Internal shaping cooling device for PVC biaxial oriented pipe

A cooling device and biaxially oriented technology, which is applied in the field of PVC pipe cooling equipment, can solve the problems that the straight section of the cone cannot be too long, the thermal retraction force is large, and cannot be moved, so as to reduce the disassembly time, uniform cooling and disassembly. With the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

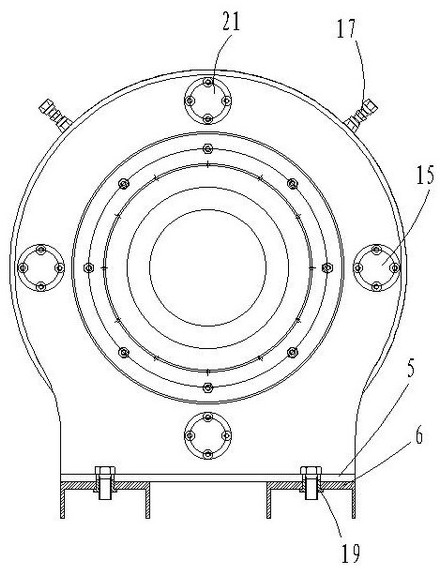

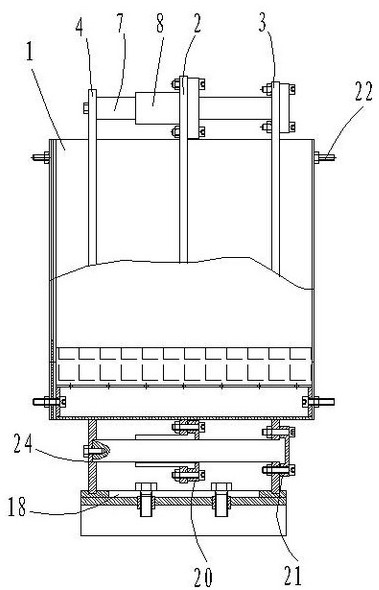

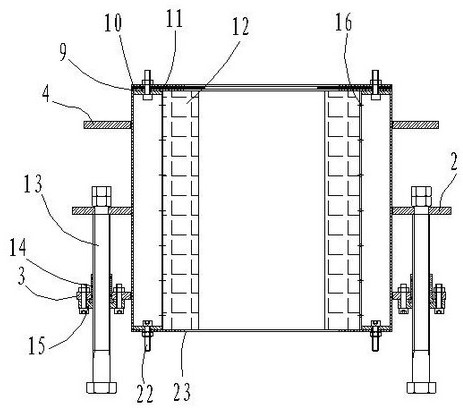

[0029] refer to figure 1 , figure 2 and image 3 , the present invention includes a water ring 1 and a support base plate 5, a support assembly and a connecting plate 2 are arranged outside the water ring 1, the support assembly is connected to the support base plate 5, a strip-shaped installation through hole 18 is provided on the support base plate 5, and the slideway 6 is fixed On the frame, the slideway 6 is provided with a chute, and the slide block 19 can move freely in the chute. A water inlet joint 17 is provided on the outer circumference of the water ring 1 for recycling of cooling water. Water outlet holes 16 are arranged on the inner wall of the water ring 1 , and a sponge cover 12 is arranged on one side of the inner wall of the water ring 1 .

[0030] One end of the water ring 1 is the end face of the inlet pipe, and the end face of the inlet pipe is successively installed with a baffle ring plate 9, an elastic sealing ring 10, and a front pressure ring plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com