Patents

Literature

56results about How to "Achieving a dynamic seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

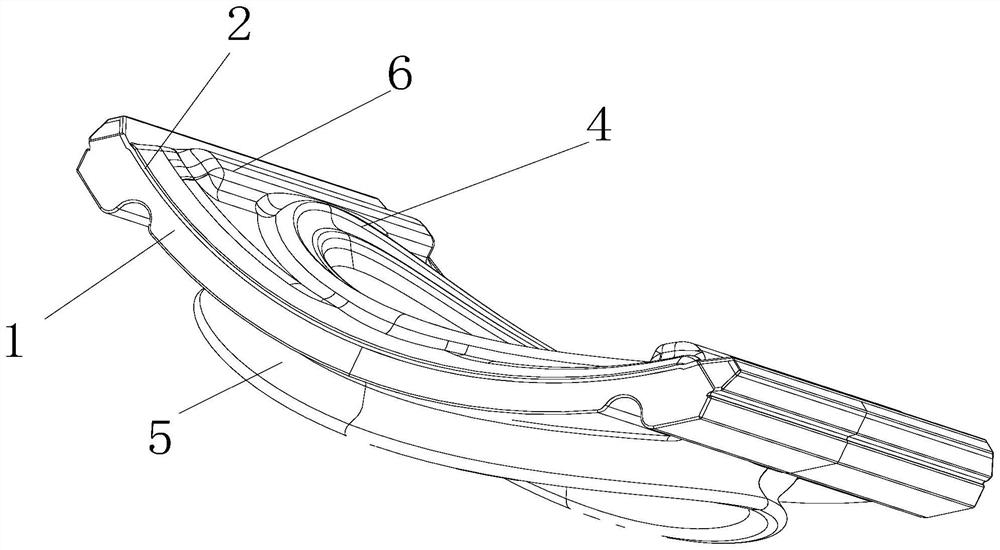

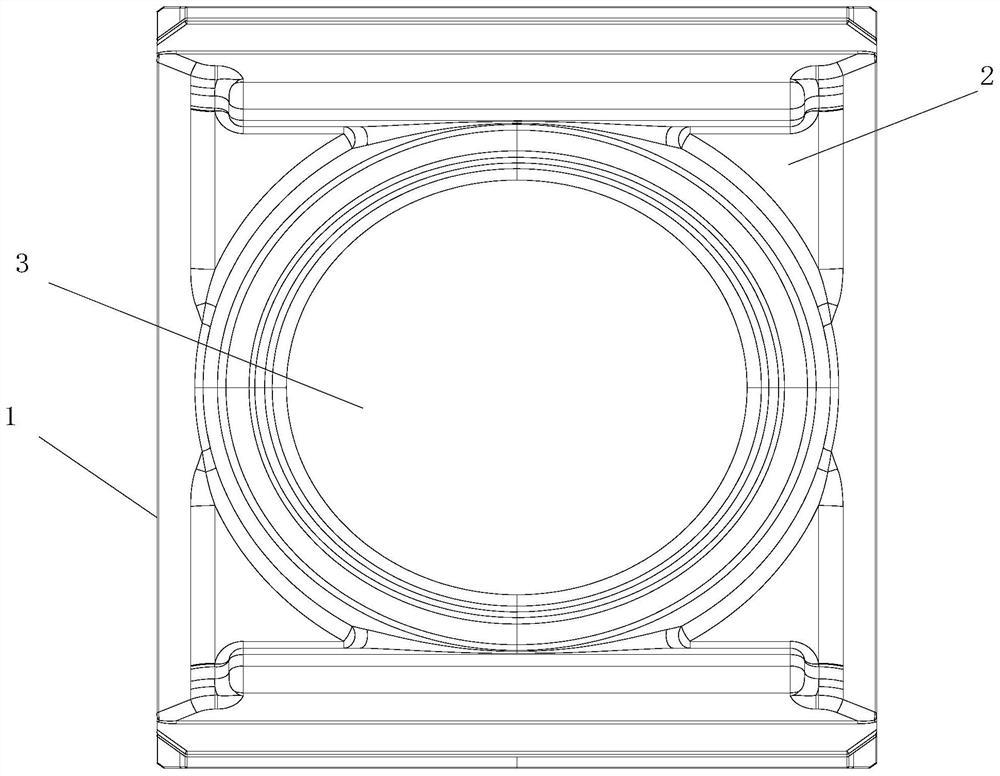

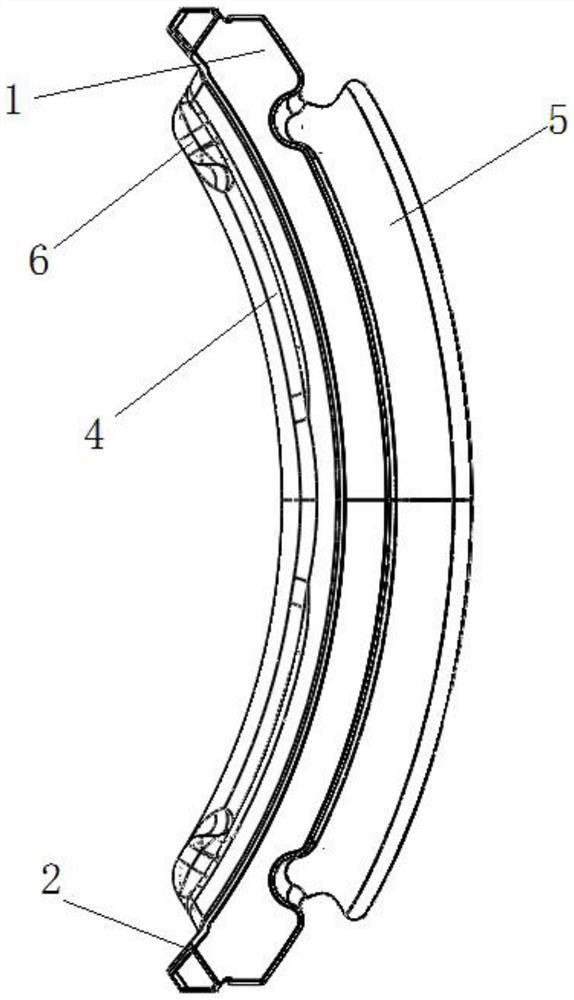

Efficient constant-pressure-difference intermittent rotation extrusion abrasive flow polishing method

ActiveCN104526531ASolve the problem of high-efficiency uniform polishing of the surfaceHigh surface aerodynamic performanceEdge grinding machinesPolishing machinesHydraulic motorImpeller

The invention relates to an efficient constant-pressure-difference intermittent rotation extrusion abrasive flow polishing method and belongs to the technical field of automatic polishing of large-size complex-curved-surface type part intermittent rotation extrusion abrasive flows which are high in surface quality uniformity requirement. The method comprises that a gear is driven by a hydraulic motor to be meshed with a negative-clearance rotation disc bearing to perform rotation grinding polishing, seal rings are arranged at all connected faces to achieve high-pressure abrasive static seal, easily abrasive seal rings are arranged at the rotation friction positions special high-pressure abrasive seal rings and high-pressure abrasive seals are arranged at the piston abrasive extrusion positions to achieve high-pressure abrasive dynamic seal, and finally, high-pressure abrasive intermittent rotation grinding and polishing are achieved. The 'over-polishing' and 'rounding' phenomena of traditional abrasive flow extrusion are prevented, efficient precise uniform polishing of complex curved surfaces of impellers, blades and the like high in pneumatic performance and surface uniformity is achieved, and the surface roughness Ra of various complex parts can be reduced below 0.8.

