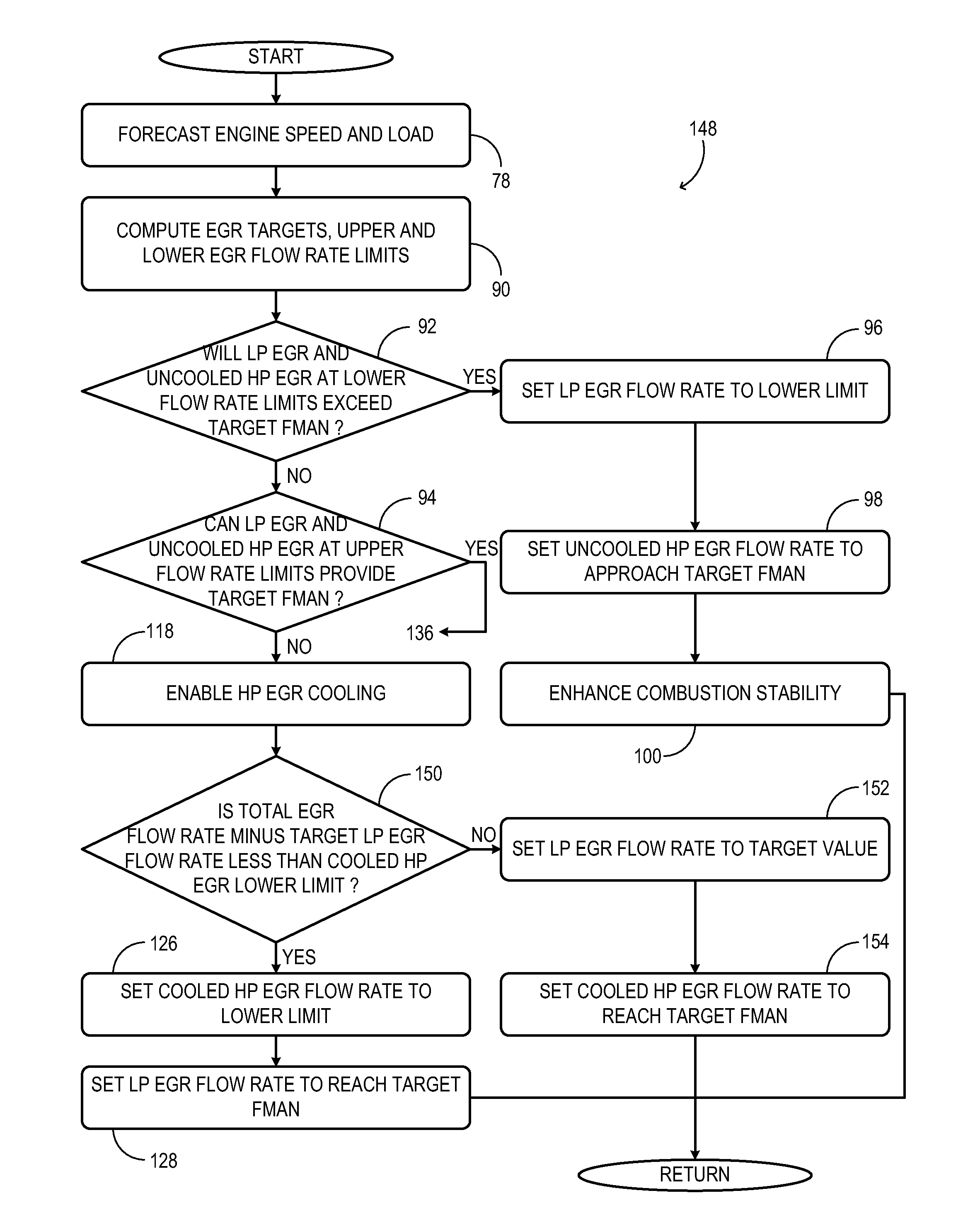

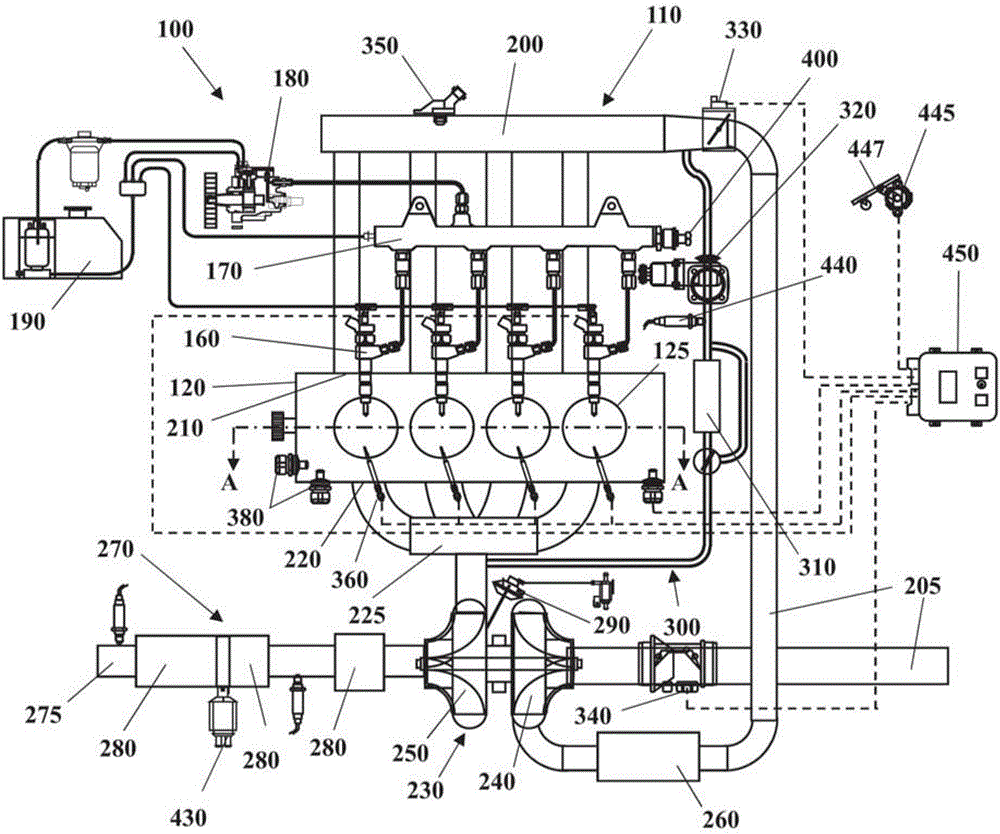

Coordination of HP and LP EGR

ActiveUS20110162626A1Low oxygenImprove fuel economyElectrical controlNon-fuel substance addition to fuelEngineeringStreamflow

A method for charging an intake manifold of an engine comprises adjusting an LP EGR flow rate and an uncooled HP EGR flow rate within first limits to maintain a target dilution level in the intake manifold at steady-state. The method further comprises adjusting the LP EGR and uncooled HP EGR rates within second limits, different from the first, to maintain the target dilution level in the intake manifold during transient conditions.

Owner:FORD GLOBAL TECH LLC

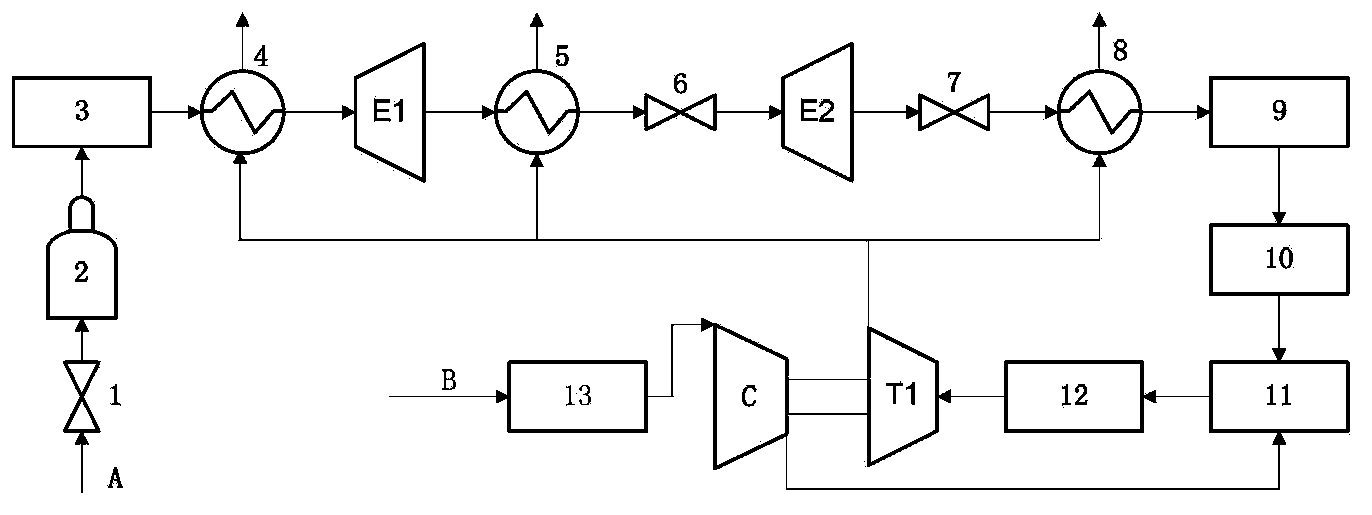

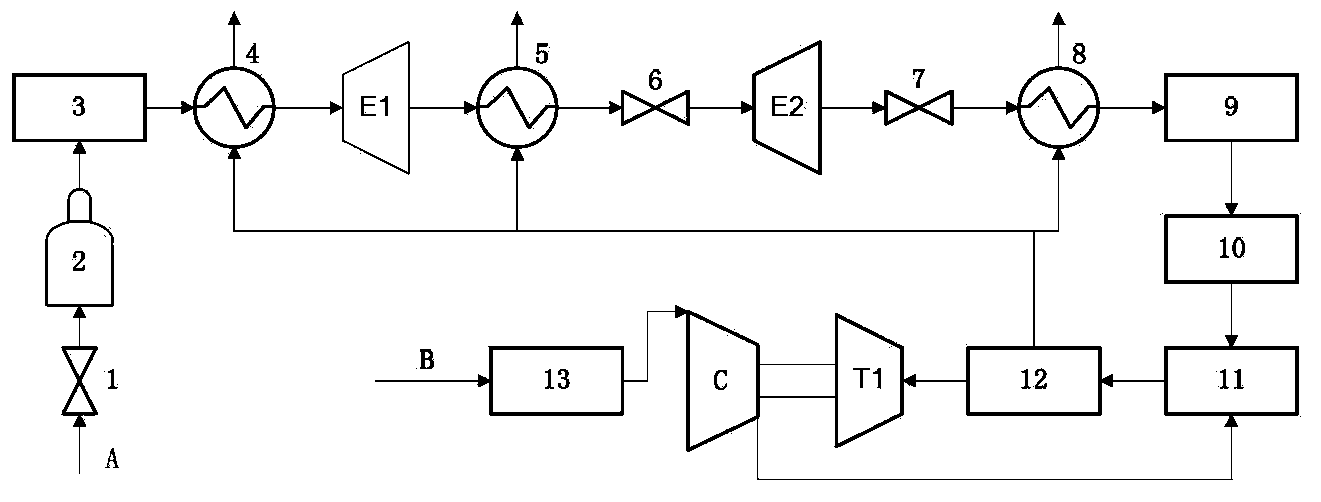

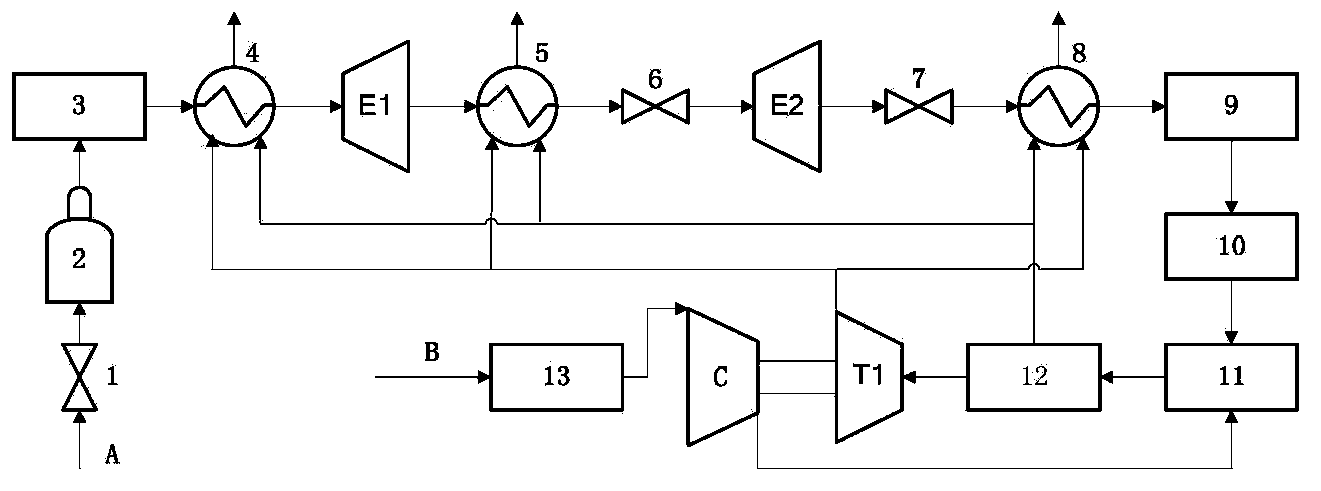

System and method for comprehensively utilizing residual heat of compressed natural gas engine (CNGE)

ActiveCN103437870APrevent "freezing" phenomenonAvoid icingInternal combustion piston enginesFuel supply apparatusNatural gas consumptionCompressed natural gas

The invention discloses a system and a method for comprehensively utilizing residual heat of a compressed natural gas engine (CNGE), which relates to a novel energy-saving technology of an engine. In the method, high-pressure fuel gas output by a high-pressure gas cylinder is heated with tail gas and / or the residual heat of water in a cylinder sleeve by using a residual heat exchanger, and the high-pressure fuel gas is depressurized and treated by using two stages of expansion machine devices (a variable-expansion-ratio expansion machine serving as one stage and a fixed-expansion-ratio expansion machine serving as the other stage), so that the fuel gas pressure needed by engine combustion is reached; meanwhile, pressure energy and residual heat are utilized comprehensively by using the expansion machines, so that the output shaft power of the engine is increased, the system efficiency of the engine is increased, the driving mileage is increased, and natural gas consumption is reduced. The device disclosed by the invention is compact in structure, and is reliable in performance; 80 percent of energy consumed in a natural gas compressing process is recovered, so that the advantage of natural gas serving as engine fuel gas is improved remarkably.

