Refining method for propofol injection

A dipropofol and rectification technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high temperature, harsh conditions, high production equipment requirements, etc., to avoid damage and mild production conditions , The effect of simple production and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

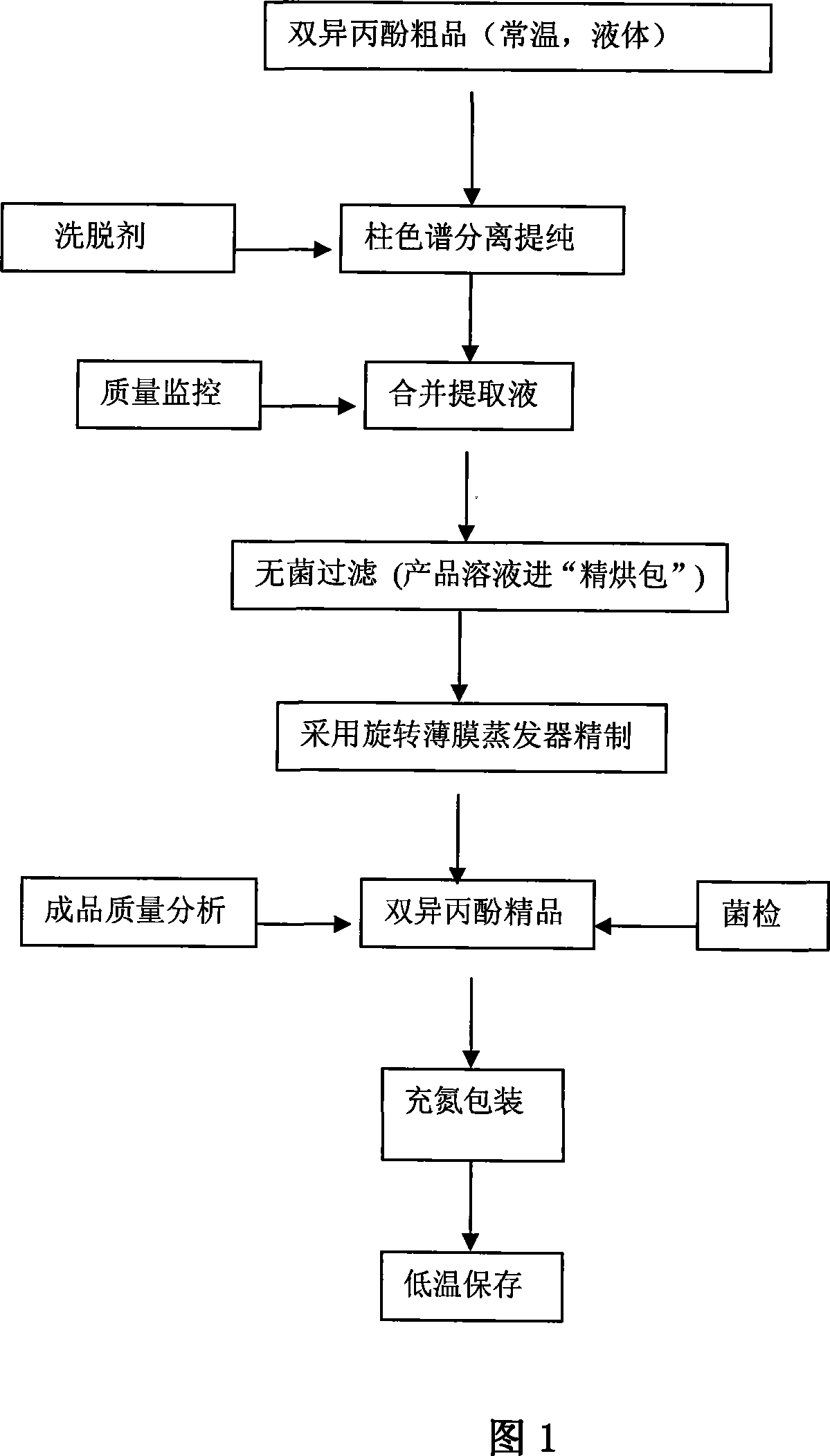

[0026] 1. Description of refining process

[0027] Referring to Figure 1, put 5g~8g of 200-300 mesh silica gel into a Φ18mm×200mm chromatography column, put a little clean sand on the upper layer of silica gel, and install it.