Owner:珂尔默(东莞)制造技术有限公司

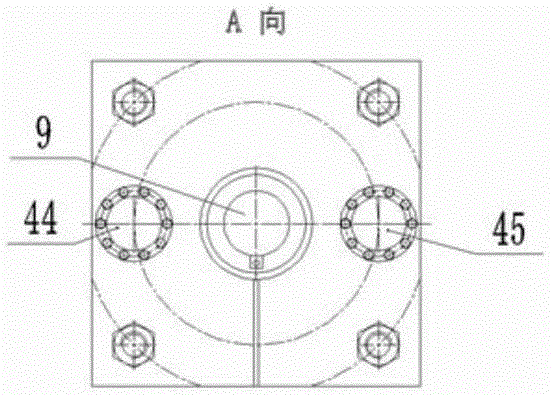

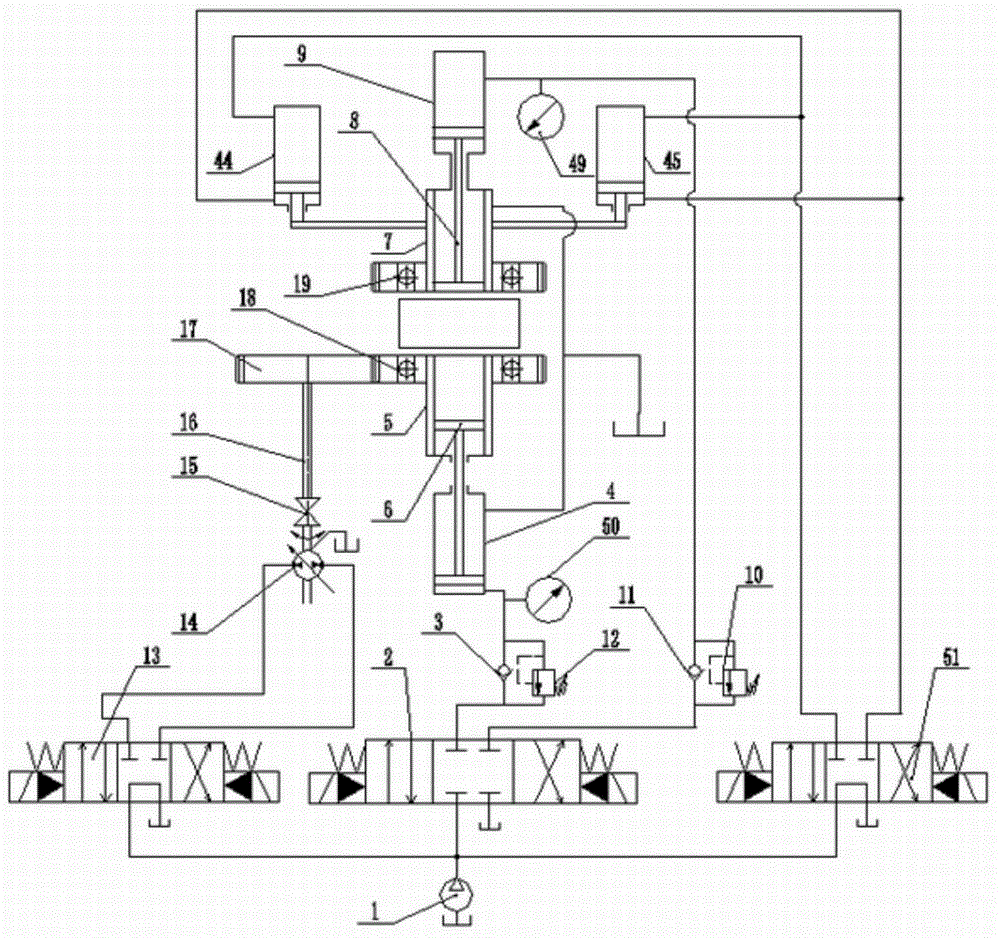

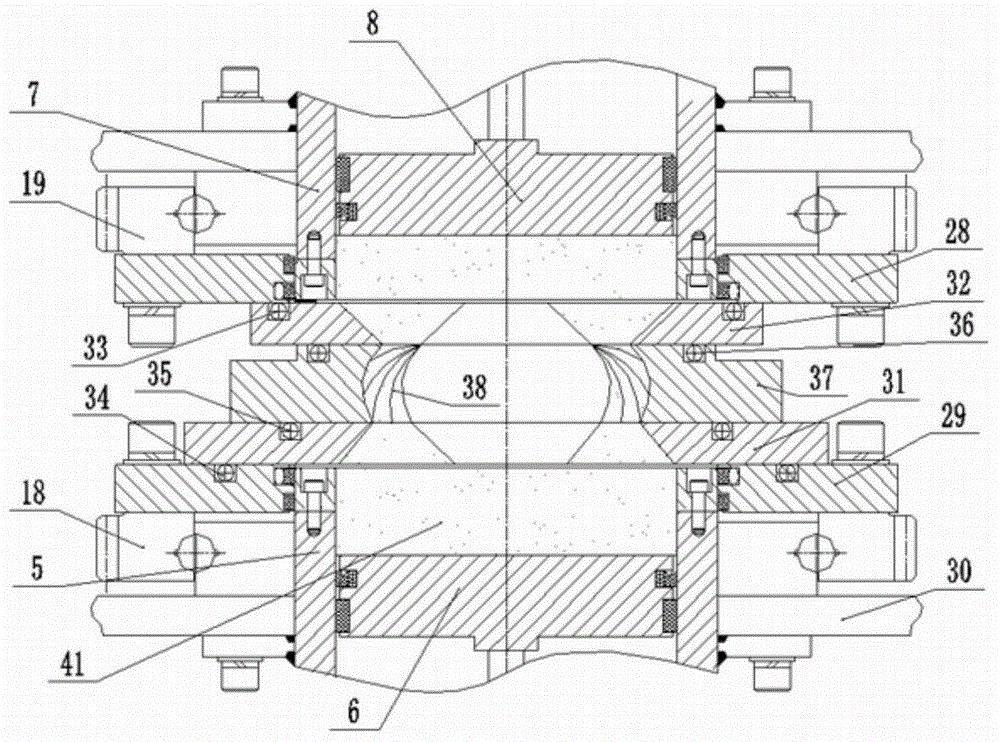

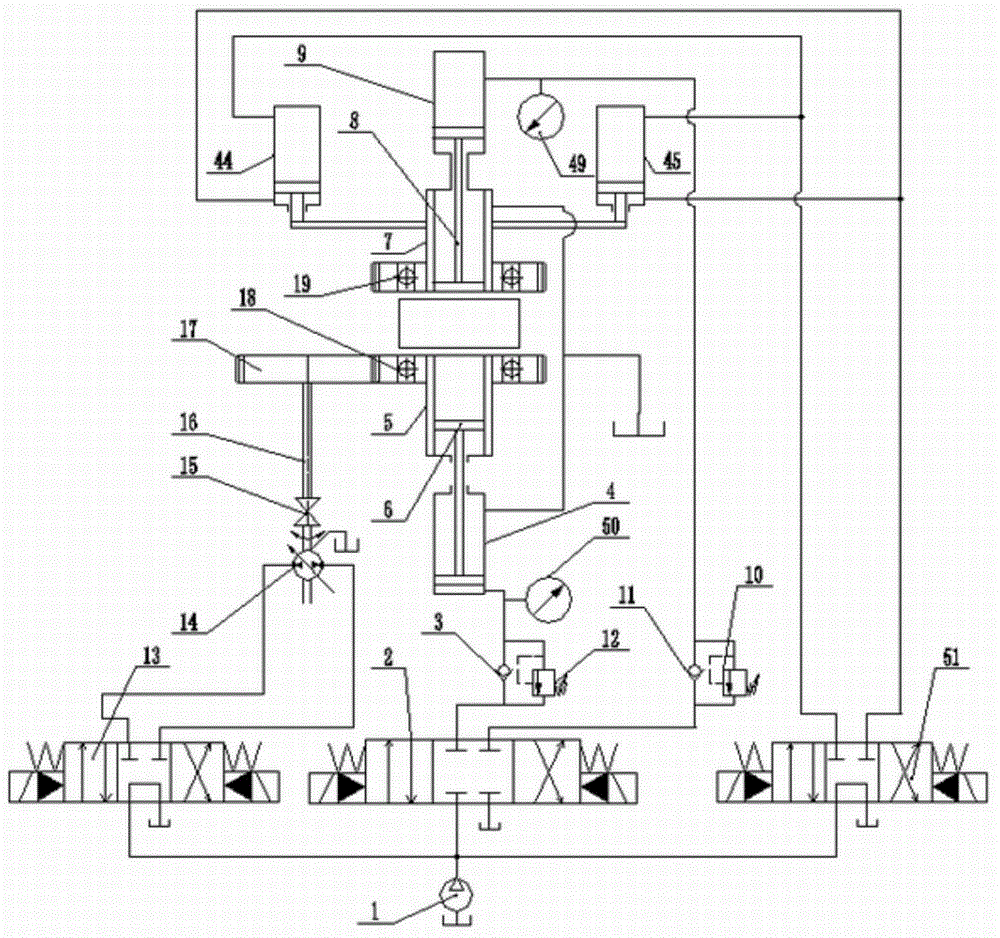

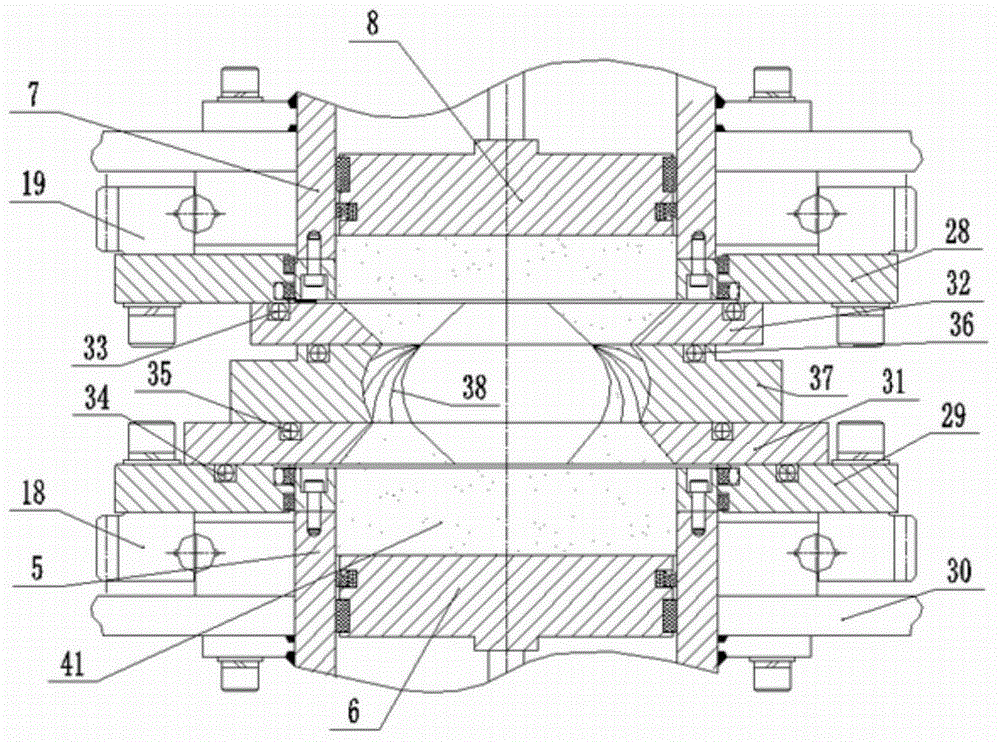

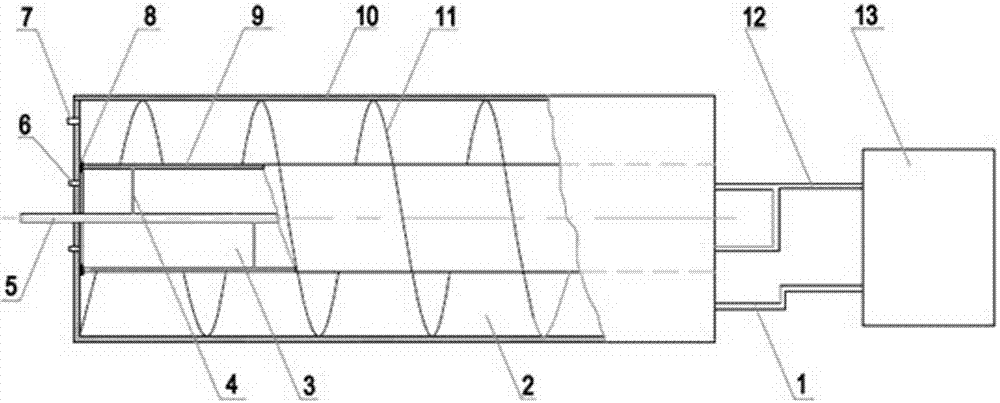

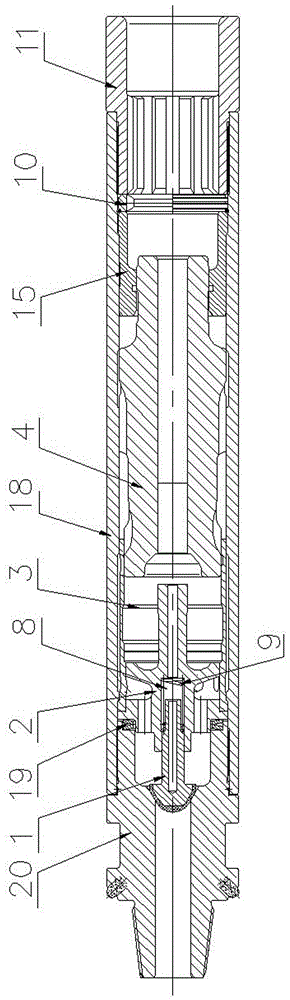

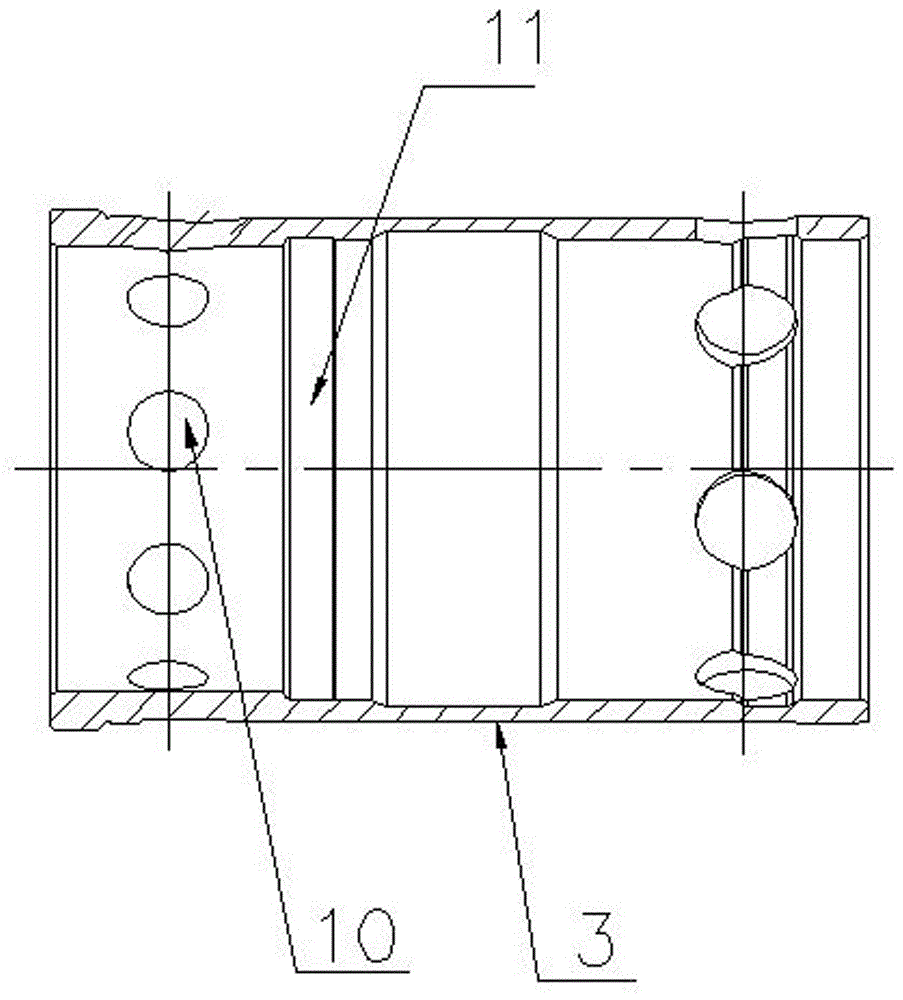

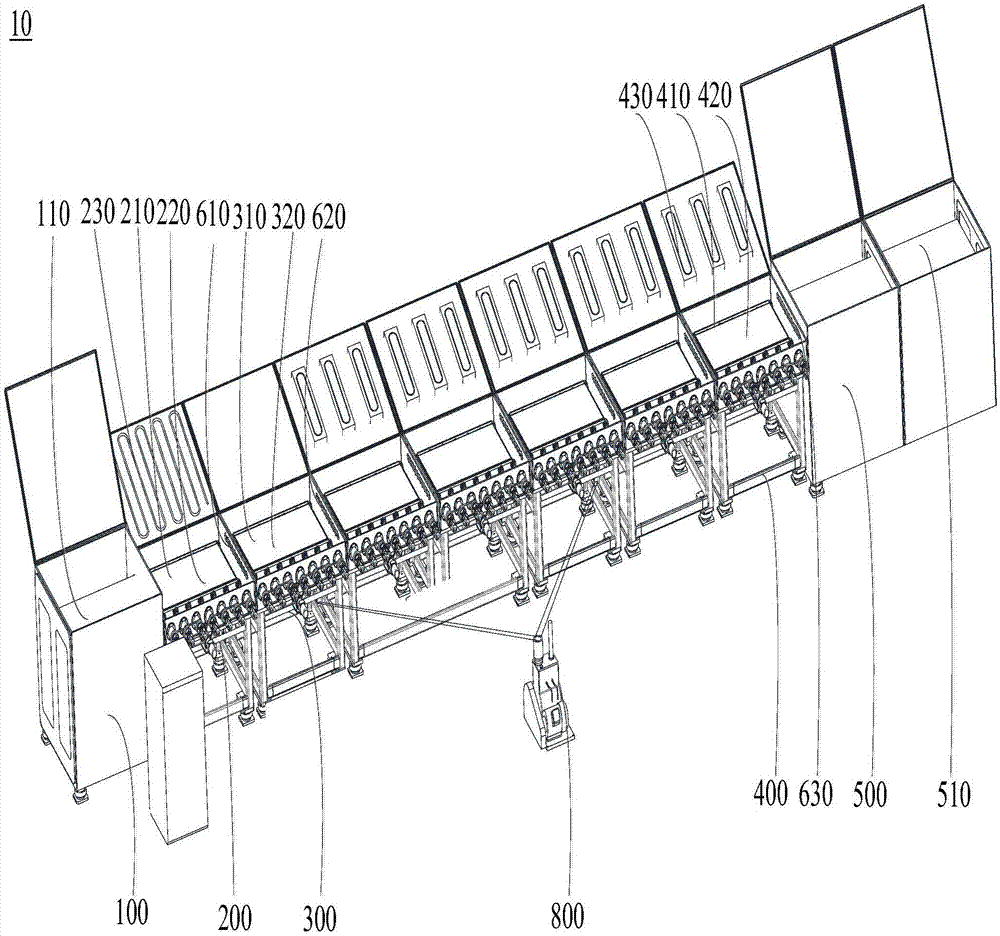

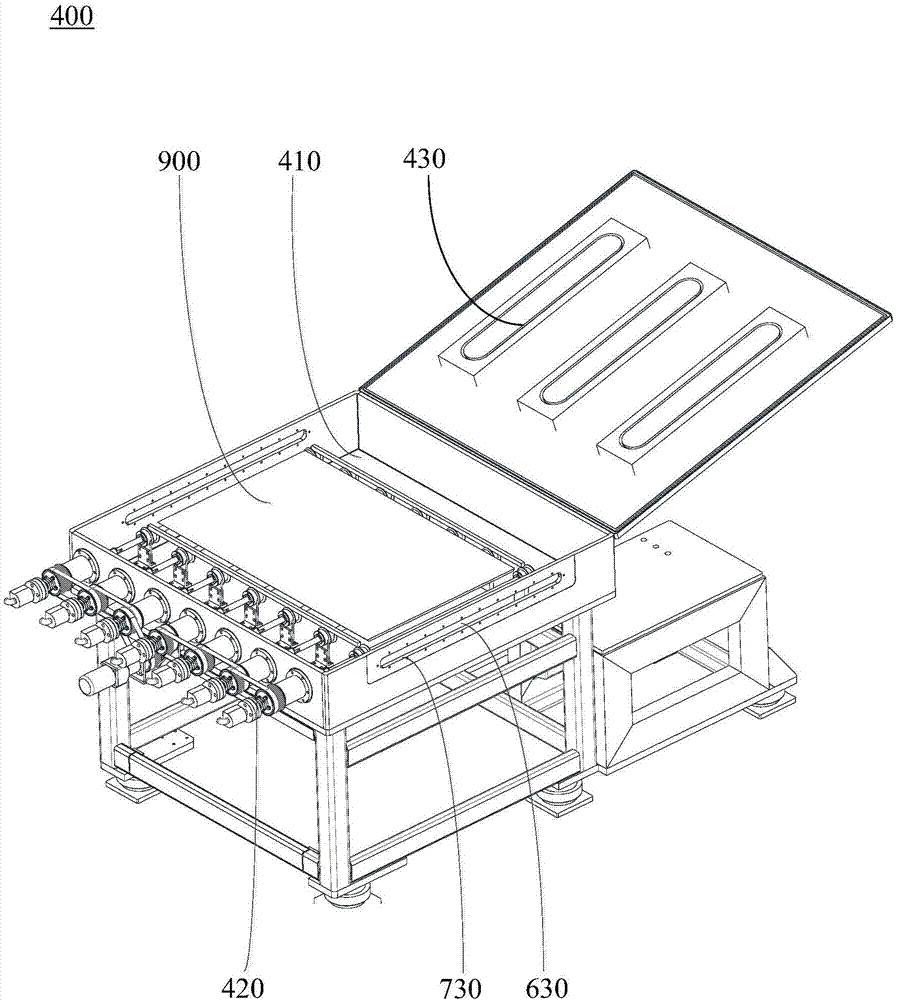

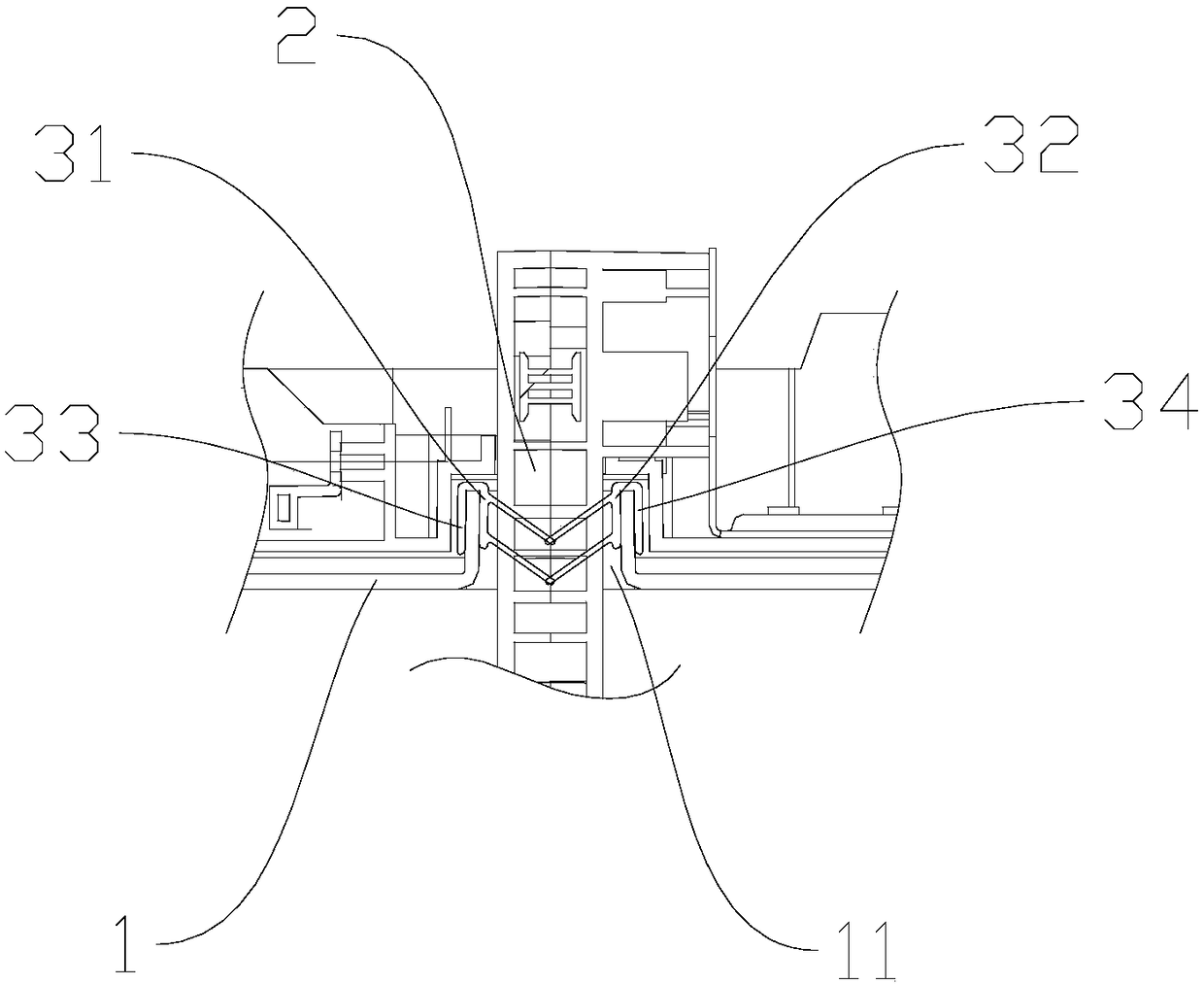

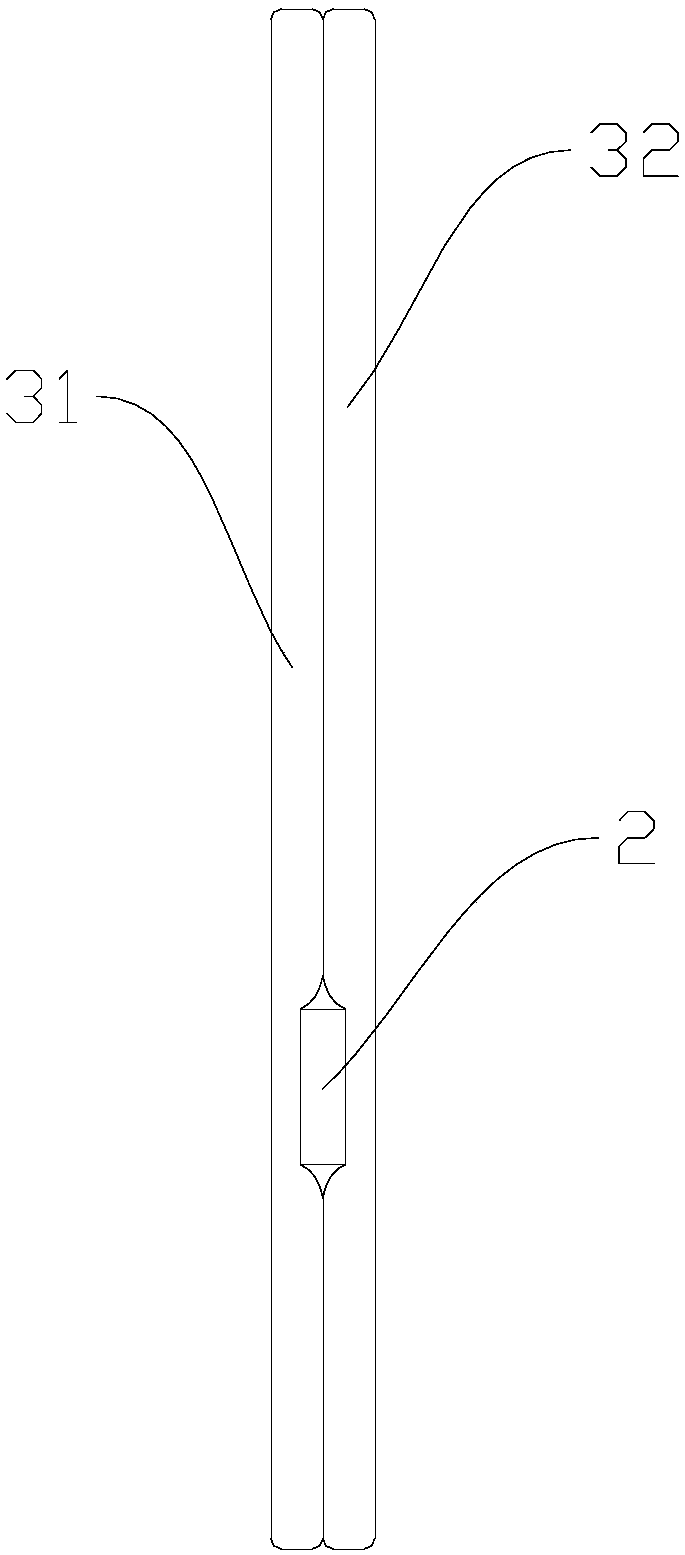

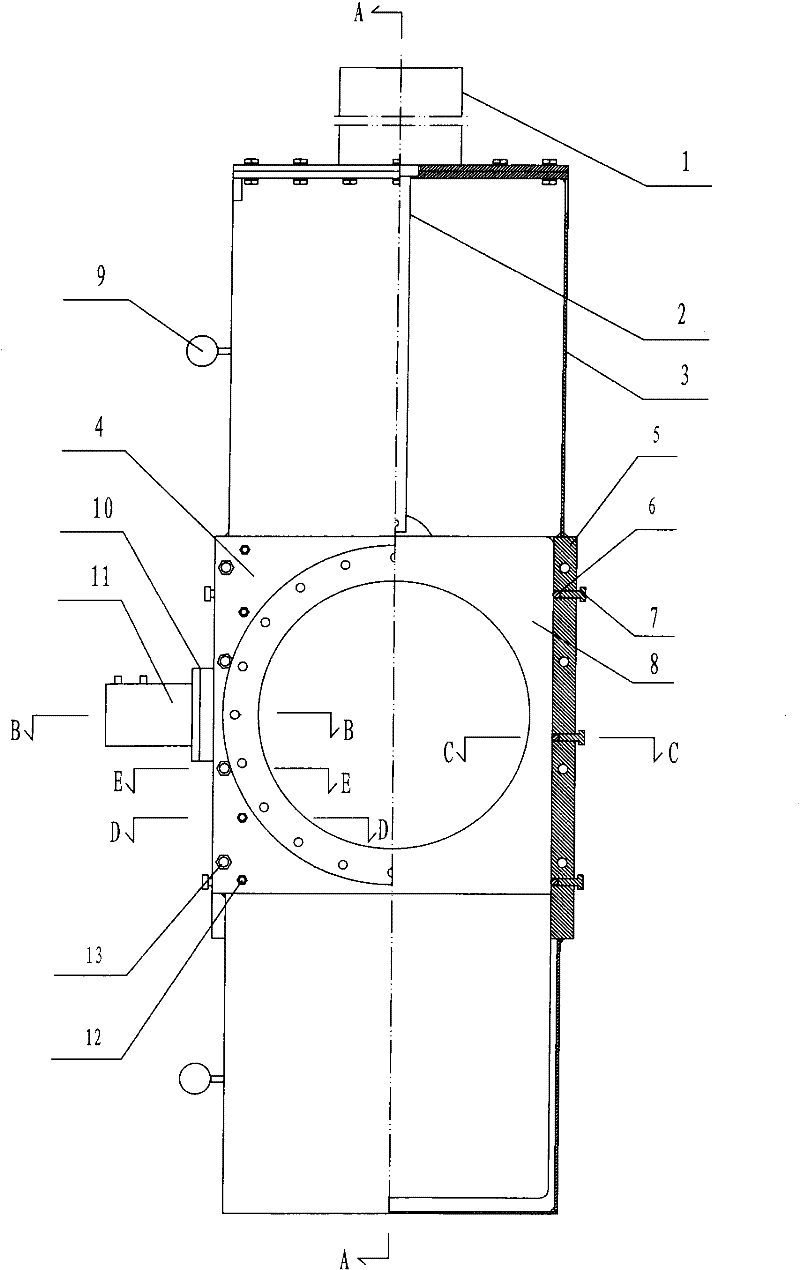

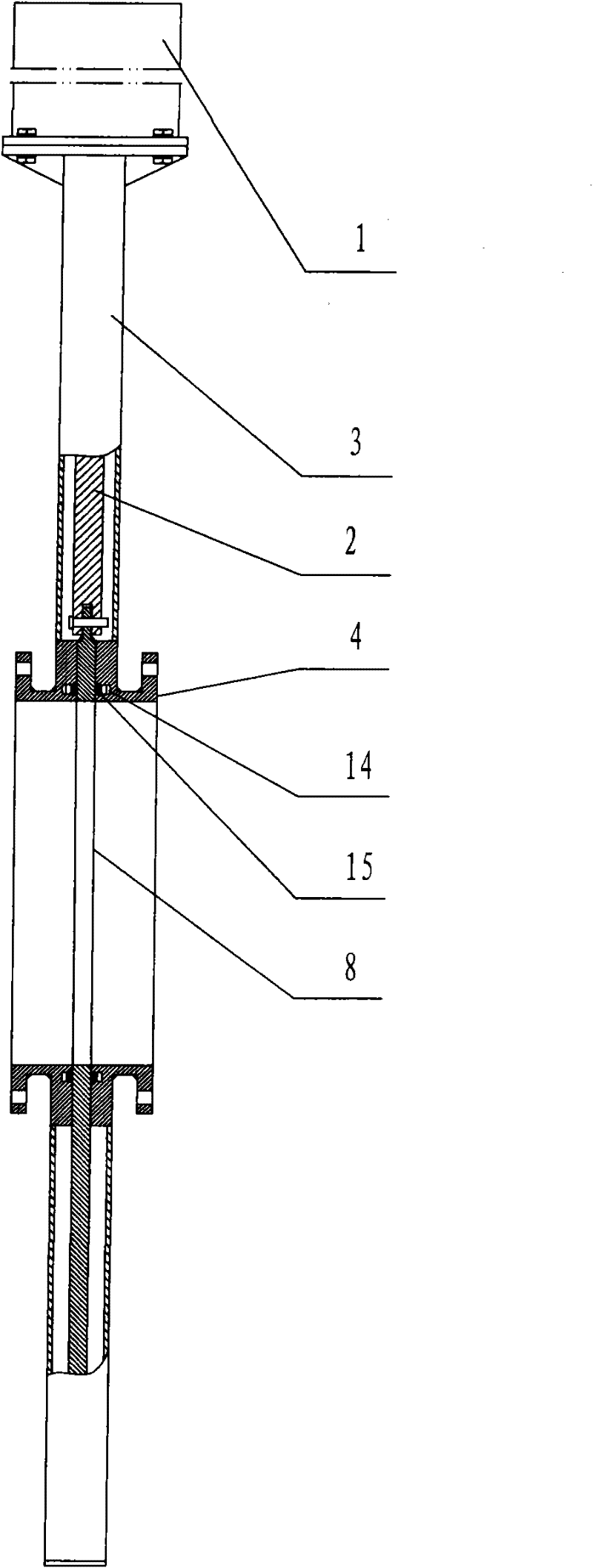

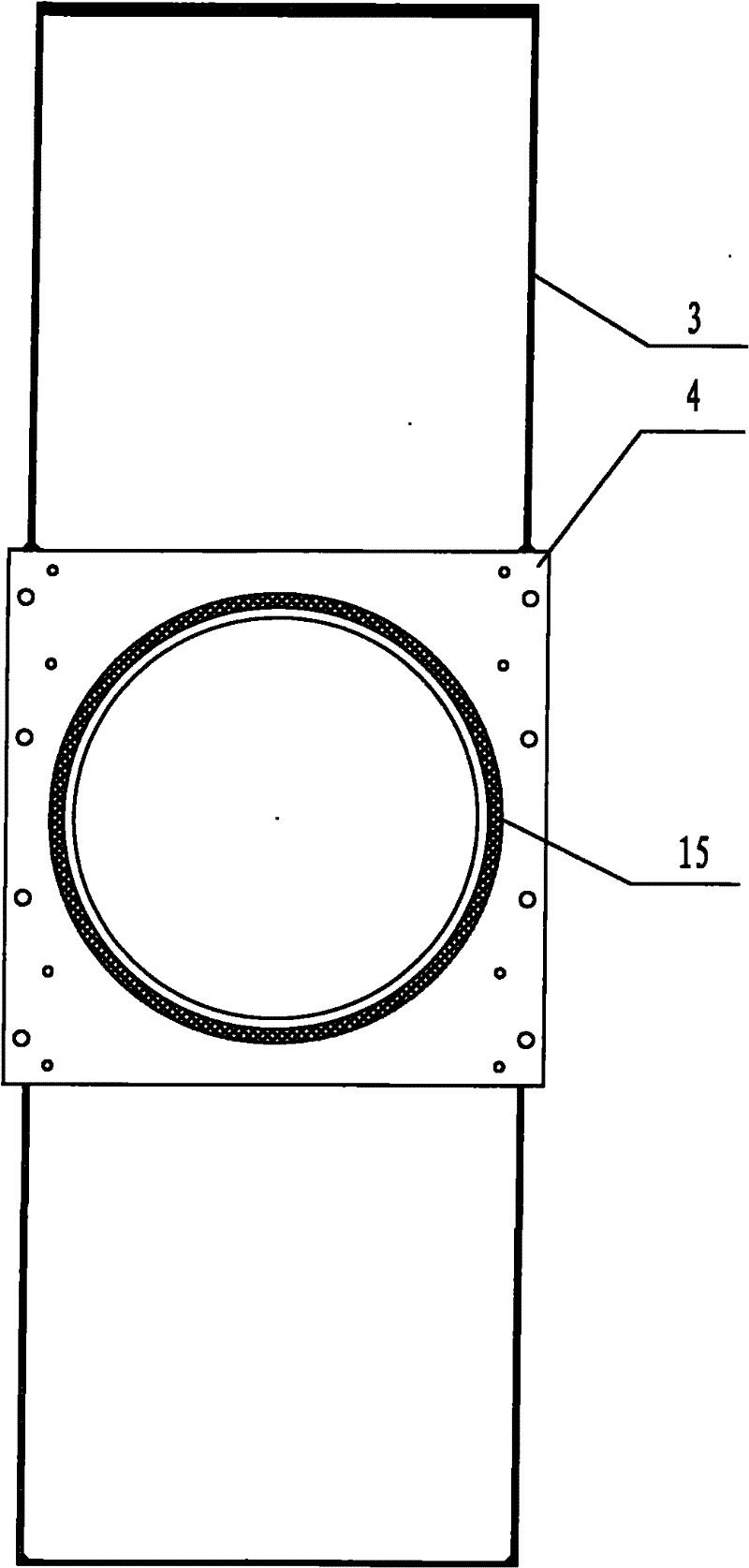

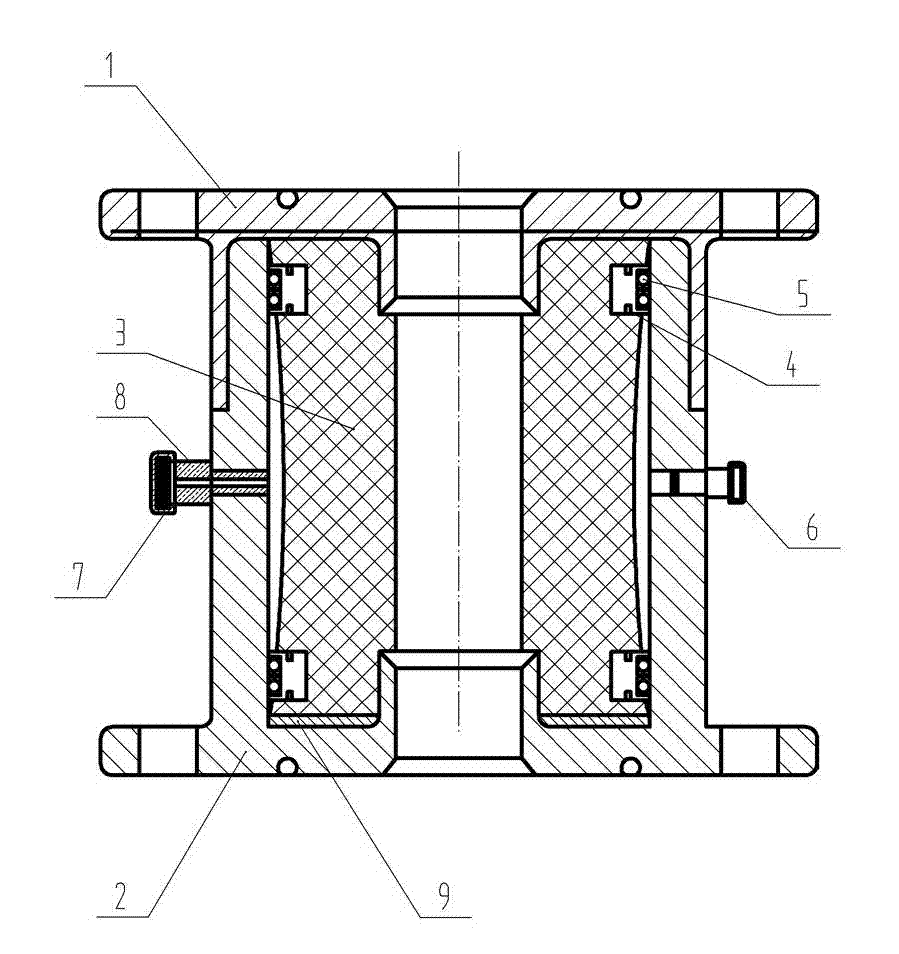

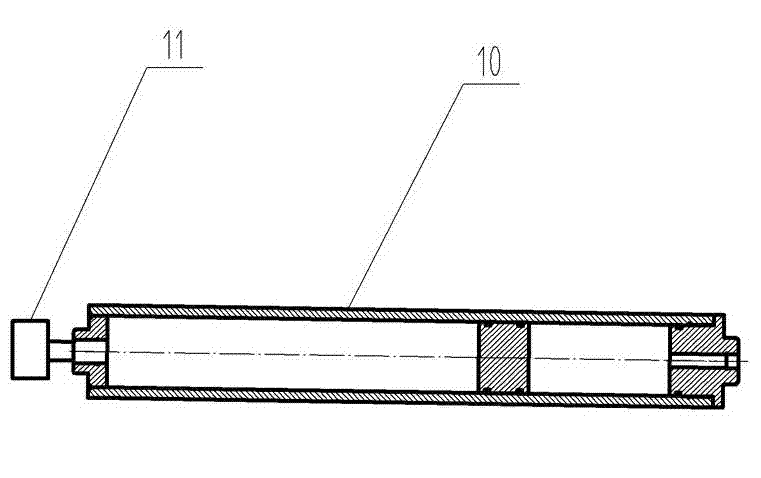

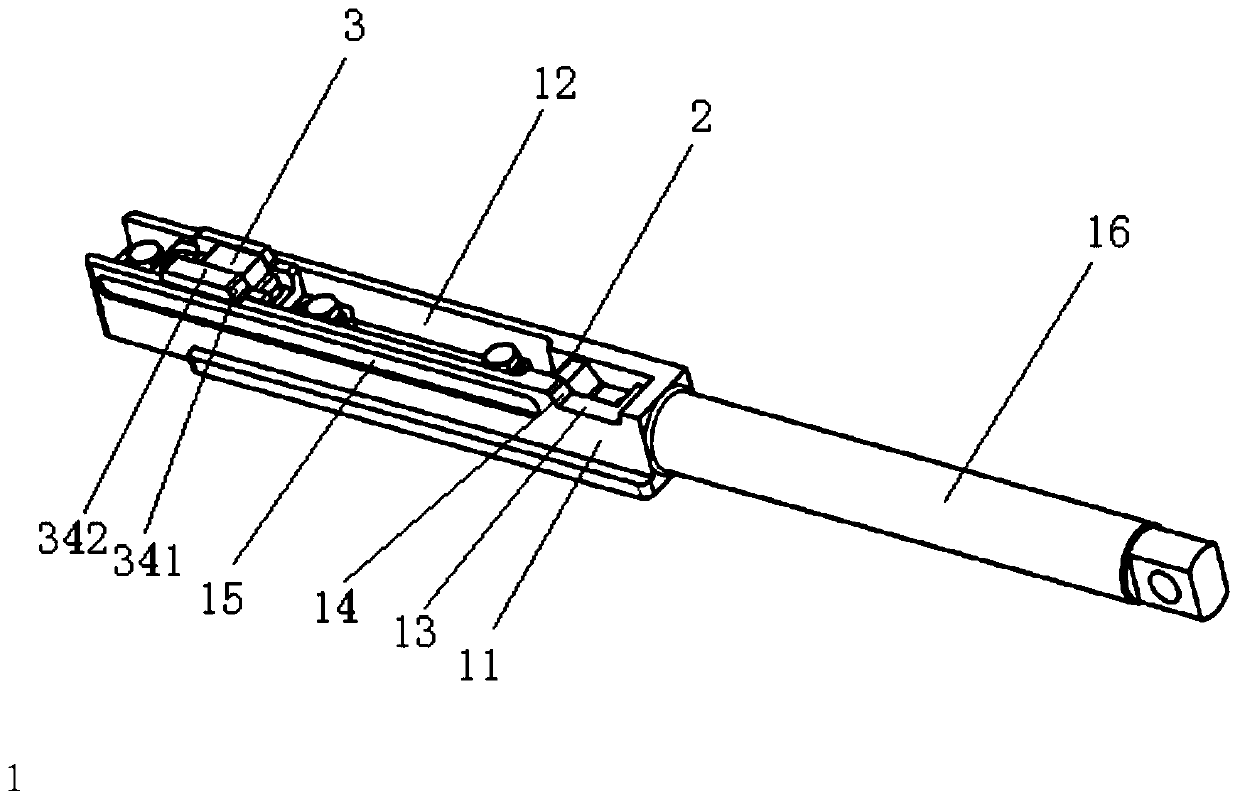

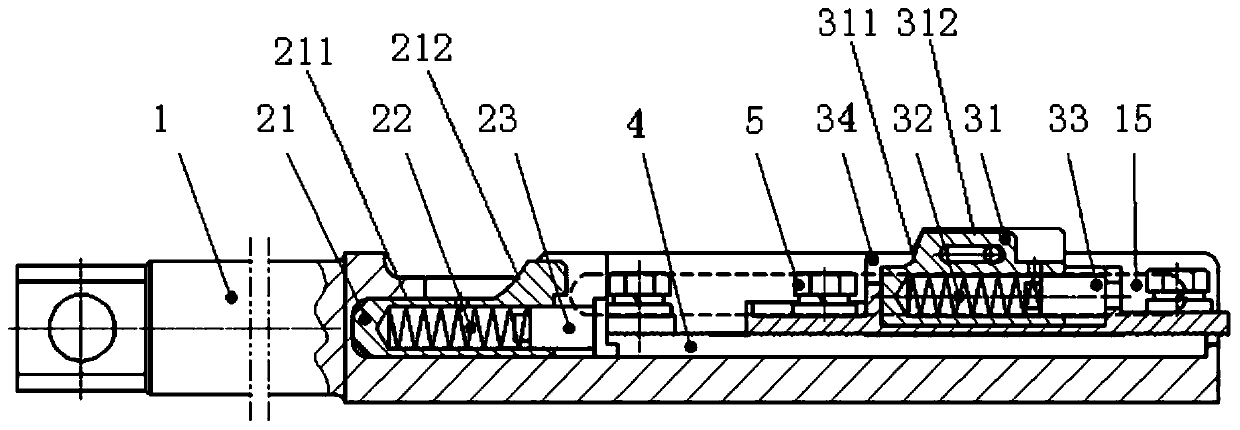

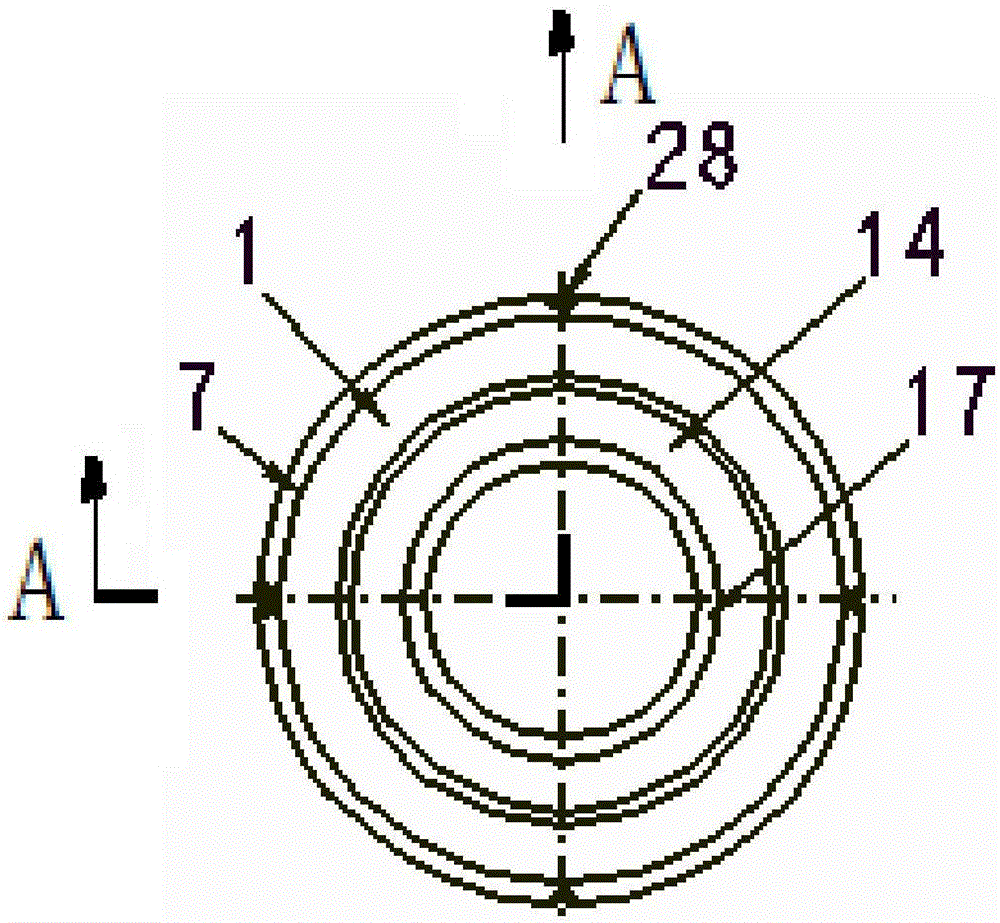

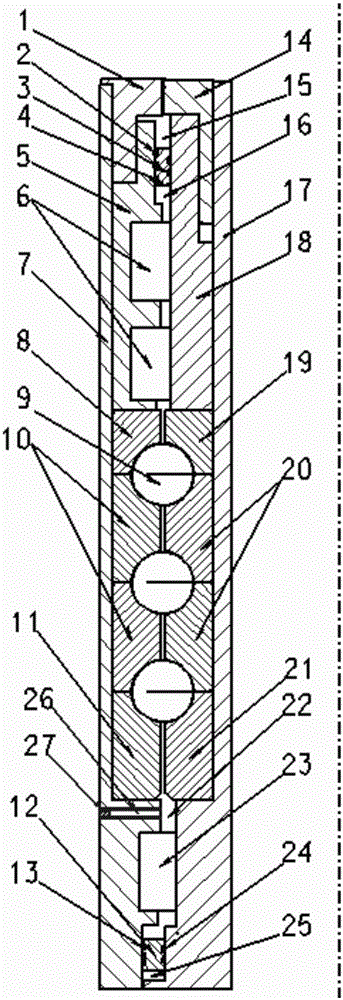

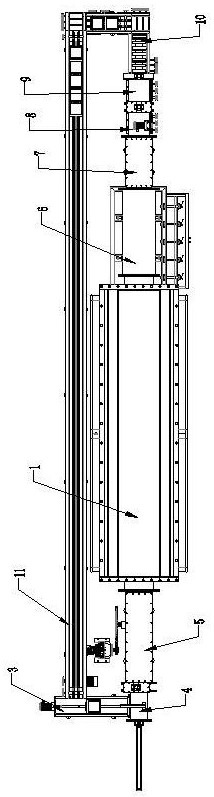

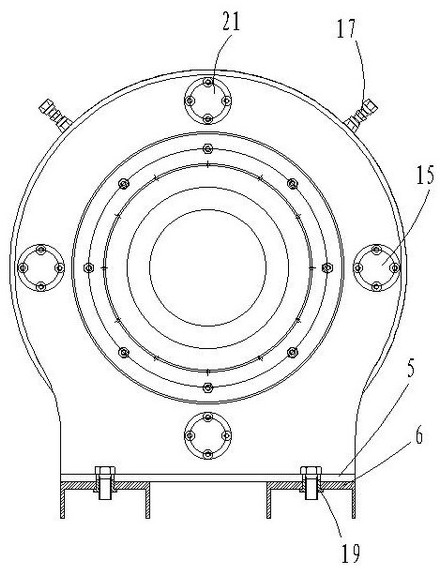

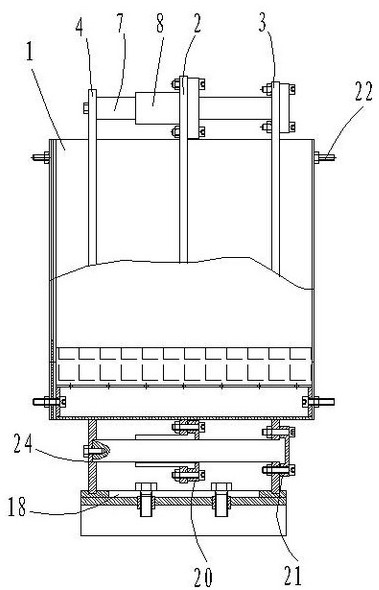

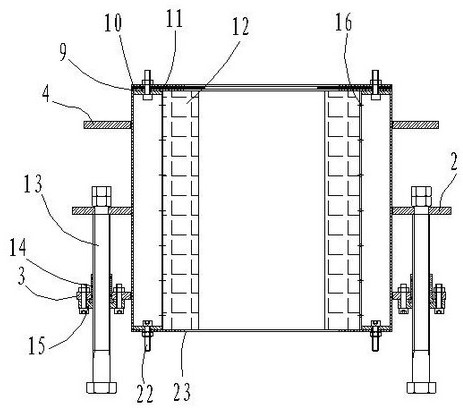

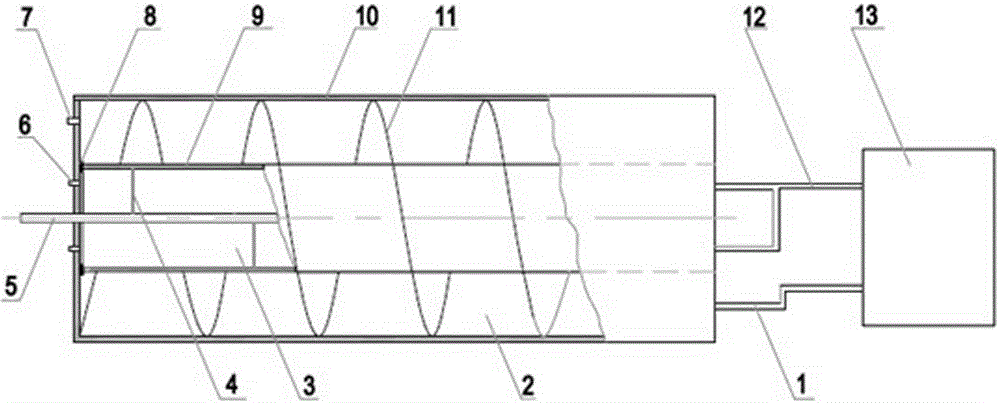

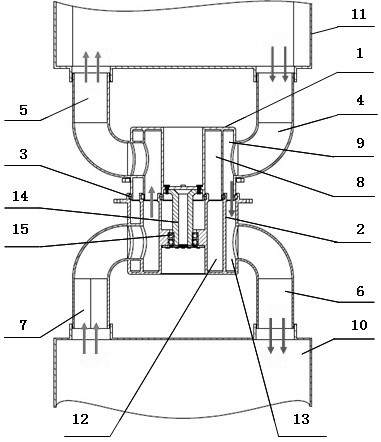

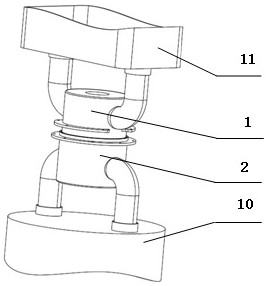

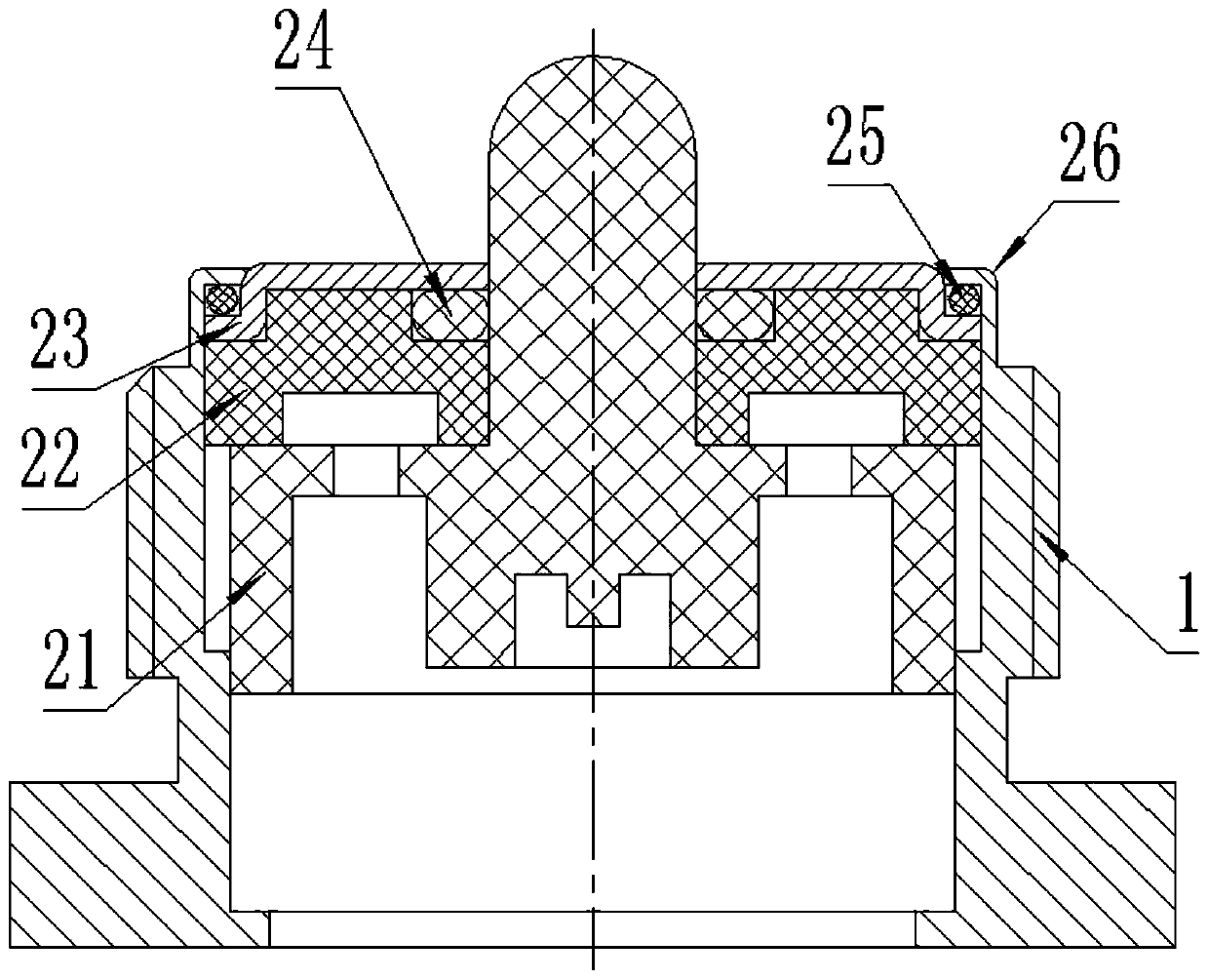

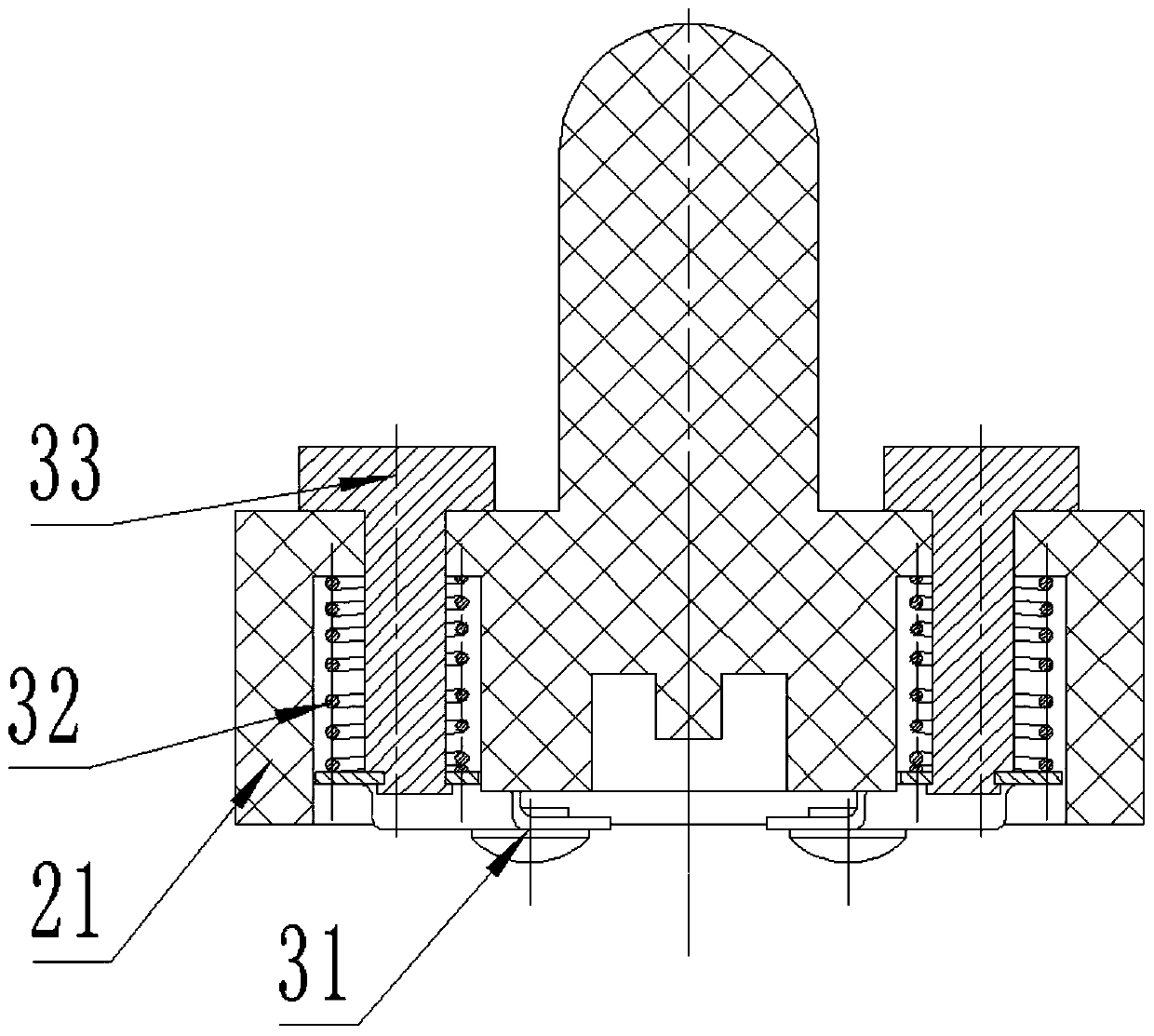

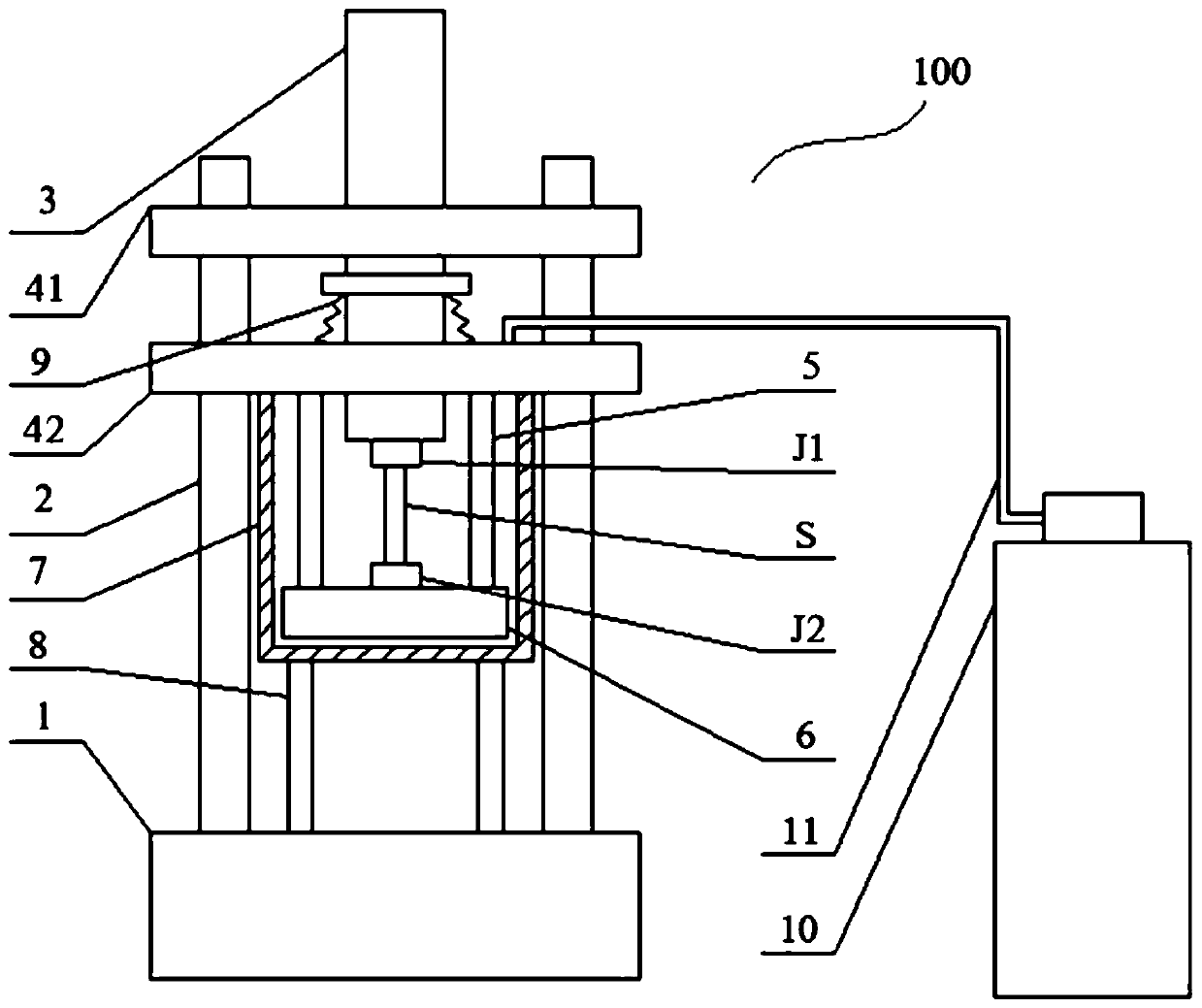

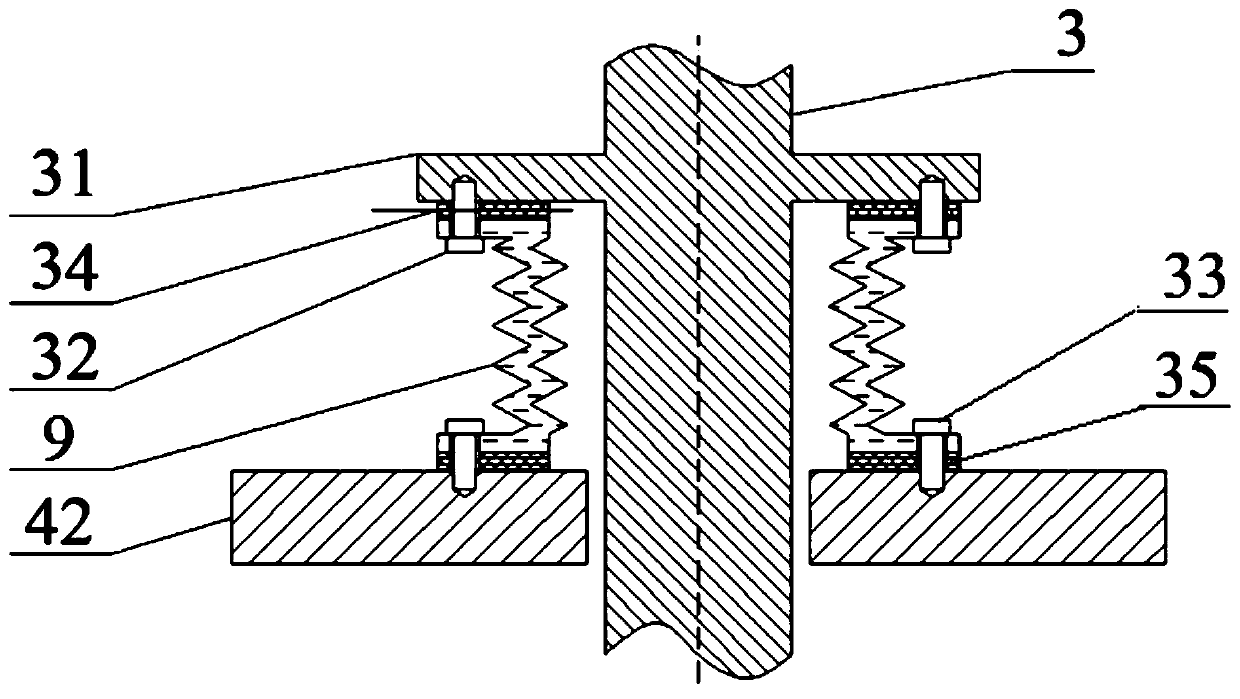

Efficient constant pressure difference intermittent rotating extrusion abrasive flow polishing device

The invention relates to an efficient constant pressure difference intermittent rotating extrusion abrasive flow polishing device and belongs to the technical field of intermittent rotating extrusion abrasive flow automatic polishing of large-size complicated curved parts with higher uniformity requirements on surface quality. The abrasive flow polishing device is a rotating grinding and polishing device where a hydraulic motor drives a gear and is engaged with a negative clearance turntable bearing; sealing rings are mounted on junction surfaces to achieve static sealing of a high-pressure abrasive; dynamic sealing of the high-pressure abrasive is achieved by mounting quick-wear sealing rings at rotating friction parts for sealing and mounting special combined high-pressure abrasive sealing ring and high-pressure abrasive seals in places where pistons extrude the abrasive; and finally, intermittent rotation grinding and polishing of the high-pressure abrasive is achieved. The device solves the problems of excessive grinding and rounding in the traditional abrasive flow extrusion, and achieves aerodynamic performances and efficient precise uniform polishing of complicated curved surfaces such as impellers and blades with the higher surface uniformity requirements. The device can reduce surface roughness Ra of various complicated parts to below 0.8.

