T-shaped door with groove-shaped cover port

A cover and groove-shaped technology, which is applied in the field of anti-theft safety door structure, can solve the problems of easy desoldering, poor prying resistance, thinness, etc., and achieve the effect of improving sealing performance and strengthening airtight performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

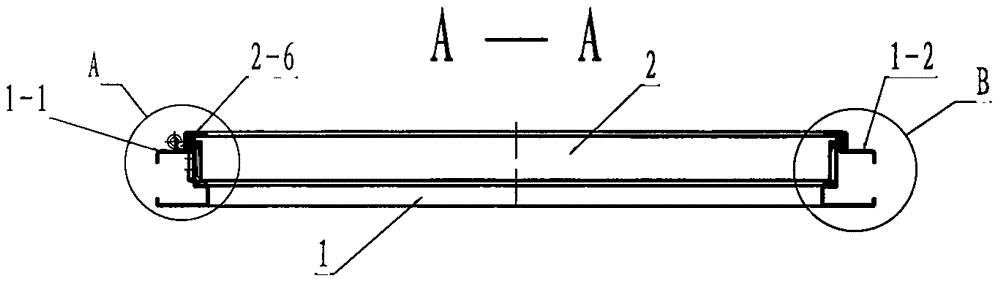

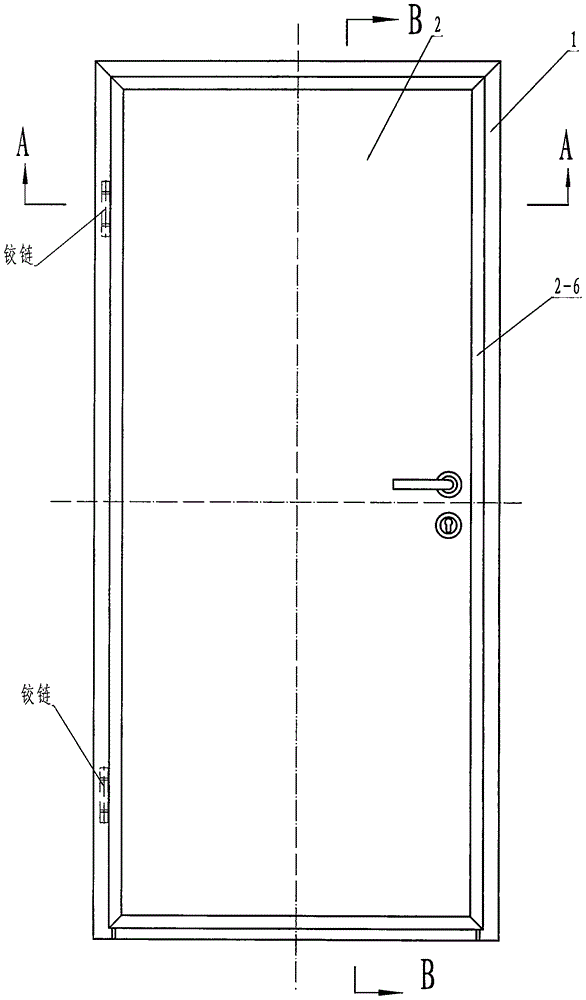

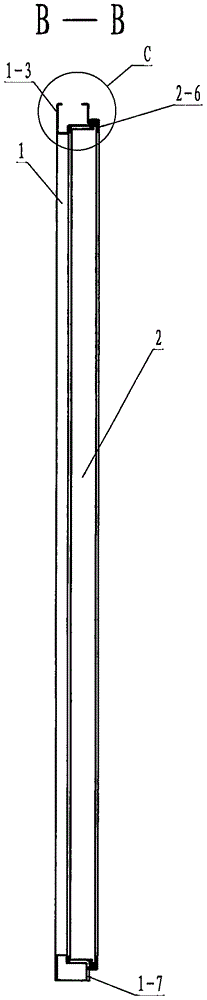

[0020] The structural features of the patent of the present invention will be further described below through the embodiments in conjunction with the accompanying drawings.

[0021] Refer to attached Figure 1 - Figure 1 0. The patent of the present invention relates to a T-shaped door with a slotted cover, which includes a door frame assembly (1) and a door leaf assembly (2). The door frame assembly (1) mainly includes a hinge frame (1-1), a lock The frame (1-2), the upper frame (1-3), the lower frame (1-7), and the door frame sealing strip (1-8) are composed. The door leaf assembly (2) mainly includes an outer door panel (2-1), an inner door panel (2-2), and a filler (2-3). The hinge frame (1-1), the lock frame (1-2) and the upper frame (1-3) of the door frame are designed with two stage ports, stage port 1 (1-4), stage port 2 (1-5). Anti-pry ribs (1-6) are designed to bulge outward at the door frame and door leaf lap 1 (1-4), and the door frame sealing strip (1-8) is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com