Owner:中科九朗(北京)能源科技有限公司

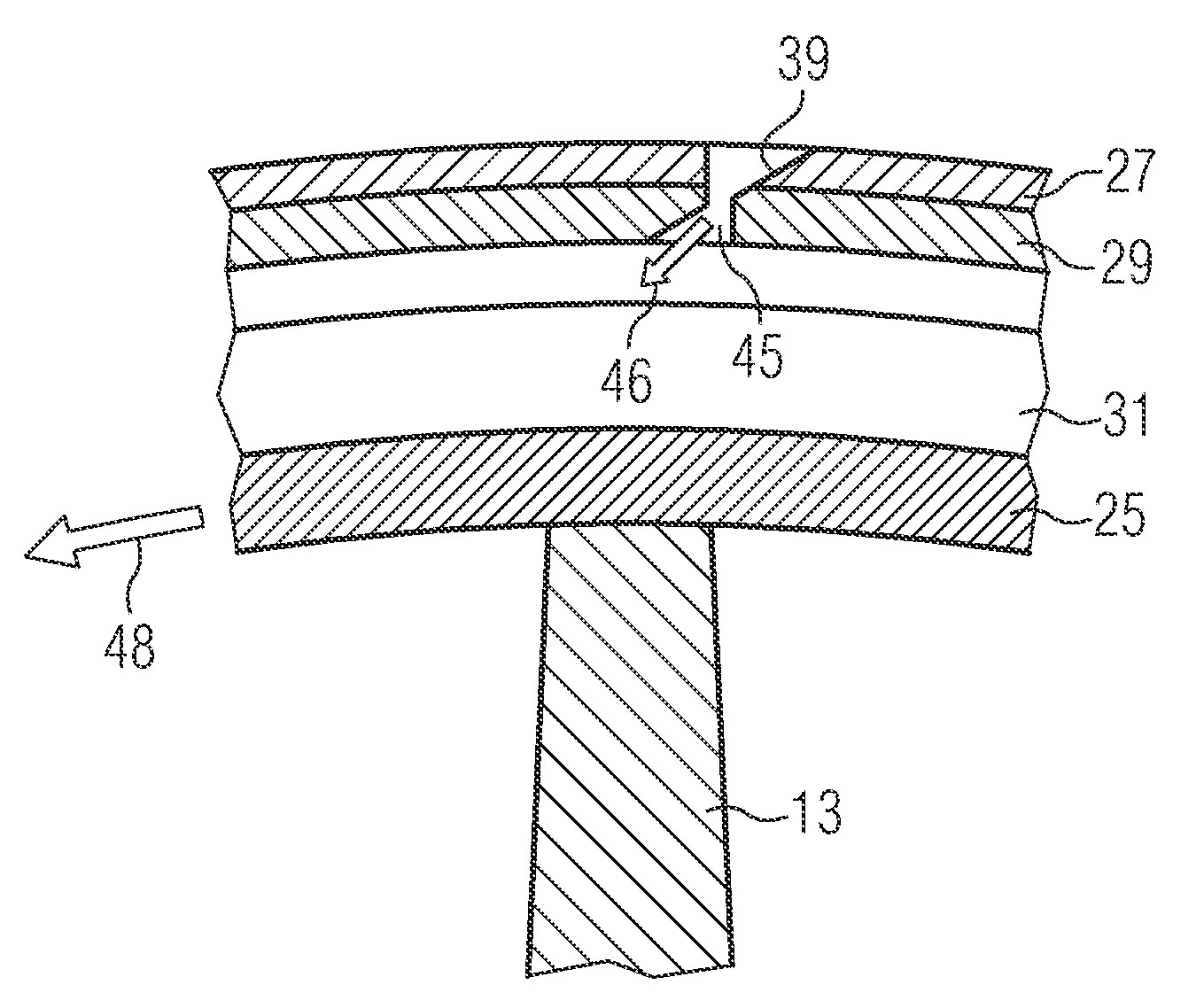

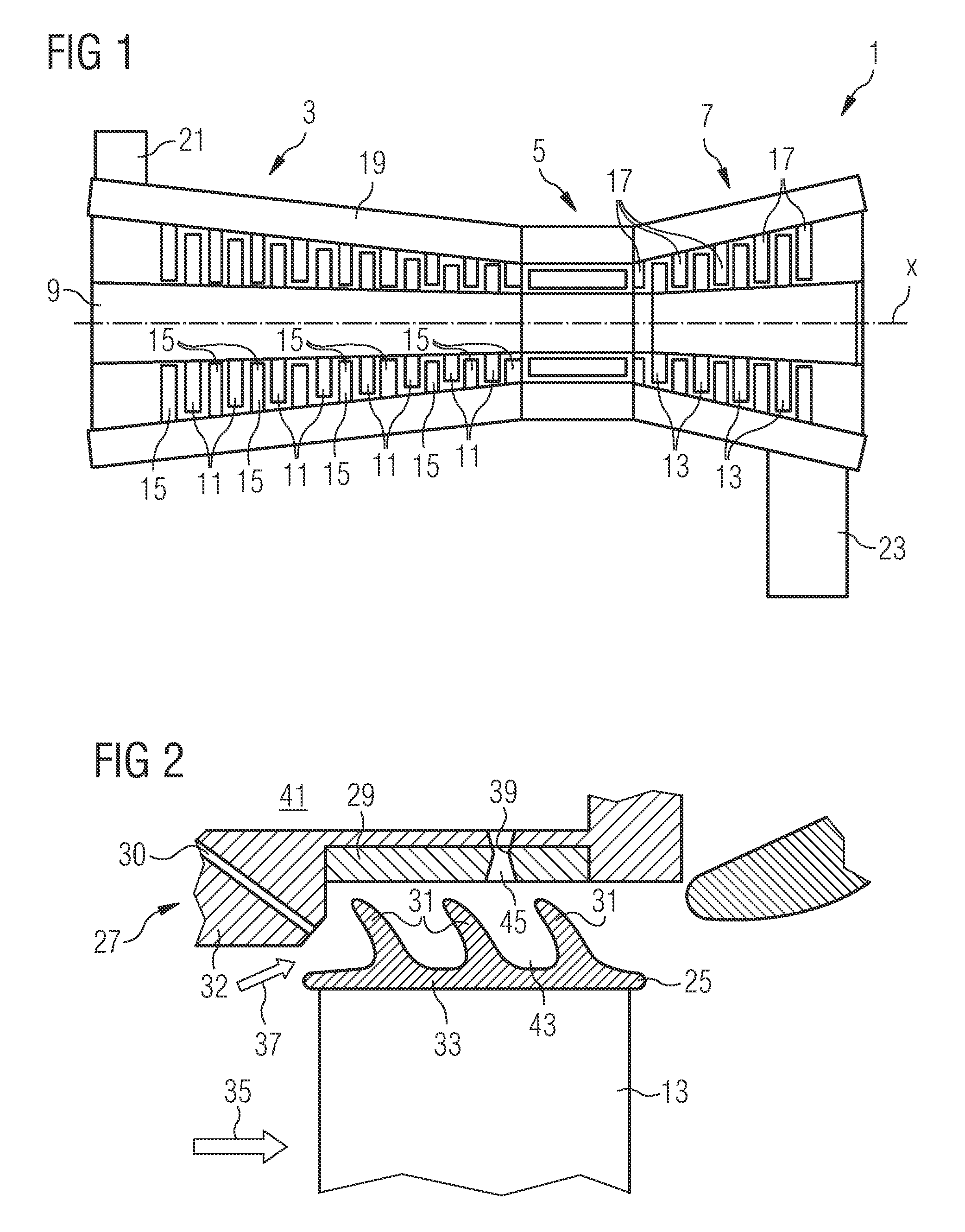

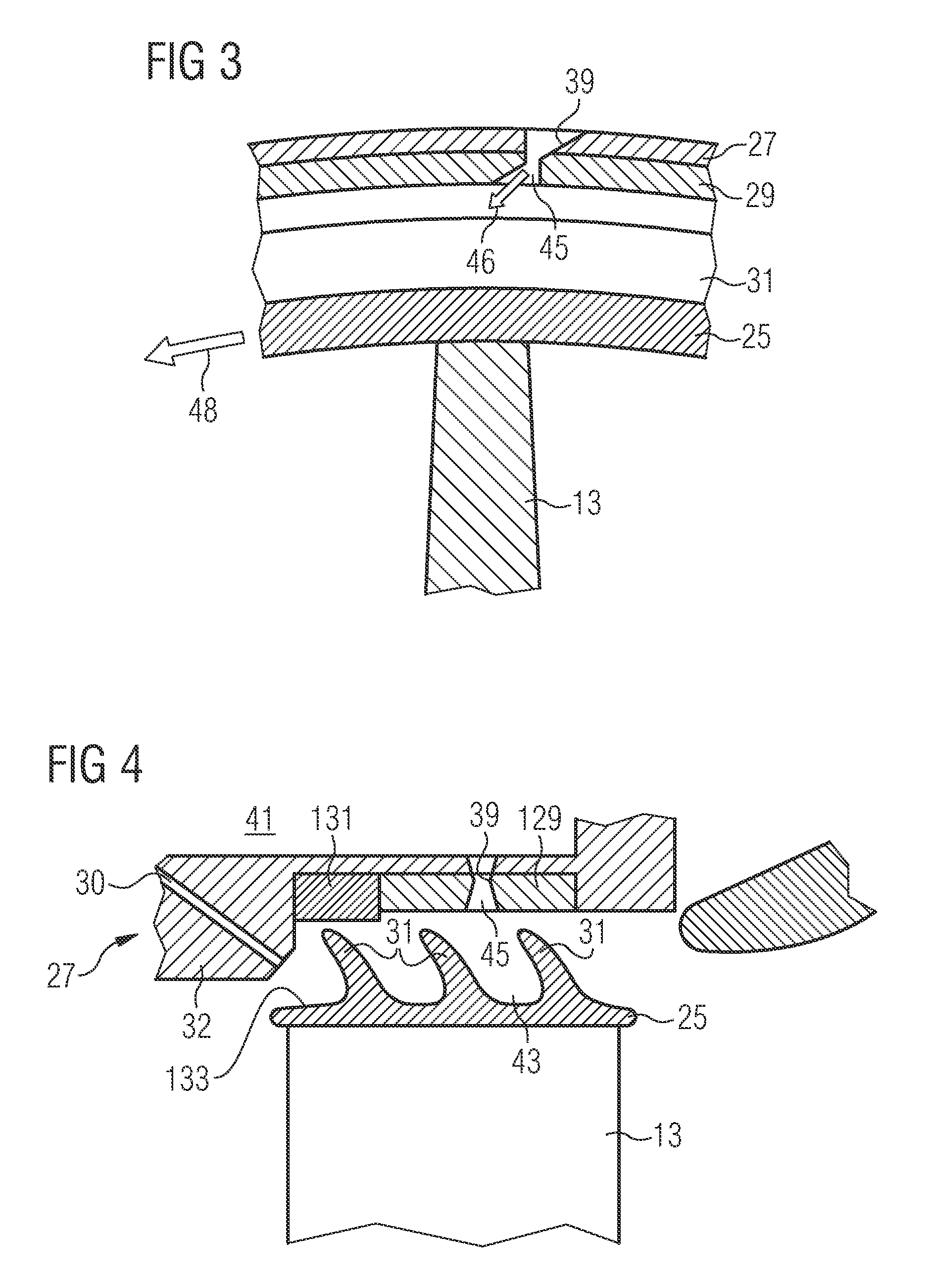

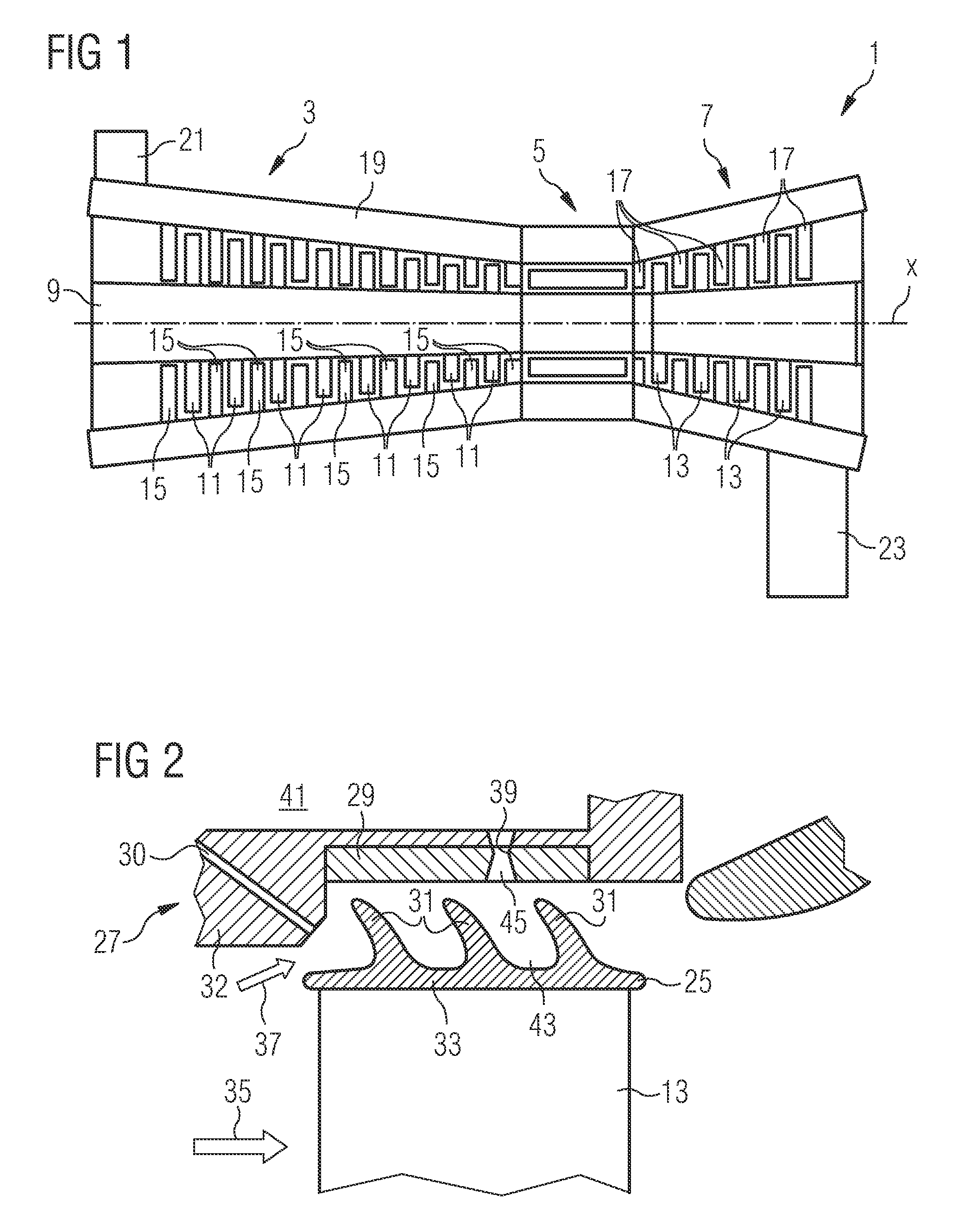

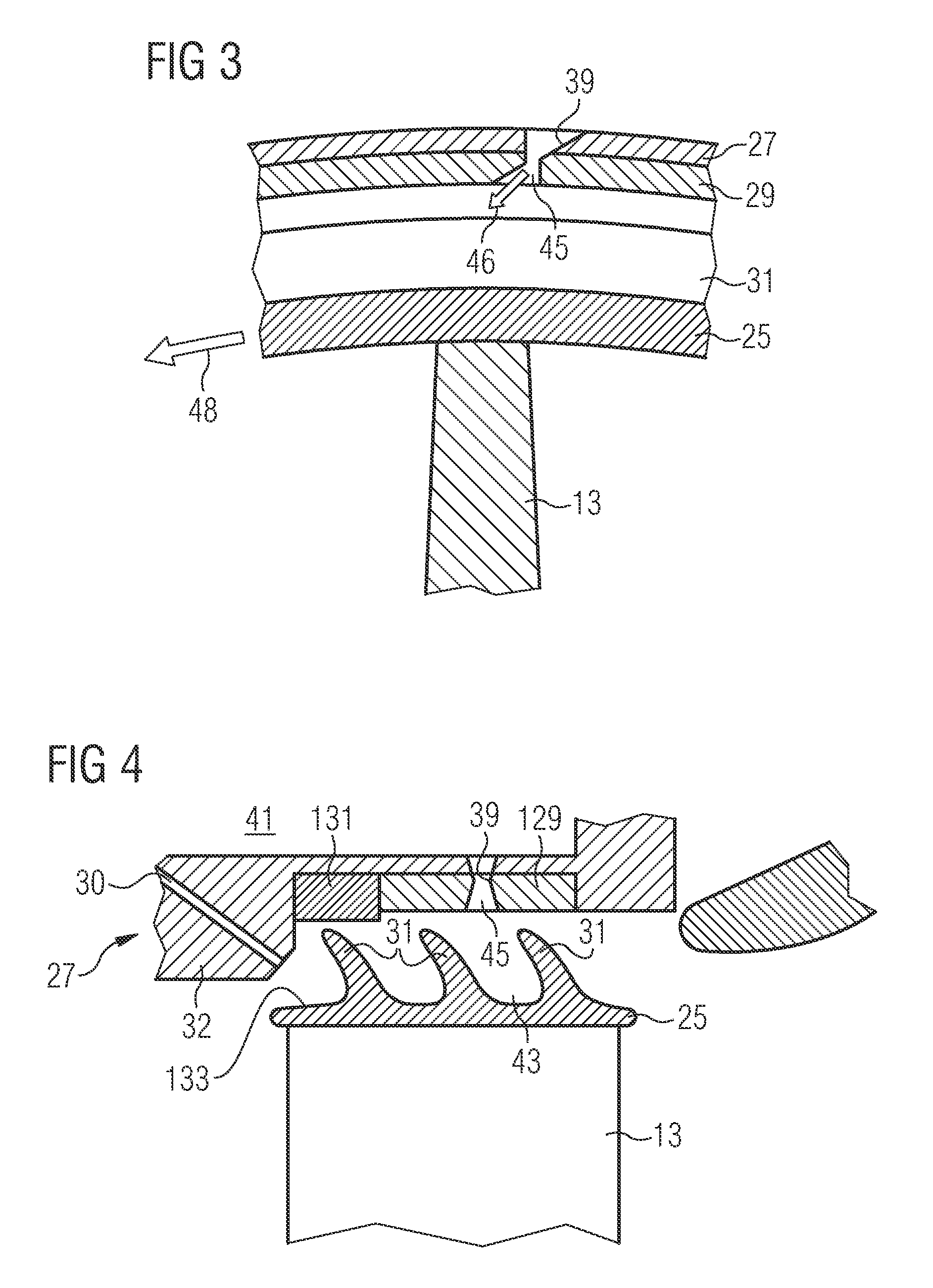

Turbine arrangement and method of cooling a shroud located at the tip of a turbine blade

InactiveUS20100189542A1Reduce the average velocityLower capability of heat dissipationEngine manufacturePump componentsCombustionTurbine blade

A turbine arrangement with a rotor and a stator surrounding the rotor forming a flow path for hot and pressurised combustion gases between the rotor and the stator is provided. The rotor defines a radial direction and a circumferential direction and includes turbine blades extending in the radial direction through the flow path towards the stator. The turbine blades have shrouds located at their tips and the stator includes a wall section along which the shrouds move when the rotor is turning. A supersonic nozzle is located in the wall section and is connected to a cooling fluid provider. The supersonic nozzle provides a supersonic cooling fluid flow towards the shroud. The supersonic nozzle is angled with respect to the radial direction towards the circumferential direction in such an orientation that the supersonic cooling fluid flow has a flow component parallel to the moving direction of the shroud.

Owner:SIEMENS AG

Coordination of HP and LP EGR

ActiveUS8042527B2Low oxygenImprove fuel economyElectrical controlInternal combustion piston enginesEngineeringInlet manifold

A method for charging an intake manifold of an engine comprises adjusting an LP EGR flow rate and an uncooled HP EGR flow rate within first limits to maintain a target dilution level in the intake manifold at steady-state. The method further comprises adjusting the LP EGR and uncooled HP EGR rates within second limits, different from the first, to maintain the target dilution level in the intake manifold during transient conditions.

Owner:FORD GLOBAL TECH LLC

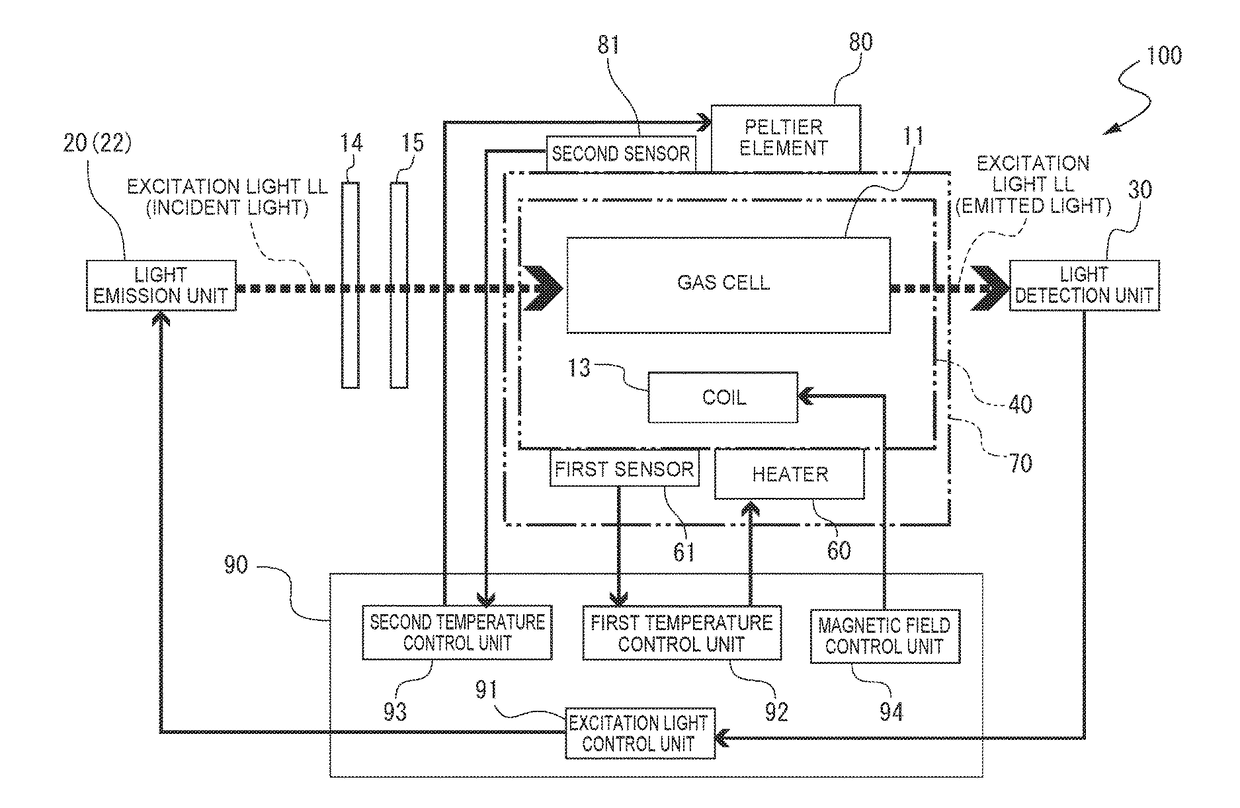

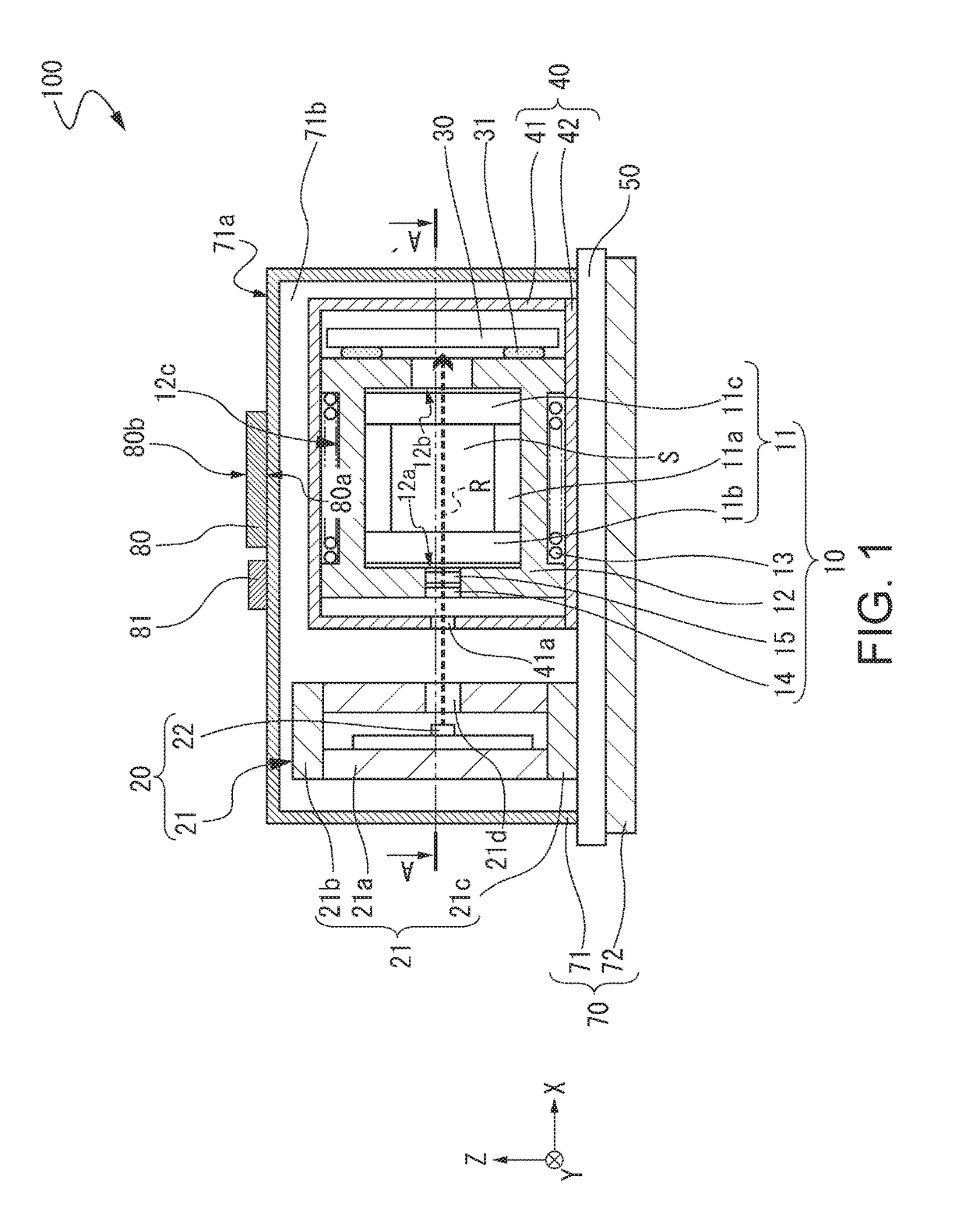

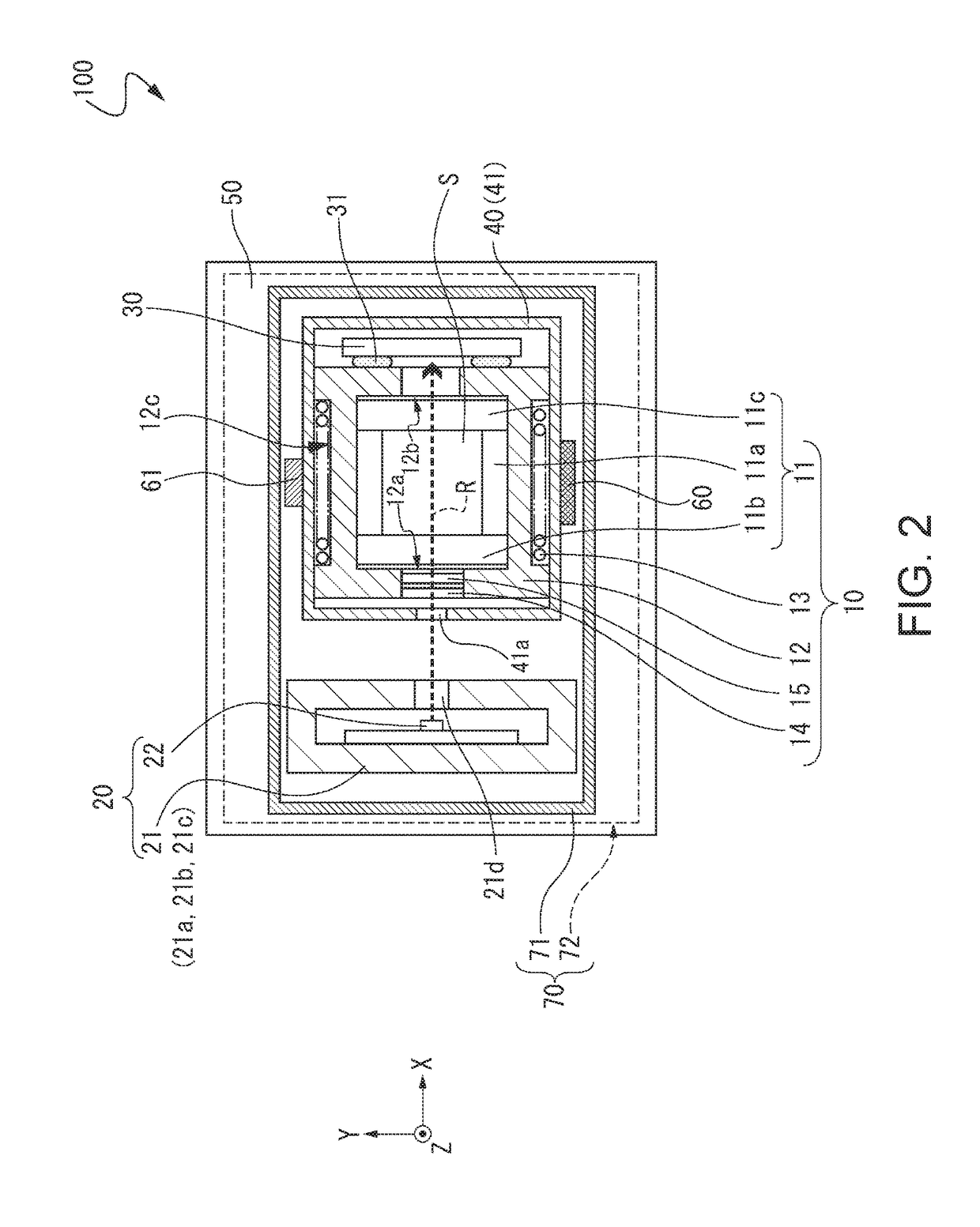

Atomic oscillator and temperature control method of atomic oscillator

ActiveUS20170141783A1Reduction in size and heightSuppress instabilityPulse automatic controlGenerator stabilizationTemperature controlEngineering

An atomic oscillator includes at least a gas cell that has metal atoms sealed therein, a coil that is disposed in a vicinity of the gas cell, a first magnetic shield that accommodates the gas cell and the coil therein, a second magnetic shield that accommodates a heater heating the gas cell, a first temperature sensor detecting a temperature of the gas cell, and the first magnetic shield therein, and a temperature adjustment unit and a second temperature sensor that are disposed outside the second magnetic shield.