Owner:珂尔默(东莞)制造技术有限公司

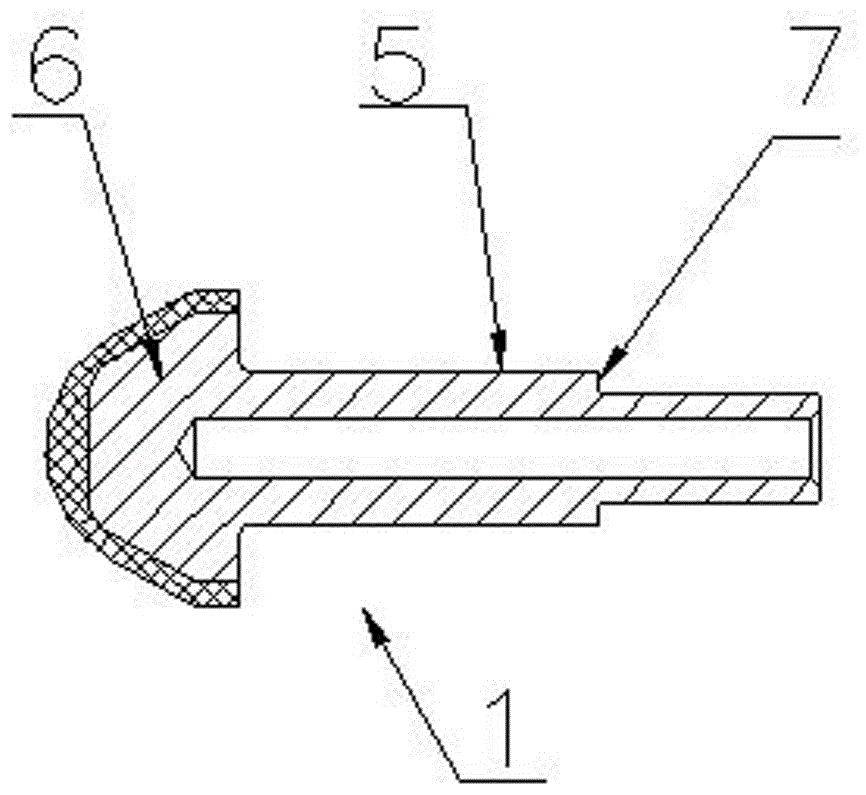

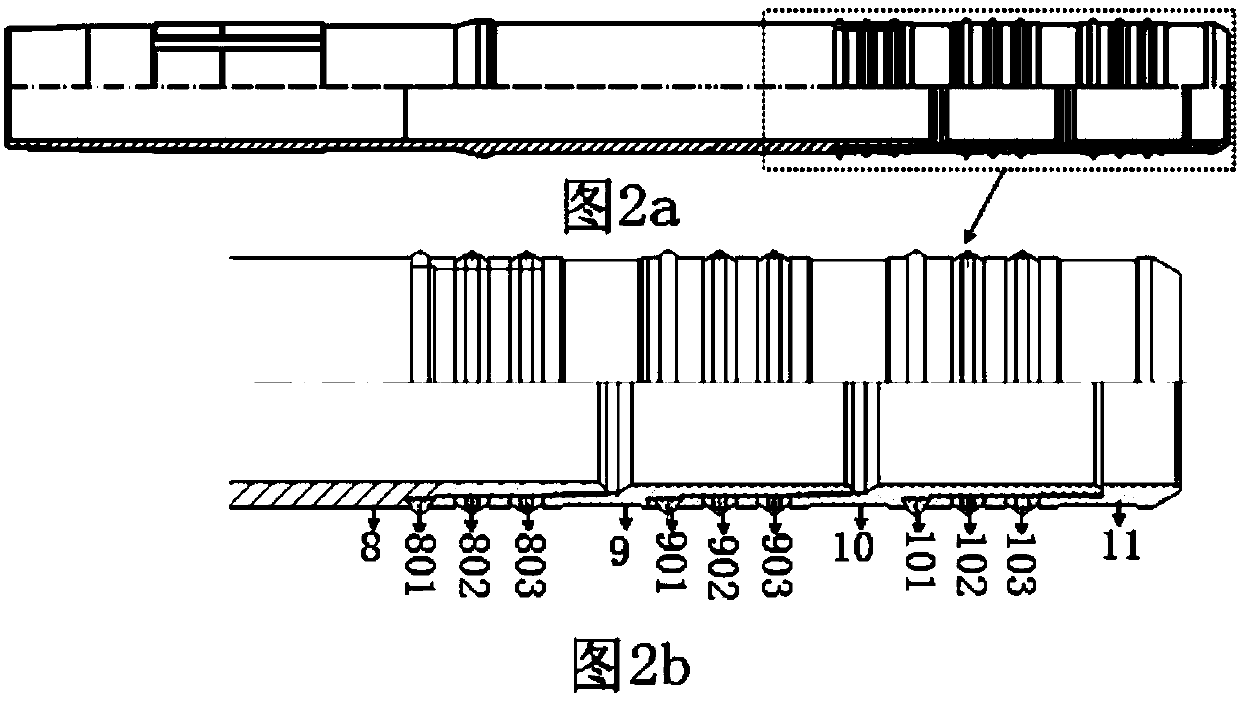

Oil well polish rod sealer with sealing padding capable of being injected

ActiveCN104120993ASolve the disadvantages of needing to stop pumping and stop production to replace packingReduce consumption costSealing/packingEngineeringMechanical engineering

An oil well polish rod sealer with sealing padding capable of being injected comprises a box body, a box seat and an elastic compensation annular part, wherein the box body is arranged on the box seat, the box body and the box seat are connected and fixed through a connector, a through cavity is formed in the box body in the axial direction, a stop ring is embedded in an upper end port of the cavity, the upper end of the elastic compensation annular part can be movably embedded in a lower end port of the box body and can be tightly attached to the inner lateral surface of the box body, the lower end of the elastic compensation annular part is contained in an annular part of the upper end of the box seat, a through hole passage is further formed in the box seat in the vertical direction and is communicated with the annular part, an annular shoulder cavity is formed between the annular part and the through hole passage, a padding chamber is formed in the part between the stop ring of the cavity and the elastic compensation annular part, an injecting port is formed in the lateral wall of the box body, and an injecting nozzle for injecting sealing padding is installed at the injecting port. When a polish rod can movably and correspondingly penetrate through the stop ring, the padding chamber, the elastic compensation annular part and the through hole passage, the outer surface of the polish rod makes sealed contact with the stop ring and the upper end of the elastic compensation annular part.

Owner:PETROCHINA CO LTD

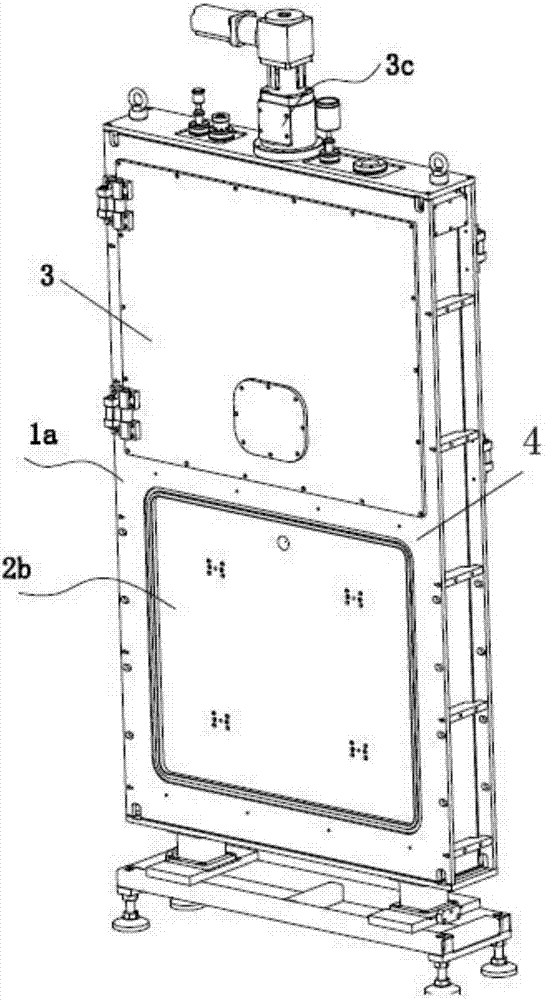

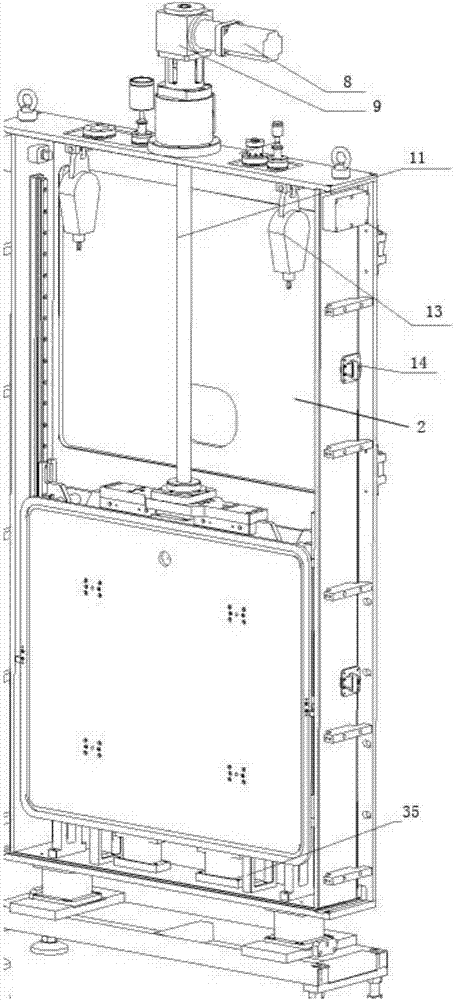

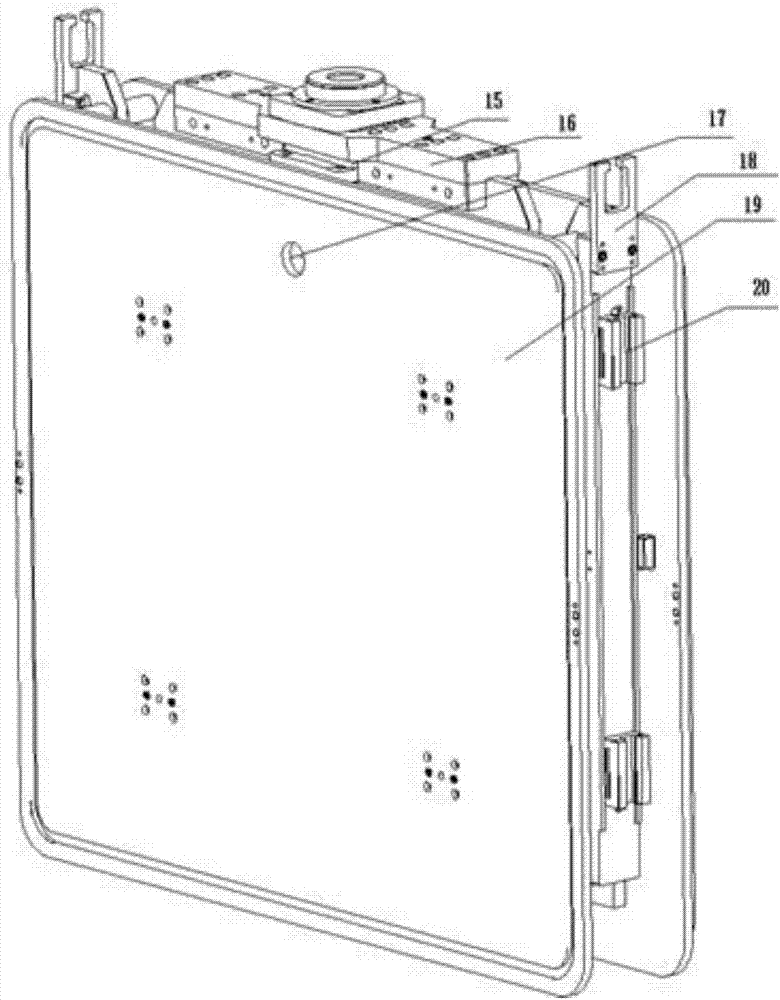

Pilot-operated type vacuum valve

PendingCN107575641AReduce vacuumReduce time-consuming problems such as vacuum breakingOperating means/releasing devices for valvesSlide valveEngineeringEnergy conservation

The invention discloses a pilot-operated type vacuum valve including a valve body, a lifting body and a screw rod driving mechanism. The valve body includes a valve framework and valve body vertical plates, wherein the valve body vertical plates and the valve framework are arranged at intervals front and back. A vacuum plate valve cavity is installed in the middle of the valve body. The lifting body is installed in the vacuum plate valve cavity and slidably connected with the valve body. The lifting body includes a lifting vertical plate, plate valve lifting doors and a plate valve opening andclosing mechanism. The lifting vertical plate is a horizontal and straight mounting plate. The top of the lifting vertical plate is connected with the screw rod driving mechanism. The plate valve lifting doors are symmetrically installed on the both sides of the lifting vertical plate separately. The plate valve opening and closing mechanism is installed between the plate valve lifting doors. According to the pilot-operated type vacuum valve, intermittent double-valve sealing is achieved by using single power, first closing and first passing of a pre-opening and pre-closing air leading hole can be completed through an automatic compaction mechanism, The pilot-operated type vacuum valve is stable in performance, and energy conservation and high efficiency are achieved.

Owner:SHENZHEN DACHENG PRECISION EQUIP CO LTD

Humidifier for proton exchange membrane fuel cell

ActiveCN102956908AReduce size and power consumptionMake up for resistanceFuel cell auxillariesExhaust gasEngineering

The invention discloses a humidifier for a proton exchange membrane fuel cell, belonging to the technical field of fuel batteriecell s. The humidifier mainly comprises an external cylinder, an internal cylinder, a spiral blade and a transmission shaft, wherein the spiral blade is fixedly arranged on the outer surface of the internal cylinder, a micropore iss are arranged in the wall of the internal cylinder, and the internal cylinder is connected with the transmission shaft by a connecting rod. The humidifier is used for humidifying before raw material gas of the proton exchange membrane fuel cell enters an electric pile, and fully utilizing moisture and heat in tail gas, can adjust the pressure of the humidified gas, has the advantages of being energy-saving, high-efficiencyt, and convenient to adjust, meets the raw material gas humidifying requirement and the pressure requirement for entering the electric pile, the energy consumption and cost of a fuel battery cell system can be reduced and lowered, the volumsize is decreased, and the effects are obvious.

Owner:BEIJING SHOTO ENERGY STORAGE TECH CO LTD

Quick energy saving impactor used for well

The invention provides a quick energy saving impactor used for a well. The quick energy saving impactor comprises a check valve, an air distributing seat, an inner cylinder and a piston, wherein the check valve comprises a long shaft part and a head part; one end, which is far away from the head part, of the long shaft part is provided with a shaft shoulder; the long shaft part is sheathed with the air distributing seat; the air distributing seat is provided with a mounting hole; the long shaft part is sheathed with a spring; one end of the spring is spaced through the shaft shoulder; the other end of the spring is in contact with the bottom of the mounting hole. The quick energy saving impactor has the advantages of reasonable structure design, small pressure loss and good energy saving effect, solves the problems that an impactor in well construction is always subjected to back-filling blockage and piston lubrication is poor and also solves the technical problems that a piston cylinder is always broken, the gas consumption of the impactor is high and working efficiency is low due to a short oriented surface.

Owner:SHANDONG TIANRUI HEAVY IND CO LTD

Intelligent dynamic sealed liquid storage tank equipped with metal ripple compensator and use method of intelligent dynamic sealed liquid storage tank

ActiveCN103515061AFor long-term storageSafe storageTransformers/inductances coolingSolenoid valveControl engineering

The invention relates to an intelligent dynamic sealed liquid storage tank equipped with a metal ripple compensator and a use method of the intelligent dynamic sealed liquid storage tank. A liquid inlet solenoid valve is arranged at the liquid inlet of the liquid storage tank; a discharge valve is arranged at the discharge opening; a liquid outlet solenoid valve and an on-line moisture detection instrument are sequentially arranged at the liquid outlet of the liquid storage tank in the liquid outlet direction; the metal ripple compensator is mounted inside the liquid storage tank; wheels are mounted at the bottom of the metal ripple compensator; a guide rail matched with the wheels are mounted in the liquid storage tank; a breathing tube communicated with the metal ripple compensator is arranged at one end of the liquid storage tank; an electric contact liquid level meter is arranged at the other end of the liquid storage tank; the liquid inlet solenoid valve, the liquid outlet solenoid valve, the on-line moisture detection instrument and the electric contact liquid level meter are electrically connected with a control module. According to the invention, the cavity of the metal ripple compensator is communicated with the outer atmosphere through the breathing tube; the breathing action of the metal ripple compensator can perform the functions of compensating and balancing volume change in the liquid storage tank. caused by change in liquid level, so as to achieve dynamic sealing.

Owner:STATE GRID CORP OF CHINA +3

Pipe column structure for CO2 flooding gas injection process

ActiveCN107605443AImprove airtight performanceImprove work efficiencyFluid removalSealing/packingWell killCo2 flooding

The invention discloses a pipe column structure for the CO2 flooding gas injection process. The pipe column structure comprises a guiding shoe, a check valve, a setting ball seat, a Y445 packer, an inserting pipe, a reverse circulation valve and an oil pipe. The guiding shoe is connected with the check valve; the upper end of the check valve is connected with the setting ball seat; the upper end of the setting ball seat is connected with the Y445 packer; the Y445 packer is connected with the inserting pipe; and the upper end of the inserting pipe is connected with the reverse circulation valveand the oil pipe in sequence. During working, the parts are connected in sequence, a pipe column is put downwards, an annulus is filled with a conventional oil-based annulus protection fluid in a reverse circulation mode, a quick-dissolving soluble ball is put, pressure injection for setting is conducted, and thus gas can be injected normally; when the pipe column is taken out, through the checkvalve, the oil pipe is directly emptied so that pressure can be released, the pipe column is lifted up, the inserting pipe is pulled out, and thus a pipe string can be taken out; if pressure relief ofthe oil pipe fails, a well killing fluid is injected in a reverse circulation mode for well killing, then the pipe column is lifted up, and thus the pipe string can be taken out; after pipe string checking work, the parts are connected in sequence, the pipe column is put downwards, the inserting pipe is inserted into the packer, and thus sealing well-completion can be conducted.

Owner:PETROCHINA CO LTD

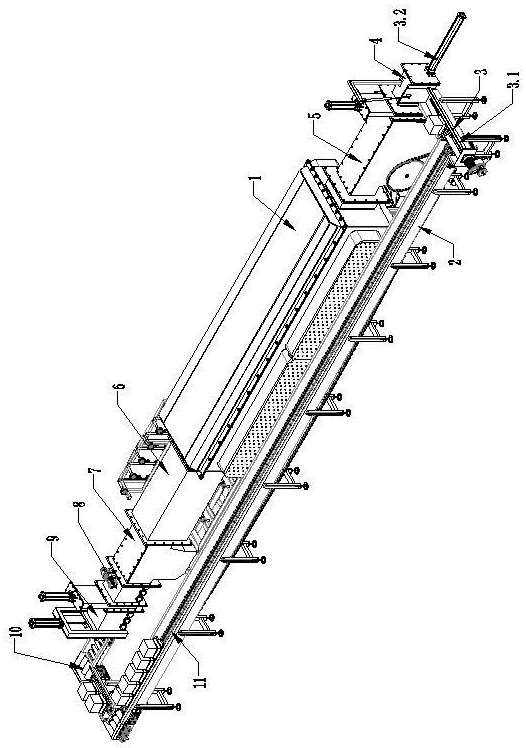

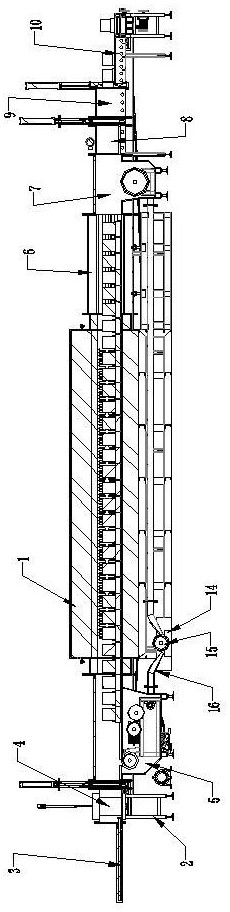

Continuous type coating device

InactiveCN107326334AStable PVD coatingCoating stabilityVacuum evaporation coatingSputtering coatingIon depositionEngineering

The invention relates to a continuous type coating device. The continuous type coating device comprises a feeding mechanism, a heating mechanism, a buffer mechanism, a coating mechanism and a discharging mechanism, and the feeding mechanism, the heating mechanism, the buffer mechanism, the coating mechanism and the discharging mechanism are arranged close to one another sequentially, can form a sealing structure independently, and are connected with a vacuumizing mechanism. The heating mechanism is used for conveying heated workpieces to the buffer mechanism through a first delivery channel. The buffer mechanism is provided with a second cavity, a second delivery channel is formed in one side wall of the second cavity, and the second delivery channel communicates with the first delivery channel. A second opening and closing part is installed in the second delivery channel. The coating mechanism comprises a third cavity and is used for conveying the workpieces subjected to ion deposition treatment to the discharging mechanism through a fifth delivery channel. The continuous type coating device can coat the workpieces such as screws and screw rods with PVD stably and continuously.

