Pipe column structure for CO2 flooding gas injection process

A process string and flooding technology, applied in the directions of sealing/packing, wellbore/well components, production fluid, etc., can solve the problems of short validity period of completion string, heavy maintenance workload, poor air tightness of the string, etc. , to achieve the effect of good air tightness, high working efficiency and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

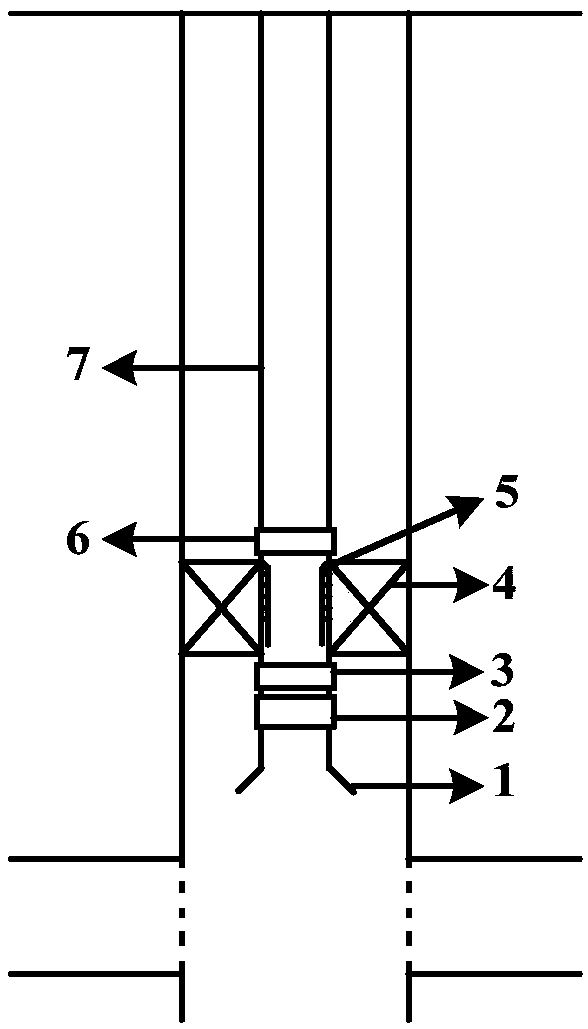

[0025] like figure 1 As shown, the present invention provides a CO 2 The pipe string structure of flooding and gas injection process includes guide shoe 1, check valve 2, setting ball seat 3, Y445 packer 4, cannula 5, reverse circulation valve 6 and tubing 7; The valve 2 is connected, the upper end of the check valve 2 is connected to the setting ball seat 3, the upper end of the setting ball seat 3 is connected to the Y445 packer 4, the Y445 packer 4 is connected to the intubation tube 5, and the upper end of the intubation tube 5 is connected to the reverse circulation in turn Valve 6 and tubing 7.

[0026] Among them, the connection button type of the pipe string structure of the present invention is a BGT button, and the annular space is an oil-based protective fluid. The Y445 packer 4 is mainly used as a permanent downhole tool, and the intubation tube 5 is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com