Owner:MICROCHIP TECH INC

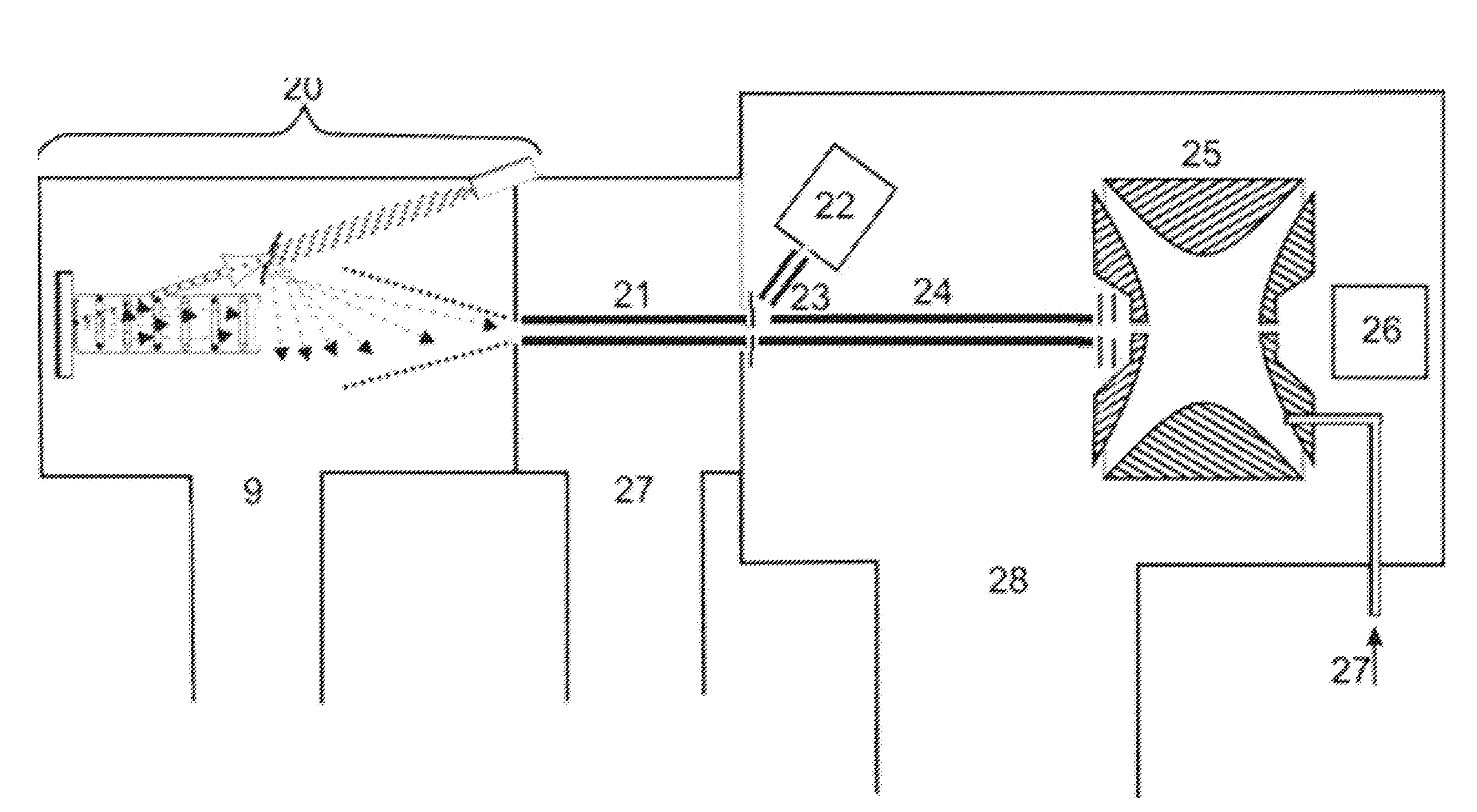

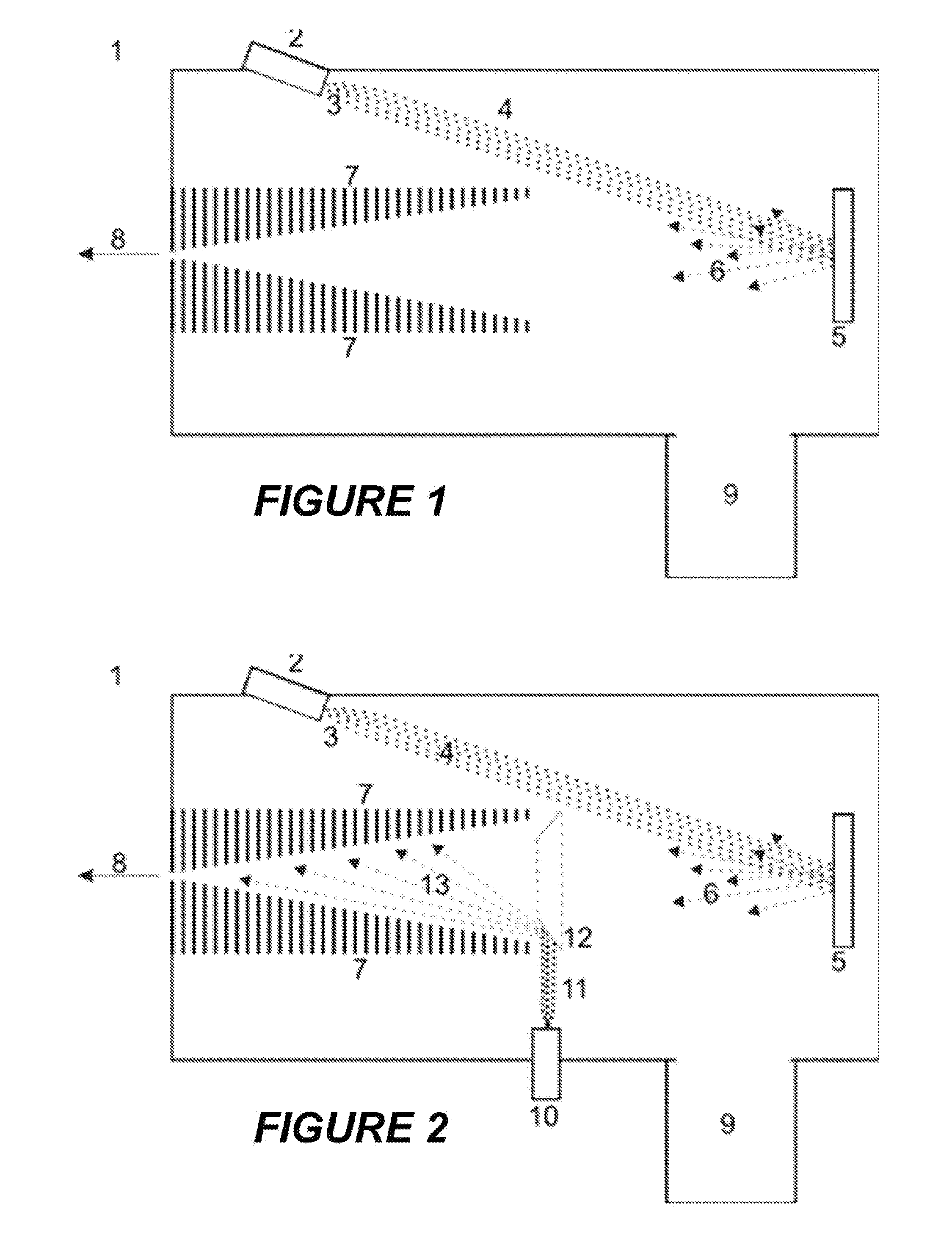

Ion generation in mass spectrometers by cluster bombardment

ActiveUS20130285552A1Thorough removalRaise the gas temperatureParticle separator tubesElectric arc lampsHigh densityAnalyte

The invention relates to devices and methods in mass spectrometers for the generation of ions of heavy molecules, especially biomolecules, by bombarding them with uncharged clusters of molecules. The analyte ions which are generated or released by cluster bombardment of analyte substances on the surface of sample support plates show a broad distribution of their kinetic energies, which prevents good ion-optical focusing. In the invention, the kinetic energies are homogenized in a higher-density collision gas. The collision gas is preferably located in an RF ion guide, more preferably an RF ion funnel, which can transfer the ions to the mass analyzer. The collision gas may be introduced with temporal pulsing, coordinated or synchronized with the pulsed supersonic gas jet. The collision gas may be pumped off again before the next supersonic gas pulse. In an advantageous embodiment, the collision gas can originate from the supersonic gas jet itself.

Owner:BRUKER DALTONIK GMBH & CO KG

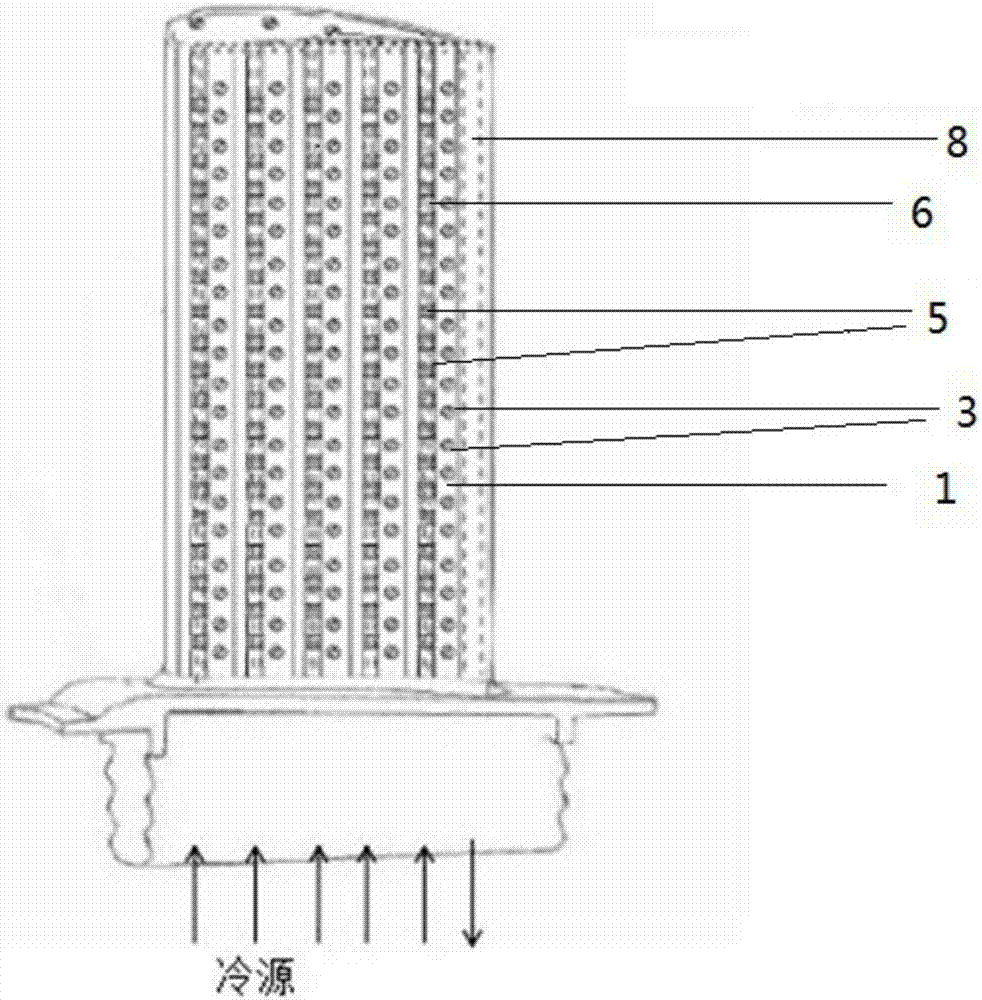

Gas-liquid coupling turbine blade cooling unit

ActiveCN107060892AImprovement of double shell type "shock/air film/disturbance" composite cooling structureReduce the temperatureBlade accessoriesMachines/enginesTurbine bladeEngineering

Based on an existing double-layer shell type impact / gas film / turbulent flow composite cooling structure, the invention discloses a gas-liquid coupling turbine blade cooling unit. The gas-liquid coupling turbine blade cooling unit comprises a plurality of mutually independent cooling subunits. Each cooling subunit comprises a cold gas wall, a hot gas wall, a plurality of impact holes formed in the cold gas wall, a plurality of gas film holes formed in the hot gas wall, a plurality of turbulent flow columns located between the cold gas wall and the hot gas wall, and a collecting table connected with the cold gas wall and the turbulent flow columns, wherein the cold gas wall and the hot gas wall are arranged oppositely, the upper surface of the collecting table is connected with the inner surface of the cold gas wall, the lower surface of the collecting table is connected with the turbulent flow columns, and at least one cold source pipeline penetrating through the collecting table longitudinally is arranged in the collecting table. Further, in the cooling subunits, the side walls of the collecting tables are smoothly connected with the inner surfaces of the cold gas walls and the side walls of the turbulent flow columns to form a smooth hook face structure together. Through the gas-liquid coupling turbine blade cooling unit, a liquid cooling path is added, and the overall temperature of a turbine is further lowered.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

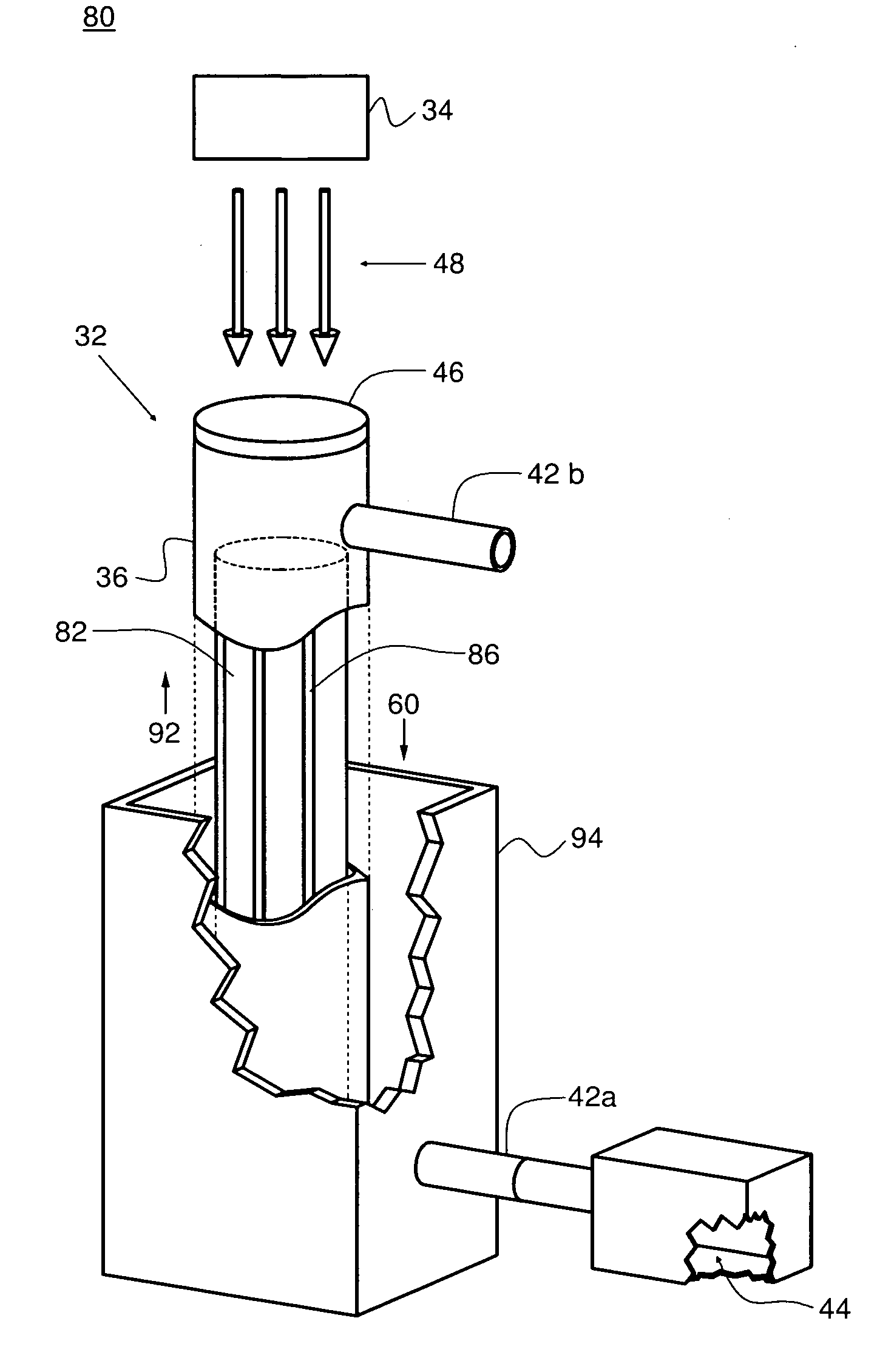

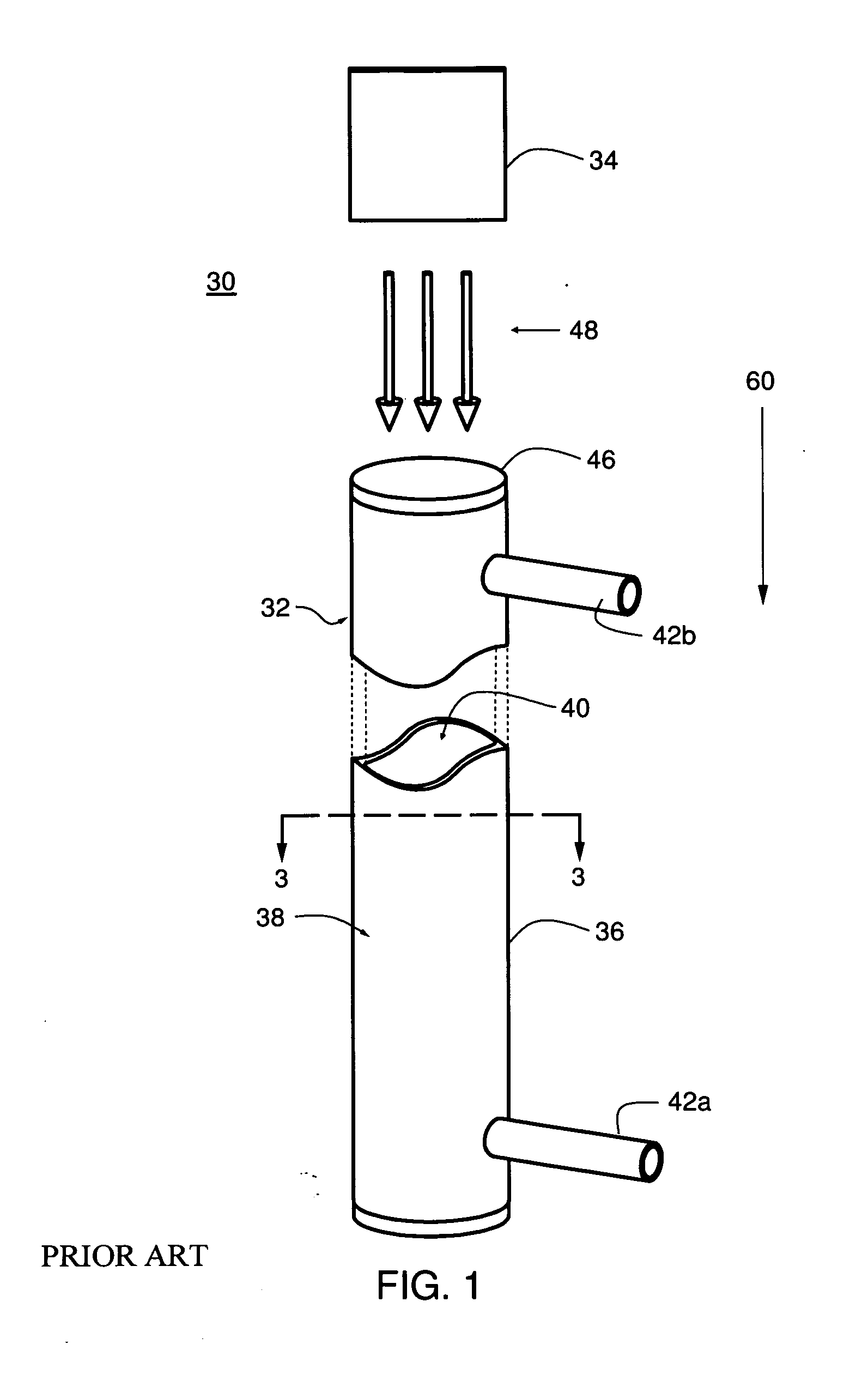

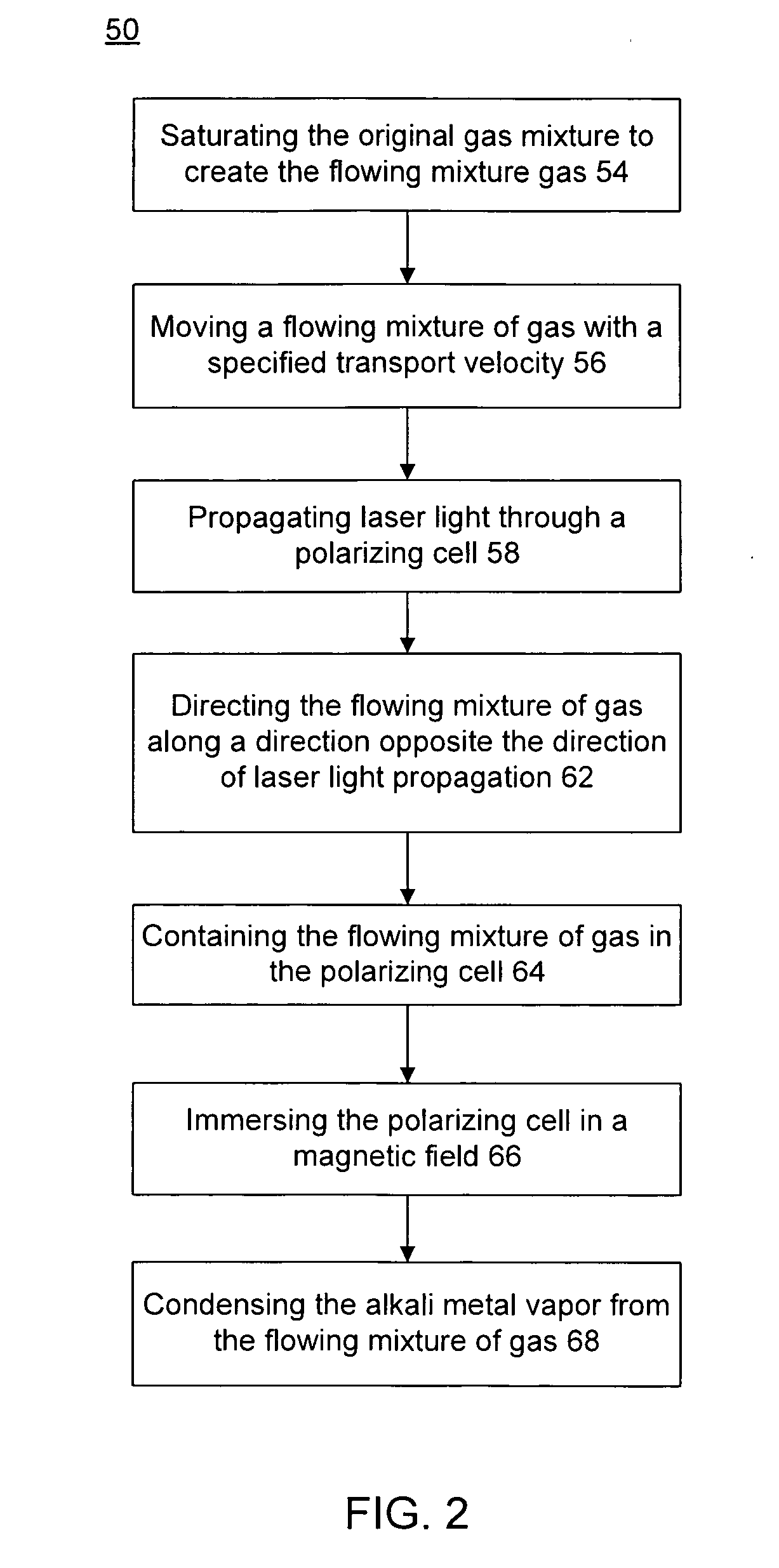

Thermal management technology for polarizing xenon

ActiveUS20080093543A1Increase ratingsLower thermal conductanceLaser detailsHandling using polarising devicesProduction rateHigh rate

A polarizing apparatus has a thermally conductive partitioning system in a polarizing cell. In the polarizing region, this thermally conductive partitioning system serves to prevent the elevation of the temperature of the polarizing cell where laser light is maximally absorbed to perform the polarizing process. By employing this partitioning system, increases in laser power of factors of ten or more can be beneficially utilized to polarize xenon. Accordingly, the polarizing apparatus and the method of polarizing 129Xe achieves higher rates of production.

