Electron component

A technology for electronic components and sealing parts, which is applied in the direction of electrical components, capacitor parts, circuits, etc., and can solve problems such as poor assembly, decreased sealing performance, and decreased airtightness of sealing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

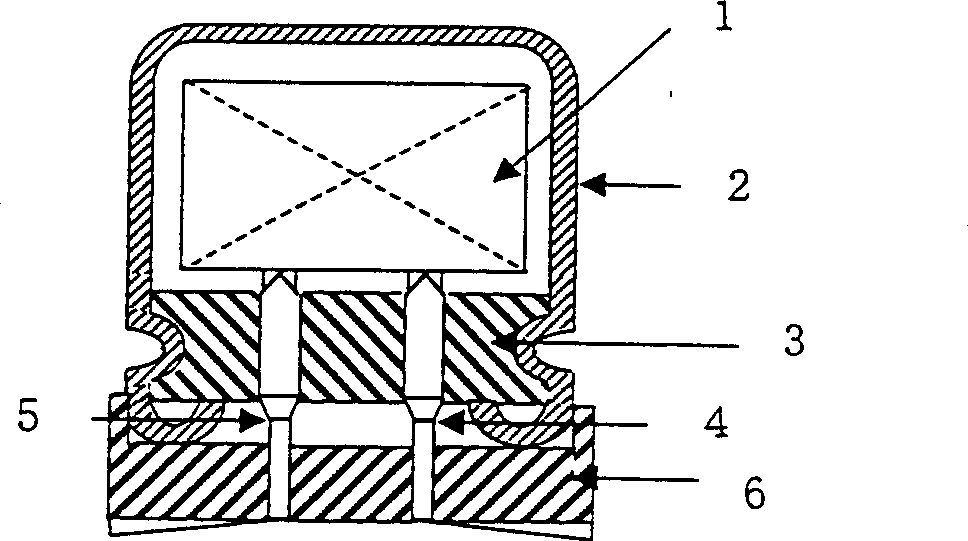

Embodiment 1

[0058] The closure is composed of a cross-linked compound containing isobutylene rubber polymer, phenolic additives and silane additives. By cross-linking the chemical structure of the isobutylene rubber polymer of the complex, an elastic cross-linked body is formed; for example, by heating the complex, the isobutyl rubber polymer undergoes chemical cross-linking to form a sealant Cross-linked body; the cross-linked body used as a sealing member has elasticity.

[0059] For example: the above-mentioned complex may contain a peroxidic compound as a cross-linking catalyst; the isobutylene rubber polymer will undergo chemical cross-linking due to the action of the peroxidic compound, resulting in a cross-linked body.

[0060] The complex can also contain carbon powder or inorganic powder; as the inorganic powder, any powder such as silicon dioxide powder and calcium carbonate powder can be used; due to the inclusion of these powders, the mechanical strength of the sealing member ...

