An online rapid refining device for oil products

A refining device and fast technology, applied in the field of chemical oil refining, can solve the problems of late contact time between oil products and refined products, high operating and manufacturing costs, and large equipment footprint, so as to shorten the time of oxidative deterioration and save cost and operating costs, reducing the effect of floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further elaborated below in conjunction with the drawings and specific embodiments.

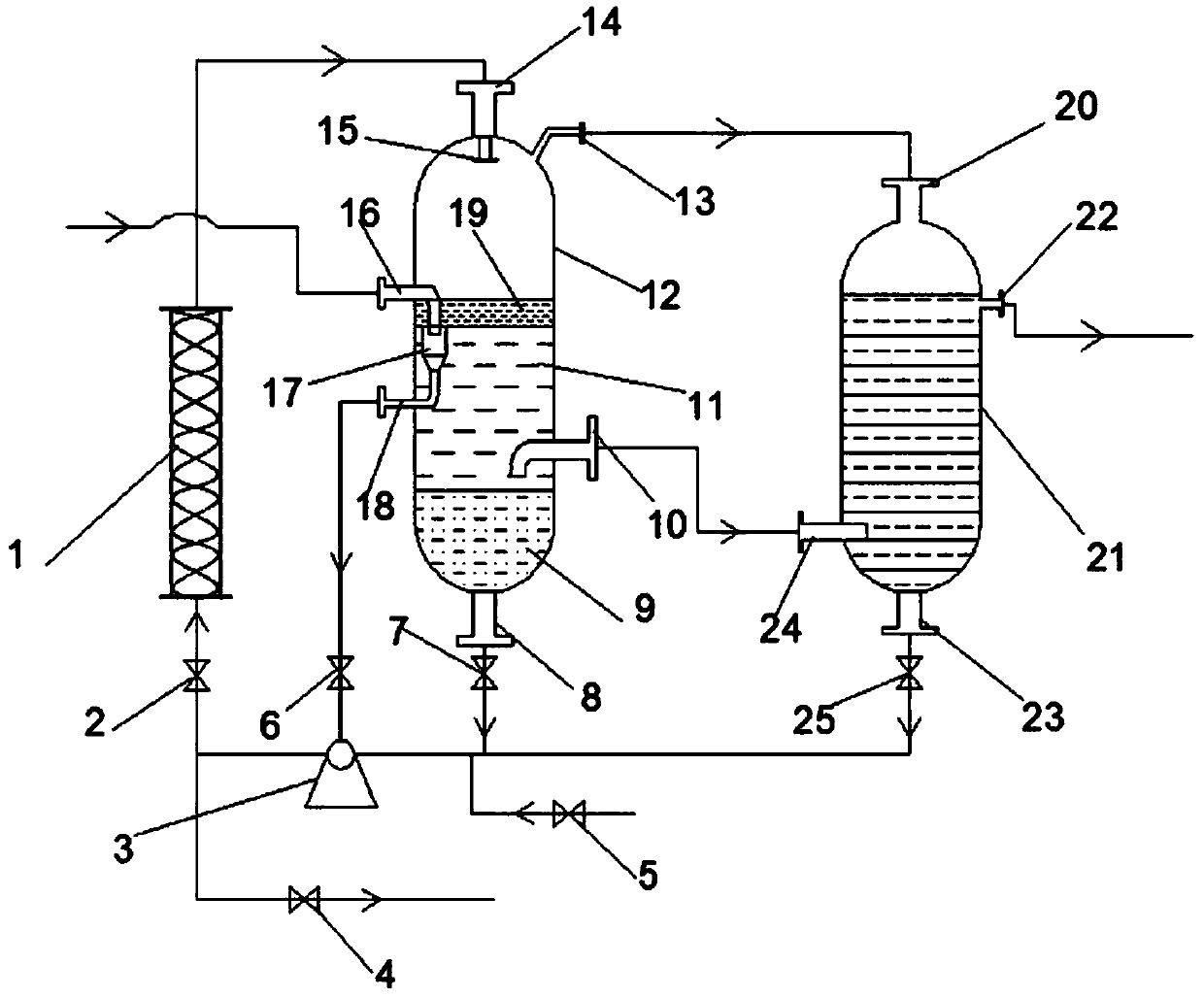

[0012] Such as figure 1 As shown, an on-line rapid refining device for oil products includes a static mixer 1, a mixing tank 12, a precipitation tank 21, and a circulating pump 3. The mixing tank 12 is provided with a mixing tank oil inlet 16 on one side, and the mixing tank receives oil The port 16 extends downwards in the mixing tank 12 through the overflow replenishment area 19 into the oil receiving hopper 17. Below the overflow replenishment area 19 is provided a sedimentation level layer 11, and the essence liquid level 9 is located at the sedimentation level layer 11 At the bottom, the design of the sedimentation level layer reduces the refining liquid residue entering the sedimentation tank. The overflow replenishment area 19 can replenish the problem of insufficient newly produced oil. At the same time, the overflow replenishment area is in the oil r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com