Owner:UNIVERSITY OF NEW HAMPSHIRE

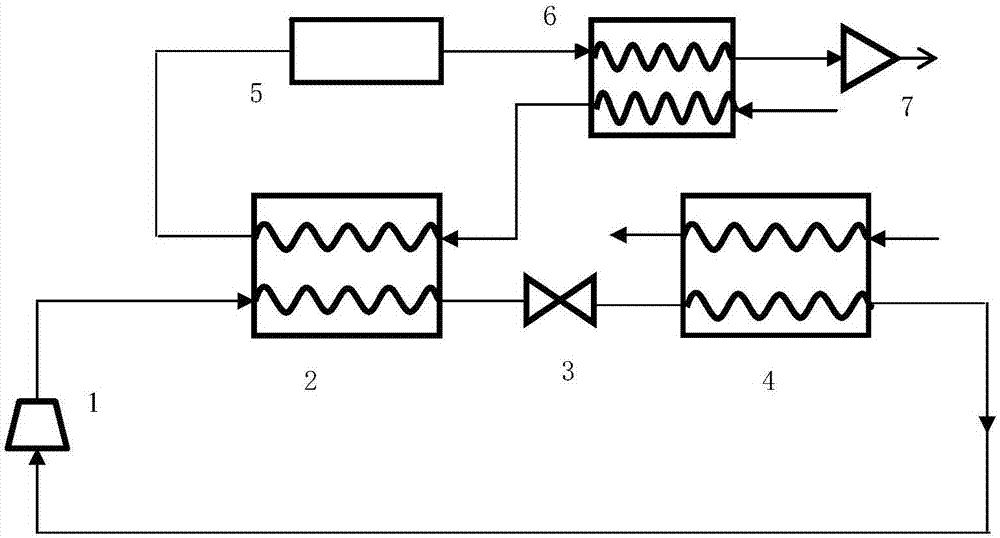

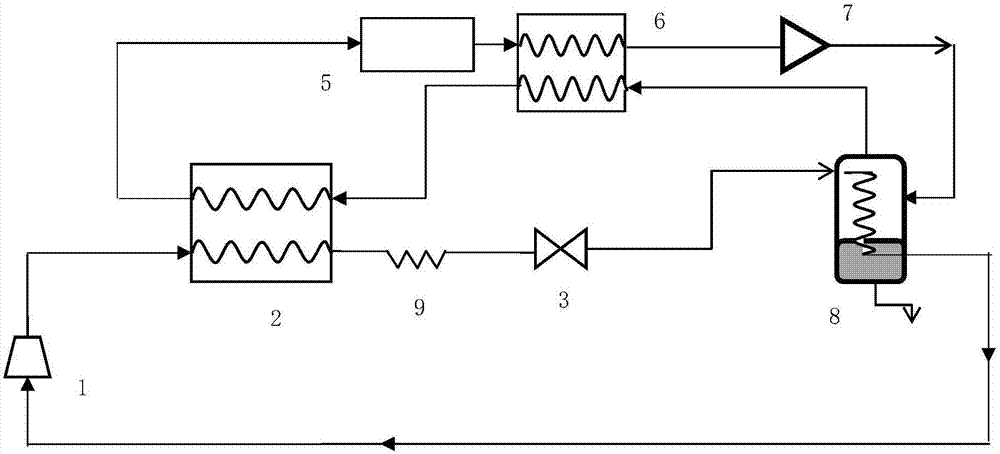

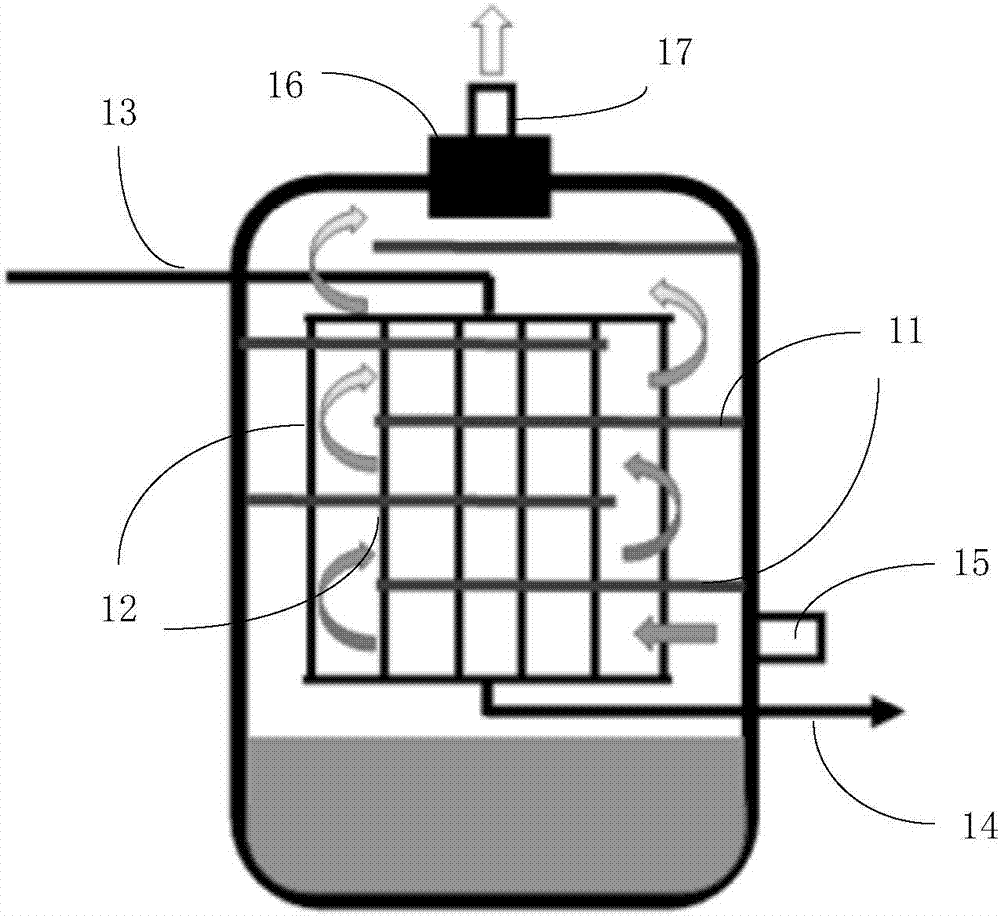

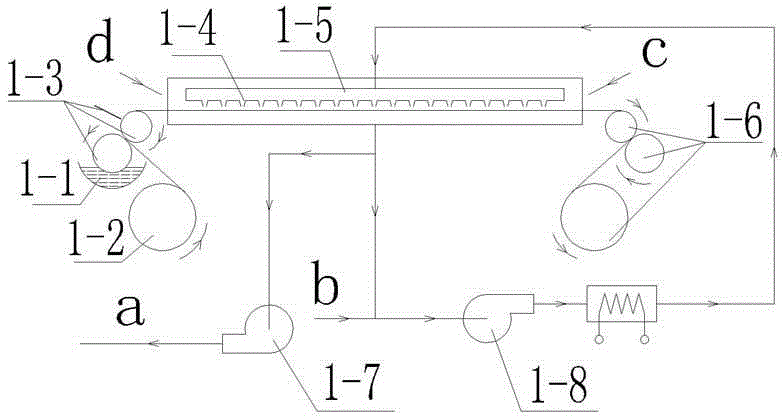

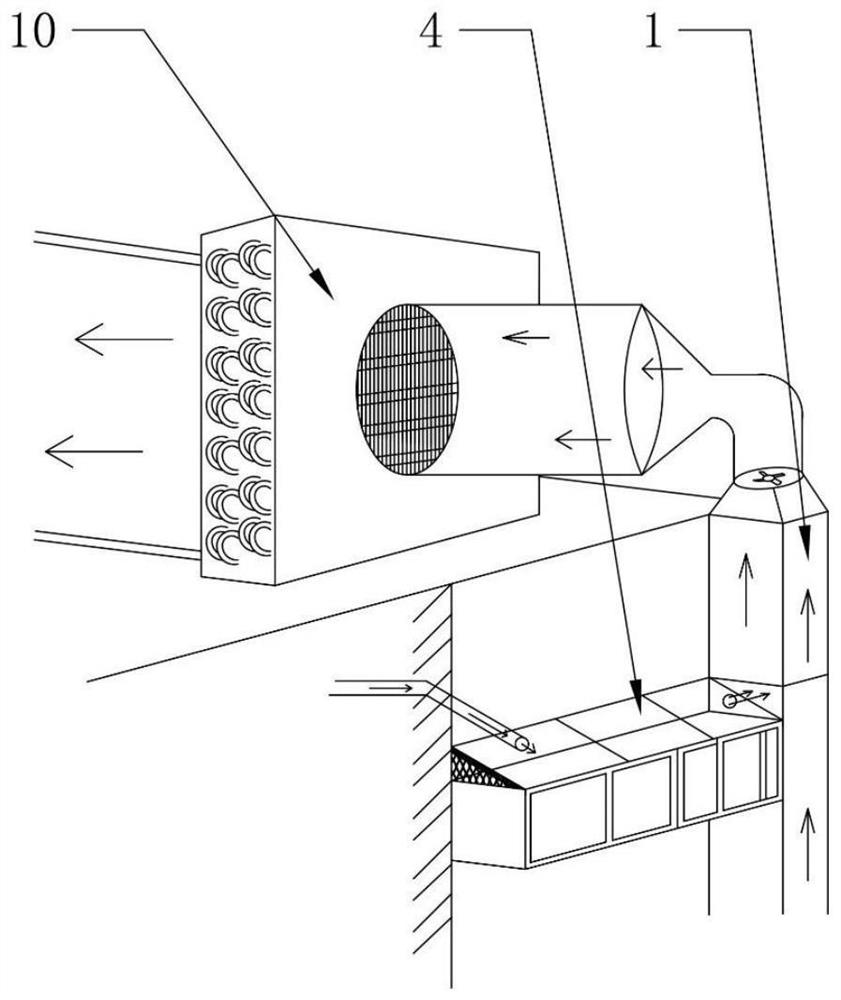

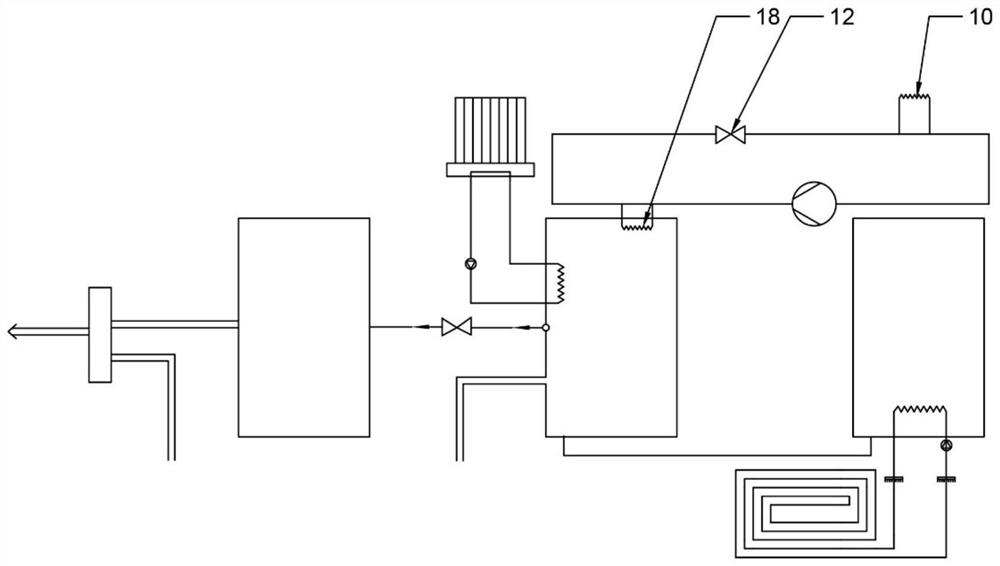

Heat pump drying system

InactiveCN107966009ARaise the gas temperatureReduce heat transfer temperature differenceMechanical apparatusHeat pumpsEvaporatorEngineering

The invention provides a heat pump drying system which comprises a compressor, a condenser, a throttling component, an evaporator, a drying chamber, a backheating heat exchanger and a draught fan. Anoutlet of the compressor is connected with a hot end inlet of the condenser, a hot end outlet of the condenser is connected with a cold end inlet of the evaporator through the throttling component, and a cold end outlet of the evaporator is connected with an inlet of the compressor; a cold end inlet of the backheating heat exchanger inputs air acted by the draught fan, a cold end outlet of the backheating heat exchanger is connected with a cold end inlet of the condenser, a cold end outlet of the condenser is connected with an inlet of the drying chamber, an outlet of the drying chamber is connected with a hot end inlet of the backheating heat exchanger, a hot end outlet of the backheating heat exchanger is connected with an inlet of the draught fan, and an outlet of the draught fan is communicated with the outside. By means of the heat pump drying system, the backheating heat exchanger is used for achieving temperature recovering of air discharged from the drying chamber, the temperature of air entering the cold end evaporator is decreased, the temperature of air entering the hot end condenser is increased, the heat exchange temperature difference can be effectively reduced, coldand heat end heat exchange is improved, and the system efficiency is improved.

Owner:北京恒泰盈创科技发展有限公司

Ablation-proof structure of solid rocket engine

Disclosed is an ablation-proof structure of a solid rocket engine. The ablation-proof structure of the solid rocket engine comprises a pressure-bearing structure casing, a thermal insulating layer and an anti-scouring low-residue protective layer, wherein the thermal insulating layer is located in the pressure-bearing structure casing, and the anti-scouring low-residue protective layer is embedded into the inner surface of the thermal insulating layer. By means of the technical scheme, solid residues generated during ablation of the thermal insulating layer can be reduced, and moving parts are prevented from being blocked.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

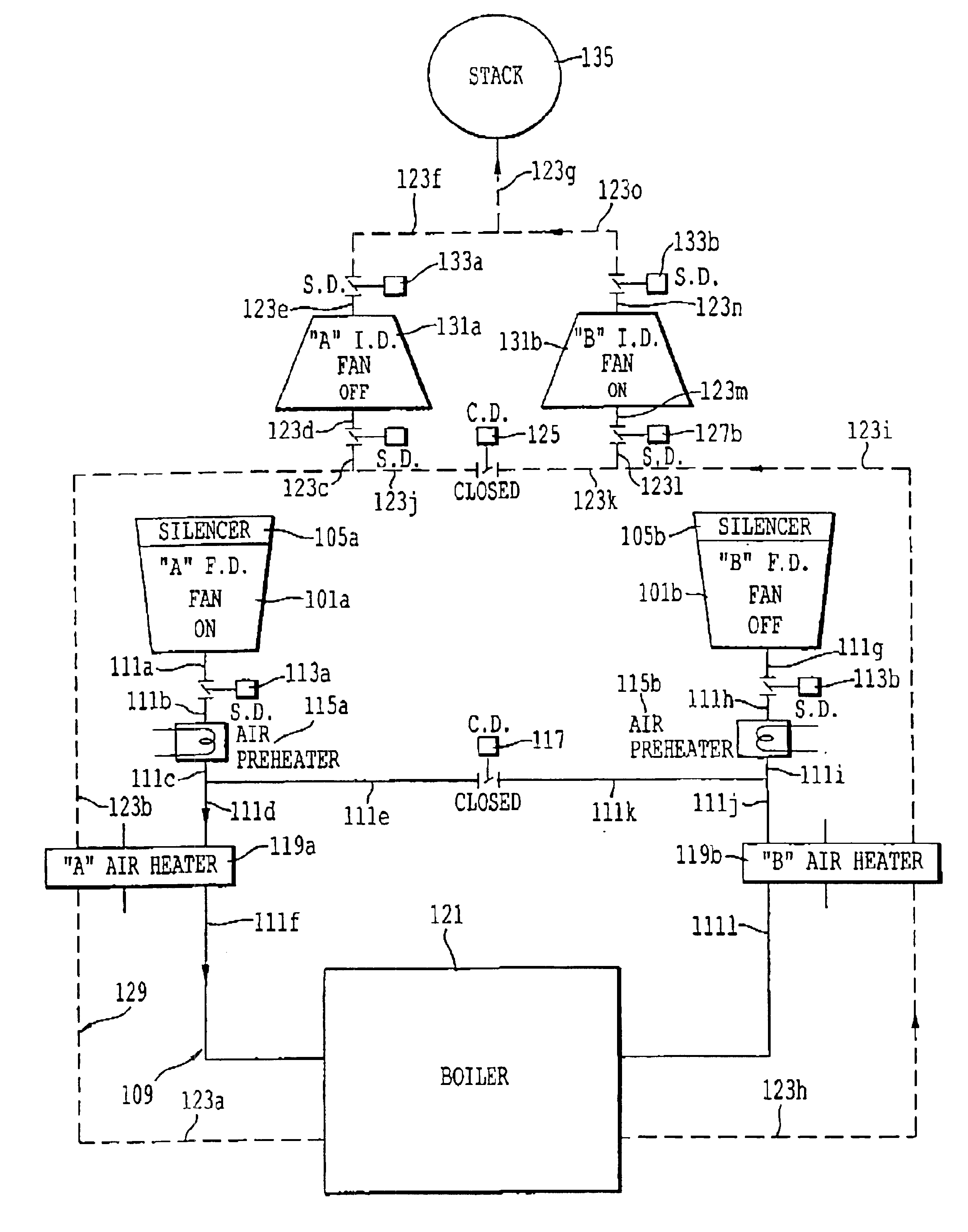

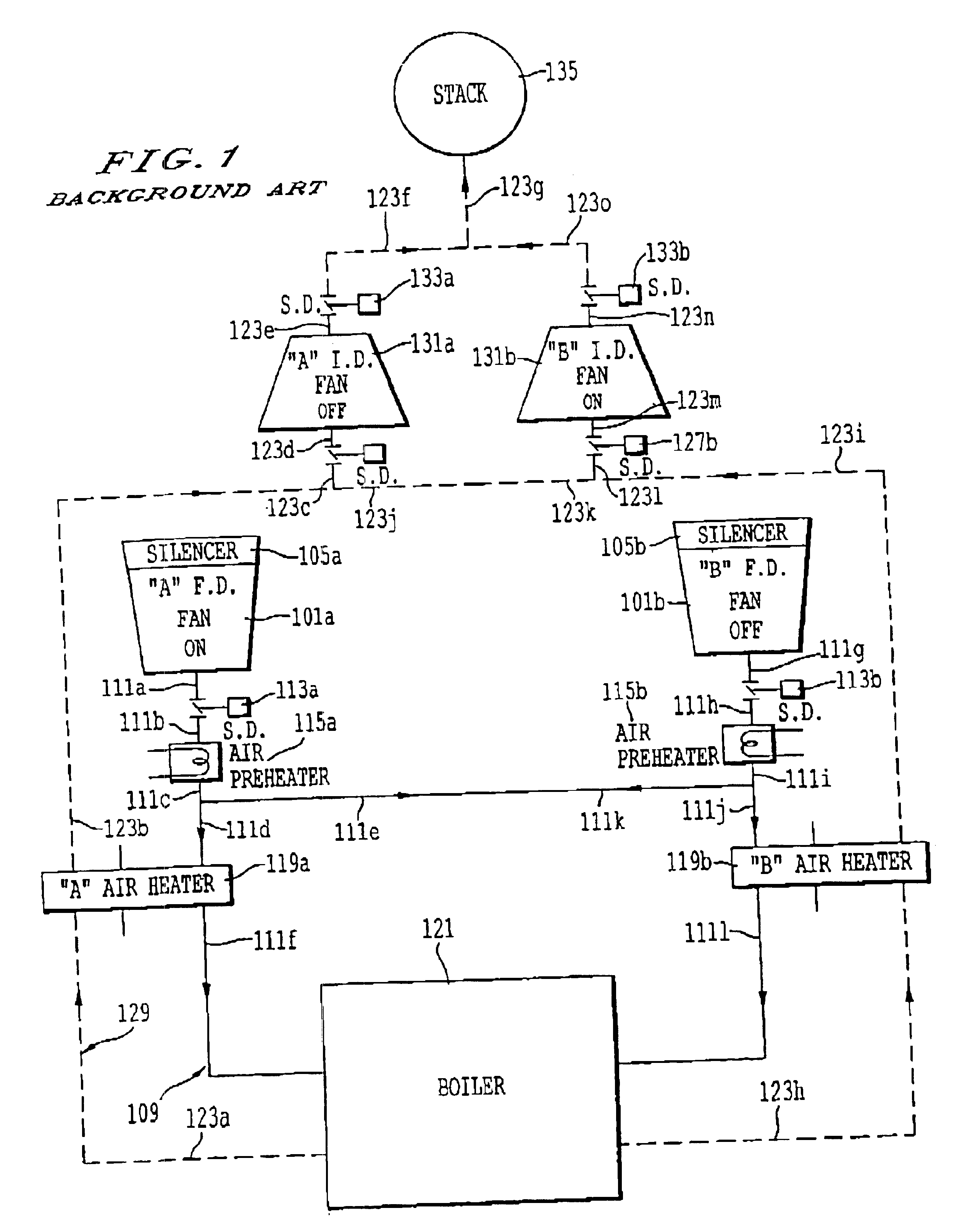

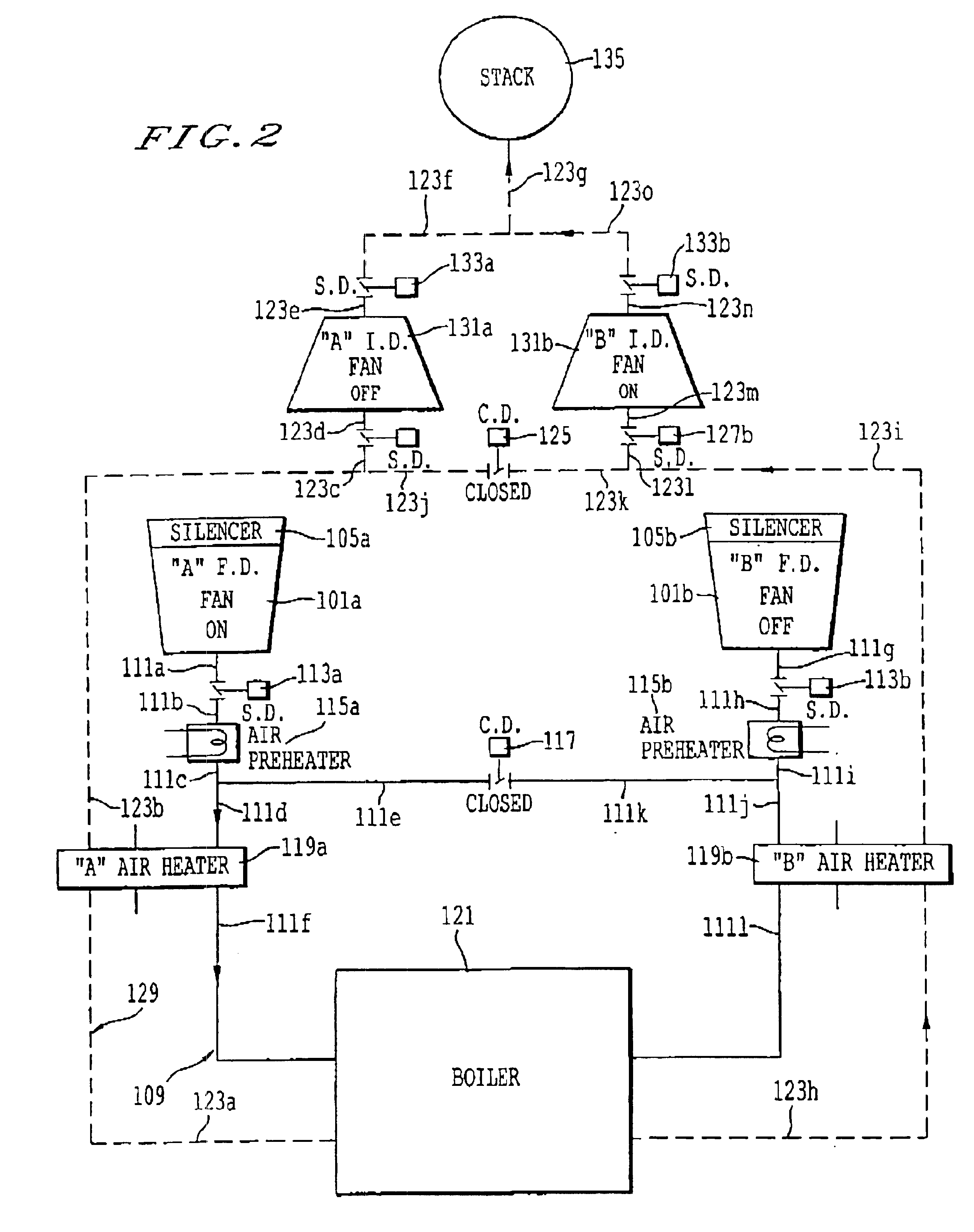

Crossflow air heater bypass

A boiler system includes combustion air conduit for directing the flow of combustion air through a first air heater (e.g., A-side heater) to a boiler and flue gas conduit for directing the flow of flue gas generated by the boiler to a second air heater (e.g., B-side heater). The combustion air conduit is configured to direct the majority of the combustion air to the first air heater, and the flue gas conduit is configured to direct the majority of the flue gas from the boiler to the second air heater.