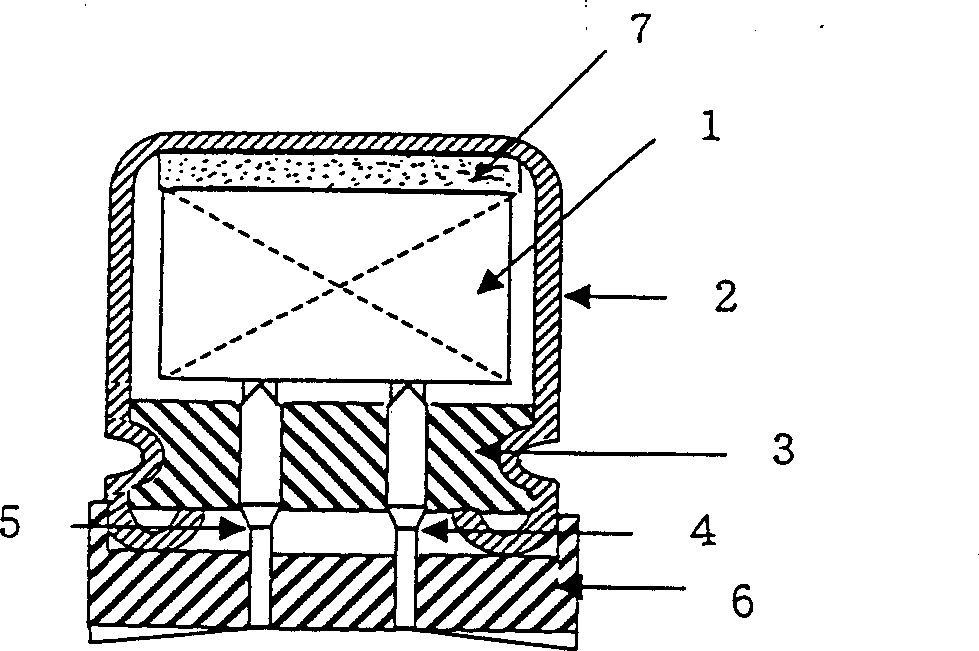

Embodiment 2

[0066] The compound of the sealing member in the present embodiment contains 100 parts by weight of isobutylene rubber polymer, 0.8 parts by weight of phenolic additive and 0.1 part by weight of silane-based additive; the phenolic additive contains phenols and phenolic derivatives; The compound is cross-linked to form a cross-linked body as a sealing member; this sealing member is elastic.

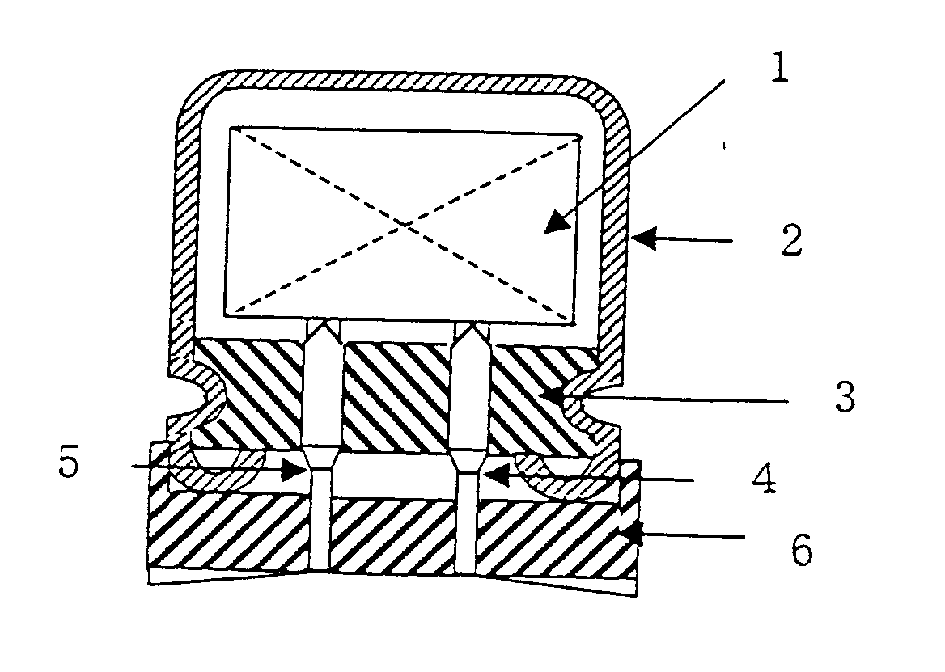

Embodiment 3

[0068] The compound of the sealing member in the present embodiment contains 100 parts by weight of isobutylene rubber polymer, 1.0 parts by weight of phenolic additive and 0.1 part by weight of silane-based additive; the phenolic additive contains phenols and phenolic derivatives; The compound is cross-linked to form a cross-linked body as a sealing member; this sealing member is elastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com