03 type rifle automat

An automaton and rifle technology, applied to firearms, breech mechanisms, weapon accessories, etc., can solve the problems of rifle performance degradation, speed and accuracy degradation, and too long casing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

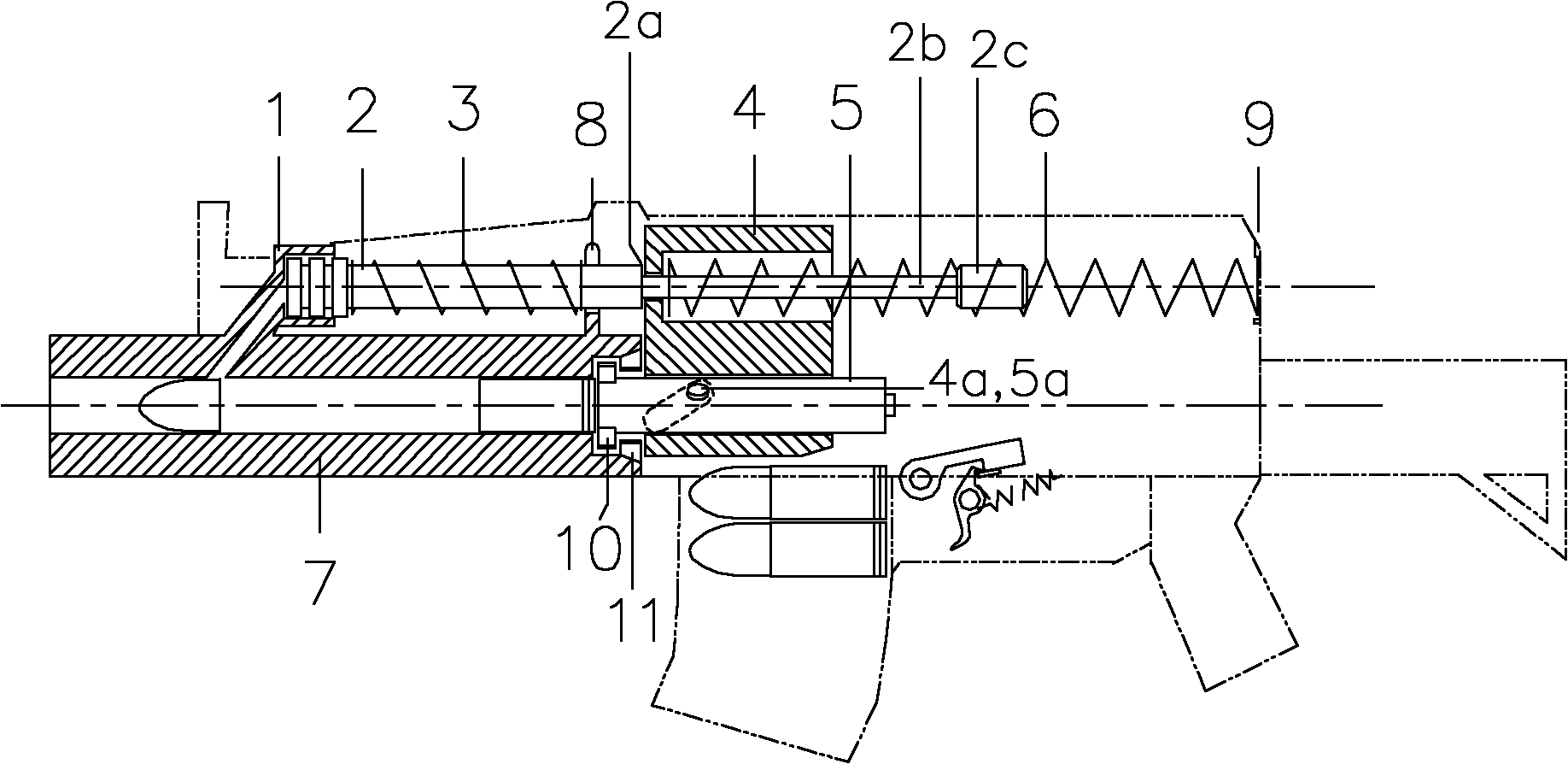

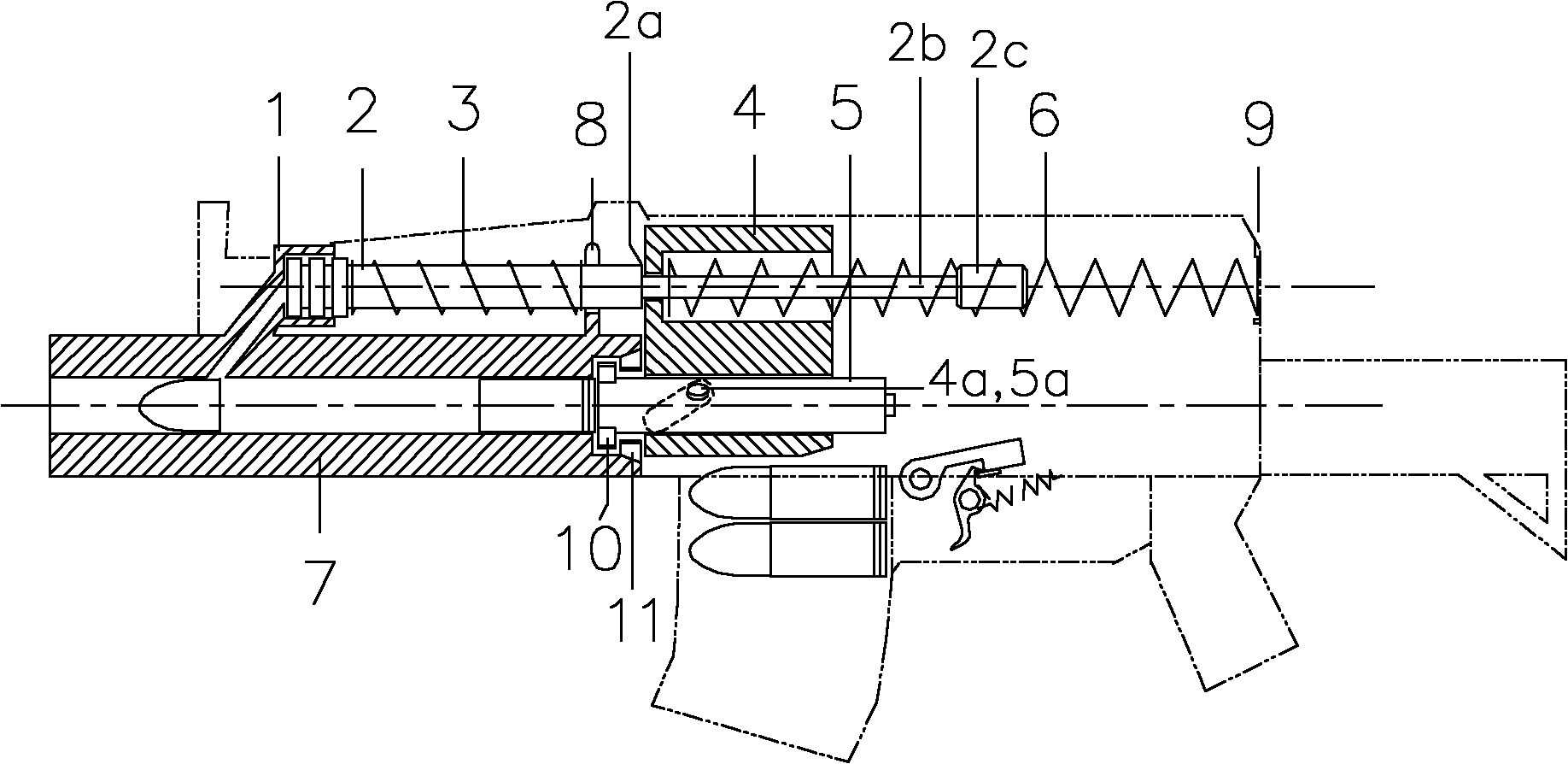

[0013] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0014] As shown in the drawings, the 03-type rifle automatic machine includes a piston cylinder 1, a piston rod 2, a piston spring 3, a bolt frame 4, a bolt 5 and a recoil spring 6. Wherein the piston barrel 1, the piston rod 2 and the piston spring 3 are the piston components, and the bolt frame 4, the bolt 5 and the recoil spring 6 are the bolt components.

[0015] The piston barrel 1 is integrated with the air suction port above the rifle barrel 7 and is located at the upper end of the air suction port. The axis of the piston barrel 1 is parallel to the axis of the gun barrel 7 . The piston rod 2 is placed in the piston cylinder 1, and the piston spring 3 is placed between the piston rod after the piston disc at the front end and the spring seat 8 provided in the barrel 7, and the rear end of the extension rod 2b behind the pressing surface 2a of the pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com