Owner:PPL

Turbine arrangement and method of cooling a shroud located at the tip of a turbine blade

InactiveUS8550774B2Reduce the average velocityLower capability of heat dissipationEngine manufacturePump componentsCombustionTurbine blade

A turbine arrangement with a rotor and a stator surrounding the rotor forming a flow path for hot and pressurized combustion gases between the rotor and the stator is provided. The rotor defines a radial direction and a circumferential direction and includes turbine blades extending in the radial direction through the flow path towards the stator. The turbine blades have shrouds located at their tips and the stator includes a wall section along which the shrouds move when the rotor is turning. A supersonic nozzle is located in the wall section and is connected to a cooling fluid provider. The supersonic nozzle provides a supersonic cooling fluid flow towards the shroud. The supersonic nozzle is angled with respect to the radial direction towards the circumferential direction in such an orientation that the supersonic cooling fluid flow has a flow component parallel to the moving direction of the shroud.

Owner:SIEMENS AG

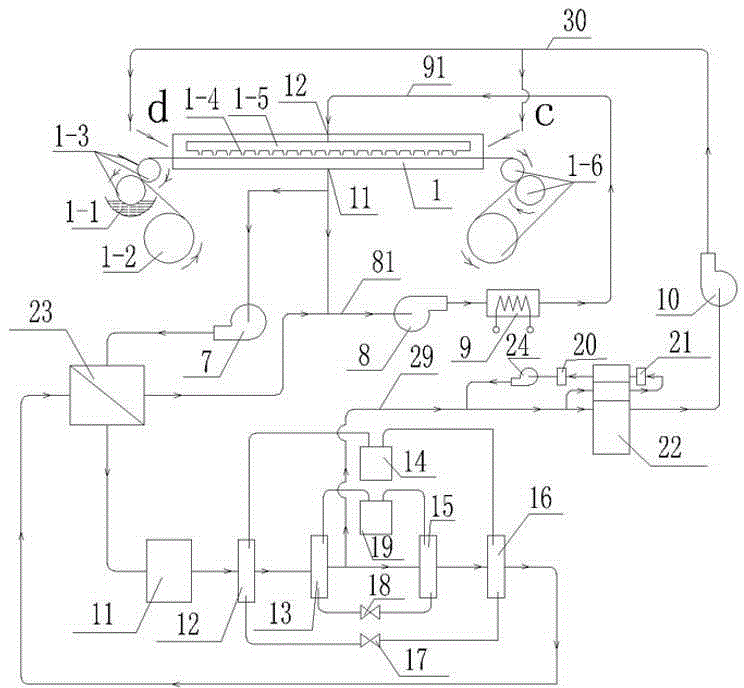

Heat pump and molecular sieve adsorption turning wheel combined cycle organic solvent recycling device

InactiveCN104084357AZero processing costLow organic solvent contentLiquid surface applicatorsHeat recovery systemsGas heaterHeat pump

The invention relates to a heat pump and molecular sieve adsorption turning wheel combined cycle organic solvent recycling device. The heat pump and molecular sieve adsorption turning wheel combined cycle organic solvent recycling device comprises an internal cycle pipeline, a sub pipeline and a branch pipeline, wherein the internal cycle pipeline comprises a gas inlet, an internal cycle fan, a gas heater and a gas outlet; the gas inlet is communicated with a gas outlet of a coating machine; the gas outlet is communicated with a gas inlet of the coating machine; the sub pipeline comprises the gas outlet of the coating machine, an exhaust fan, a hot gas introducing and discharging opening of a gas-gas heat exchanger, an air cooler, an evaporator of the high-temperature heat pump, an evaporator of a low-temperature heat pump, a condenser of the low-temperature heat pump, a condenser of the high-temperature heat pump, a cold gas introducing and discharging opening of the gas-gas heat exchanger and a gas inlet; the branch pipeline comprises a branch pipeline gas inlet, an adsorption area of a molecular sieve concentration turning wheel, a processing fan and a branch pipeline gas outlet; the branch pipeline gas inlet is connected with a gas outlet of the evaporator of the low-temperature heat pump, and the branch pipeline gas outlet is communicated with a machine head and a machine tail of the coating machine. According to the device, a heat pump is used for recycling an organic solvent, and meanwhile the gas temperature is increased, so that energy sources are saved; meanwhile, zero emission under the condition of saving the coating energy sources is realized.

Owner:马军

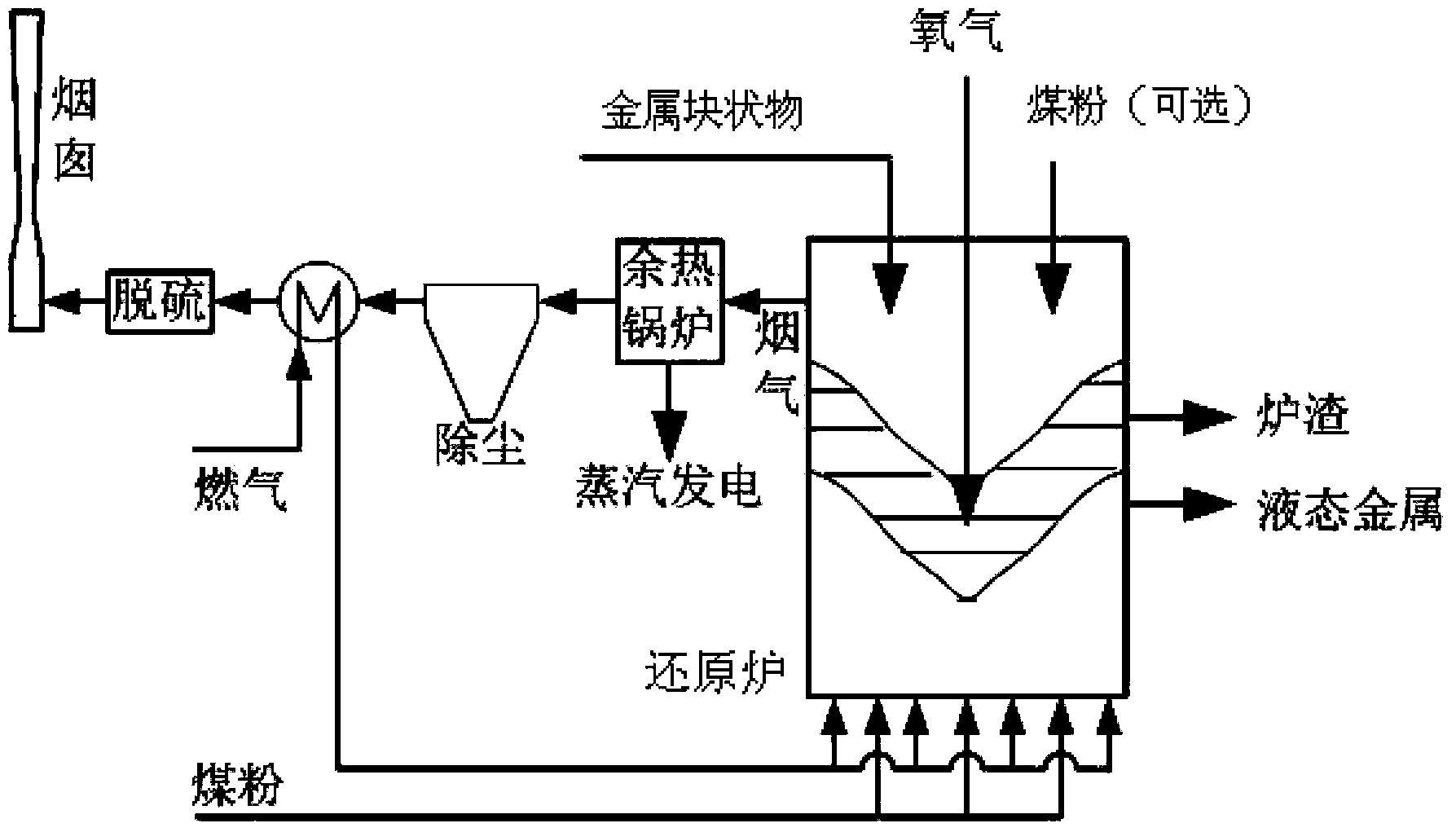

Method for preparing metal elementary substance

ActiveCN103667564AImprove recovery rateReduce contentProcess efficiency improvementGas emission reductionReduction rateReduction treatment

The invention discloses a method for preparing a metal elementary substance. The method comprises the steps of performing smelting reduction treatment on a metal block and a fluxing agent in a reducing furnace to form a slag layer and meltwater; introducing a reducing agent, fuel gas and oxygen into the reducing furnace so that part of the reducing agent is burnt to generate heat and high-temperature flue gas; reducing the metal oxide in the metal block by use of the remaining reducing agent to obtain the metal elementary substance, wherein the waste heat is recycled by use of high-temperature flue gas; the high-temperature flue gas after dust removal is used for preheating the fuel gas; the preheated fuel gas is mixed with the reducing agent, and the reducing agent is blown into the reducing furnace by the preheated fuel gas; the oxygen is directly introduced into the slag layer. By adopting the method, the added output value in a preparation process of the metal elementary substance can be effectively increased, and the reduction rate and production efficiency of metal are improved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

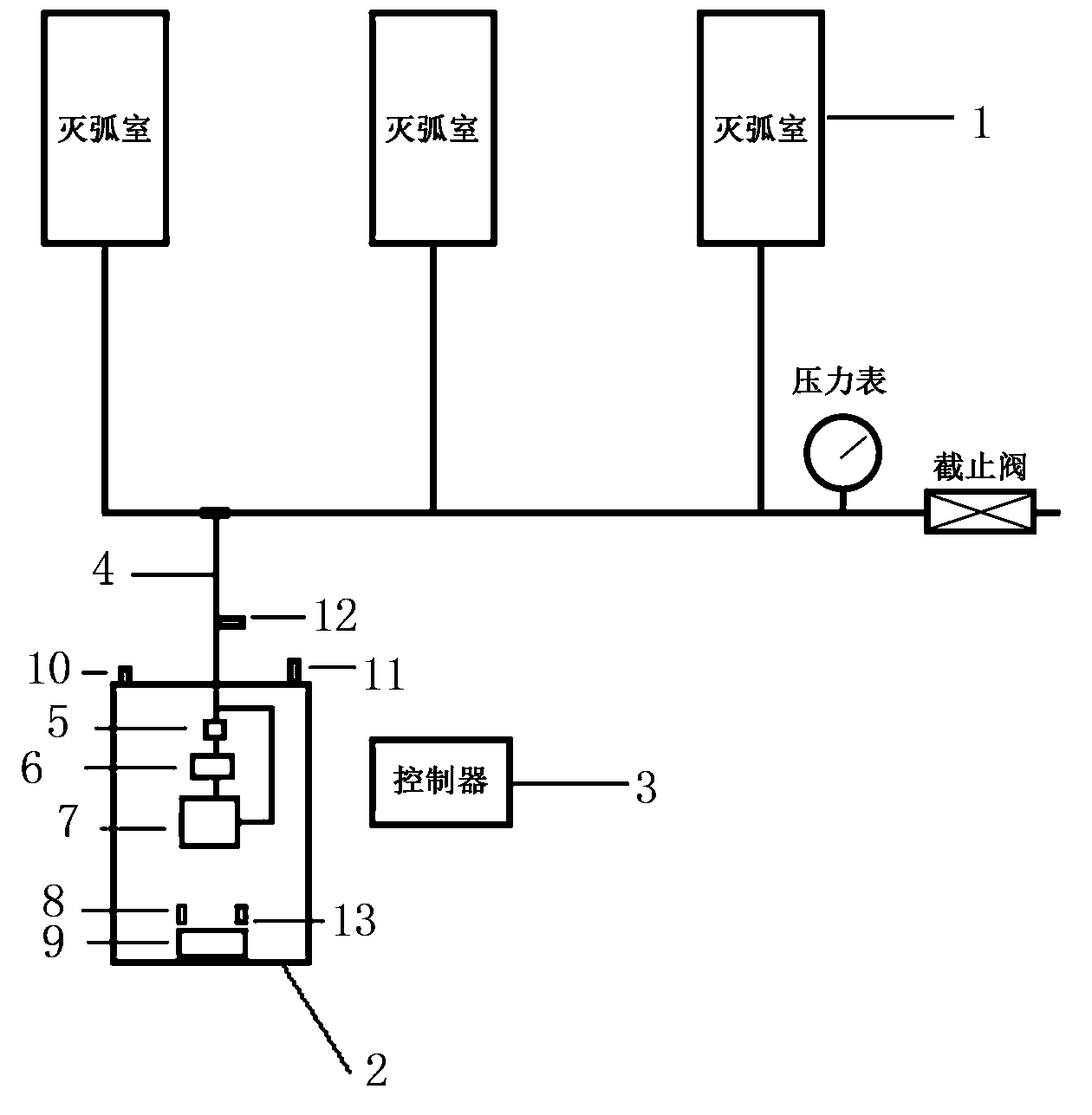

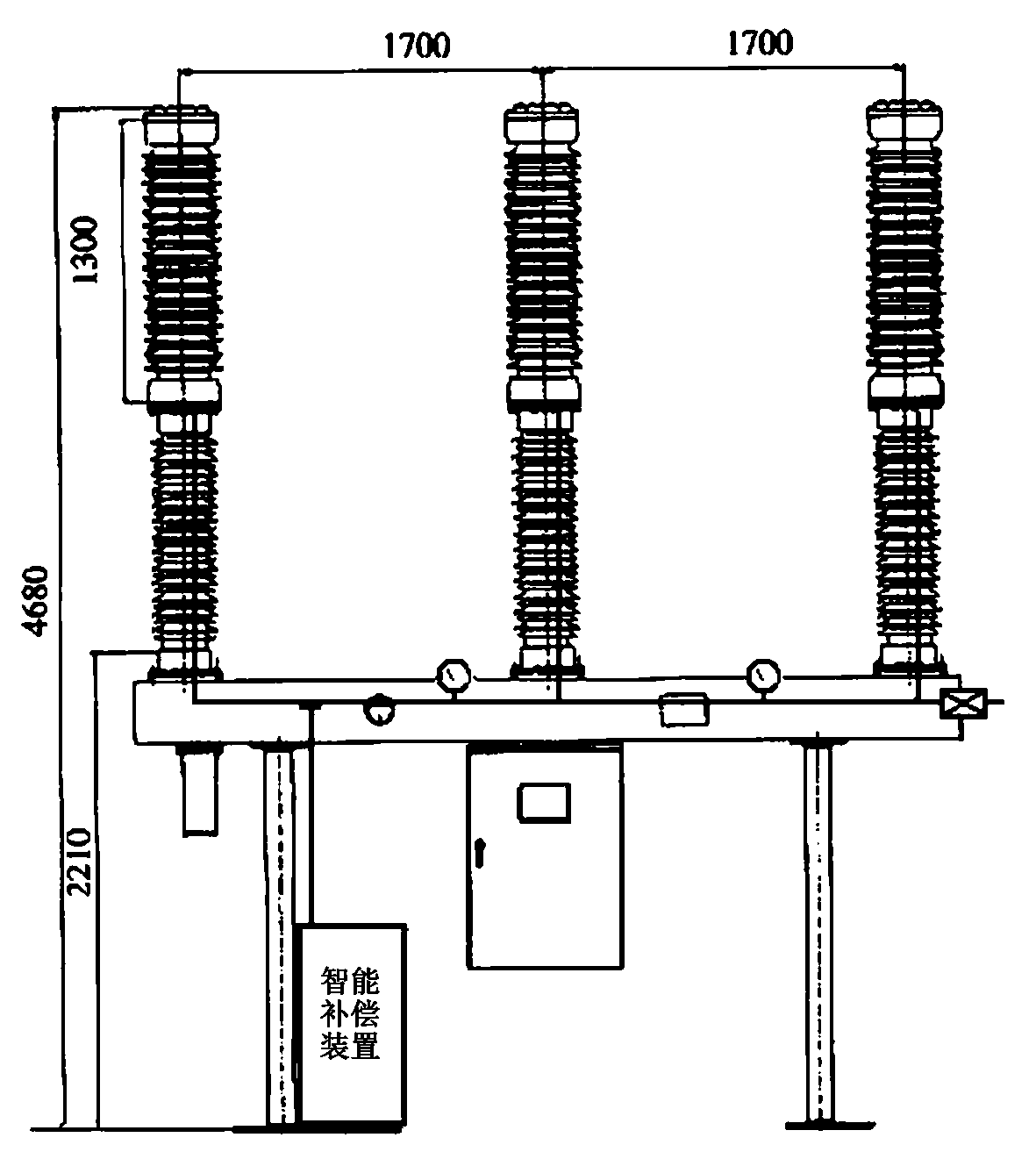

Gas intelligent compensation device of sulfur hexafluoride breaker

ActiveCN103594276AIncrease temperatureRaise the gas temperatureHigh-tension/heavy-dress switchesAir-break switchesProcess engineeringElectricity

The invention relates to a gas intelligent compensation device of a sulfur hexafluoride breaker. The breaker comprises at least one breaker body. The compensation device comprises a gas storage tank and a controller, a gas pumping in and out system is arranged inside the gas storage tank, the gas storage tank is connected with the breaker body through a guide pipe, and the controller and the gas storage tank are electrically connected with the pumping in and out system used for controlling the inner portion of the gas storage tank. The compensation device guarantees the fact that the problems of low-temperature alarming and locking cannot exist in operating equipment. Meanwhile, the device has the breaker body air pressure field display and background monitor function, the pressure intelligent adjusting functions of body micro-leaking air supply and high-temperature automatic air leakage, the SF6 gas leakage reminding function and other practical functions.

Owner:STATE GRID CORP OF CHINA +1

Maximum reaction rate converter system for exothermic reactions

ActiveUS7371361B2Reduce volumeSpeed up the conversion processHydrogenOrganic compound preparationReaction temperatureEquilibrium curve

An ammonia converter system and method are disclosed. The reactor can alter the conversion of ammonia by controlling the reaction temperature of the exothermic reaction along the length of the reactor to parallel the equilibrium curve for the desired product. The reactor 100 can comprise a shell 101 and internal catalyst tubes 109. The feed gas stream enters the reactor, flows through the shell 101, and is heated by indirect heat exchange with the catalyst tubes 109. The catalyst tubes 109 comprise reactive zones 122 having catalyst and reaction limited zones 124 that can comprise inert devices that function to both separate the reactive zones, increase heat transfer area, and reduce the temperature of the reaction mixture as the effluent passes through the catalyst tube 109.

Owner:KELLOGG BROWN & ROOT LLC

Preheating device of the pipeline between air pressure source and humidifier

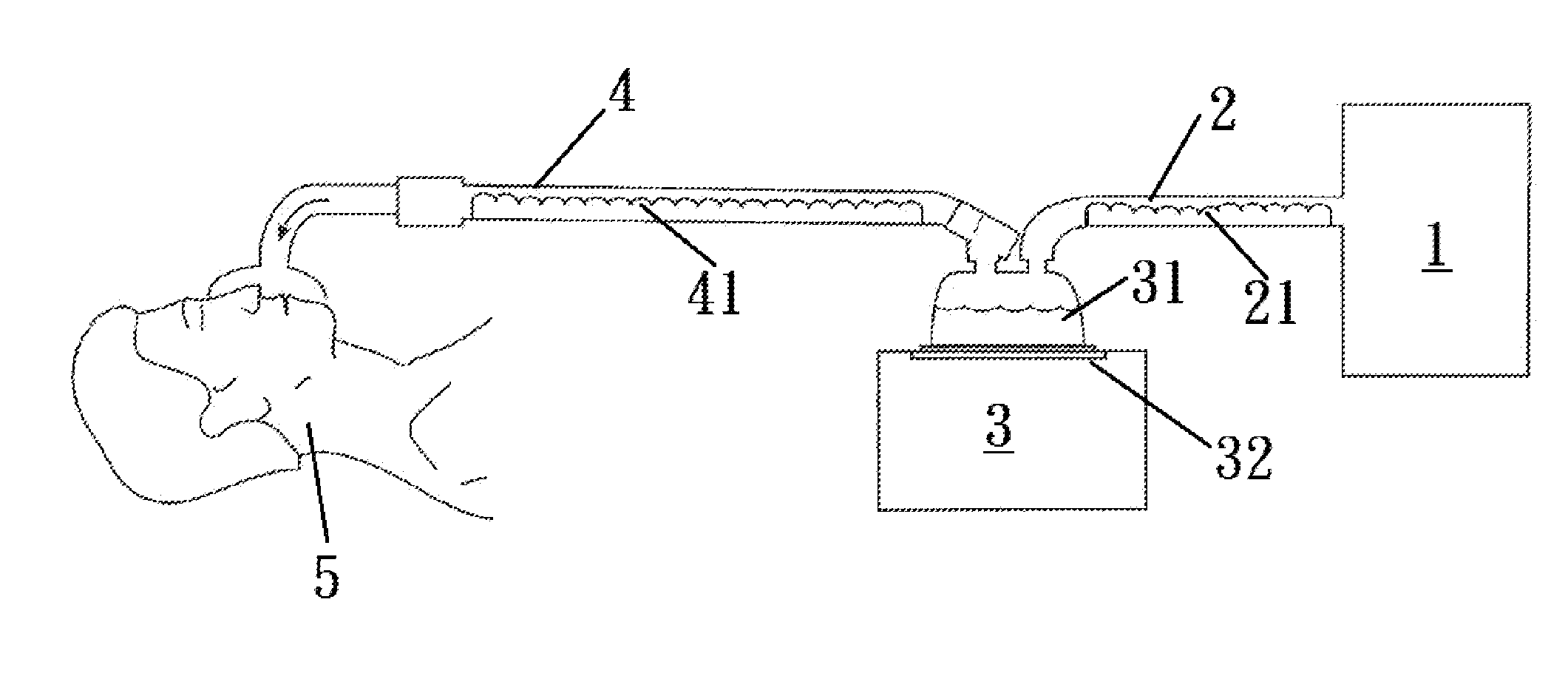

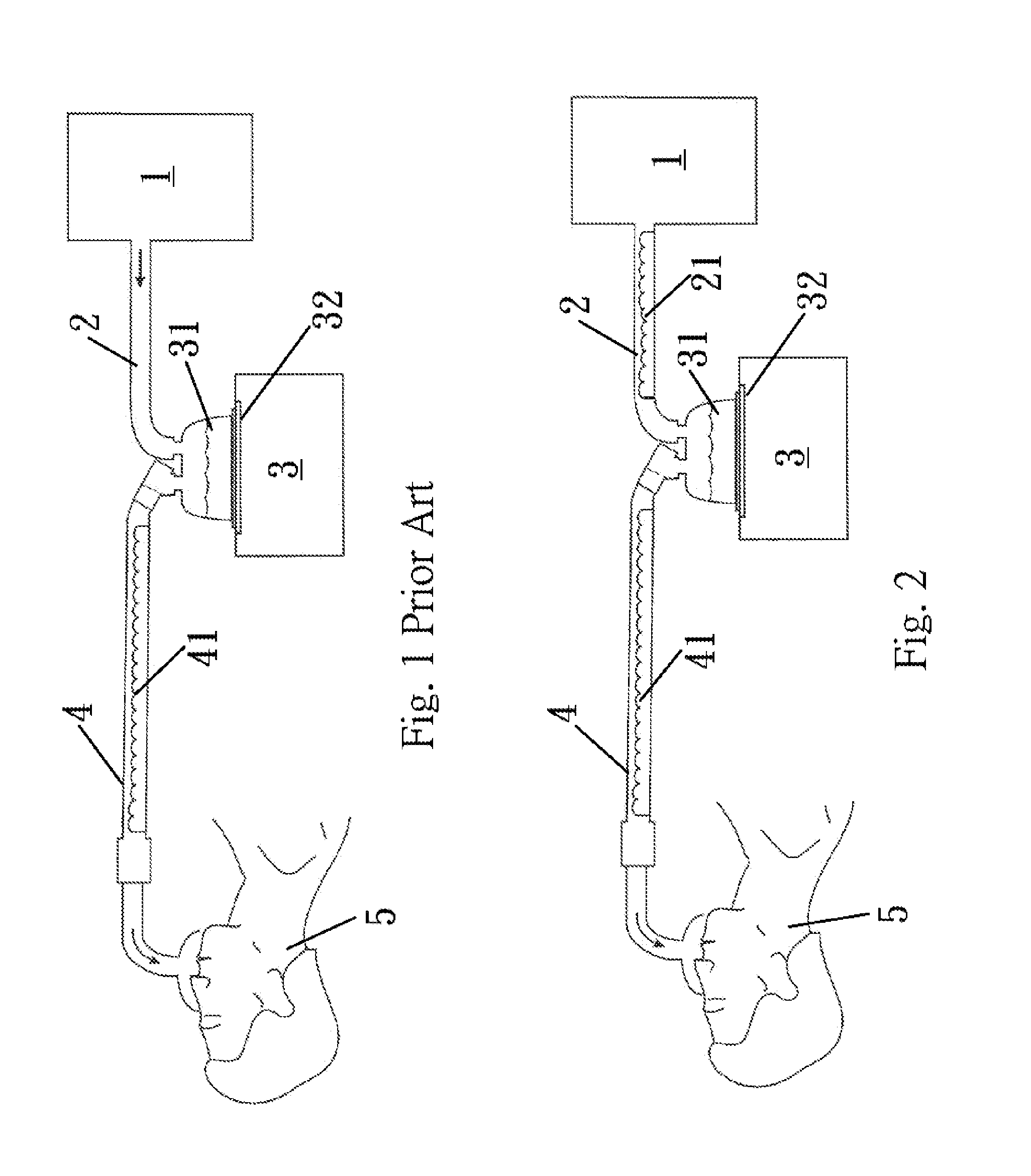

InactiveUS20140261418A1Less discomfortEasy to humidifyRespiratorsGaseous fuel burnerEngineeringRelative humidity

A preheating device is installed to the pipeline connecting between an air pressure source and a humidifier to increase the temperature of the gas entering the humidifier and to reduce the relative humidity. The gas can fully mix with vapor generated by a heated water carrier within a short time, thereby preventing the humidifier from excessively outputting condensed water.

