Technology for high-vacuum treatment of deep soft soil foundation through composite film

A soft soil foundation and high vacuum technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of poor engineering mechanical properties, low bearing capacity, poor permeability, etc., to reduce secondary consolidation settlement, pressure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0042] The present invention will be described in detail with reference to the accompanying drawings.

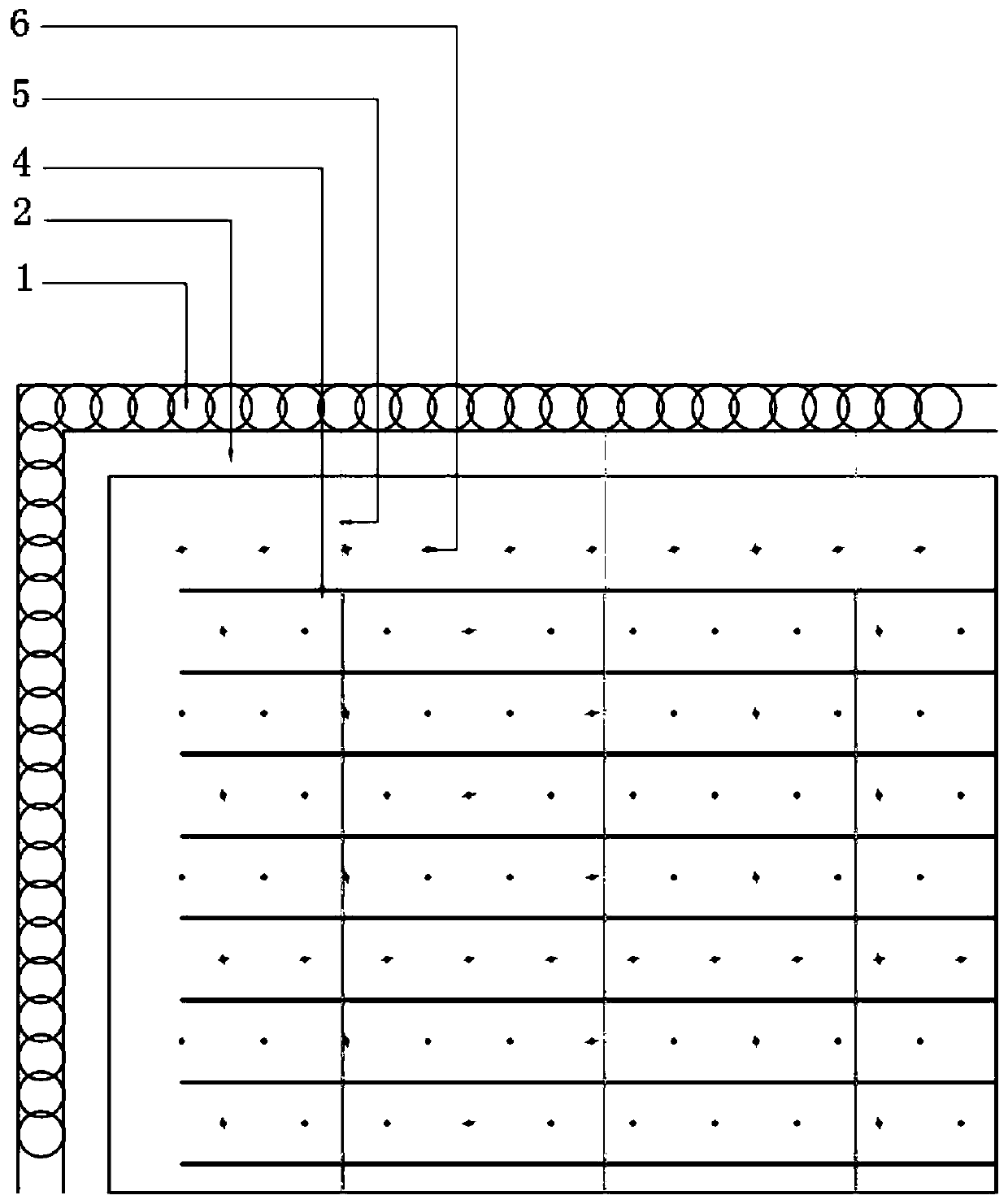

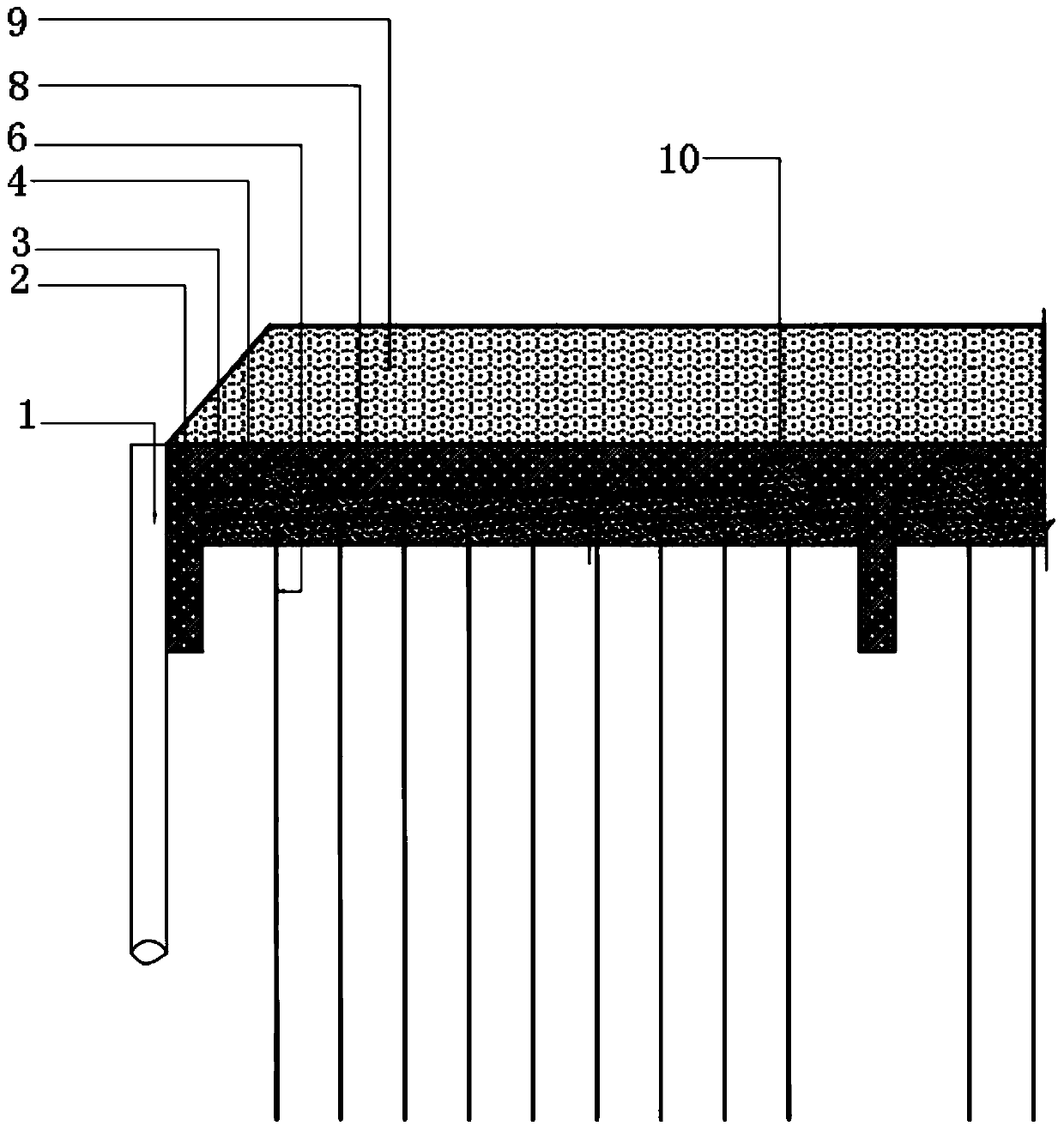

[0043] Specific embodiments of the present invention are as follows: figure 1 , figure 2 shown:

[0044] Step 1: Lay out the vacuum system

[0045] 1. Apply the drainage board 6

[0046] The site is cleared and leveled, and the vacuum unit block is planned according to 5000-10000m2 square meters. The site is laid with 0.6-1.0m medium sand pads, and the drainage plates 6 are mechanically applied. The distance between the drainage plates 6 is 0.8-1.0m. The drainage plates 6 are arranged in a plum-shaped or rectangular shape.

[0047] 2. Set up sealing ditch 2. Cofferdam with bagged soil

[0048] A bagged soil cofferdam shall be set around the vacuum unit block with a height and width of not less than 0.5m, and the sealing trench 2 of the vacuum unit bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com