Owner:VITALNK IND SHENZHEN

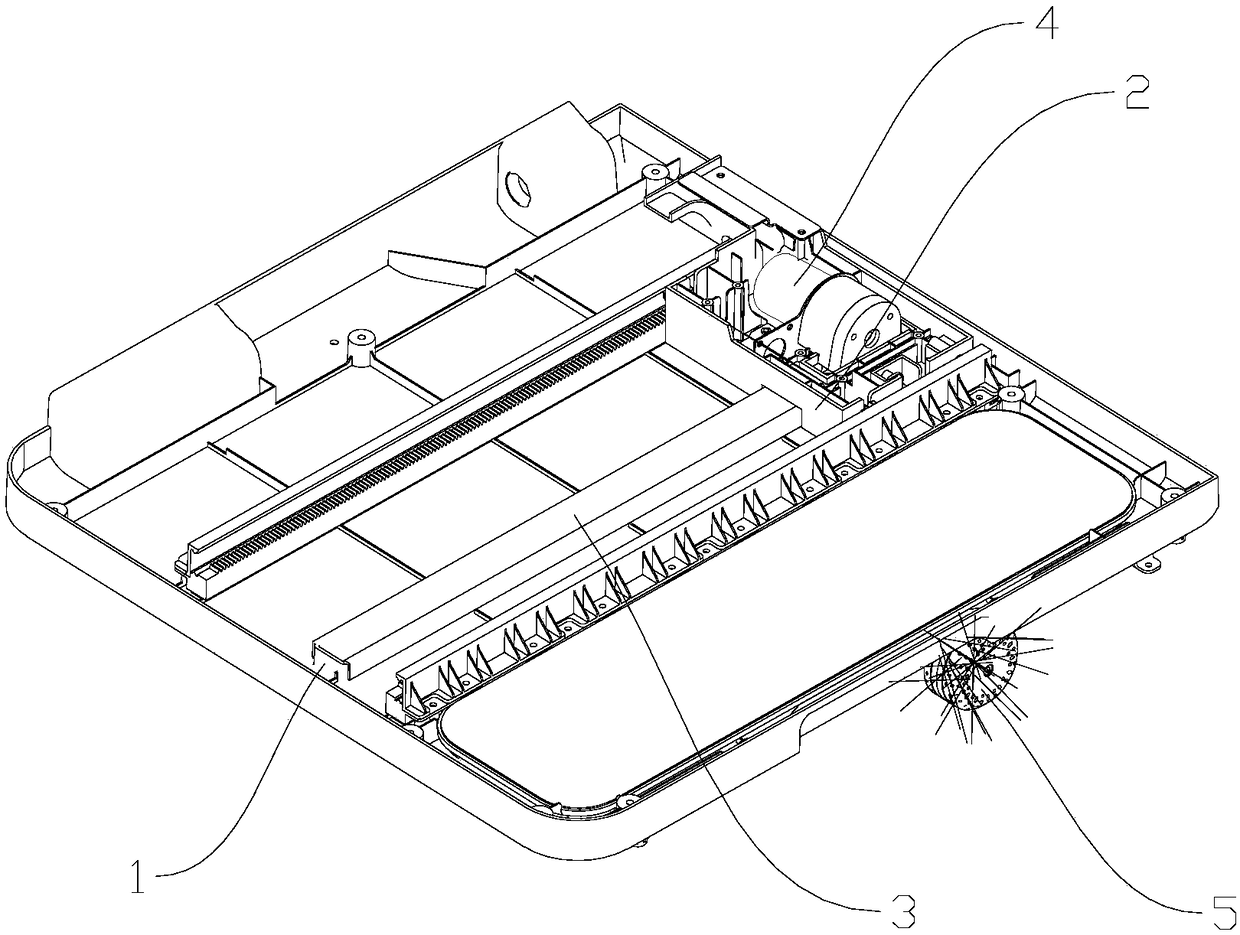

Sealing mechanism used for shoe washing machine, and shoe washing machine

PendingCN109424745AEasy to fixAchieving a static sealEngine sealsFootwear cleanersEngineeringMechanical engineering

The invention belongs to the technical field of shoe washing machines, and aims at solving the problem that damage to a power mechanism is easily caused due to the lack of a sealing mechanism in an existing shoe washing machine. For this, the invention provides a sealing mechanism used for a shoe washing machine, and the shoe washing machine. The shoe washing machine comprises a fixed member and aslide mechanism arranged on the fixed member in a slide manner, wherein the sealing mechanism is arranged between the slide mechanism and the fixed member, and used for sealing the fixed member. According to the sealing mechanism used for the shoe washing machine, and the shoe washing machine, through the arrangement for the sealing mechanism between the slide mechanism and the fixed member, sealing for the fixed member can be realized, so that in a shoe washing process of the shoe washing machine, splashing water cannot enter into the power mechanism through the fixed member, and then damageto the power mechanism due to dip dyeing of water is avoided; and meanwhile, the drive efficiency and the service life of the power mechanism cannot be influenced.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

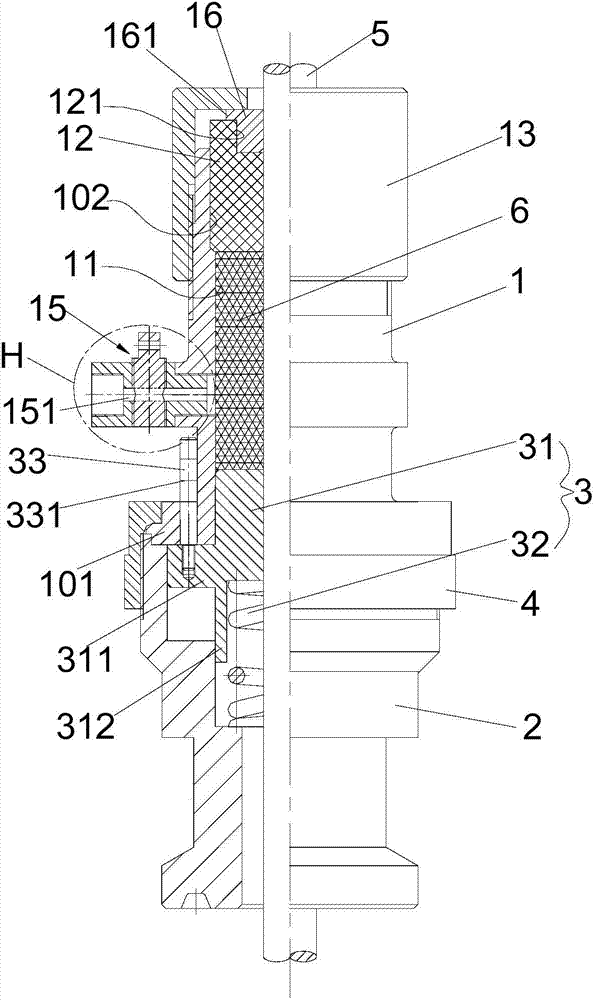

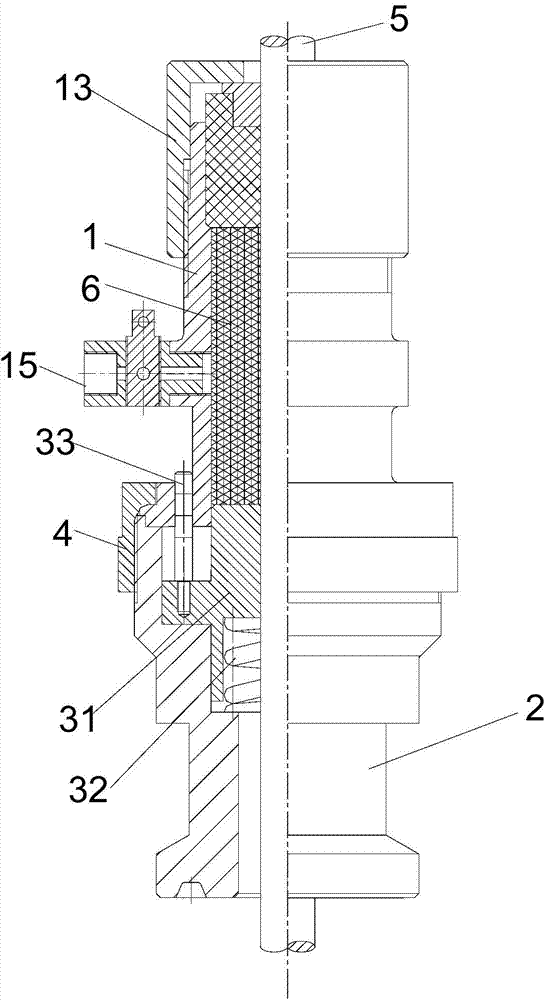

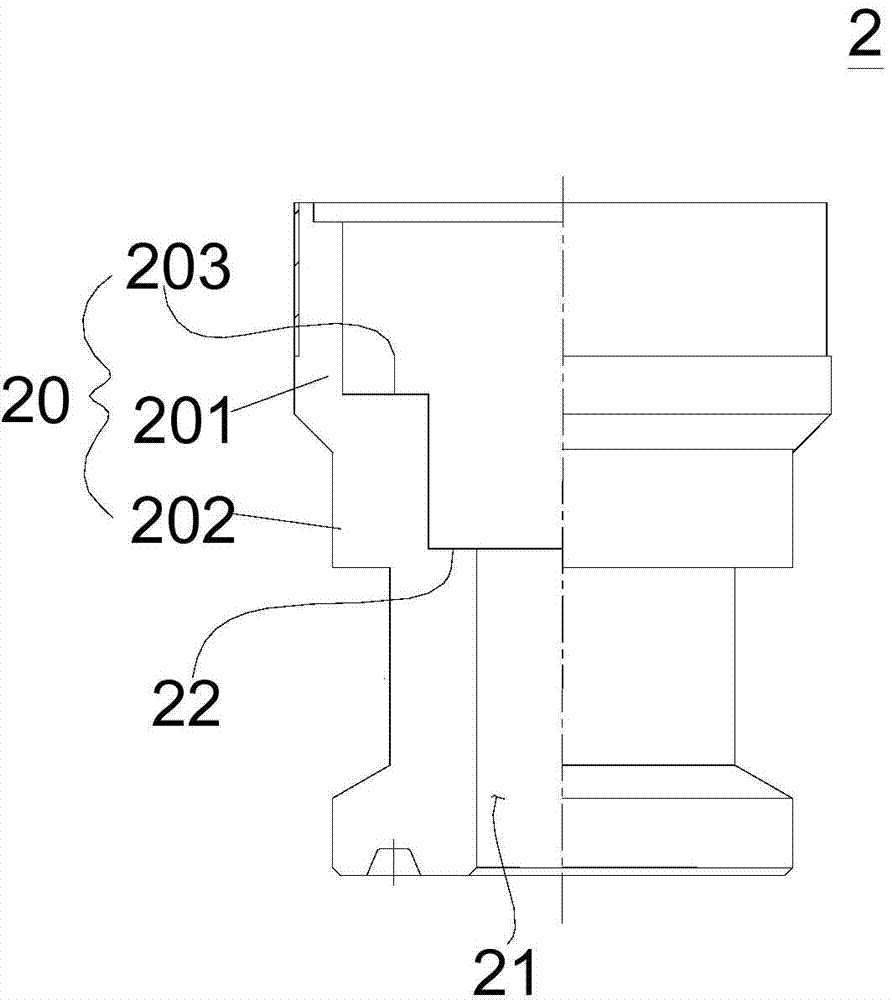

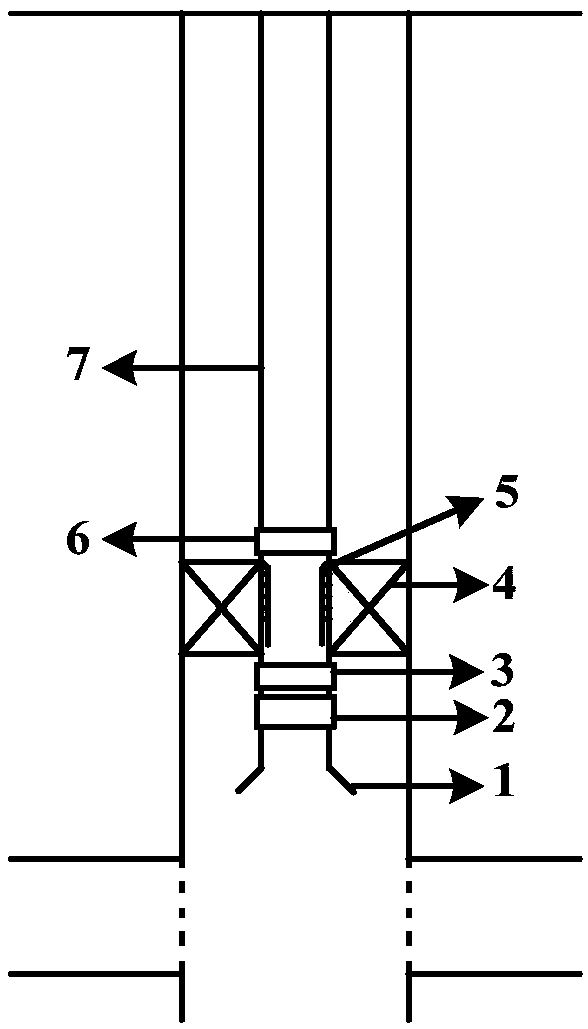

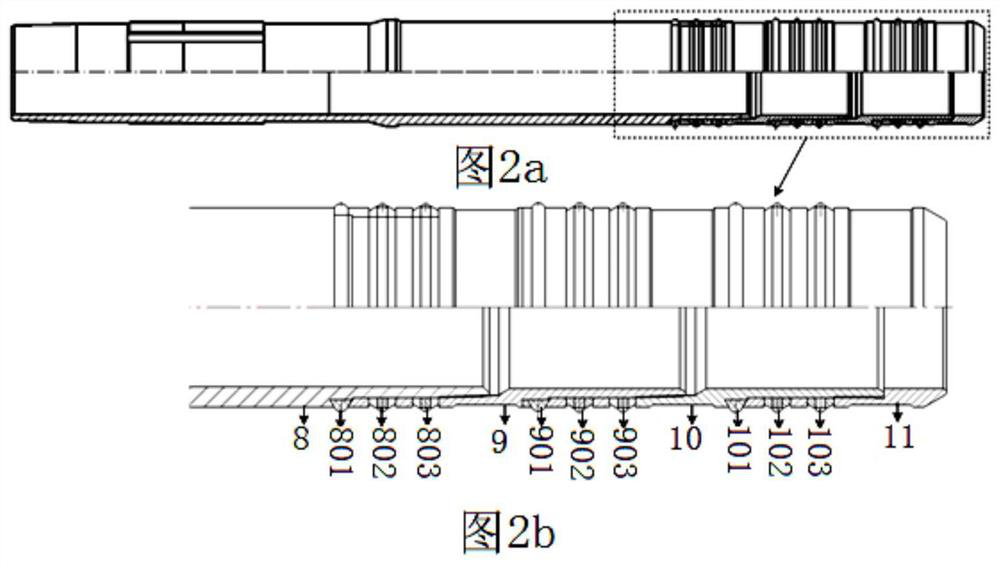

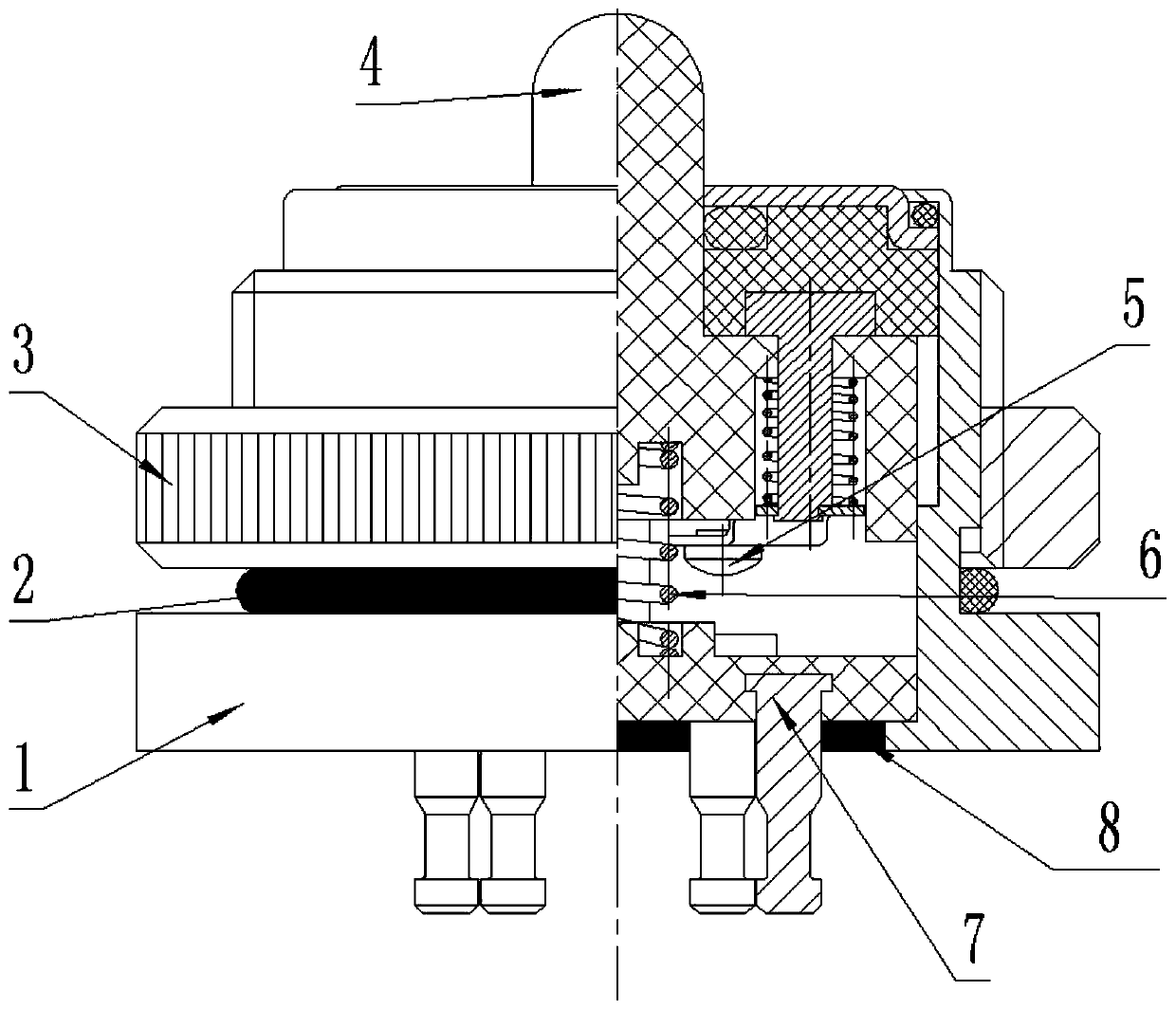

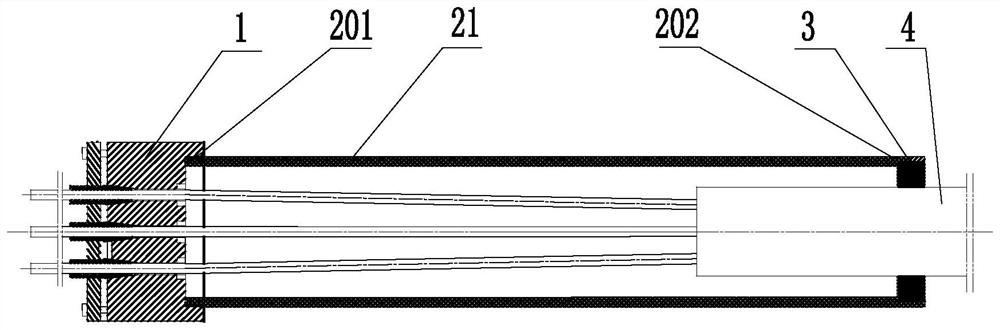

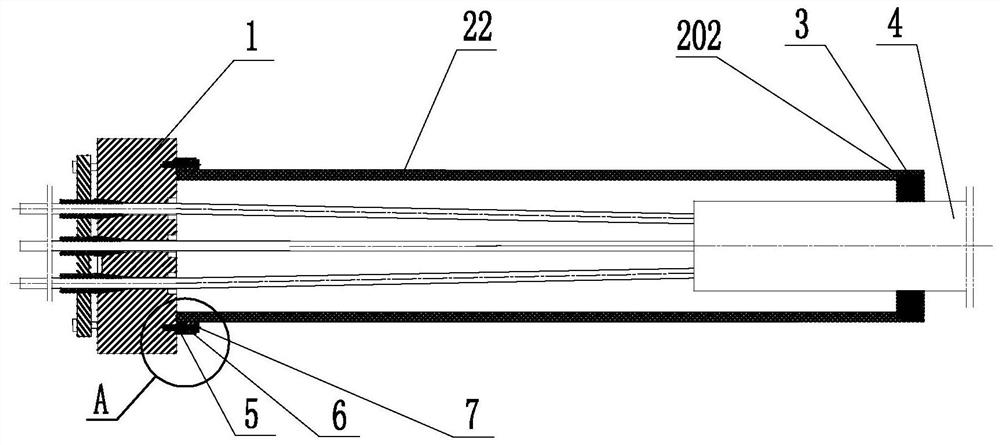

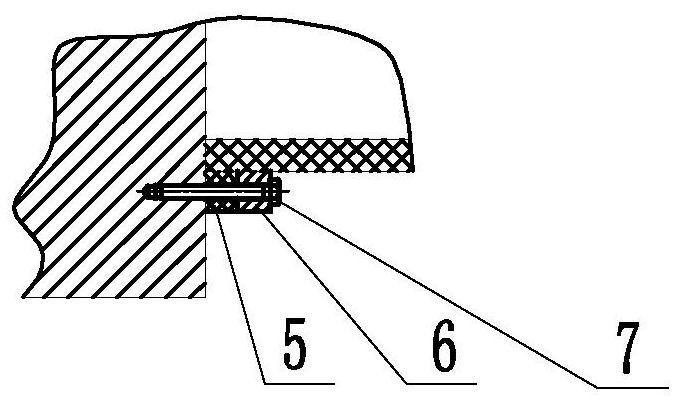

Self-clamping dynamic sealing device capable of feeding electrode wires in wriggled mode

ActiveCN103273153ASmooth and precise creep feedEven consumptionEngine sealsElectrical-based auxillary apparatusMechanical engineeringElectrode

The invention relates to a self-clamping dynamic sealing device capable of feeding electrode wires in a wriggled mode. The self-clamping dynamic sealing device capable of feeding the electrode wires in the wriggled mode comprises a hollow main shaft of a motor, a gland, a rigid sealing ring and a flexible sealing ring. The bottom end of the hollow main shaft of the motor is linked with the gland in a threaded and sealed mode. An inner cavity is formed in the gland. The rigid sealing ring and the flexible sealing ring are filled in the inner cavity of the gland from top to bottom. Hollow electrode wires penetrate through the hollow main shaft of the motor, the rigid sealing ring, the flexible sealing ring and the gland. A seam is reserved between the upper end face of the rigid sealing ring and the lower end face of the hollow main shaft of the motor. The inner side surface of the rigid sealing ring is in clearance fit with the hollow electrode wires and a seam is reserved between the outer side surface of the rigid sealing ring and the inner side face of the gland. The upper end face of the flexible sealing ring is contacted with the rigid sealing ring. The inner side face of the flexible sealing ring is clearance fit with the hollow electrode wires. The outer side face of the flexible sealing ring is contacted with the inner side face of the gland. The lower end face of the flexible sealing ring is contacted with the bottom face in the gland. The self-clamping dynamic sealing device capable of feeding the electrode wires in the wriggled mode is simple in structure, low in cost and capable of automatically clamping and dynamically sealing the electrode wires.

Owner:YANTAI UNIV

Planetary grinding head with oil leakage prevention mechanism

InactiveCN107283300AAvoid enteringAchieving a dynamic sealGrinding headsGrinding/polishing safety devicesBall bearingGear wheel

The invention discloses a planetary grinding head with an oil leakage prevention mechanism. The planetary grinding head comprises a planetary gear shaft and a bearing pedestal, wherein the bearing pedestal is in sleeved connection with the planetary gear shaft, and a planetary gear is arranged at the top of the planetary gear shaft; a first annular groove is formed in the lower end face of a base body of the planetary gear, and a first annular convex slot in clearance fit with the first annular groove is formed in the upper end face of a base body of the bearing pedestal; the bearing pedestal is further provided with a pressure relief channel which is arranged at the bottom of the first annular convex slot, and the pressure relief channel communicates with the outer wall of the base body of the bearing pedestal. The planetary gear rotates around the axis of the planetary gear under the action of external force so that the planetary gear shaft can be driven to rotate at a high speed relative to the bearing pedestal. The pressure relief channel is arranged at the top of a deep groove ball bearing assembly, excessive lubricating grease permeating into the bearing pedestal can be drained off under the condition that the planetary grinding head is oblique laterally or inverted, and high pressure caused by internal temperature rising of the bearing pedestal can also be released.

