A high-temperature pyrolysis reactor and a system and method for treating oil sludge or waste oil by hydropyrolysis

A high-temperature pyrolysis and hydropyrolysis technology, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of reducing processing efficiency and achieve the effects of increasing reaction rate, improving work efficiency and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

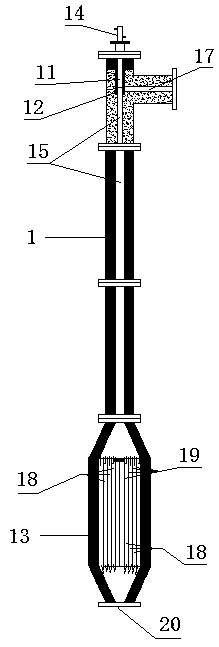

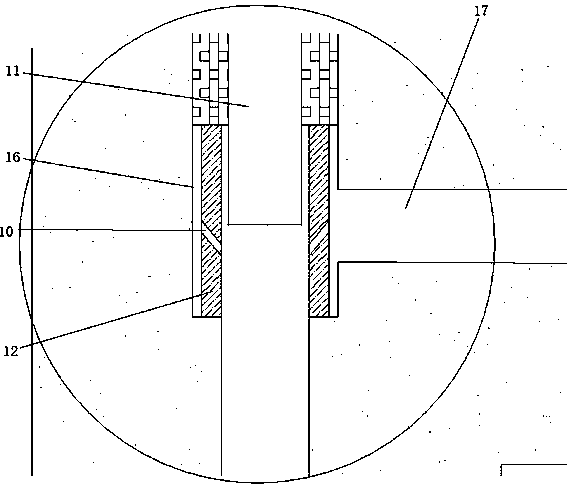

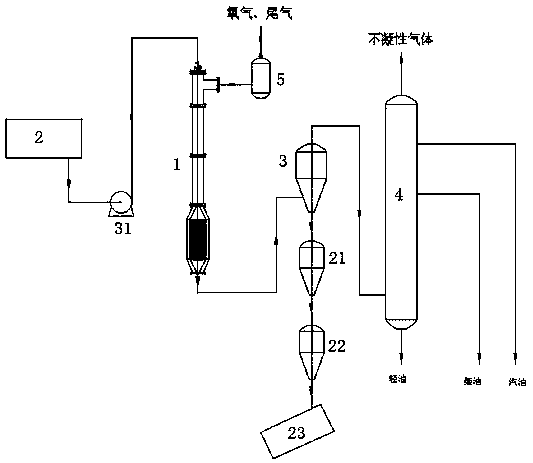

[0041] Such as figure 1 with 2As shown, the high-temperature pyrolysis reactor of the present invention includes a reactor body 1, a nozzle 11, a mixer 12, a heat exchanger 13, and a slurry inlet pipe 14. The reactor body 1 is a straight tower body, so The reactor body 1 is provided with a slurry nozzle 11, a mixer 12, and a reaction pipeline 15 connected in sequence along its longitudinal direction; the lower end of the nozzle 11 stretches into the mixer 12 from the inlet, and the mixer The outlet of 12 communicates with the upper end of the reaction pipeline 15, and the outer wall of the mixer 12 is located below the nozzle 16, and 4-6 through holes 10 are evenly arranged along the circumference of the outer wall of the mixer 12; the outer wall of the mixer 12 and the reactor A gap is left between the inner walls of the body 1 to form a buffer bin 16; the bottom of the reaction pipeline 15 is provided with a heat exchanger 13; the bottom of the reaction pipeline 15 is provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| working pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com