System and method for comprehensively utilizing residual heat of compressed natural gas engine (CNGE)

A technology for compressing natural gas and engines, which is applied to engine components, combustion engines, machines/engines, etc. It can solve problems such as serious throttling loss, no voltage stabilization, pressure source pressure attenuation, etc., to increase gas temperature and prevent "freezing" , the effect of saving heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

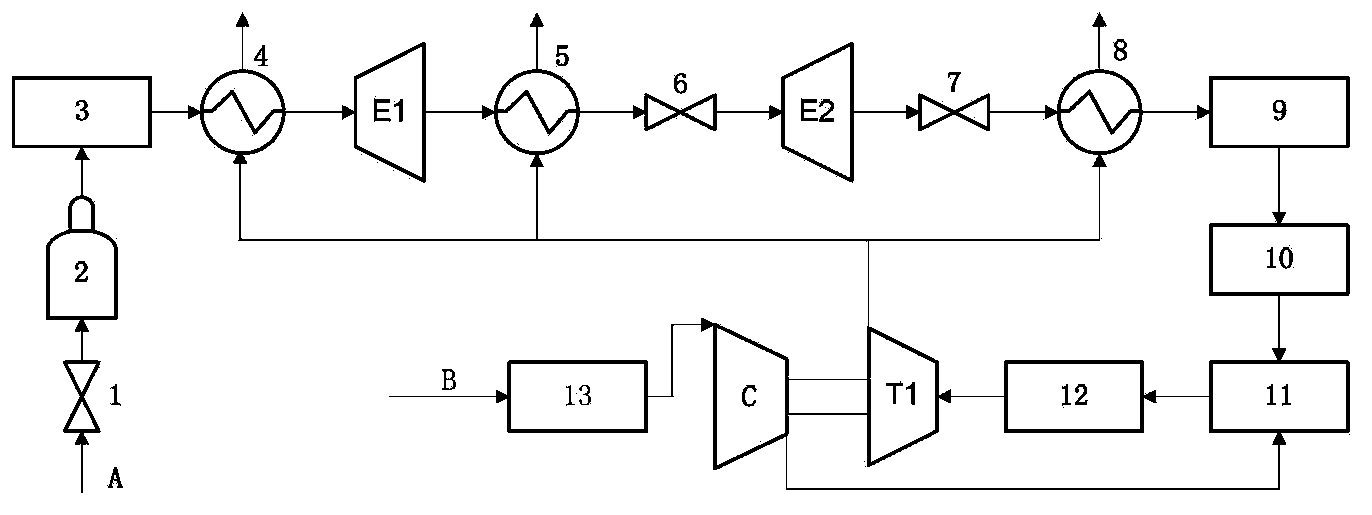

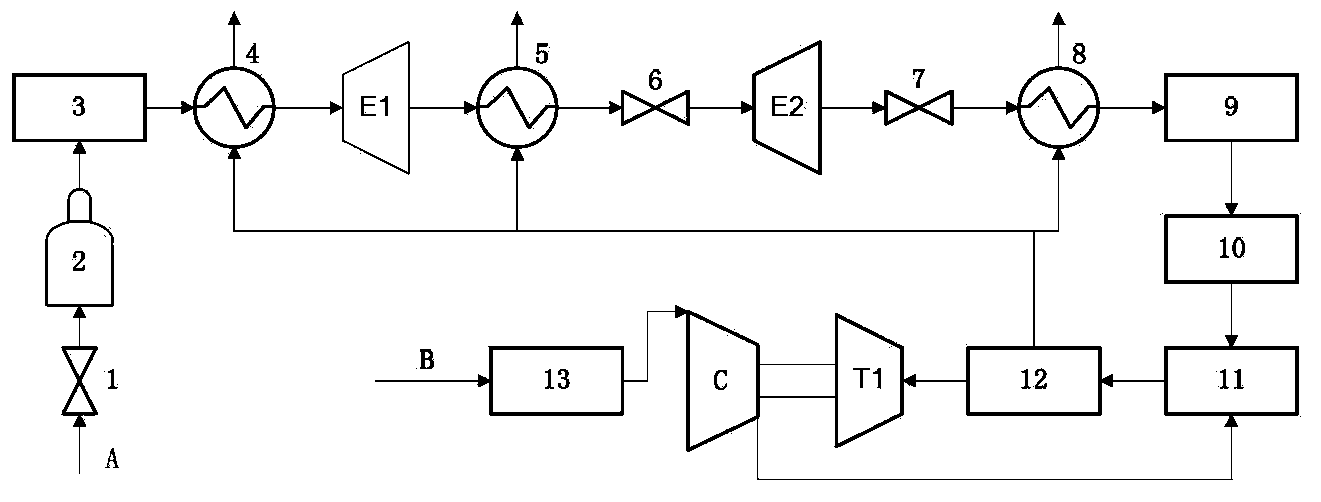

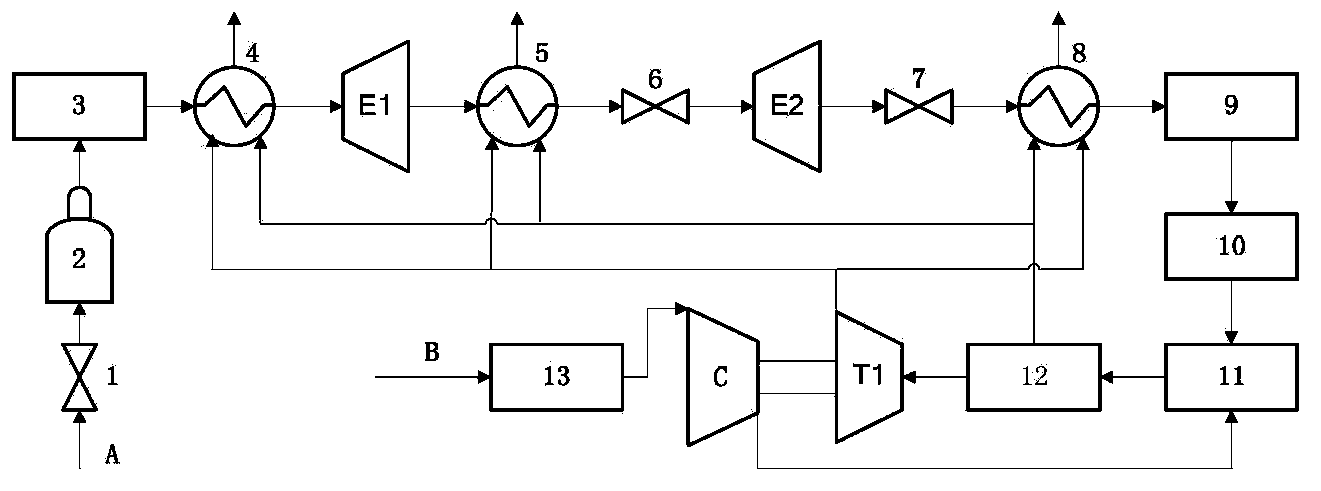

[0035] figure 1 Be embodiment 1 of the present invention. The CNGE waste heat efficient utilization system of the present invention includes an air charging valve 1, a gas cylinder 2, a solenoid valve 3, heat exchangers 4, 5, 8, pressure stabilizing valves 6, 7, a filter 9, a gas nozzle 10, a mixer 11, and an engine Combustion chamber 12, air filter 13, natural gas source A, air B, expansion unit E1 / E2, turbocharger turbine T1, supercharger compressor C. The expansion unit E1 / E2 includes a first-stage variable expansion ratio expander E1 and a second-stage constant expansion ratio expander E2. The expansion ratio of the first-stage expander E1 is variable, and the working range is 3 to 20. The inlet passes through the heat exchanger 4 It is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com