Owner:HUANG NEO

Methods and reactors for producing acetylene

InactiveUS20150165411A1Raise the gas temperatureHydrocarbon by dehydrogenationUltra-high pressure processesShock waveEngineering

Methods and reactors are provided for producing acetylene. The method includes combusting a fuel with oxygen in a combustor to produce a carrier gas, and accelerating the carrier gas to a supersonic speed in a converging / diverging nozzle prior to the carrier gas entering a reaction zone. A nozzle exit temperature of the carrier gas is controlled from about 1,200 degrees centigrade (° C.) to about 2,500° C. by adding a heat sink gas to the carrier gas before the reaction zone, where the heat sink gas is different than the fuel and the oxygen. Methane is added to the carrier gas in the reaction zone, and a shock wave is produced in the reaction zone by adjusting a back pressure such that the methane reacts to form acetylene.

Owner:UOP LLC

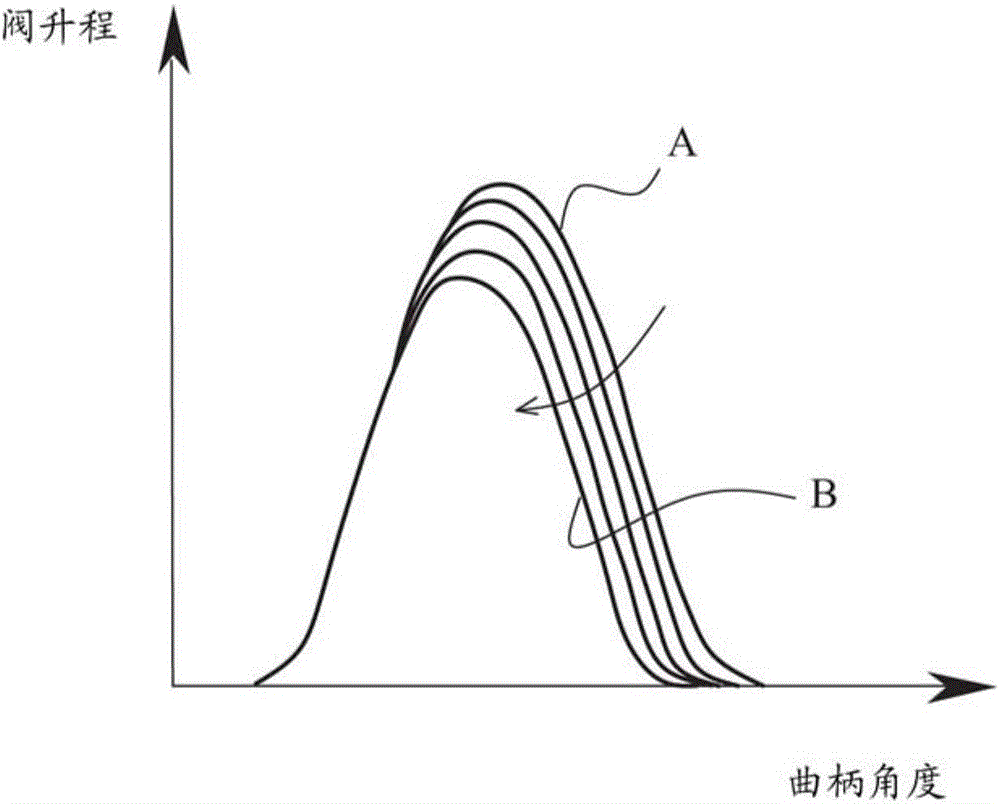

Method of operating an internal combustion engine

ActiveCN106438061AUnfavorable consumptionReduce dilutionElectrical controlInternal combustion piston enginesExhaust valveExternal combustion engine

A method is disclosed for operating an internal combustion engine equipped with an aftertreatment device. The internal combustion engine is equipped with a cylinder having an exhaust gas port intercepted by an exhaust valve, the exhaust valve being actuated by means of a Variable Valve Actuation (VVA) system, An aftertreatment device regeneration is detected, and the exhaust valve closure is anticipated using the Variable Valve Actuation (VVA) system during the aftertreatment device regeneration to provide an exhaust valve actuation profile having an anticipated exhaust valve closure with respect to a baseline exhaust valve actuation profile.

Owner:GM GLOBAL TECH OPERATIONS LLC

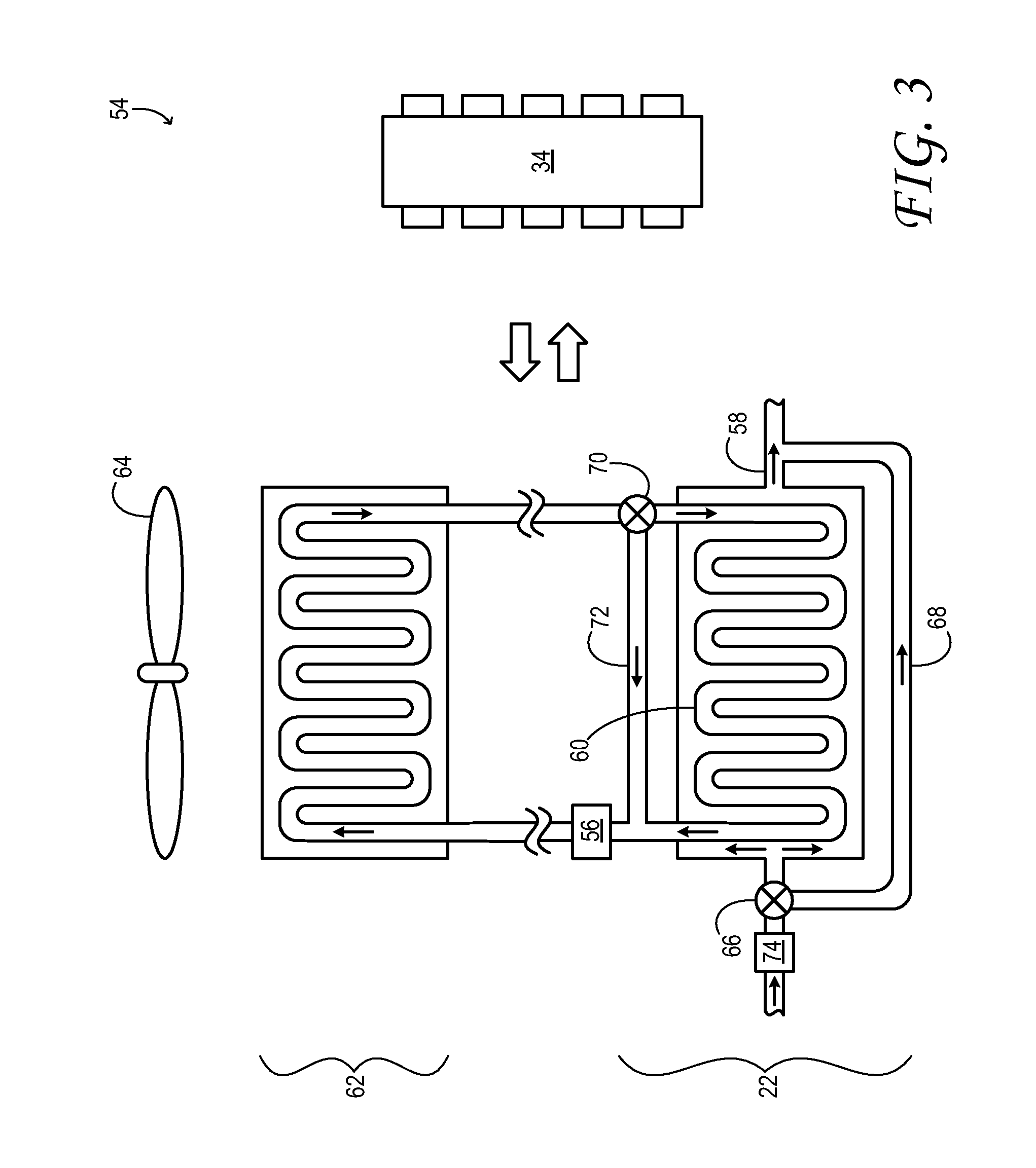

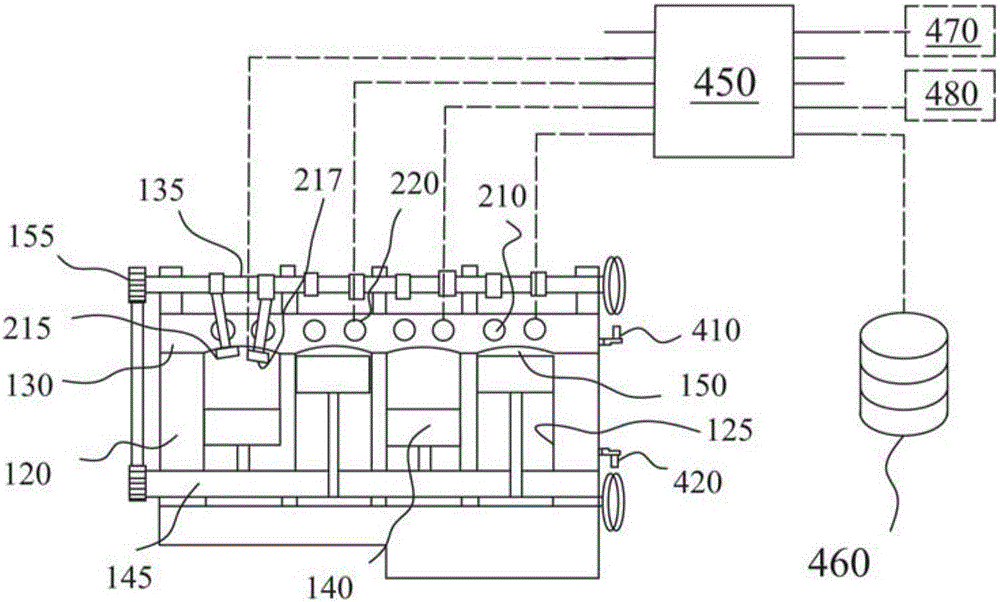

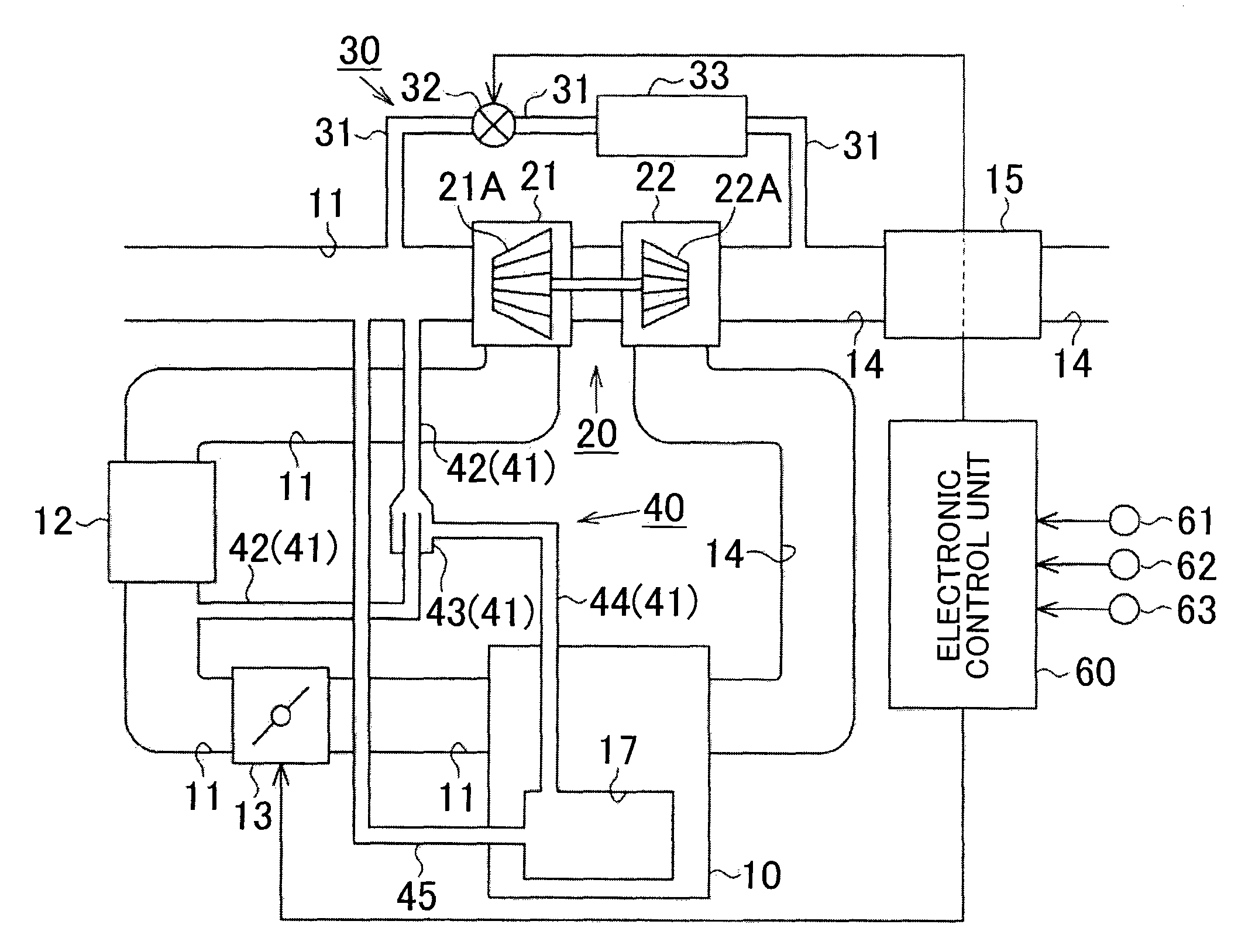

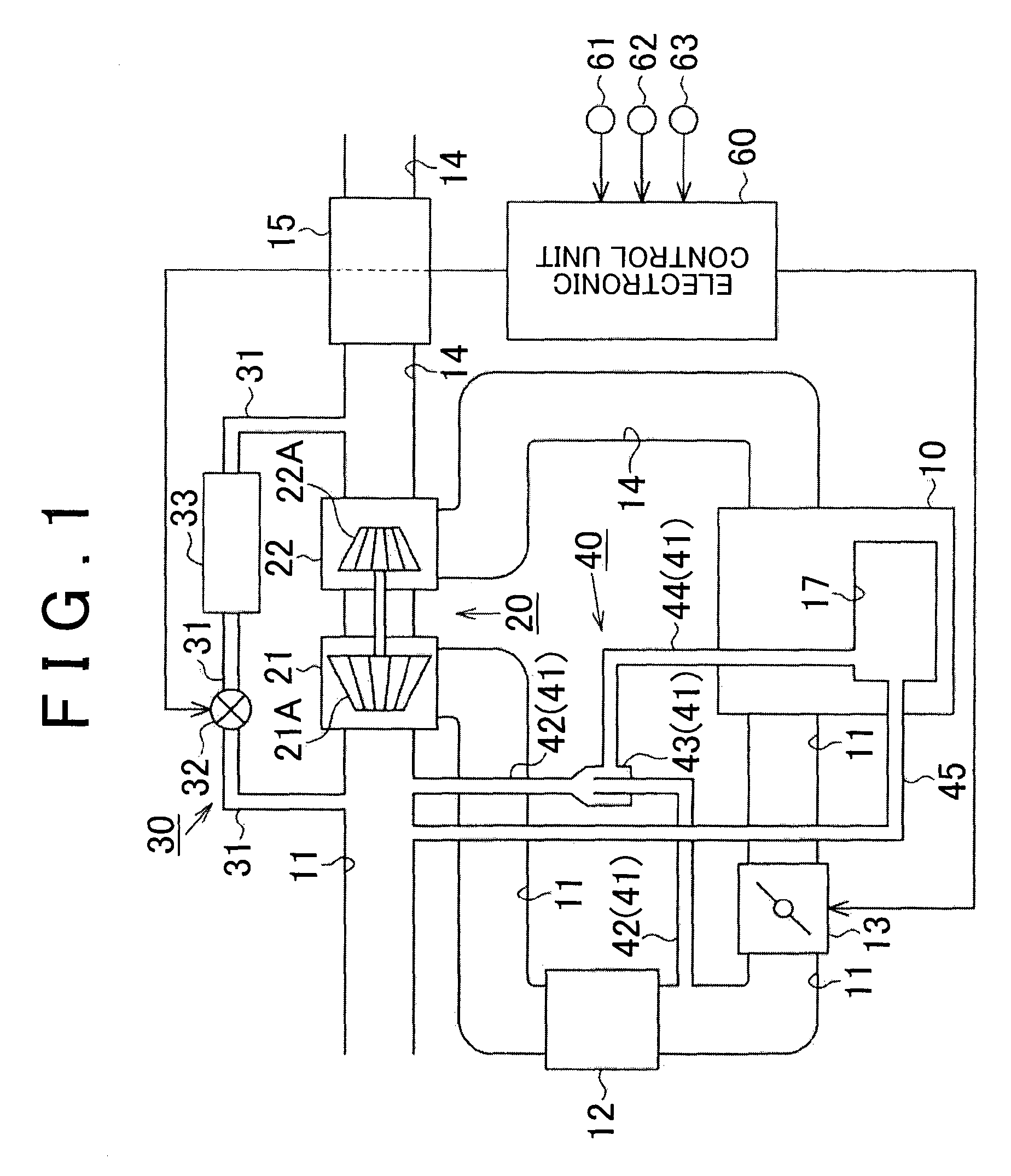

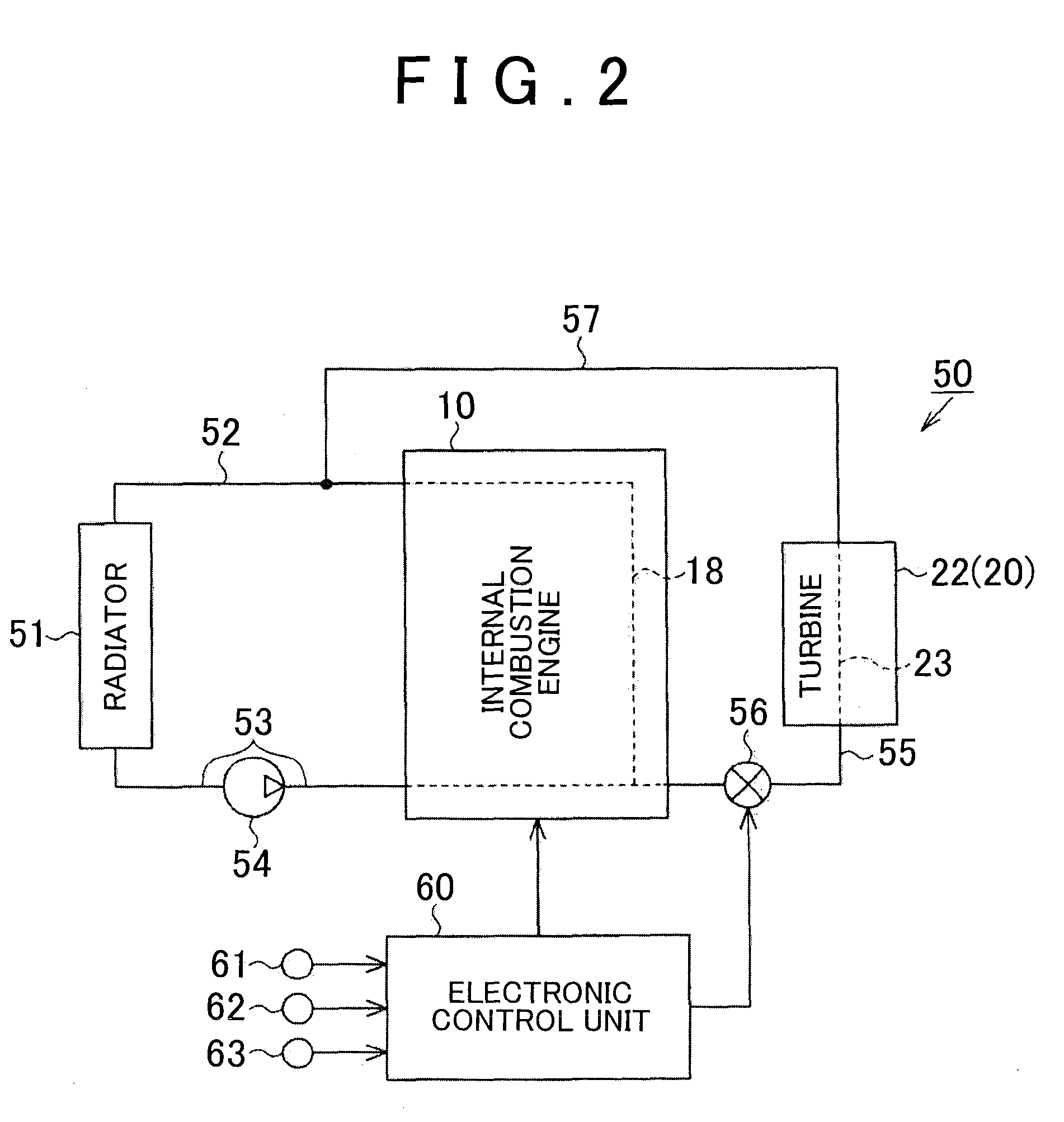

Engine system and controller, control system and control method for engine system

InactiveUS20160319732A1Decreased compressibilityReduce efficiency of turbochargerElectrical controlExhaust gas recirculationElectronic control unitCooling Units

A controller for an engine system includes an exhaust-driven turbocharger including a compressor and a turbine, an exhaust gas recirculation unit configured to recirculate exhaust gas from a downstream portion of the turbine in an exhaust gas passage to an upstream portion of the compressor in an intake gas passage, and a cooling unit configured to cool the turbine, the controller includes an electronic control unit. The electronic control unit is configured to set a degree of cooling of the turbine based on a predetermined condition in which a gas temperature at an outlet portion of the compressor is higher than a predetermined temperature and the recirculating of exhaust gas is performed, and set a higher degree of cooling of the turbine when the predetermined condition is satisfied compared to a degree of cooling of the turbine when the predetermined condition is not satisfied.

