On-line KR desulfuration residue treatment device and method applied to hot metal pretreatment process

A technology of molten iron pretreatment and processing equipment, applied in mechanical cleaning, manufacturing tools, metal processing equipment, etc., can solve the problems of high sulfur content in slag iron slag inclusions, poor equipment pertinence, low recovery rate of slag iron, etc. Achieve the effect of reducing the content of impurities, high utilization rate of resource classification and recycling, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

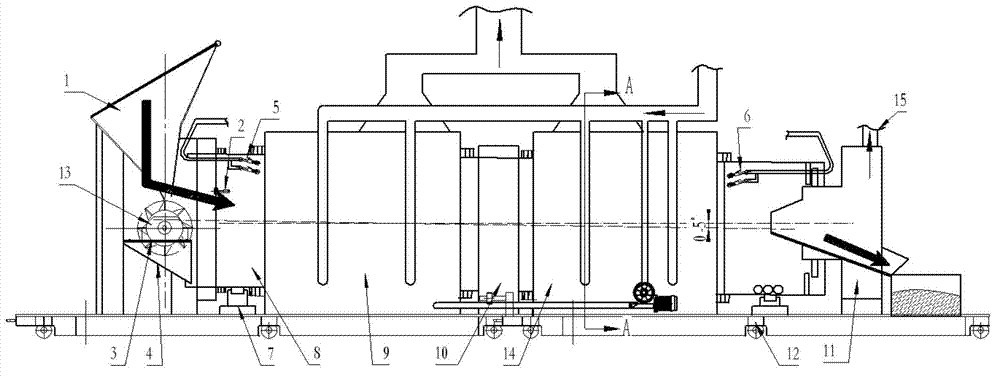

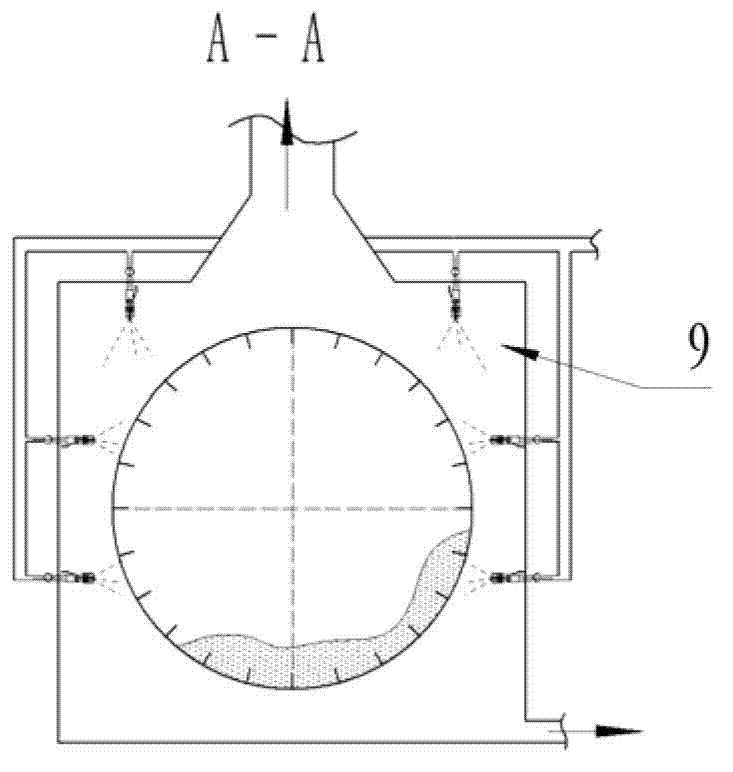

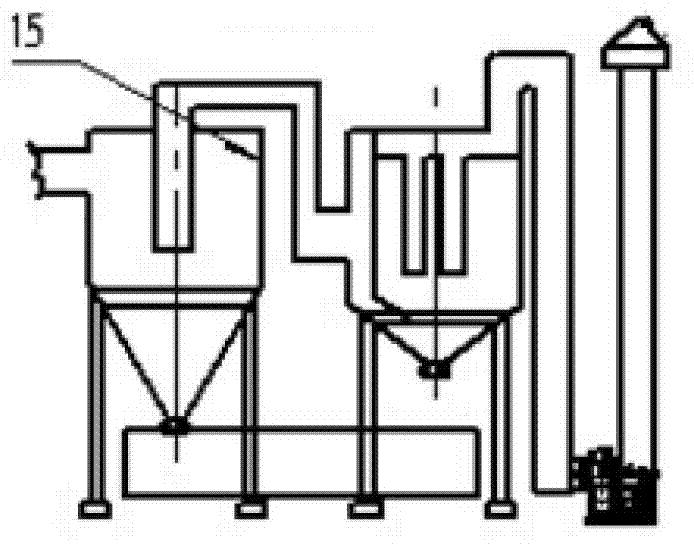

[0030] Such as Figure 1-4 As shown, the technical solution provided by the present invention is an online KR desulfurization slag processing device applied in the molten iron pretreatment process. The online processing device includes a breaking system 13, a cooling slag system 14, a dust removal system 15, system, electric control system, the walking system is arranged at the bottom of the breaking system 13 and the cold slag system 14, the front end of the breaking system 13 is provided with a slag receiving hopper 1, and the KR desulfurization slag is pretreated by molten iron After the KR desulfurization treatment, it directly enters the online processing device, and the high-temperature hot KR desulfurization slag enters the dispersing system 13 through the slag receiving hopper 1; the dispersing system 13 is connected with the cold slag system 14, and the The cold slag system 14 is equipped with a double cooling system.

[0031] An inlet auxiliary temperature control d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com