Owner:GUANGDONG SINID TECH

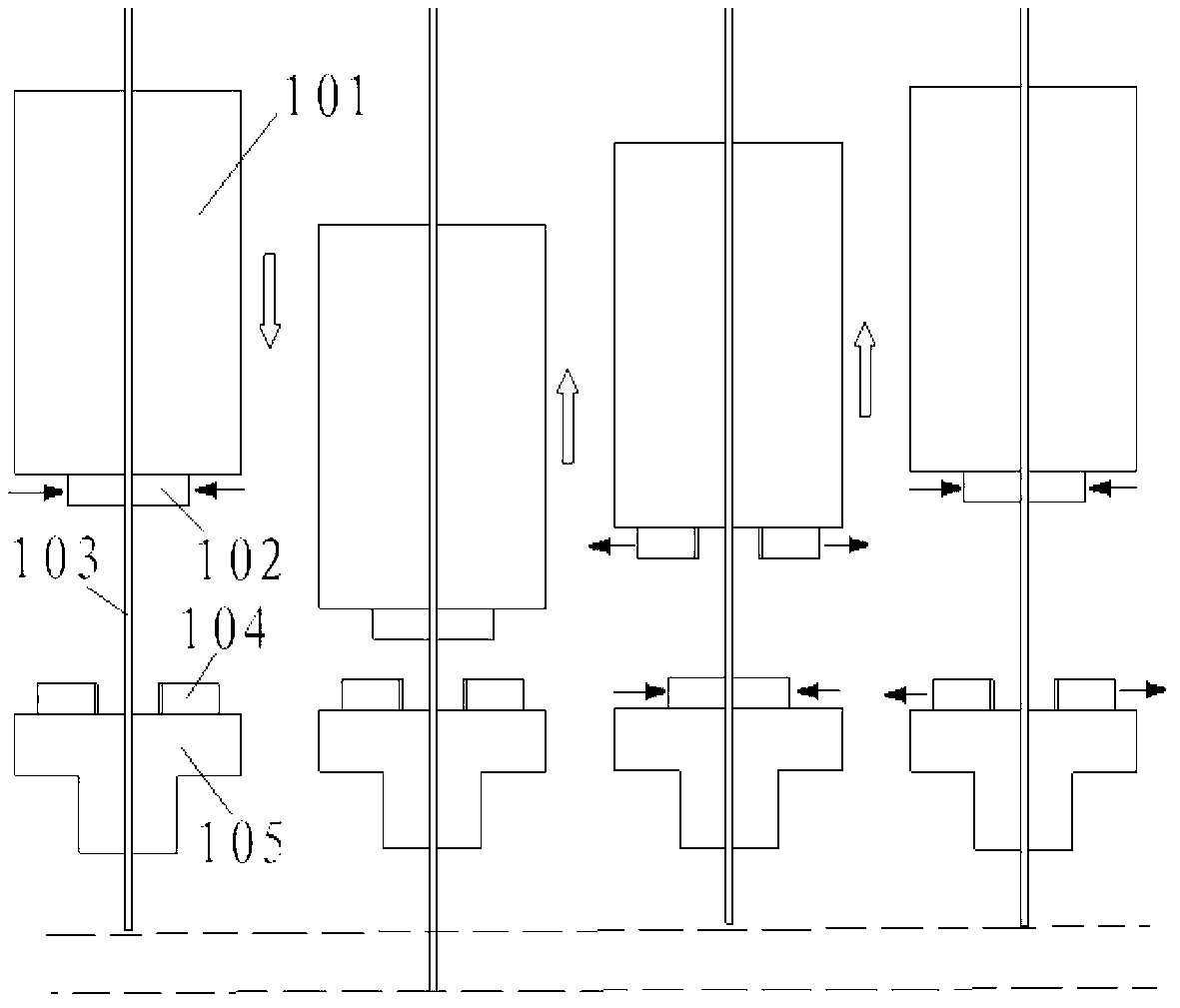

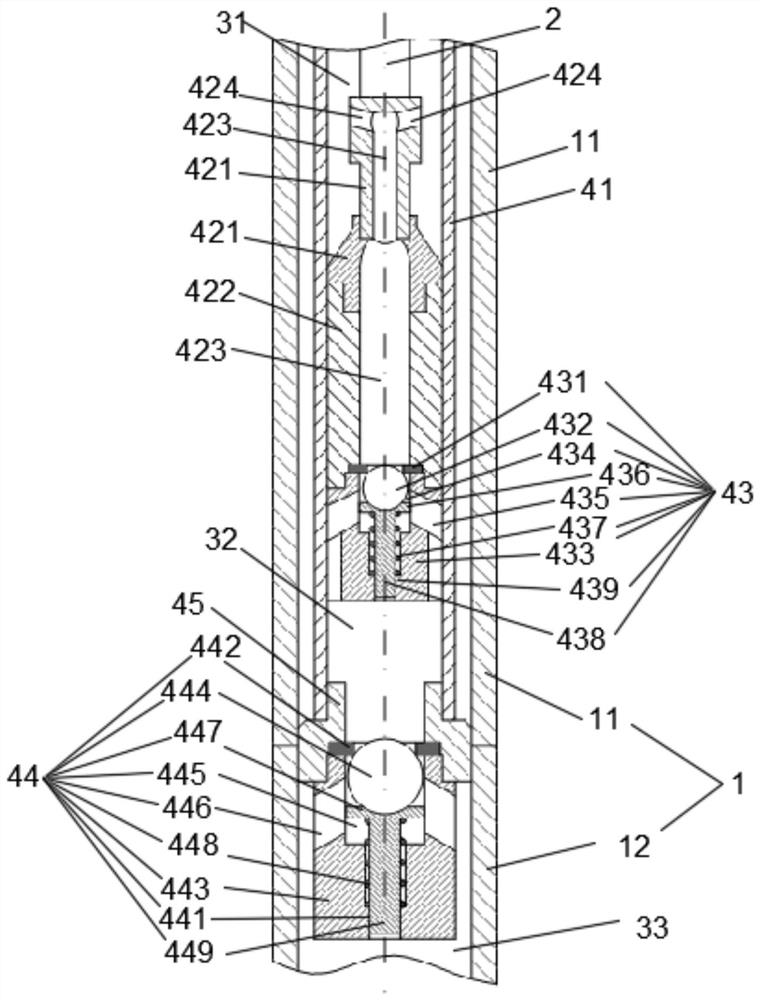

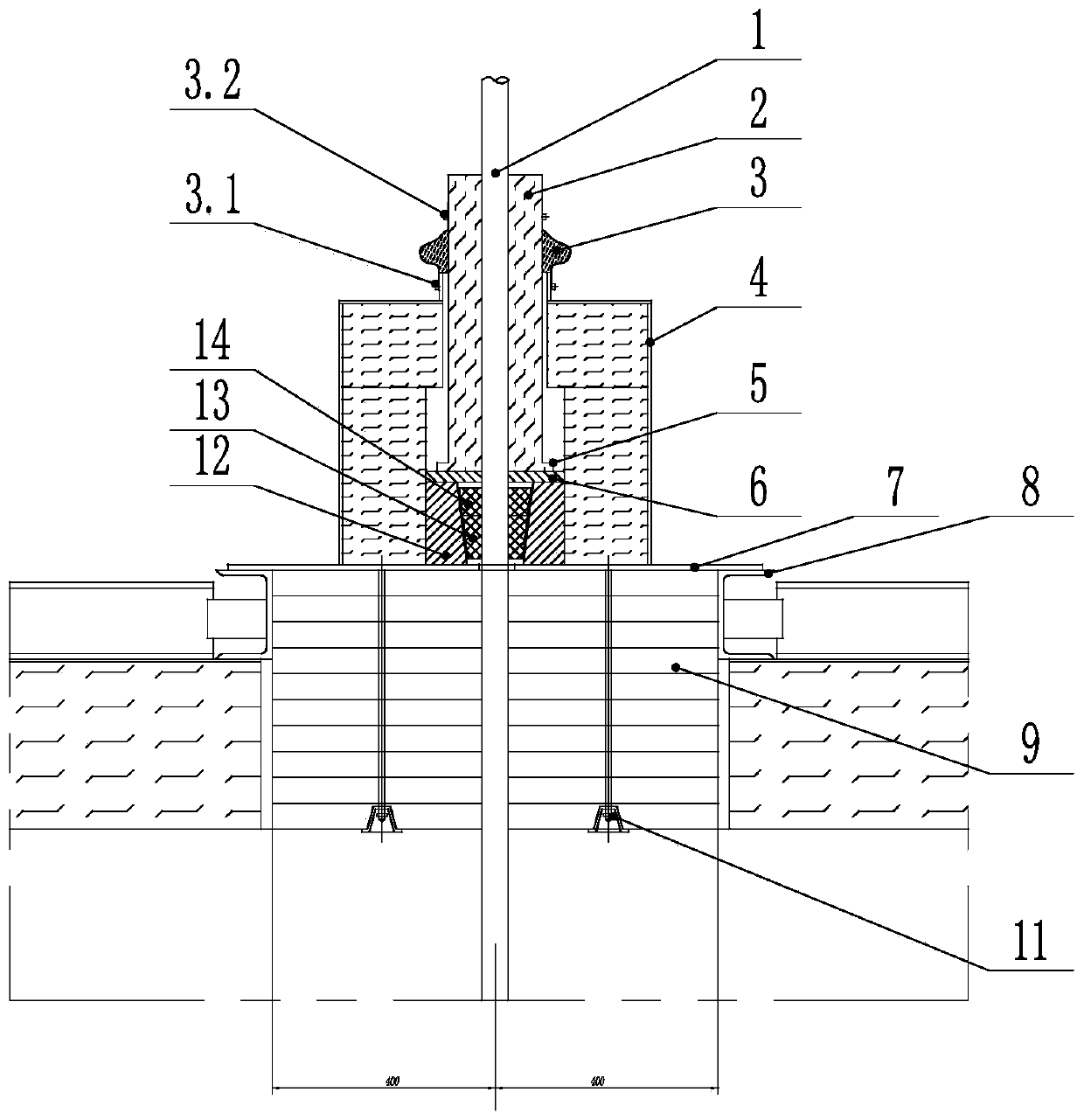

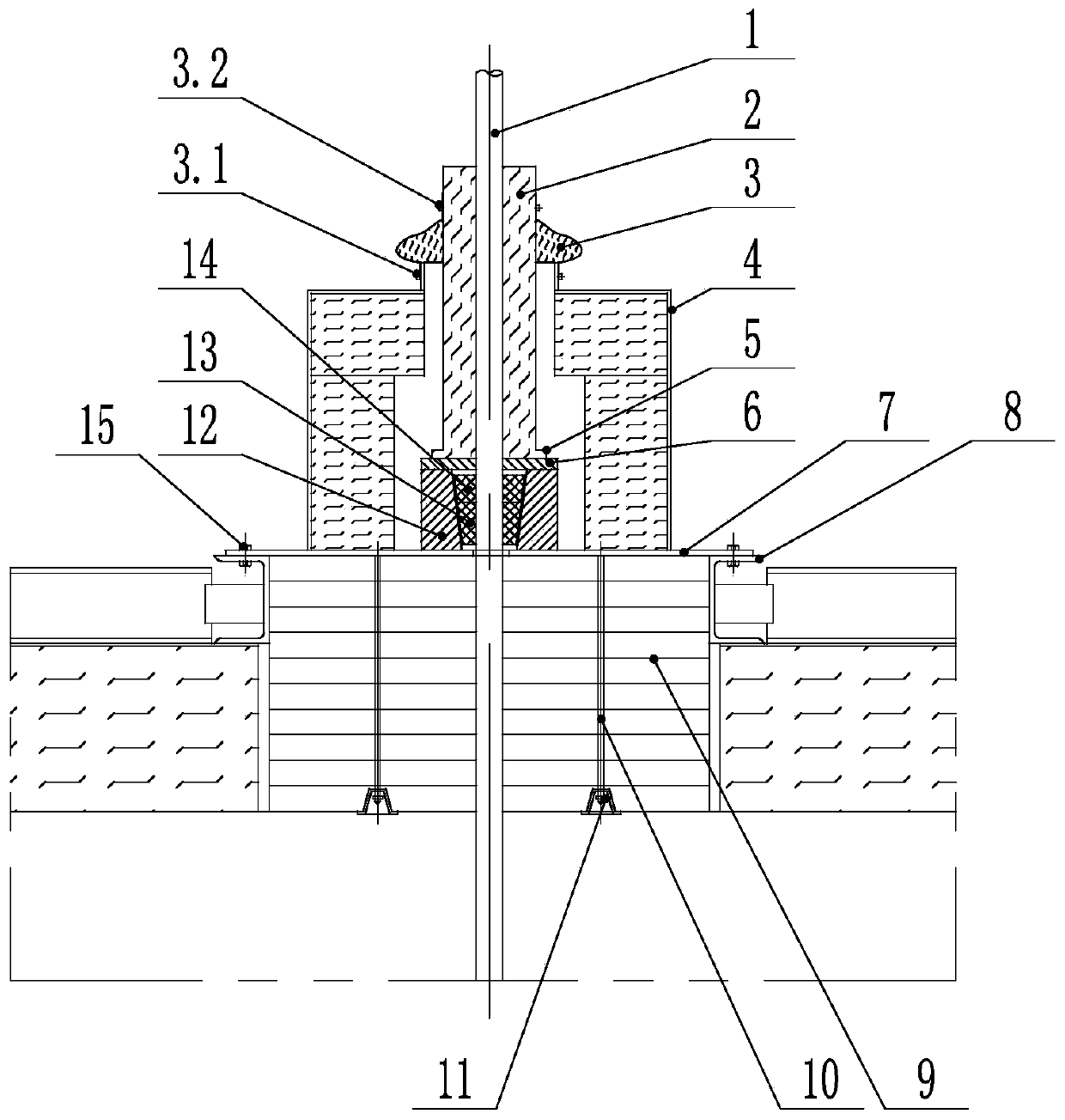

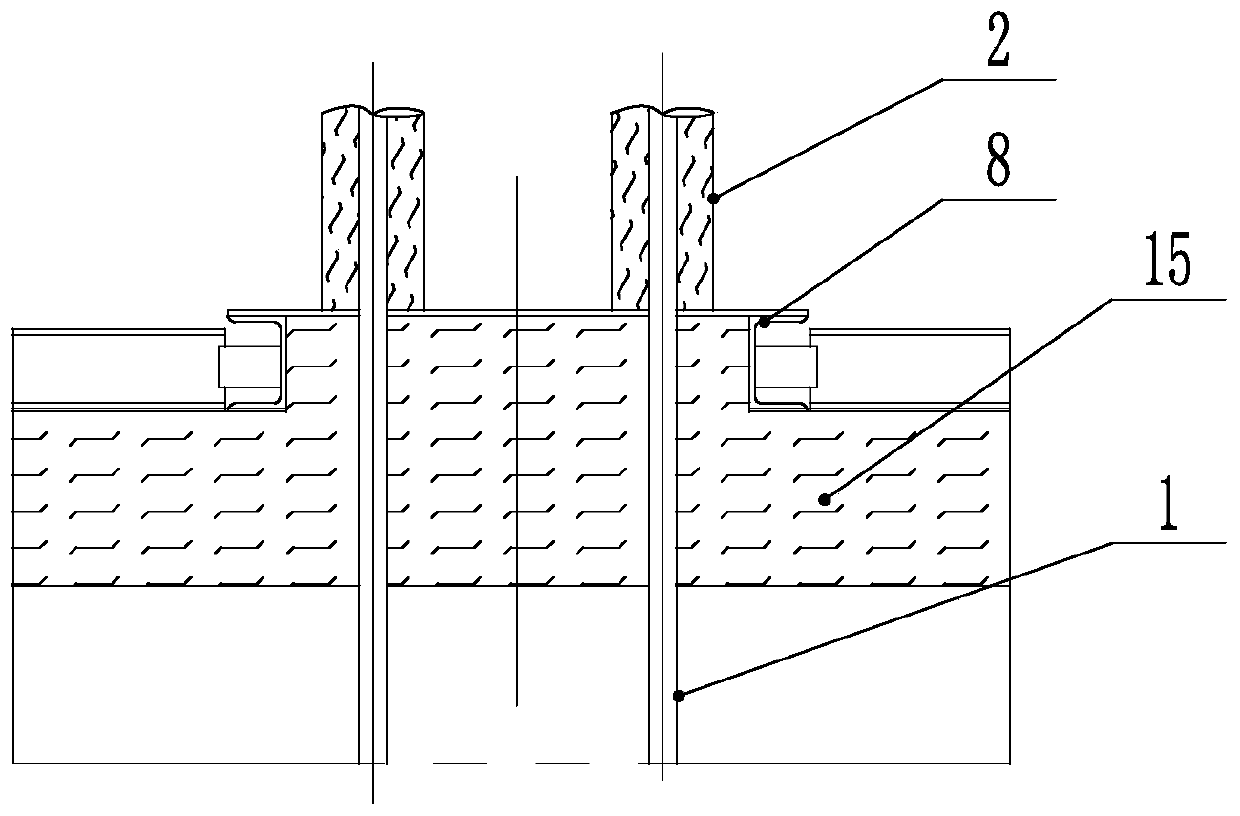

Downhole pressurizing water injection device and method

PendingCN112302590AWater injection safetyImprove reliabilityPositive displacement pump componentsFluid removalWater wellPiston

The invention discloses a downhole pressurizing water injection device. The downhole pressurizing water injection device comprises a water injection pipe, a water injection rod column, a driving device, a piston type pressurizing device, a wellhead connector and a water supply device, wherein the water injection pipe is arranged inside a well, the lower end of the water injection pipe communicateswith an oil layer, the piston type pressurizing device is fixedly connected to the inner wall of the water injection pipe and the connecting portion is sealed, the bottom end of the water injection rod column is fixedly connected with a piston of the piston type pressurizing device, the wellhead connector is arranged at a wellhead, the top end of the water injection pipe is connected with the wellhead connector in a sealed mode, the top end of the water injection rod column upwards penetrates out of the wellhead connector and then is connected with the driving device, the driving device and the water supply device are both arranged on the ground of the wellhead, and the water supply device communicates with the water injection pipe. The invention further provides a downhole pressurizing water injection method adopting the above downhole pressurizing water injection device. According to the downhole pressurizing water injection device and method, a ground pressurizing device is not needed, more safety is achieved, and technical support is provided for water injection failure and remote well single well tank water injection caused by the fact that a mechanical production well is converted into a water injection well and the wellhead pressure of the water injection well is high.

Owner:PETROCHINA CO LTD

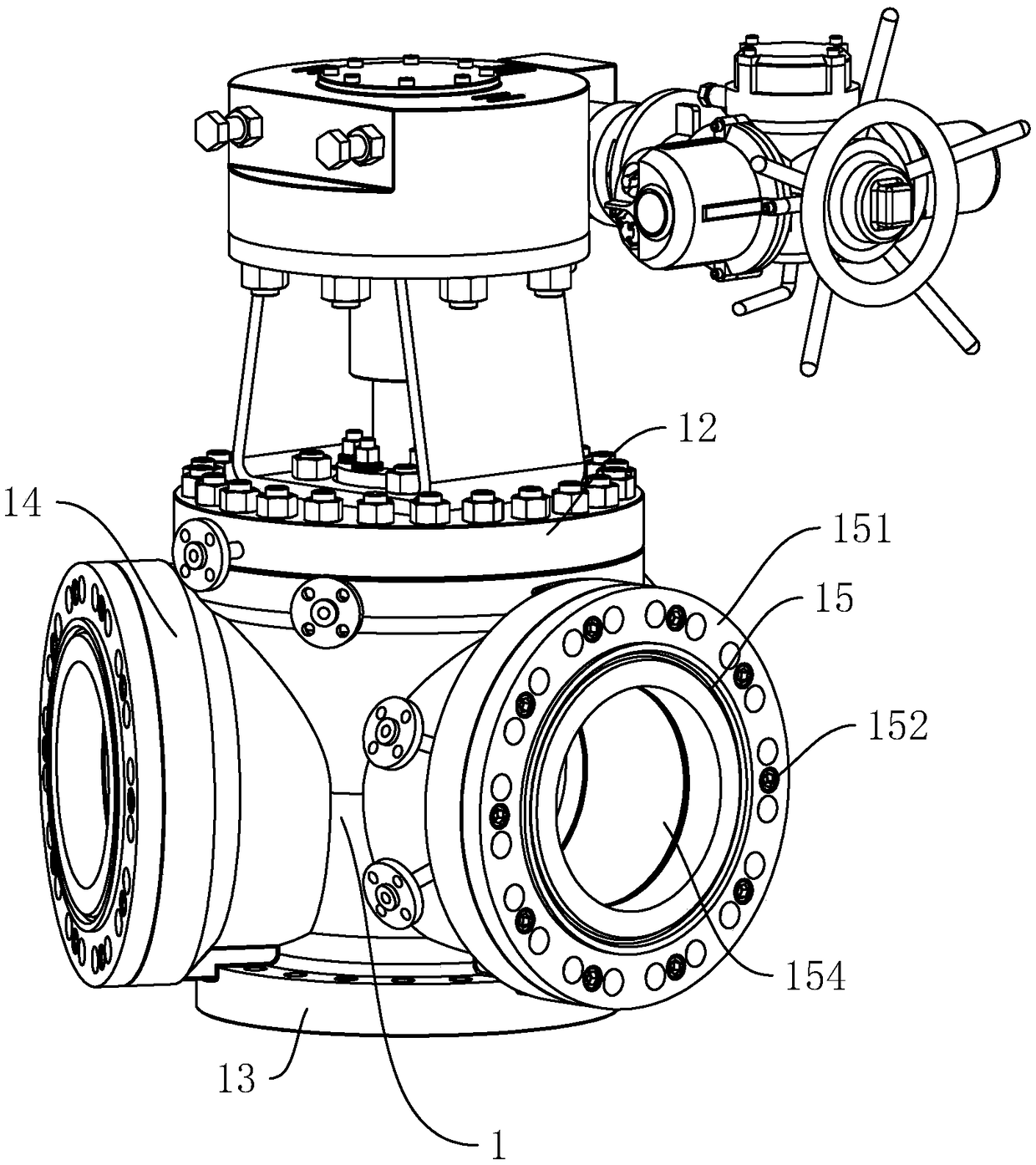

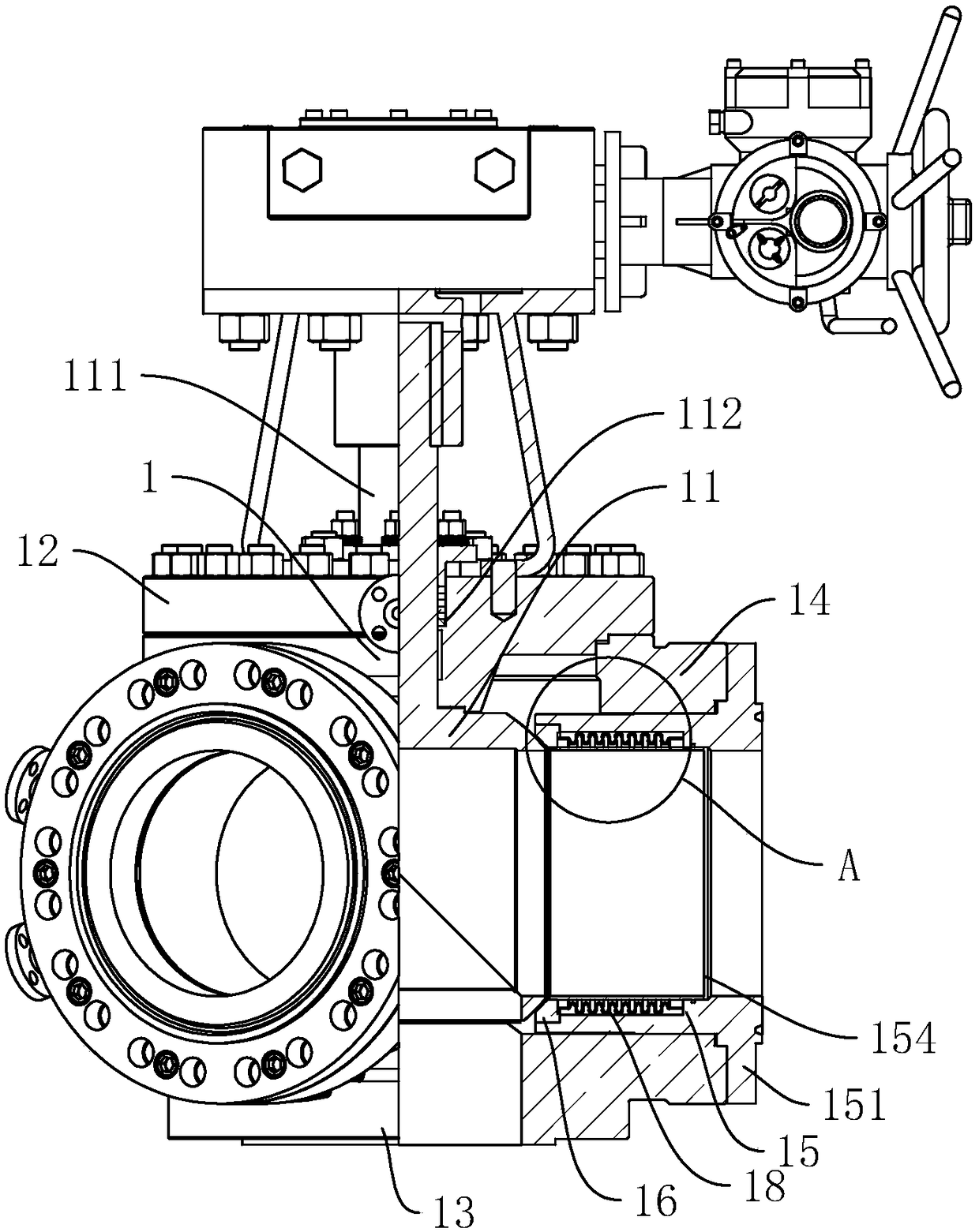

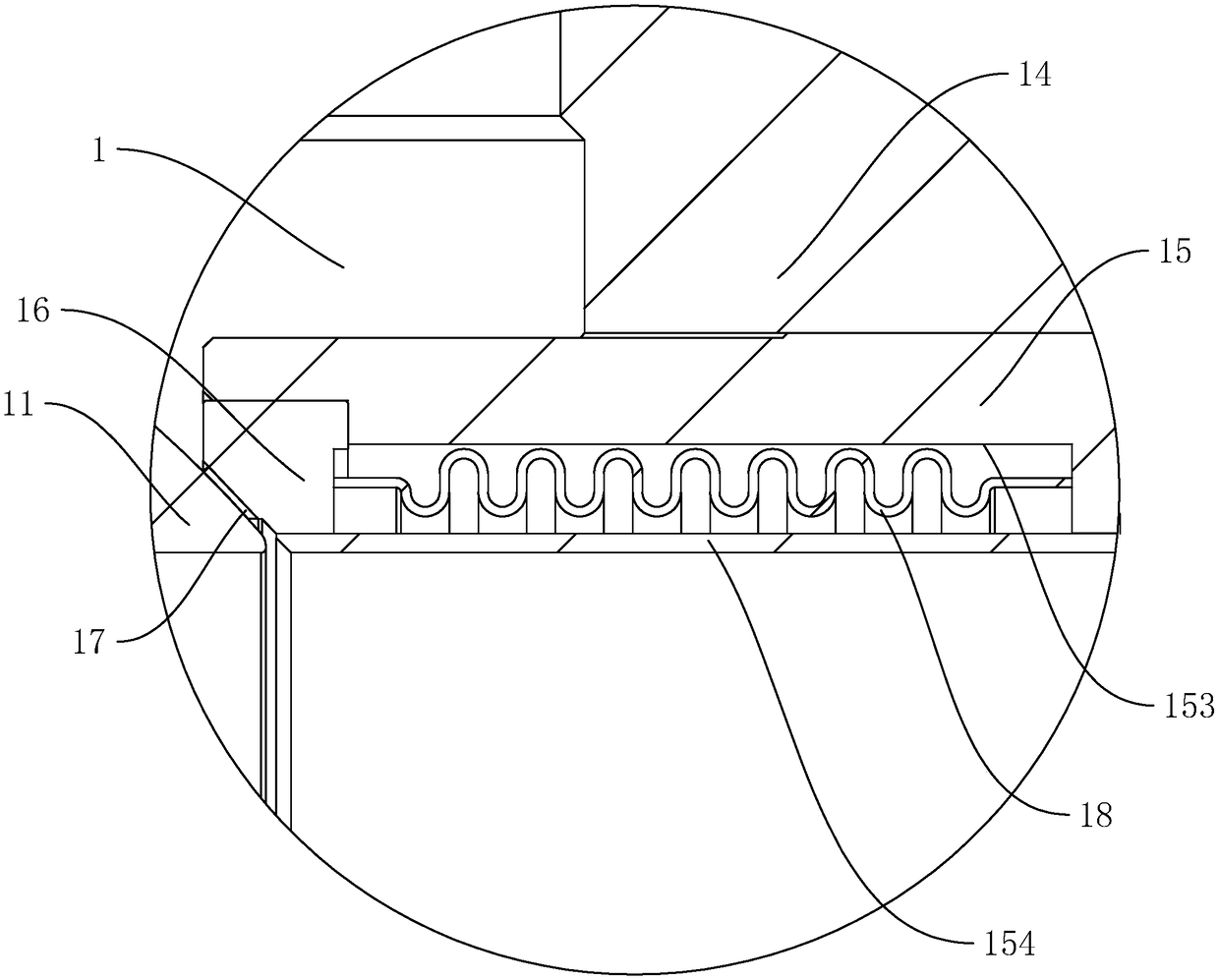

Multi-channel high-temperature all-metal sealing ball valve

InactiveCN108980415AAvoid corrosionIncrease elasticityPlug valvesMultiple way valvesEngineeringTemperature resistance

The invention discloses a multi-channel high-temperature all-metal sealing ball valve, and relates to valves. The multi-channel high-temperature all-metal sealing ball valve aims at solving the problem that in the prior art, due to limitation of a sealing piece, the high-temperature resistance is insufficient. According to the key points of the technical scheme, the multi-channel high-temperatureall-metal sealing ball valve comprises a valve body, a ball arranged in the valve body and a valve cover used for sealing the upper end of the valve body; the valve body is provided with an inlet connecting pipe and at least two outlet connecting pipes; the outlet connecting pipes are fixedly provided with valve sleeves, valve seats are arranged at the ends, facing the ball, of the valve sleeves,and the valve seats are provided with scrapers; and the scrapers are attached to the spherical surface of the ball, and the valve seats are provided with corrugated pipes used for pushing the valve seats. According to the multi-channel high-temperature all-metal sealing ball valve, under the premise of ensuring sealing performance, application of materials such as rubber with the insufficient high-temperature resistance is avoided, thus the high-temperature resistance of the multi-channel high-temperature all-metal sealing ball valve is improved, and the multi-channel high-temperature all-metal sealing ball valve can be used normally in the 650 DEG C high temperature environment.