Owner:TOYOTA JIDOSHA KK

Systems and methods for dedicated EGR cylinder exhaust gas temperature control

InactiveUS9581114B2Improve the level ofReduce the temperatureElectrical controlInternal combustion piston enginesTemperature controlExhaust gas

Owner:FORD GLOBAL TECH LLC

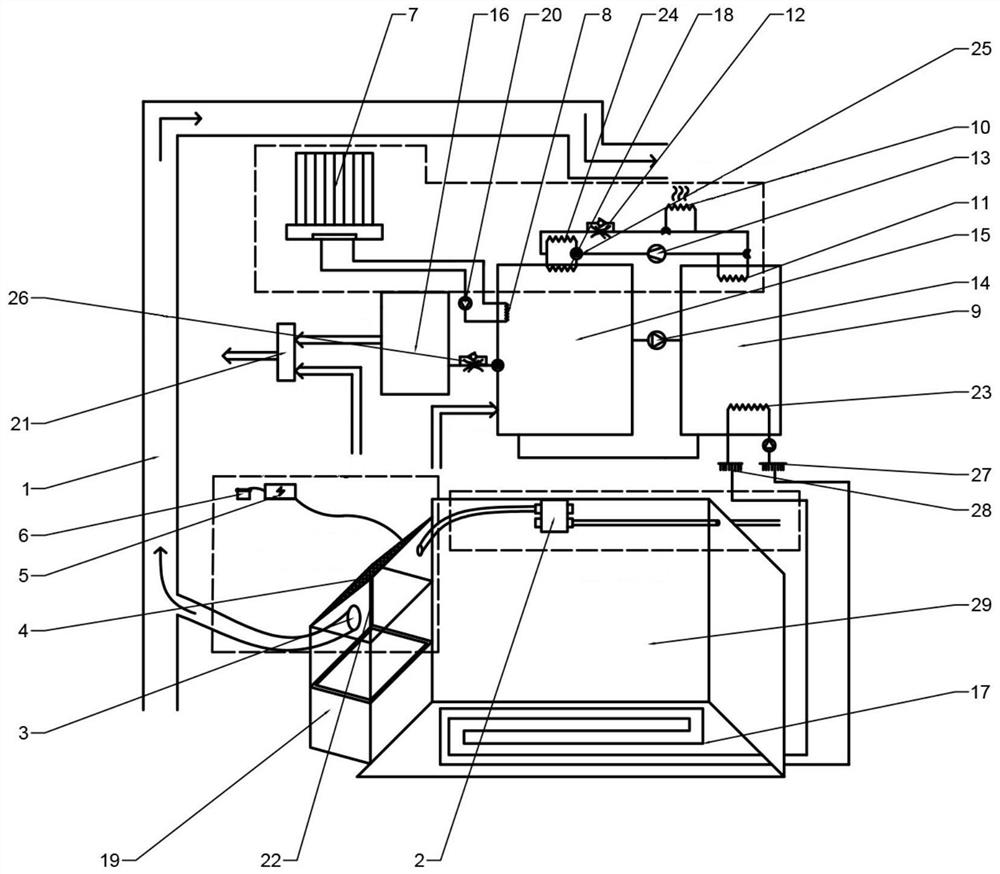

Comprehensive energy-saving type temperature control water supply system for living building

PendingCN111678193AImprove efficiency and longevityRaise the gas temperatureEnergy efficient heating/coolingCorrosion preventionWater supply networkExhaust fumes

The invention discloses a comprehensive energy-saving type temperature control water supply system for a living building. The comprehensive energy-saving type temperature control water supply system comprises a building body, a ventilation system, a photovoltaic power generation system and a solar energy-air energy combined triple co-generation system, wherein the ventilation system, the photovoltaic power generation system and the solar energy-air energy combined triple co-generation system are arranged in the building body. Waste gas exhausted by a total heat exchanger passes through a ventilation pipeline, passes through a photovoltaic power generation panel and is collected into a centralized pipeline, forced heat dissipation is carried out on a photovoltaic assembly, the service lifeof the photovoltaic power generation panel is prolonged, and the efficiency of the photovoltaic power generation panel is improved; indoor waste gas exhausted along the photovoltaic power generation panel cools the photovoltaic power generation panel and then is collected by the centralized pipeline to be conveyed to the first evaporator side in the air energy system at the roof, the temperature of gas at an inlet of the evaporator is increased, the frosting problem of the evaporator is effectively prevented, and the efficiency of the air energy system is improved; and by means of the structure that different condensers and evaporators are matched with waterway circulation, stable temperature control and water supply can be achieved in winter and summer respectively.

Owner:XUHAI COLLEGE CHINA UNIV OF MINING & TECH

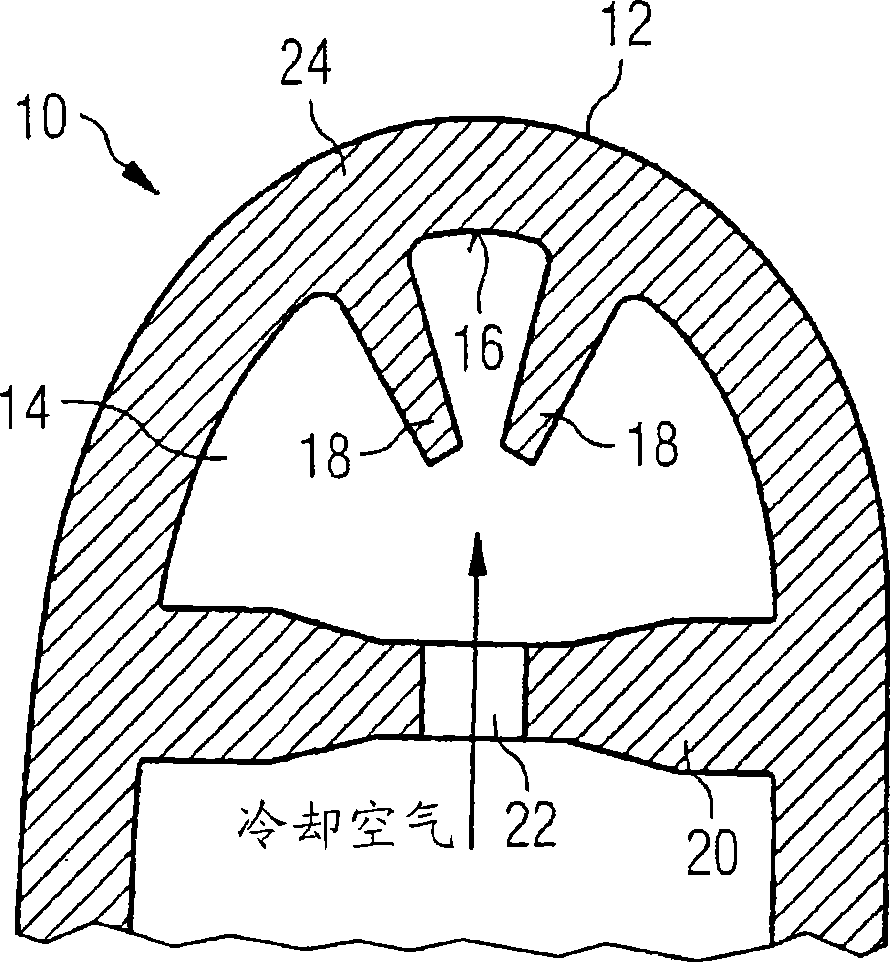

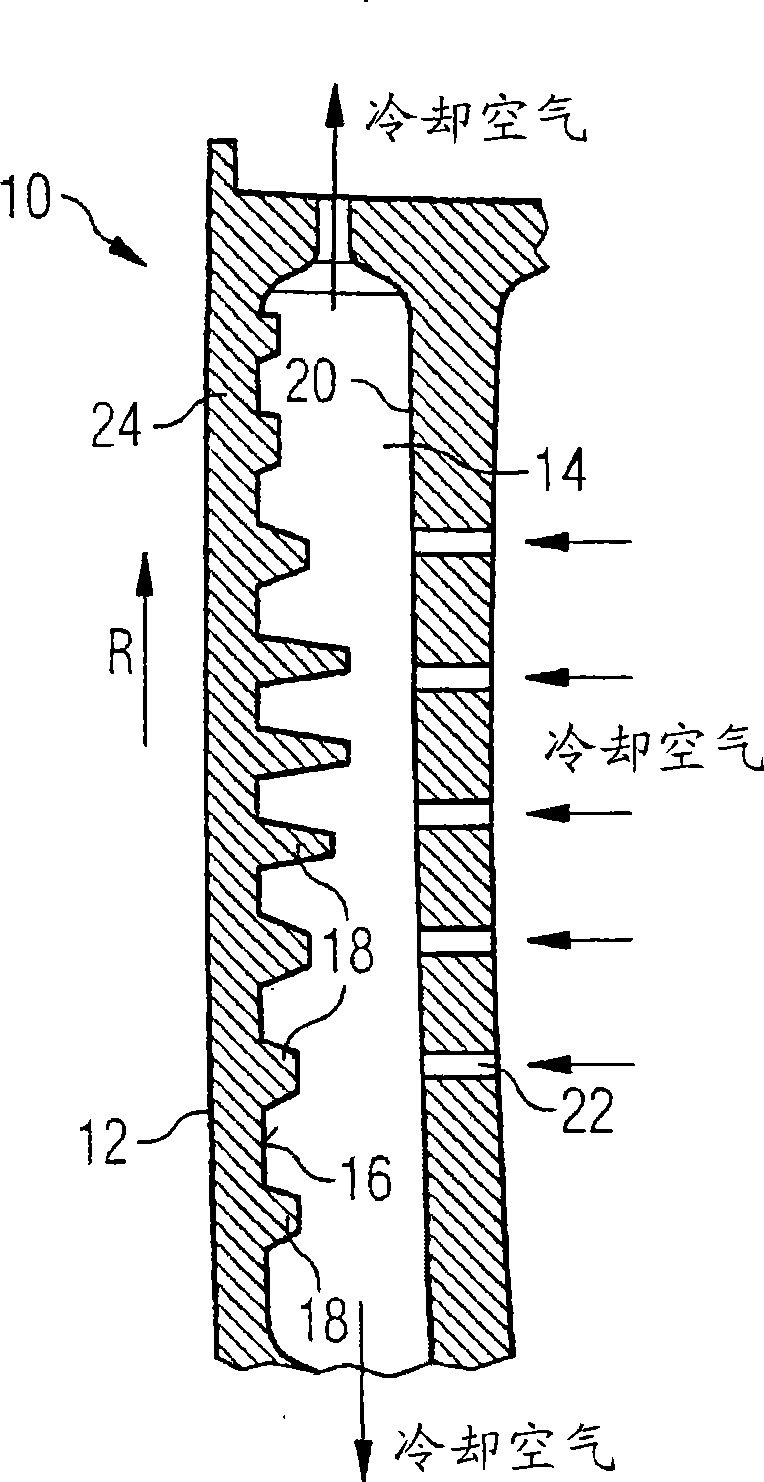

Turbine blade

InactiveCN101535602AImprove cooling effectFast heat conductionEngine fuctionsBlade accessoriesLeading edgeTurbine blade

The invention relates to a turbine blade (10) comprising at least one cooling element (18) and a cooling duct (14) for conducting a cooling medium therethrough. The at least one cooling element (18) is disposed within the flow of the cooling medium and is designed in a cog-shaped manner. The invention further relates to a turbine blade comprising a leading edge (12), a cooling duct (14) which is formed within the turbine blade (10) for conducting cooling air therethrough and extends along the flow attacking edge (12) in at least some sections, and a number of cooling elements (18) that are successively arranged in a stationary manner inside the cooling duct (14) in the longitudinal direction thereof. Each individual cooling element (18) has a cooling capacity that is adapted to a predefined cooling requirement for the leading edge (12) in the surroundings of the cooling element (18).

Owner:SIEMENS AG

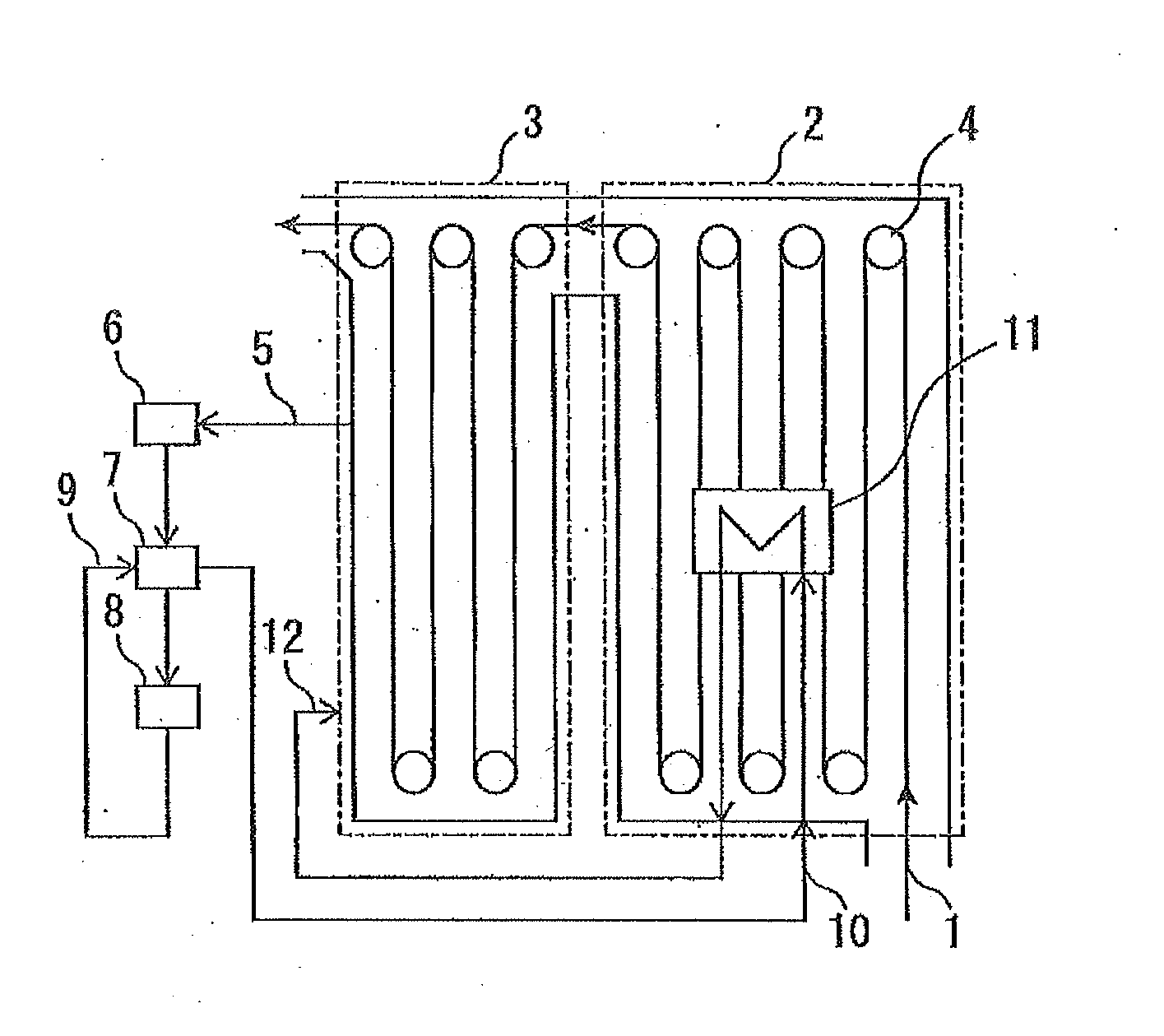

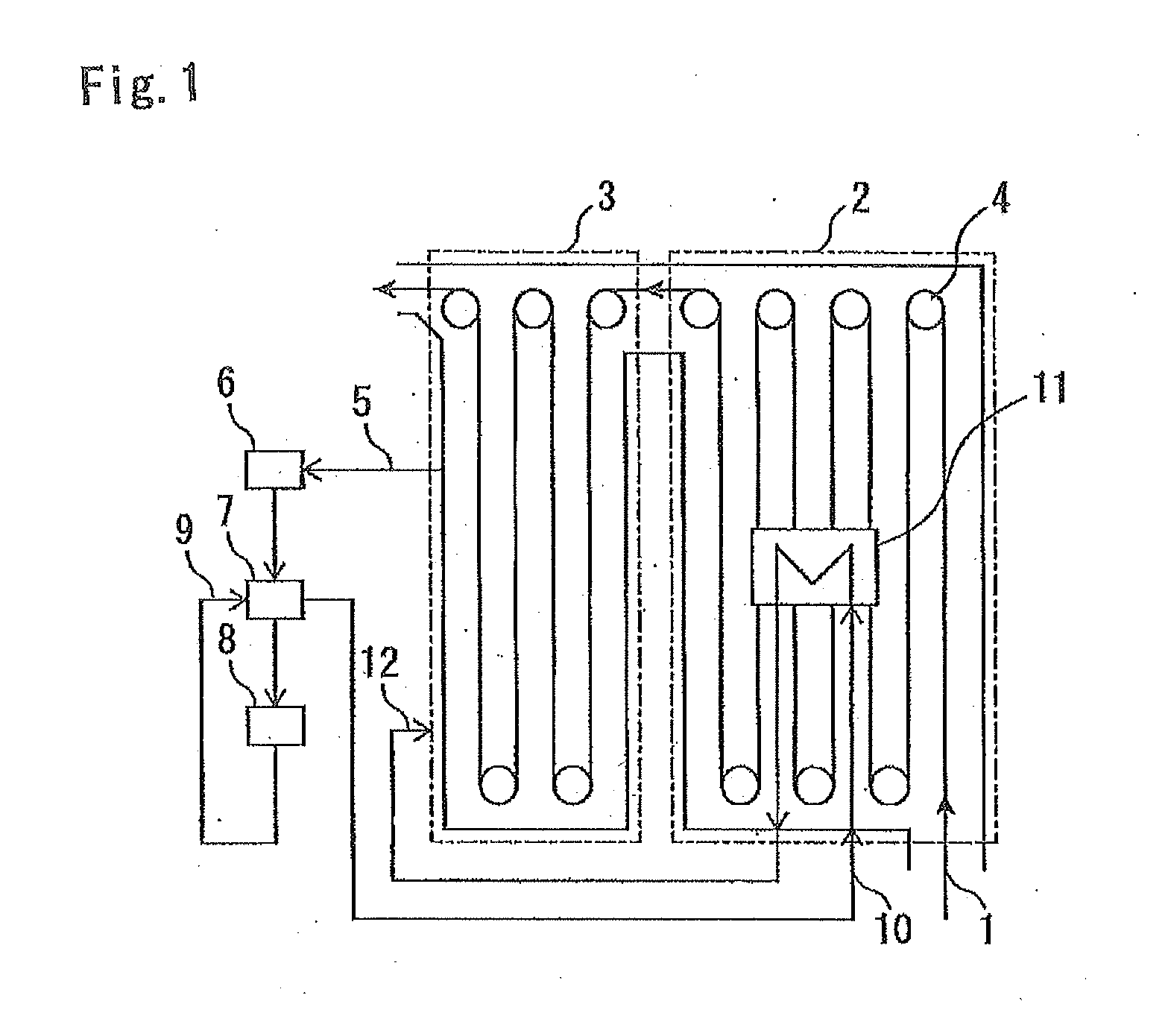

Method for adjusting furnace atmosphere in continuous annealing furnace (as amended)

InactiveUS20150322539A1Raise the gas temperatureReduce pointsMaintainance of heating chambersFurnace typesDew pointMetallurgy

A problem with existing technologies that, when decreasing the dew point of the inside of a continuous annealing furnace by using a refiner, a decrease in the temperature of a part of the inside of the furnace cannot be prevented without supplying additional heat, is to be solved. Provided is a method for adjusting a furnace atmosphere in a continuous annealing furnace, the method including drawing a gas, which is a part of the furnace atmosphere, into a refiner 8 disposed outside the furnace and dehumidifying and deoxidizing the gas; causing the gas that has been dehumidified and deoxidized and that has exited the refiner 8 to exchange heat with a gas that is to be drawn into the refiner 8 in a heat exchanger 7 disposed outside the furnace; causing the gas to exchange heat with the furnace atmosphere in a furnace heat exchanger 11 disposed in the furnace; and reinjecting the gas into the furnace.