Owner:WUZHOU VALVE

Dynamic sealing gas gate valve

The invention discloses a dynamic sealing gas gate valve which comprises a valve body, a gate valve plate and a cylinder, wherein both sides of the gate valve plate of the valve body are provided with sealing boxes of the gate valve plate; the sealing boxes are provided with electric connecting pressure gauges; and the valve body is provided with a mobile sealing ring and a guidance device of thegate valve plate. The invention has the advantages that: when the valve is closed, the mobile sealing ring is pressed tightly on the valve plate due to the action of oil pressure in order to ensure tight sealing between the valve plate and the valve body and leakage; when the valve needs opening, a gas cylinder relieves pressure, hydraulic oil refluxes; the mobile sealing ring is depressurized, the valve plate is easily opened for realizing dynamic sealing of the valve; both sides of the gate valve plate of the valve body are provided with the sealing boxes which ensure that only a small quantity of gas leaks in the sealing boxes rather than outside the valve body in the processes of opening and closing the gate valve plate; moreover, the sealing boxes are provided with the electric connecting pressure gauges for detecting gas leakage, executing early warning and ensuring system safety; and the valve body is provided with the guidance device of the gate valve plate for ensuring that the gate valve plate is flexibly opened and closed without blockage.

Owner:HUNAN JINZHONG ENVIRONMENTAL PROTECTION EQUIP CO LTD

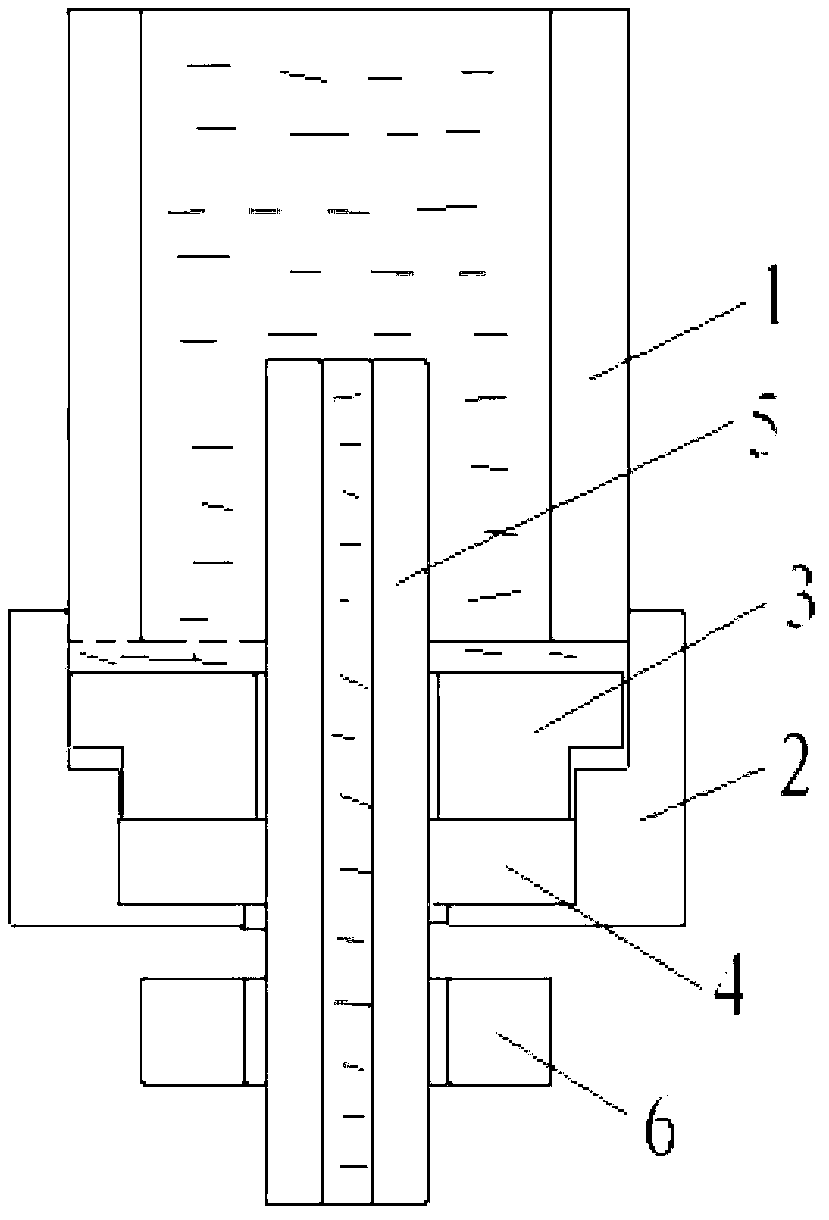

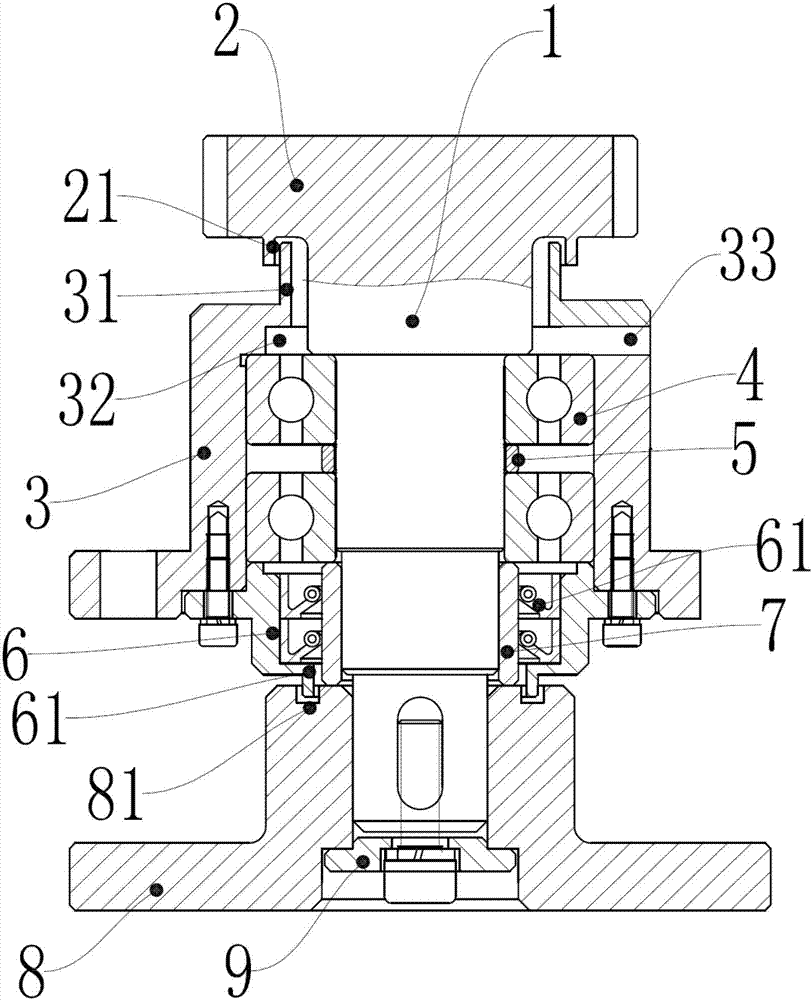

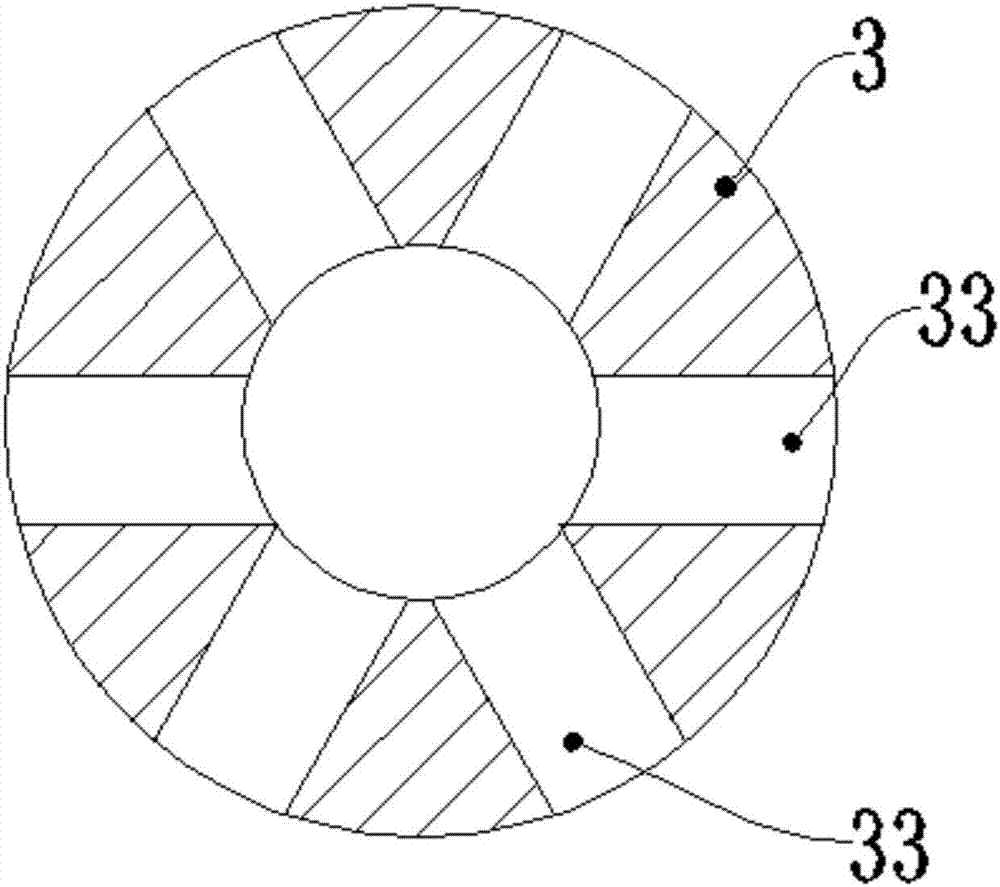

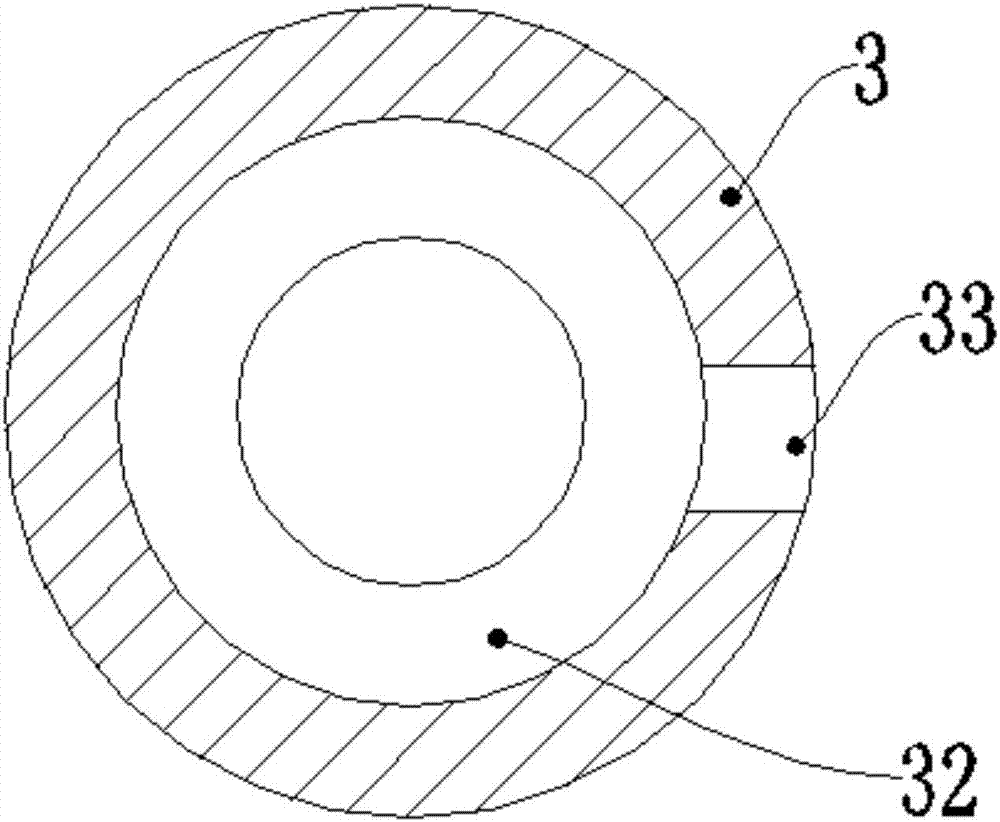

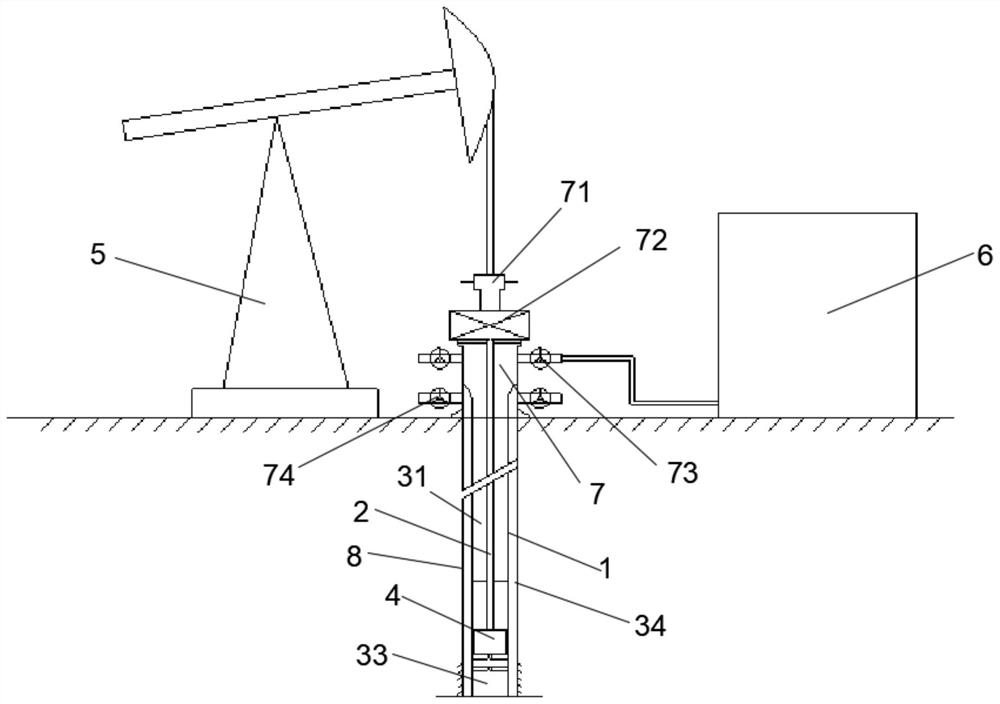

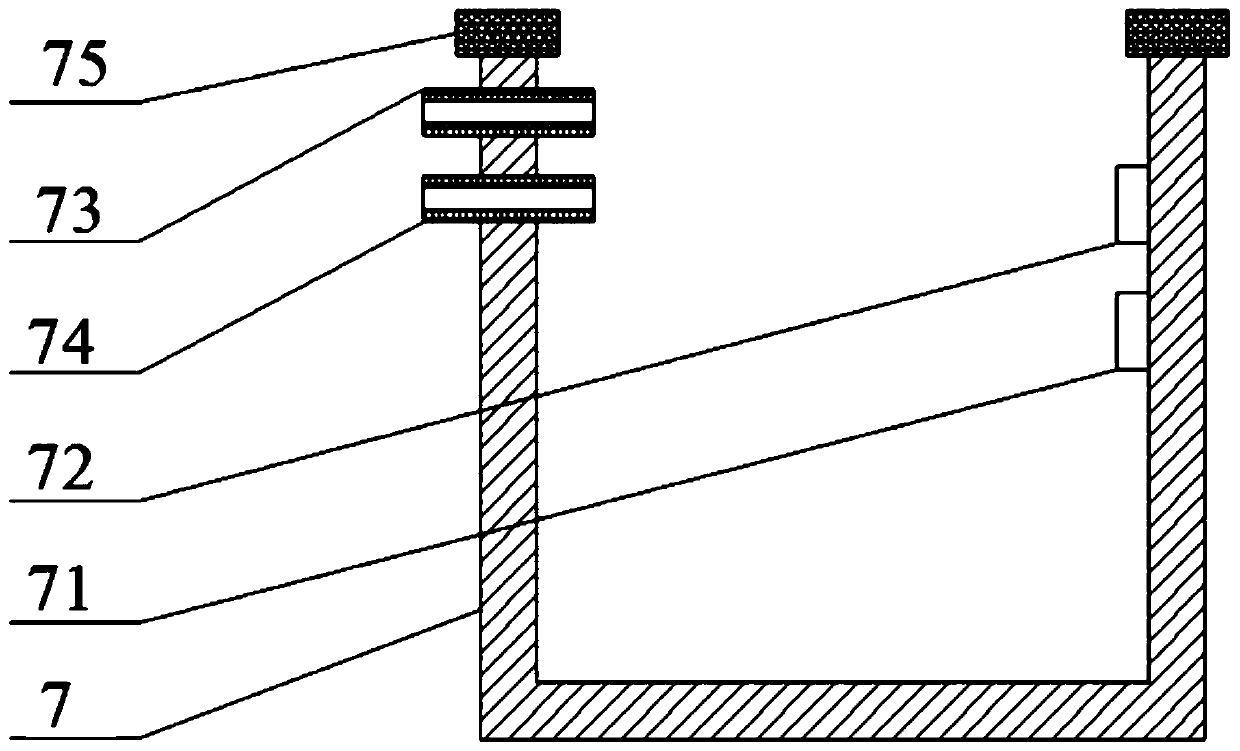

Hydraulic well sealing device

InactiveCN103089190AAchieving a dynamic sealAchieving tightnessSealing/packingEngineeringMechanical engineering

The invention relates to a wellhead hydraulic automatic sealing device, in particular to a hydraulic well sealing device. The hydraulic well sealing device comprises an upper body and a lower body. The upper body and the lower body are connected to form an H shape. A rubber cylinder body is further connected with the upper body and the lower body. A rubber cylinder frame is arranged between the rubber cylinder body and the lower body. The rubber cylinder frame is combined with the lower body through an O-shaped sealing ring to form a closed annular space. One side of the lower body is provided with a joint. The hydraulic well sealing device is high in sealing pressure and a safety factor, simple in structure, convenient to install, favorable for pressure discharging, capable of reducing environment pollution, improving production efficiency and reducing operation cost, long in service life and reusable.

Owner:濮阳市中发石油机械有限公司

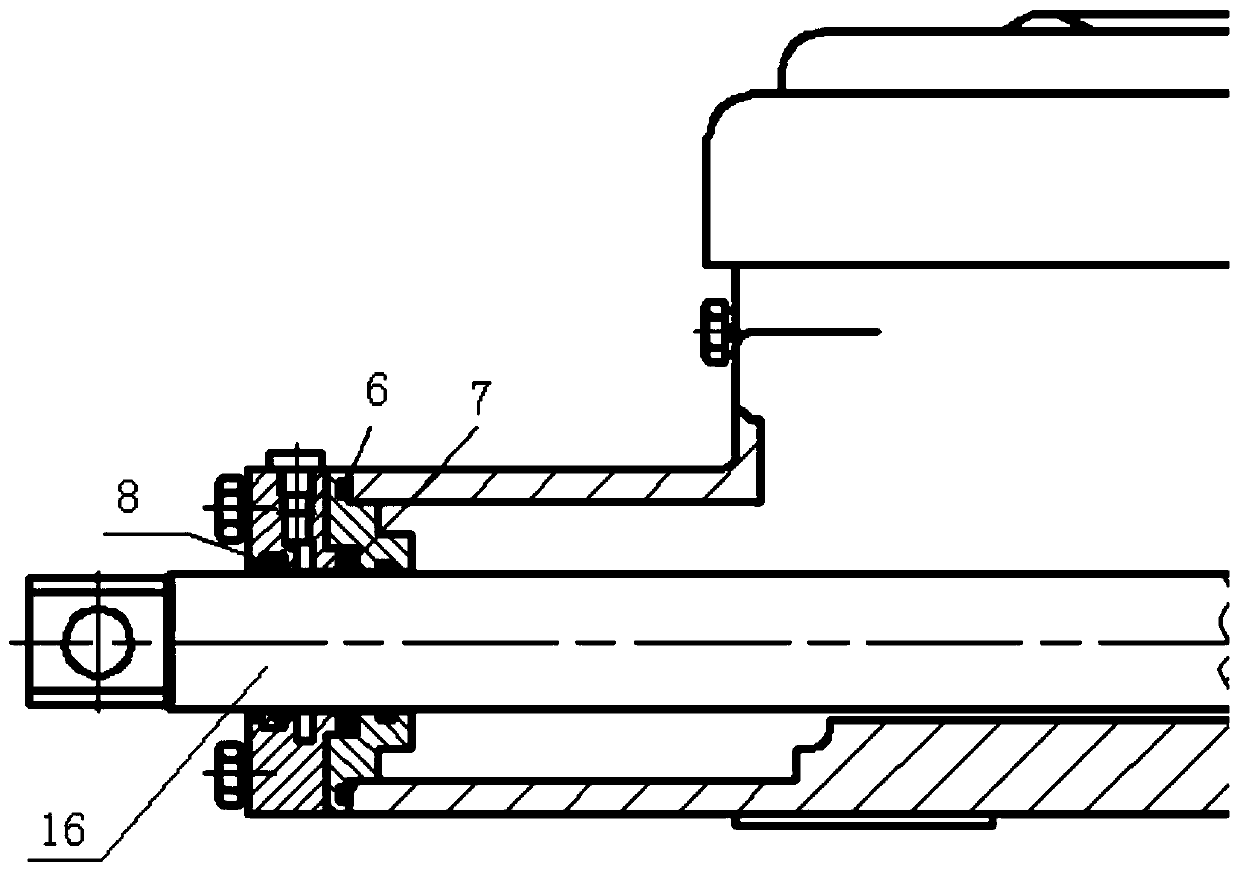

Turnout close-fitting inspection rod device and turnout close-fitting inspector

PendingCN111452833AAdjustable strokeAccurate and reliable reflectionRailway auxillary equipmentRailway profile gaugesEngineeringStructural engineering

The invention discloses a turnout close-fitting inspection rod device. The turnout close-fitting inspection rod device comprises an inspection rod, and a close-fitting position detection unit and a repulsion position detection unit which are arranged on the inspection rod; the inspection rod comprises a square rod and a circular rod; a groove is formed in the upper surface of the square rod; the close-fitting position detection unit and the repulsion position detection unit are arranged in the groove along the axial direction of the square rod; the close-fitting position detection unit comprises a first quick-acting piece, the repulsion position detection unit comprises a repelling adjusting base and a second quick-acting piece, the repelling adjusting base is movably fixed to the bottom of the groove, and the side portion of the repelling adjusting base is further provided with a repelling inclined face and a repelling plane which extend to the upper surface of the side wall of the groove. And a displacement sensor information strip is arranged on the outer side wall of the inspection rod. The invention further discloses a turnout close-fitting inspector. The turnout close-fittinginspection rod device and the turnout close-fitting inspector can realize turnout stroke adjustment of the position, away from the point rail, of the check point within the range of 60 mm-175 mm, full stroke monitoring of the position of the check point of the turnout is achieved, good dustproof and waterproof sealing is achieved, and the protection level can reach IP66 or above.

Owner:TAIYUAN JINGFENG RAILWAY EQUIP MANUFCTURING CO LTD

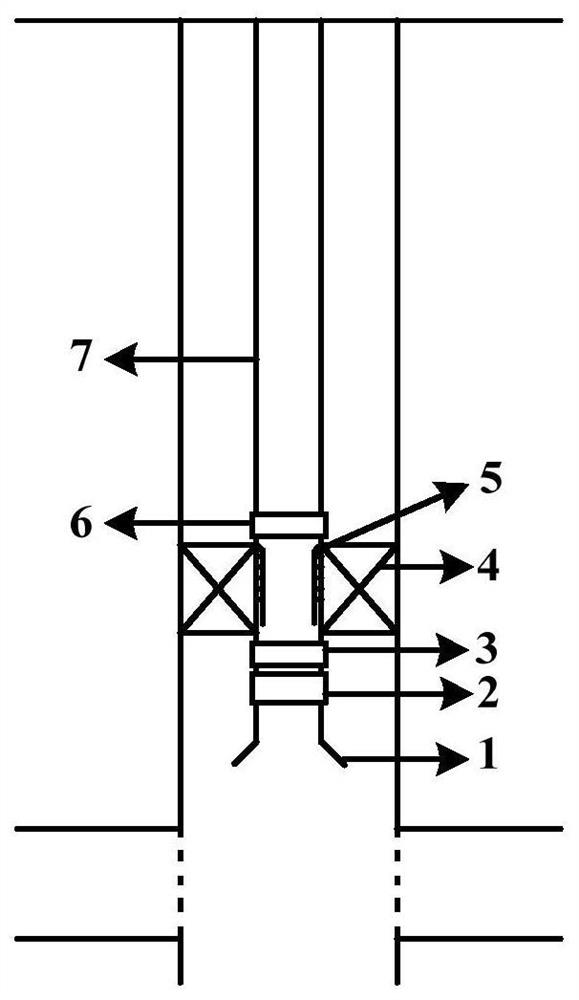

A undermine sealing and righting thrust bearing system

InactiveCN106351948AAvoid interactionExtended service lifeBall and roller bearingsBearing componentsThrust bearingStructural engineering

The invention disclosed a undermine sealing and righting thrust bearing system which consists of shell and bearing bush. The shell is round and the bearing bush is installed into the shell with both sharing the same central point. Between the shell and the bearing bush, there is upper transverse bearing, thrust bearing and lower transverse bearing. At the top of the upper transverse bearing and the bottom of the lower transverse bearing, the dynamic sealing components are equipped which can bear the load from the axial and the radial directions and achieve the righting purpose, especially under various load changing and complex working conditions undermine. The bearing system is an independent system which can be used jointly with features of simple installation and maintenance.

Owner:KINGDREAM PLC CO +1

Continuous sealed high-temperature mesh belt furnace

The invention discloses a continuous sealed high-temperature mesh belt furnace. The continuous sealed high-temperature mesh belt furnace comprises a furnace body and a rack, the continuous sealed high-temperature mesh belt furnace further comprises a feeding propulsion mechanism, a double-door front discharging replacement chamber, a sealed mesh belt driving chamber arranged at the front end of the furnace body, and the continuous sealed high-temperature mesh belt furnace further comprises a furnace body water cooling section, a sealed mesh belt rotating chamber, a sealed discharging driving roller set, a double-door rear discharging replacement chamber, a material moving mechanism and a material circulating conveying mechanism arranged at the rear end of the furnace body. According to themesh belt furnace, all the parts are connected in a sealed mode, especially the parts connected with the front portion and the rear portion of the furnace body in a sealed mode, sealing of the mesh belt furnace is achieved, and compared with an open-type mesh belt furnace, the gas consumption can be reduced, and the atmosphere using cost is saved.

Owner:湖南汉冶科技有限公司

Internal shaping cooling device for PVC biaxial oriented pipe

The invention belongs to the technical field of PVC pipe cooling equipment, and particularly relates to an internal shaping cooling device for a PVC biaxial oriented pipe. The internal shaping coolingdevice comprises a water ring, wherein a water inlet connector is arranged on the outer circumference of the water ring; water outlet holes are formed in the inner wall of the water ring, a sponge sleeve is arranged on one side of the inner wall of the water ring, and a front ring pressing plate and a rear ring pressing plate are arranged at the two ends of the water ring correspondingly; and supporting assemblies and a connecting plate are arranged outside the water ring, a guide column is arranged between the supporting assemblies, the connecting plate is provided with a guide column sleeve, the water ring can freely move along the guide column through the guide column sleeve arranged on the connecting plate, and the connecting plate is connected with the supporting assemblies through an arranged lead screw. According to the internal shaping cooling device for the PVC biaxial oriented pipe, the lead screw enables the water ring to move to finely adjust the pipe diameter, the front ring pressing plate and the rear ring pressing plate clamp an elastic sealing ring to limit the elastic freedom degree of the elastic sealing ring, and the heating and cooling boundary of an orientation part can be accurately adjusted according to needs, so that the production process is guaranteed; and the structure is simple, cost is low, and dismounting and mounting are convenient, so that application and popularization are facilitated.

Owner:XINJIANG TIANYE GRP

Humidifier for proton exchange membrane fuel cell

Owner:BEIJING SHOTO ENERGY STORAGE TECH CO LTD

Sealing system of radiation chamber furnace tube of tube-type heating furnace

InactiveCN109708472AImprove sealingThe sealing effect is maintained continuouslyFurnace typesElectric heating for furnacesEngineeringSlide plate

The invention relates to a sealing system of a radiation chamber furnace tube of a tube-type heating furnace, and belongs to the technical field of tube-type heating furnace sealing. The sealing system comprises a furnace top sliding plate arranged around the furnace tube, wherein the furnace top sliding plate is used for slip connection with a furnace top; a sealing element surrounding the furnace tube is arranged on the furnace top sliding plate; a heat preservation sleeve is arranged above the sealing element around the furnace tube; a sealing box is arranged outside the sealing element andthe heat preservation sleeve; the heat preservation sleeve extends out from the sealing box; the sealing element comprises a sealing base; the bottom of the sealing base is connected to the furnace top sliding plate; a taper hole is formed in the sealing base in a longitudinal direction and penetrates the sealing base; a taper sealing element is arranged in the taper hole and is matched with thetaper hole; the upper end of the taper hole has a big opening; the taper sealing element is set as split type taper sealing elements arranged around the furnace tube; the split type sealing elements are not fixedly connected to each other; a pressure plate is arranged above the sealing base; and the heat preservation sleeve is arranged above the pressure plate. The radiation chamber furnace tube sealing system has a simple structure and a good sealing effect.

Owner:王振清 +1

The usage method of intelligent dynamic sealed liquid storage tank with flexible capsule

ActiveCN103523405BAchieve intrusionFor long-term storageTransformers/inductances coolingSolenoid valveLiquid storage tank

The invention relates to an intelligent dynamic sealing liquid storage tank with a flexible capsule and a using method of the intelligent dynamic sealing liquid storage tank with the flexible capsule. A liquid inlet and a venting port are formed in the upper portion of the liquid storage tank, a liquid inlet solenoid valve is arranged on the liquid inlet, a vent valve is arranged on the venting port, and a liquid outlet is formed in the lower portion of the liquid storage tank. A liquid outlet solenoid valve and on-line moisture detectors are sequentially arranged on the liquid outlet in the liquid outlet direction. An air tube and an electric contact liquid level meter are further arranged on the liquid storage tank, the flexible capsule is arranged in the liquid storage tank, and the surface of the capsule is surrounded by liquid. An inner cavity of the flexible capsule is communicated with outside atmosphere through the air tube, and the liquid inlet solenoid valve, the liquid outlet solenoid valve, the on-line moisture detectors and the electric contain liquid level meter are electrically connected to a control module. Due to the fact that the inner cavity of the flexible capsule is communicated with the outside atmosphere through the air tube, the breathing effect of the flexible capsule plays a role in compensating and balancing volume changes caused by changes of the liquid level in the liquid storage tank, and dynamic sealing is achieved.

Owner:STATE GRID CORP OF CHINA +3

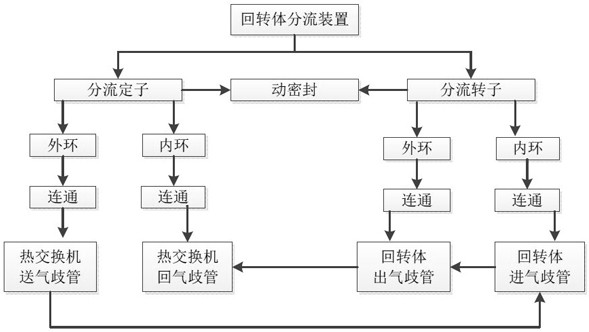

Revolving body shunting device

ActiveCN113847835ASolve the entanglementAchieving a dynamic sealHeat exhanger sealing arrangementHeat exchanger casingsShunt DeviceMechanical engineering

The invention discloses a revolved body shunting device. The revolved body shunting device comprises a heat exchanger, a shunting stator, a shunting rotor, a dynamic seal and a revolved body, the shunting stator communicates with the heat exchanger through an air supply manifold and an air return manifold, the shunting stator comprises a first inner ring channel and a first outer ring channel, the shunting rotor communicates with the revolved body through an air inlet manifold and an air outlet manifold, the shunting rotor comprises a second inner ring channel and a second outer ring channel, the first inner ring channel is connected with the second inner ring channel, the first outer ring channel is connected with the second outer ring channel, dynamic seals are arranged between the first inner ring channel and the second inner ring channel and between the first outer ring channel and the second outer ring channel for sealing, the outer ring channel communicates with the inner ring channel, and the inner ring channel does not communicate with the outer ring channel. According to the revolved body shunting device, dynamic shunting exchange of the revolved body is realized, the problem of winding of pipelines of the revolved body is solved, dynamic sealing of the pipelines is realized, liquid exchange and shunting exchange of the revolved body at different rotary angles can be carried out, and the revolved body can rotate within 360 degrees at the rotary angle.

Owner:凯迈(洛阳)测控有限公司

a co 2 String Structure of Gas Flooding and Injection Process

ActiveCN107605443BImprove airtight performanceImprove work efficiencyFluid removalSealing/packingWell killCo2 flooding

The invention discloses a pipe column structure for the CO2 flooding gas injection process. The pipe column structure comprises a guiding shoe, a check valve, a setting ball seat, a Y445 packer, an inserting pipe, a reverse circulation valve and an oil pipe. The guiding shoe is connected with the check valve; the upper end of the check valve is connected with the setting ball seat; the upper end of the setting ball seat is connected with the Y445 packer; the Y445 packer is connected with the inserting pipe; and the upper end of the inserting pipe is connected with the reverse circulation valveand the oil pipe in sequence. During working, the parts are connected in sequence, a pipe column is put downwards, an annulus is filled with a conventional oil-based annulus protection fluid in a reverse circulation mode, a quick-dissolving soluble ball is put, pressure injection for setting is conducted, and thus gas can be injected normally; when the pipe column is taken out, through the checkvalve, the oil pipe is directly emptied so that pressure can be released, the pipe column is lifted up, the inserting pipe is pulled out, and thus a pipe string can be taken out; if pressure relief ofthe oil pipe fails, a well killing fluid is injected in a reverse circulation mode for well killing, then the pipe column is lifted up, and thus the pipe string can be taken out; after pipe string checking work, the parts are connected in sequence, the pipe column is put downwards, the inserting pipe is inserted into the packer, and thus sealing well-completion can be conducted.

Owner:PETROCHINA CO LTD

Valve sealing gasket for new energy automobile cooling system

PendingCN114658850AAchieving a dynamic sealAchieving a static sealEngine sealsRotational axisFriction torque

The invention provides a valve sealing gasket for a new energy automobile cooling system. The valve sealing gasket comprises a sealing gasket base body and a PTEF diaphragm framework. A through hole is formed in the middle of the sealing gasket base body in a penetrating mode, the first side face of the sealing gasket base body protrudes outwards to form an inner sealing rib annularly arranged around the through hole, and the second side face of the sealing gasket base body protrudes outwards to form an outer sealing lip annularly arranged around the through hole. The PTEF diaphragm framework is connected with the first side face of the sealing gasket base body and wraps the inner sealing rib. According to the sealing gasket, the rigidity can be effectively reduced, meanwhile, bidirectional self-tightening sealing can be achieved, the sealing effect is guaranteed, meanwhile, the PTEF diaphragm framework wraps the first side face of the sealing gasket base body to make contact with the rotating shaft core, the PTEF diaphragm framework makes direct contact with the rotating shaft core, the abrasion resistance of the sealing gasket is effectively improved, the friction torque is reduced, and the performance requirement of the sealing gasket is met.

Owner:ANHUI ZHONGDING SEALING PARTS

A push button switch with double redundant overtravel and full sealing function

The invention provides a button switch with a dual-redundancy overtravel and a full sealing function. The button switch comprises a shell, an upper seat, an overtravel mechanism and a base assembly, wherein the upper seat, the overtravel mechanism and the base assembly are all mounted in a limiting block; the upper seat and the overtravel mechanism at the middle part of the shell; the base assembly is mounted at the lower end of the limiting block; reset devices are arranged between the upper seat and the overtravel mechanism and between the limiting block and the base assembly; and a sealingdevice is arranged on the shell. The button switch is capable of normally working under the condition of unbalance load pressing, so that the reliability of the switch is ensured.

Owner:GUIZHOU ZHENHUA HUALIAN ELECTRONICS

Liquid oxygen environment fatigue testing system and method

ActiveCN110411875AAchieving a dynamic sealDischarge safetyFluid pressure measurementMachines/enginesElectro hydraulicEngineering

The invention provides a liquid oxygen environment fatigue testing system which is high in leak tightness and safety, and a method using the testing system. The testing system comprises a fatigue testing device, a liquid oxygen environment control unit, a liquid oxygen environment sealing unit and a liquid oxygen supply unit. The fatigue testing device comprises a rack, an electro-hydraulic servocontroller and the like, wherein the rack comprises a base, a plurality of supporting rods, a piston, an upper transverse beam and a lower transverse beam; the liquid oxygen environment control unit comprises a liquid oxygen environment box, a lifting machine, a liquid level sensor, a pressure sensor, a liquid supply electromagnetic valve and a release valve; the liquid oxygen environment sealingunit comprises a corrugated pipe. When a liquid oxygen environment fatigue test is carried out, the liquid oxygen environment box, the low transverse beam, the piston and the corrugated pipe form a sealed liquid oxygen environment, the liquid level sensor monitors the level of liquid oxygen, and it is ensured that the test is carried out in a stable liquid oxygen environment. The pressure sensor monitors gas pressure in the liquid oxygen environment box and maintains the pressure within a proper range, and dynamic sealing of the liquid oxygen environment is achieved through the corrugated pipe.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Prestress inhaul cable anchorage device with elastic sealing cylinder

PendingCN112942102AAchieving a dynamic sealRealize shock absorption and buffering effectBridge structural detailsBridge materialsScrew threadThermal shrinkage

A prestress inhaul cable anchorage device with an elastic sealing cylinder comprises an anchor head and a sealing device which is connected between the anchor head and a cable body and composed of the elastic sealing cylinder and a sealing lantern ring, and the elastic sealing cylinder is an elastic sealing cylinder I or an elastic sealing cylinder II and is respectively connected with the anchor head and the sealing lantern ring in a threaded or flange connection mode. The elastic sealing cylinder I is a PE sealing cylinder made of a PE material or an HDPE sealing cylinder made of an HDPE material, the two ends of the elastic sealing cylinder I are provided with a thread I and a thread II respectively, the elastic sealing cylinder II is made of thermal shrinkage rubber or the PE material or the HDPE material, one end of the elastic sealing cylinder II is provided with an internal thread II, a hot melting flange is arranged at the joint of the elastic sealing cylinder II and the anchor head, and the elastic sealing cylinder II is connected with the anchor head 1 through a pressing ring and a bolt. Due to the fact that the sealing cylinder of the prestress inhaul cable anchorage device is elastic, the prestress inhaul cable anchorage device can adapt to automatic deviation correction of installation errors, dynamic sealing is achieved, damping and buffering effects are achieved, and construction quality is guaranteed.

Owner:LIUZHOU OVM MASCH CO LTD +1

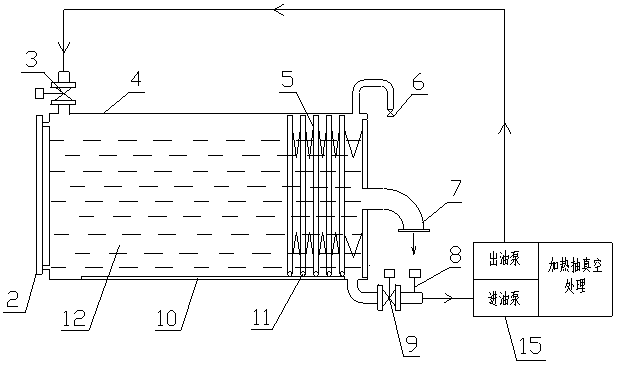

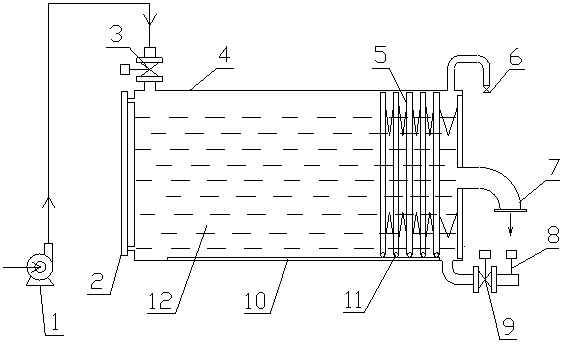

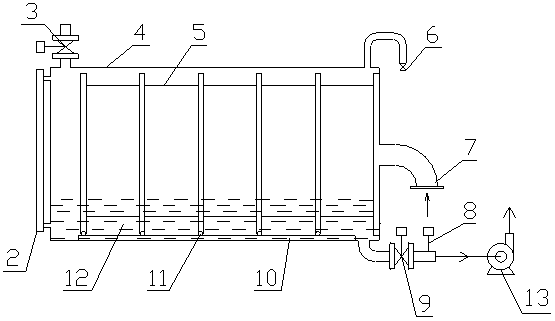

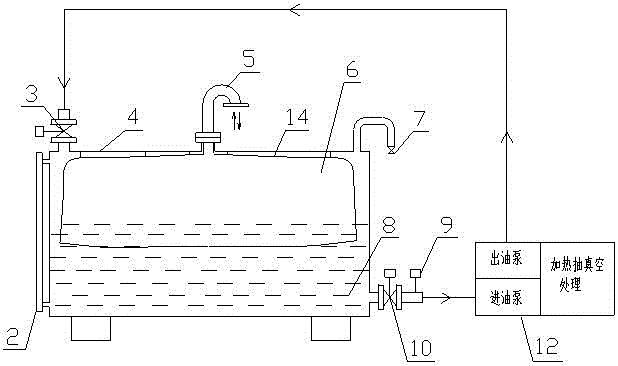

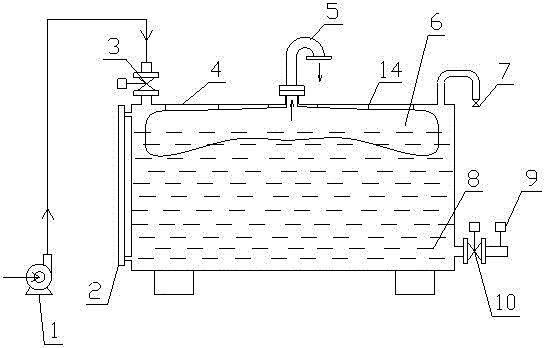

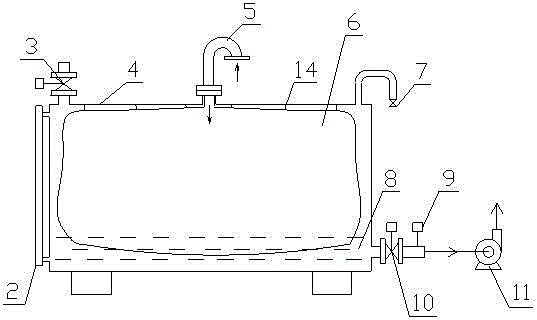

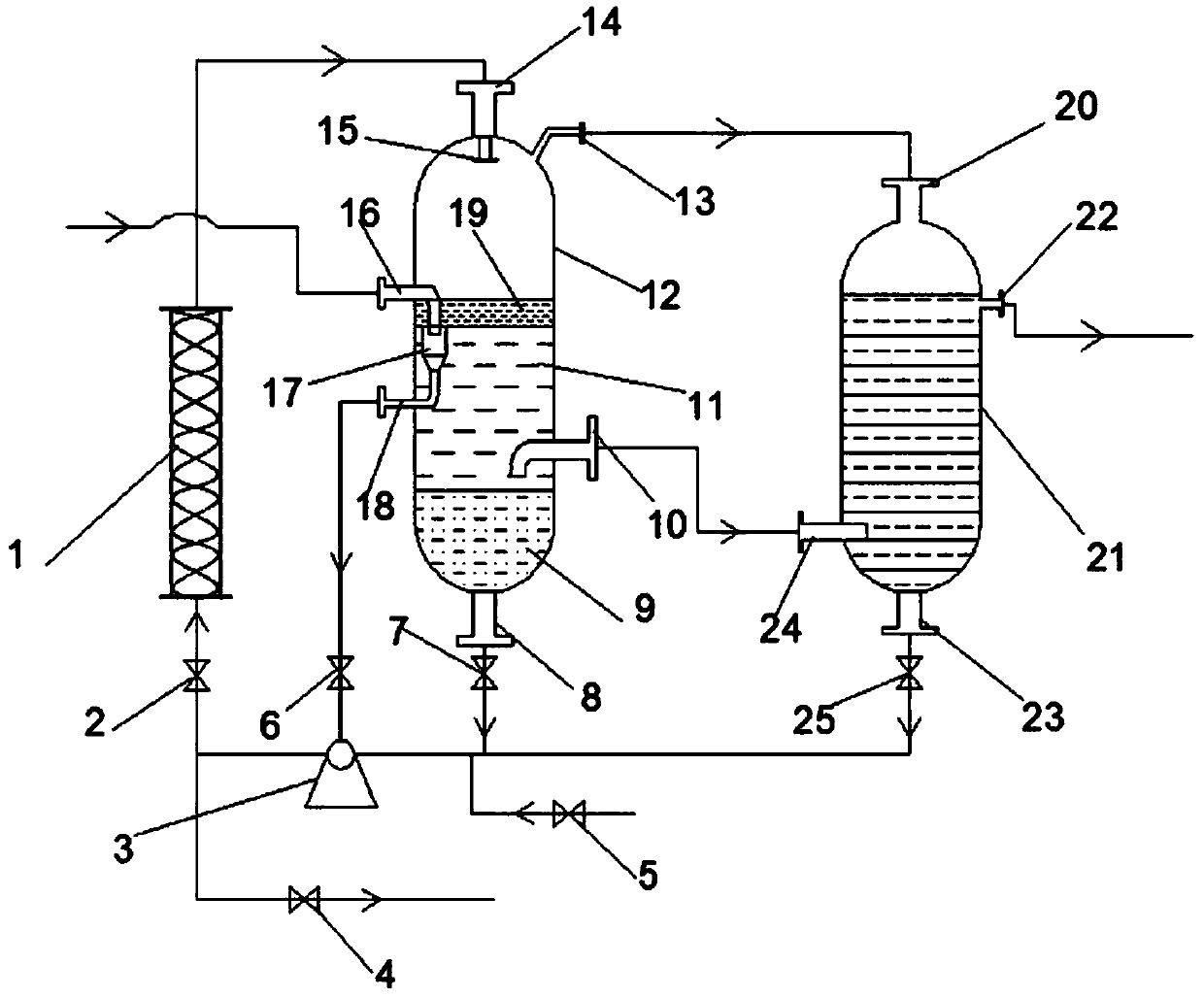

An online rapid refining device for oil products

ActiveCN107129829BReduce refining timeShorten the time of oxidative deteriorationTreatment with plural serial refining stagesLiquid slagEngineering

The invention discloses a rapid online oil refining device which comprises a static mixer, a mixing tank and a depositing tank. An oil inlet of the mixing tank is formed in one side of the mixing tank, the oil inlet in the mixing tank extends downwards to an oil receiving bucket, the oil receiving bucket is connected with an oil outlet of the oil receiving bucket, the oil outlet of the oil receiving bucket is connected with an inlet of a circulating pump, an air guide port of the mixing tank and an oil return port of the mixing tank are formed in the top of the mixing tank, the oil return port of the mixing tank is connected with the static mixer through a pipeline, a refining agent outlet is formed in the bottom of the mixing tank and connected with the inlet of the circulating pump through a pipeline, an outlet of the circulating pump is connected with the static mixer and a precipitation liquid slag discharging pipe through a tee, a refining liquid inlet pipe is arranged at the end of the inlet of the circulating pump, an oil outlet of the depositing tank is formed in one side of the depositing tank, and a precipitation slag discharging port is formed in the bottom of the depositing tank and connected with the inlet of the circulating pump. According to the device, oxidation and deterioration time of oil is shortened, product quality is ensured, and manufacturing and operating cost is reduced.

Owner:郎溪品旭科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com