Owner:JFE STEEL CORP

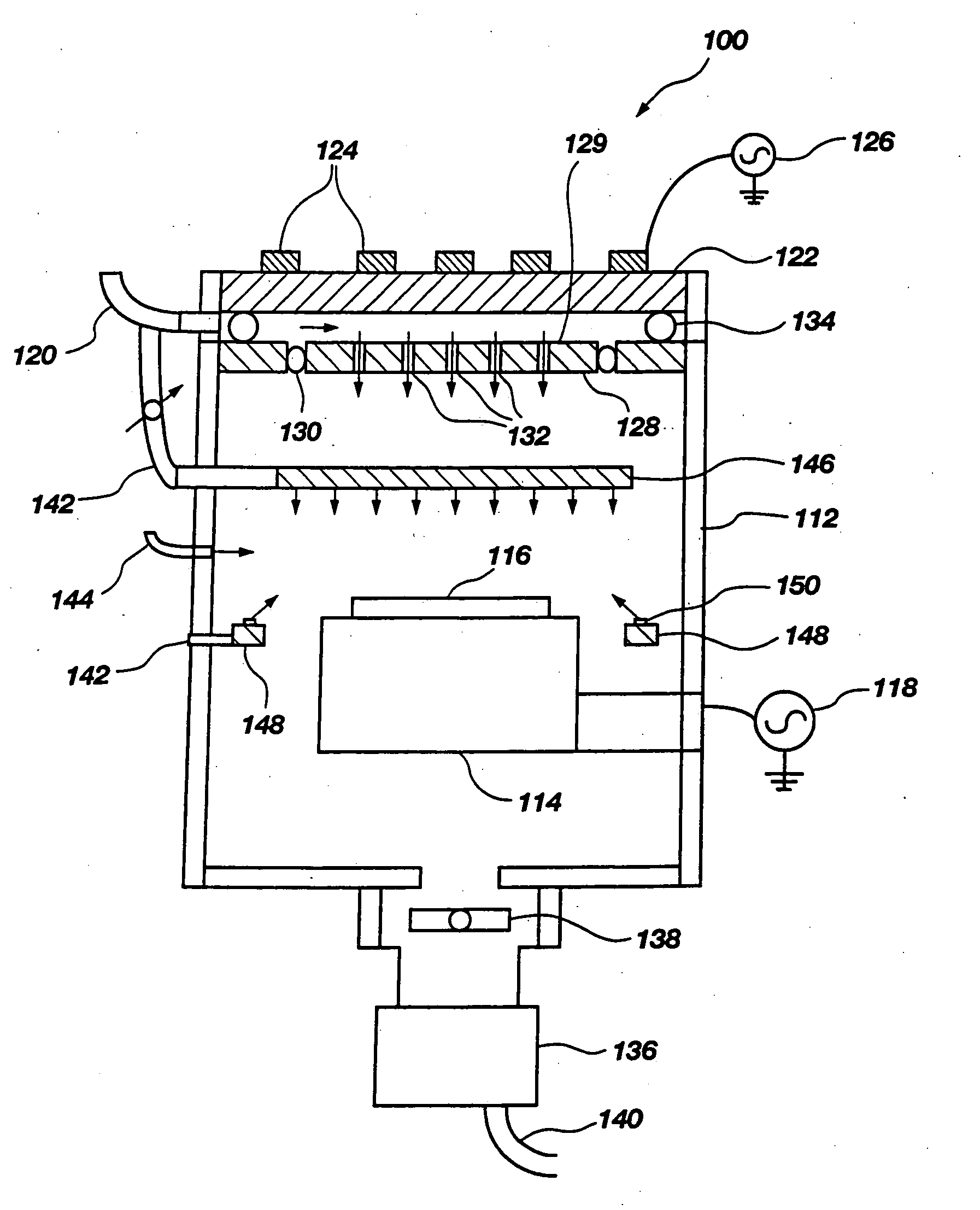

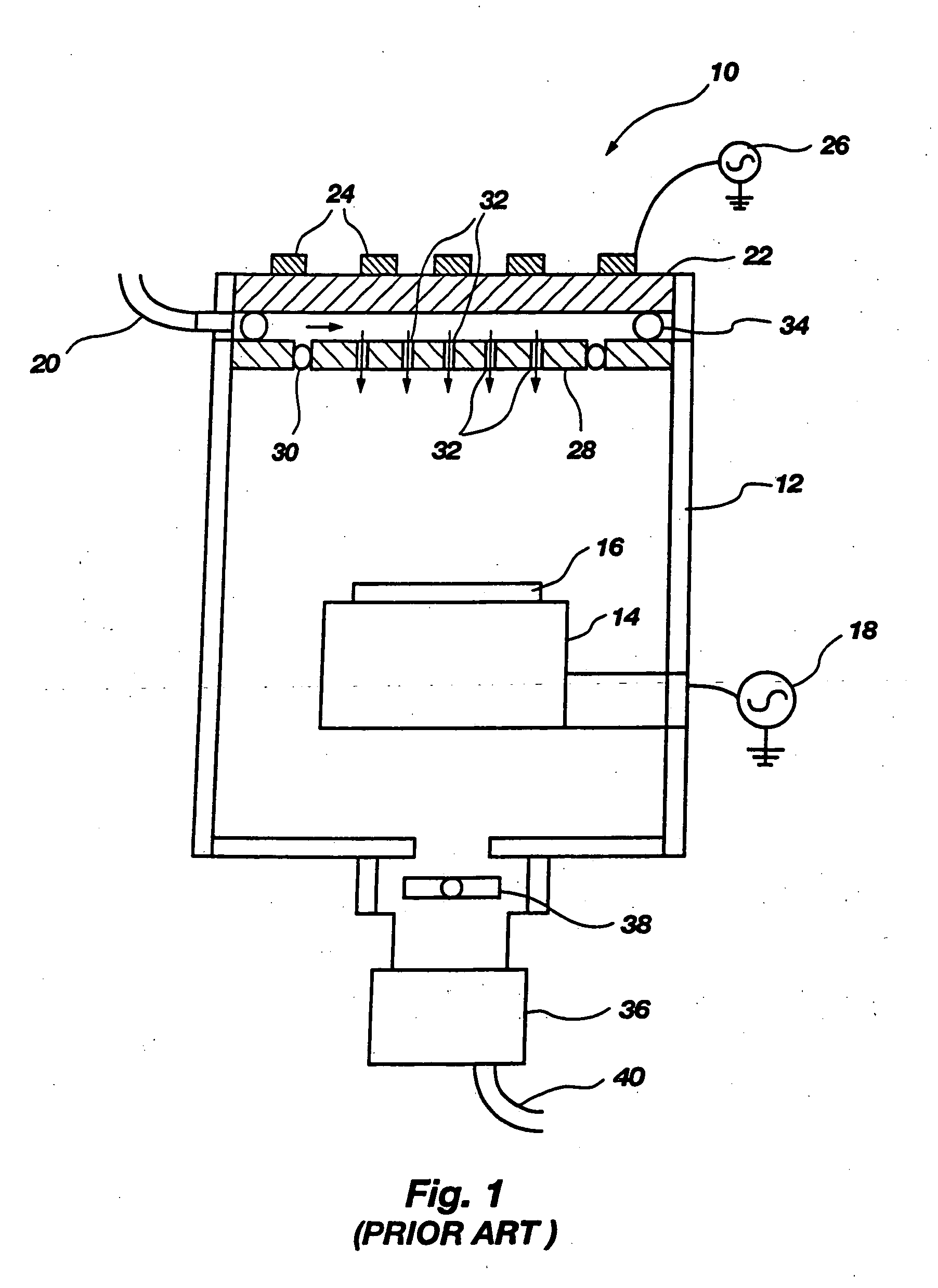

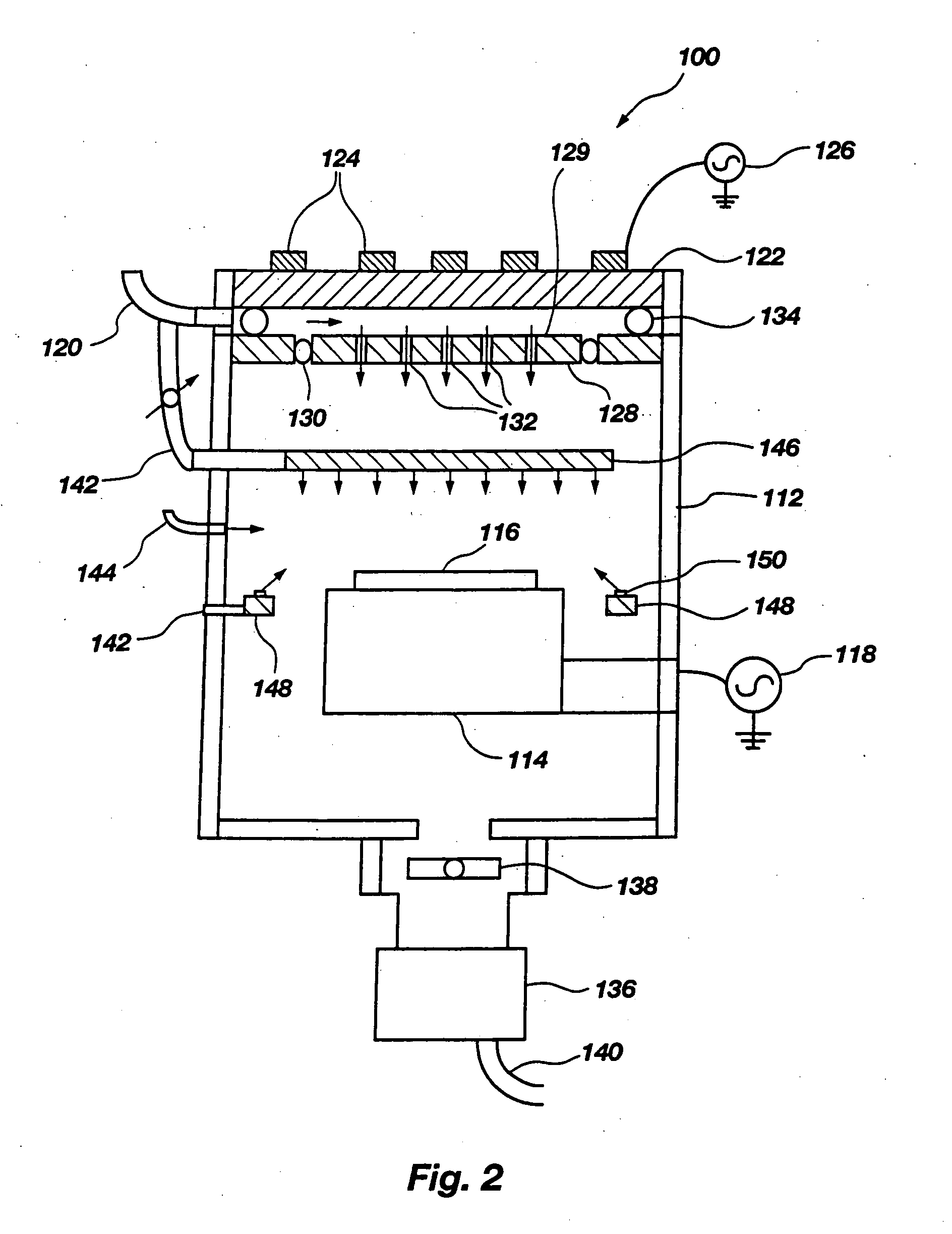

Method for controlling the temperature of a gas distribution plate in a process reactor

InactiveUS20060021969A1Great control in varyingImprove cleanlinessElectric discharge tubesDecorative surface effectsStream flowProcess engineering

A plasma process reactor and method is disclosed that allows for greater control in varying the functional temperature range for enhancing semiconductor processing and reactor cleaning. The temperature is controlled by splitting the process gas flow from a single gas manifold that injects the process gas behind the gas distribution plate into two streams where the first stream goes behind the gas distribution plate and the second stream is injected directly into the chamber. By decreasing the fraction of flow that is injected behind the gas distribution plate, the temperature of the gas distribution plate can be increased. The increasing of the temperature of the gas distribution plate results in higher O2 plasma removal rates of deposited material from the gas distribution plate. Additionally, the higher plasma temperature aids other processes that only operate at elevated temperatures not possible in a fixed temperature reactor.

Owner:DONOHOE KEVIN G +1

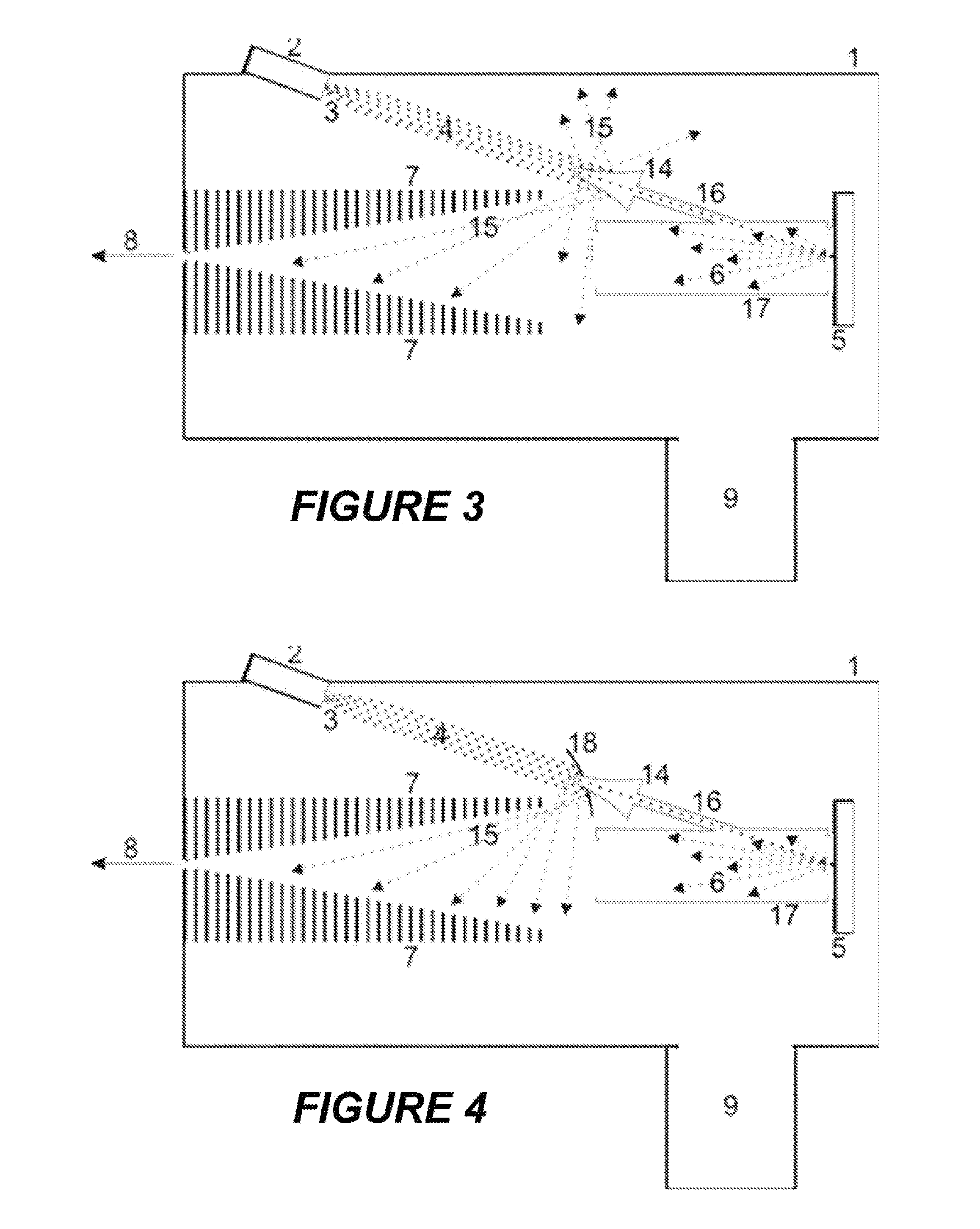

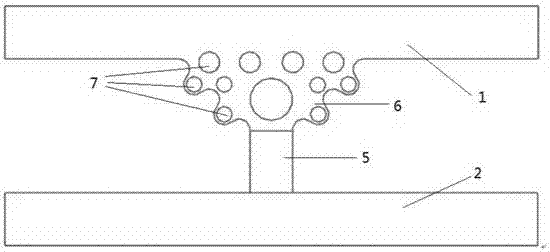

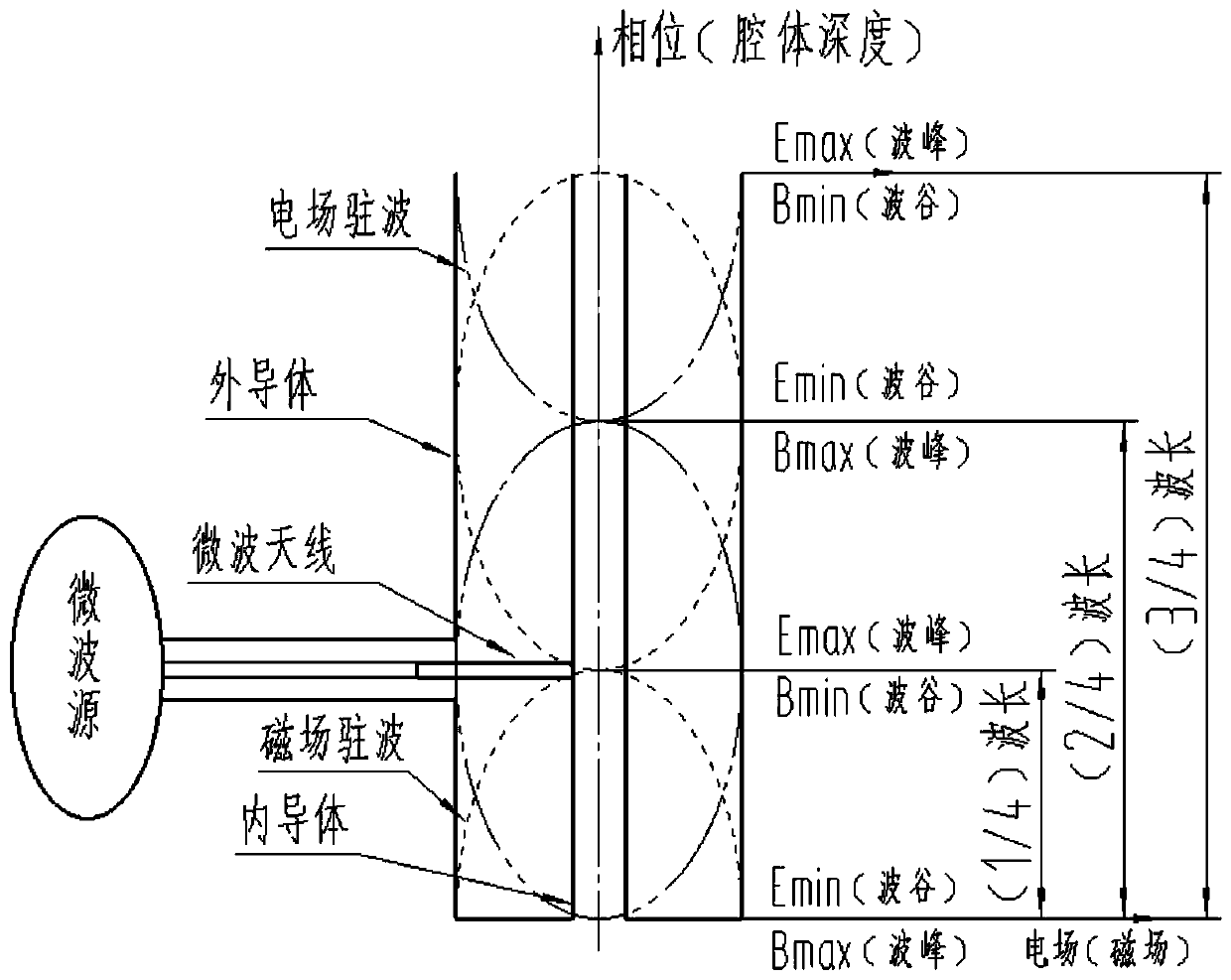

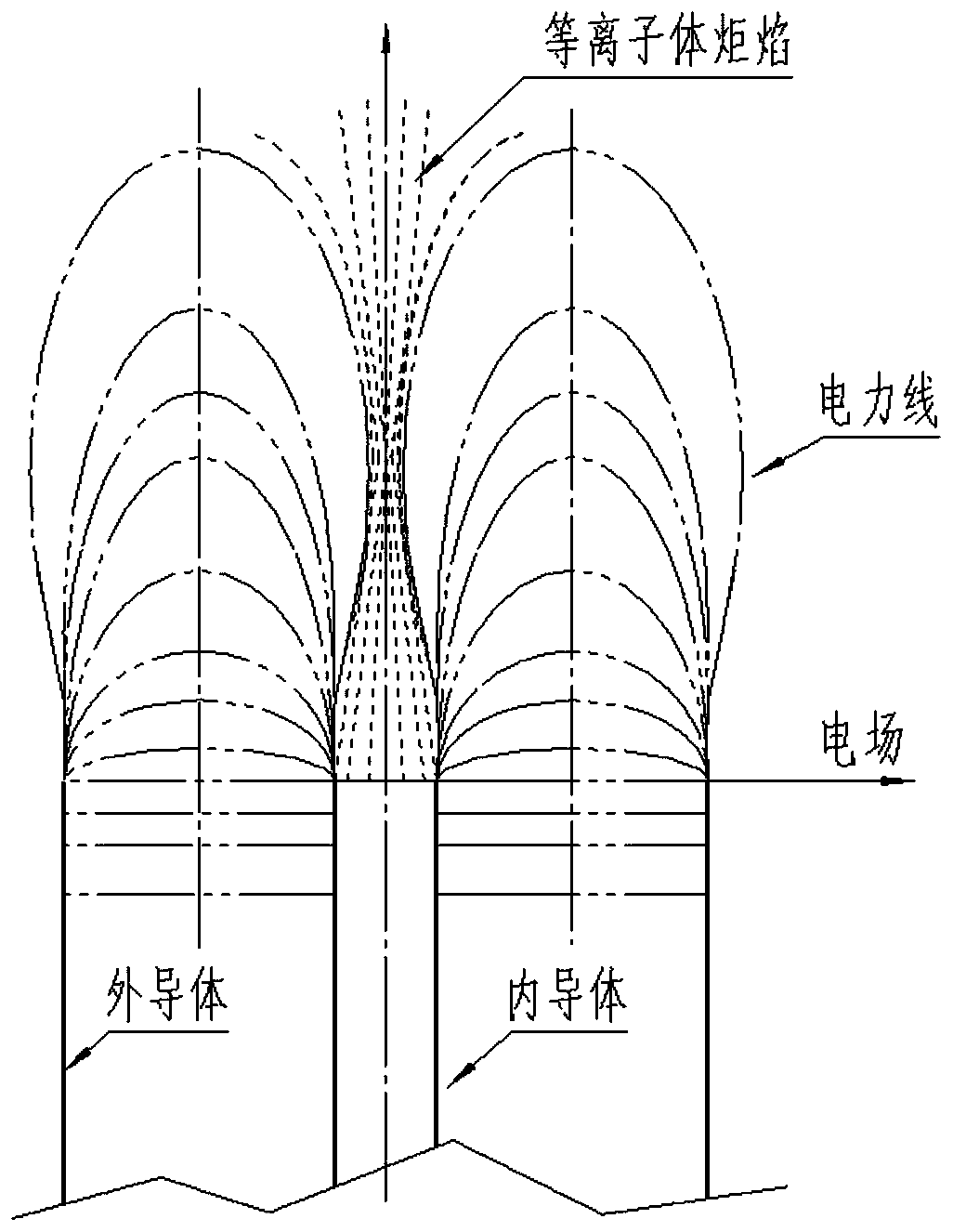

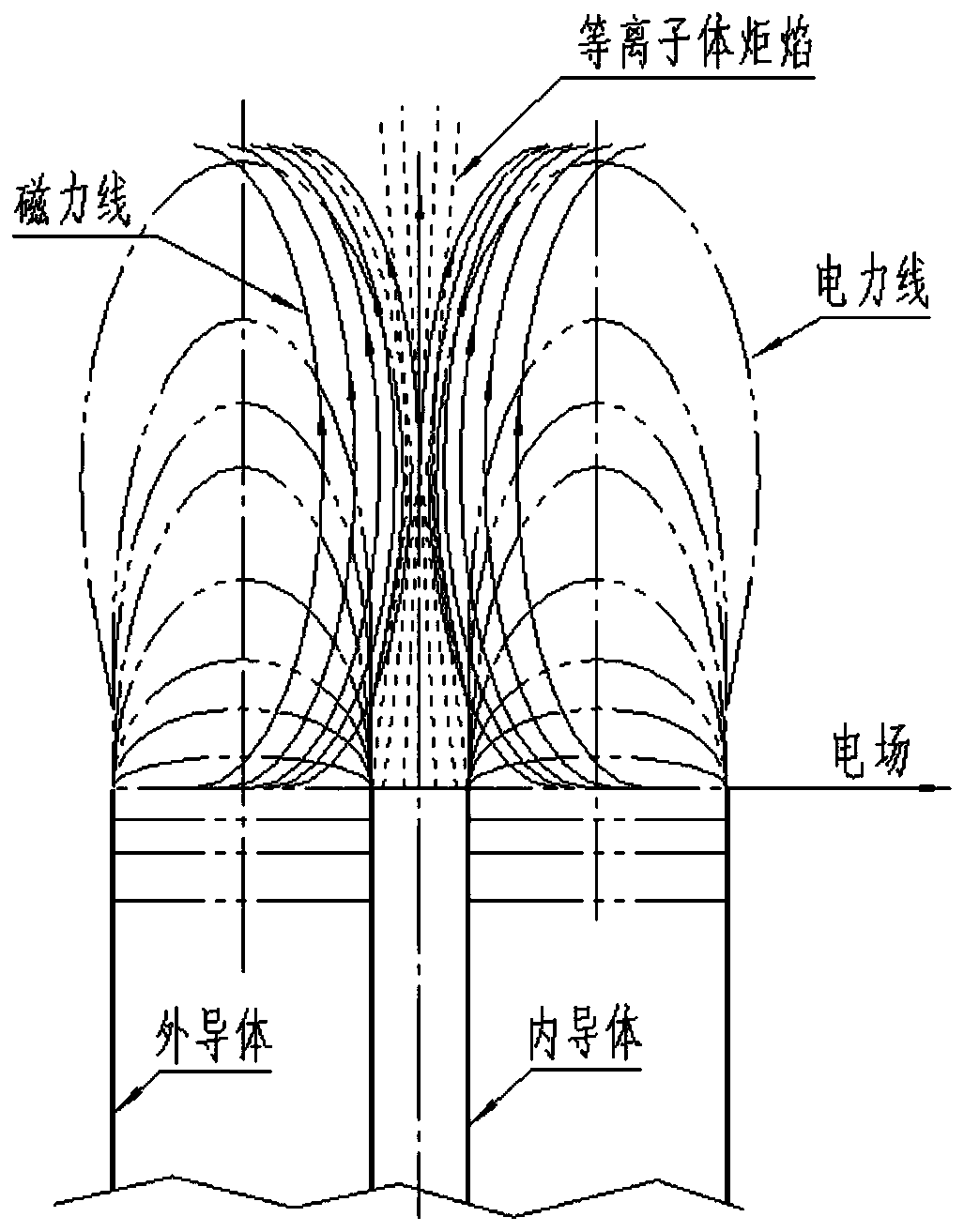

Microwave coupled plasma generating device with electromagnetic energy dual-excitation function

The invention discloses a microwave coupled plasma generating device with an electromagnetic energy dual excitation function, and belongs to the technical field of microwave energy application. The microwave coupled plasma generating device is composed of a microwave coaxial resonant cavity part and a magnetic field generating part, wherein the microwave coaxial resonant cavity part comprises an outer conductor (1), a microwave antenna (2), an inner conductor (3), a middle tube (4), an inner tube (5), a sample tube (6) and an impedance matching cylinder (7), and the magnetic field generating part consists of an excitation lower part (8), an excitation middle part (9) and an excitation upper part (10). Compared with the prior art, the device of the invention has the advantages of improvingthe electron density of the plasma, improving the utilization efficiency of microwave energy, improving the atomization capacity of the plasma and the like.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com