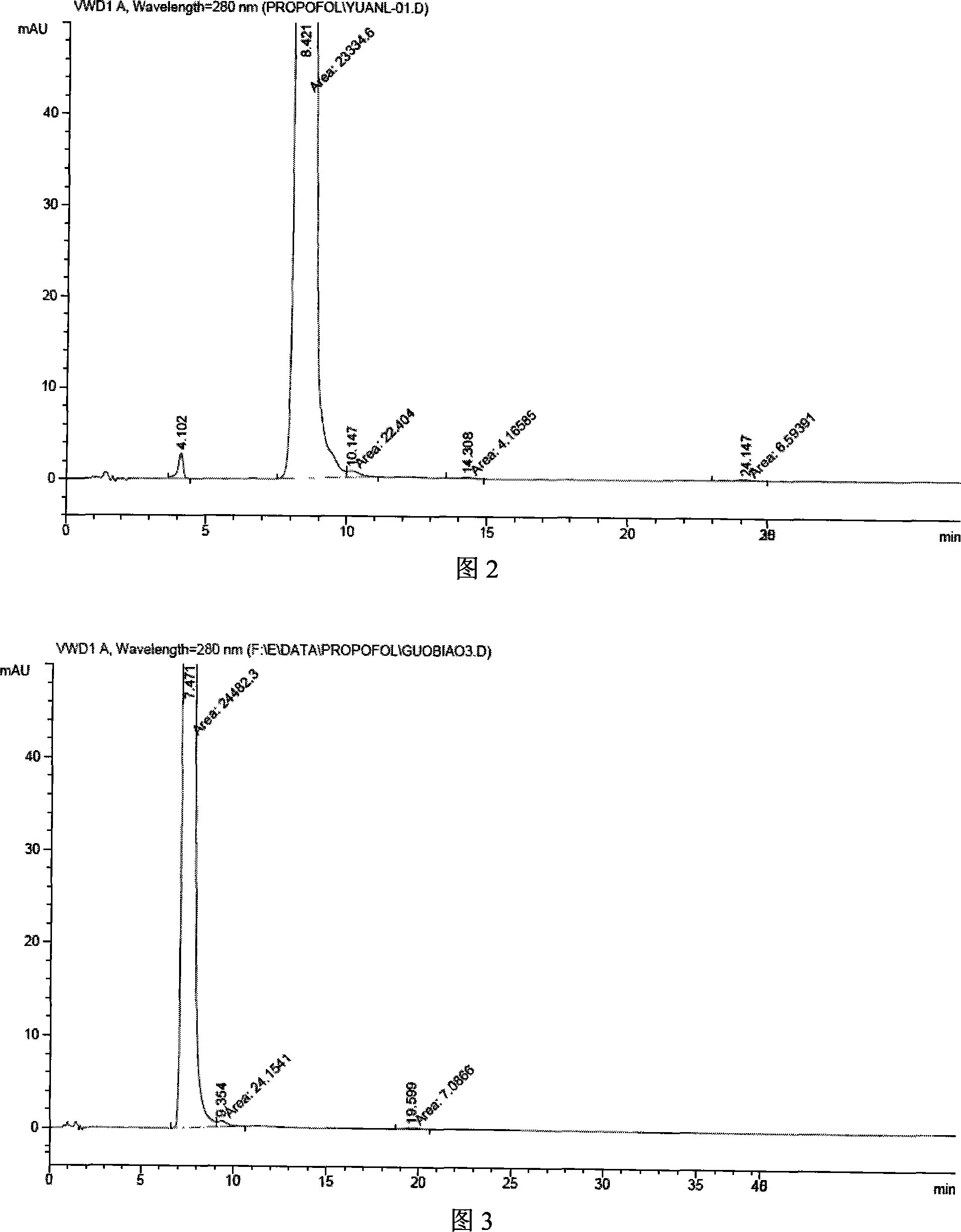

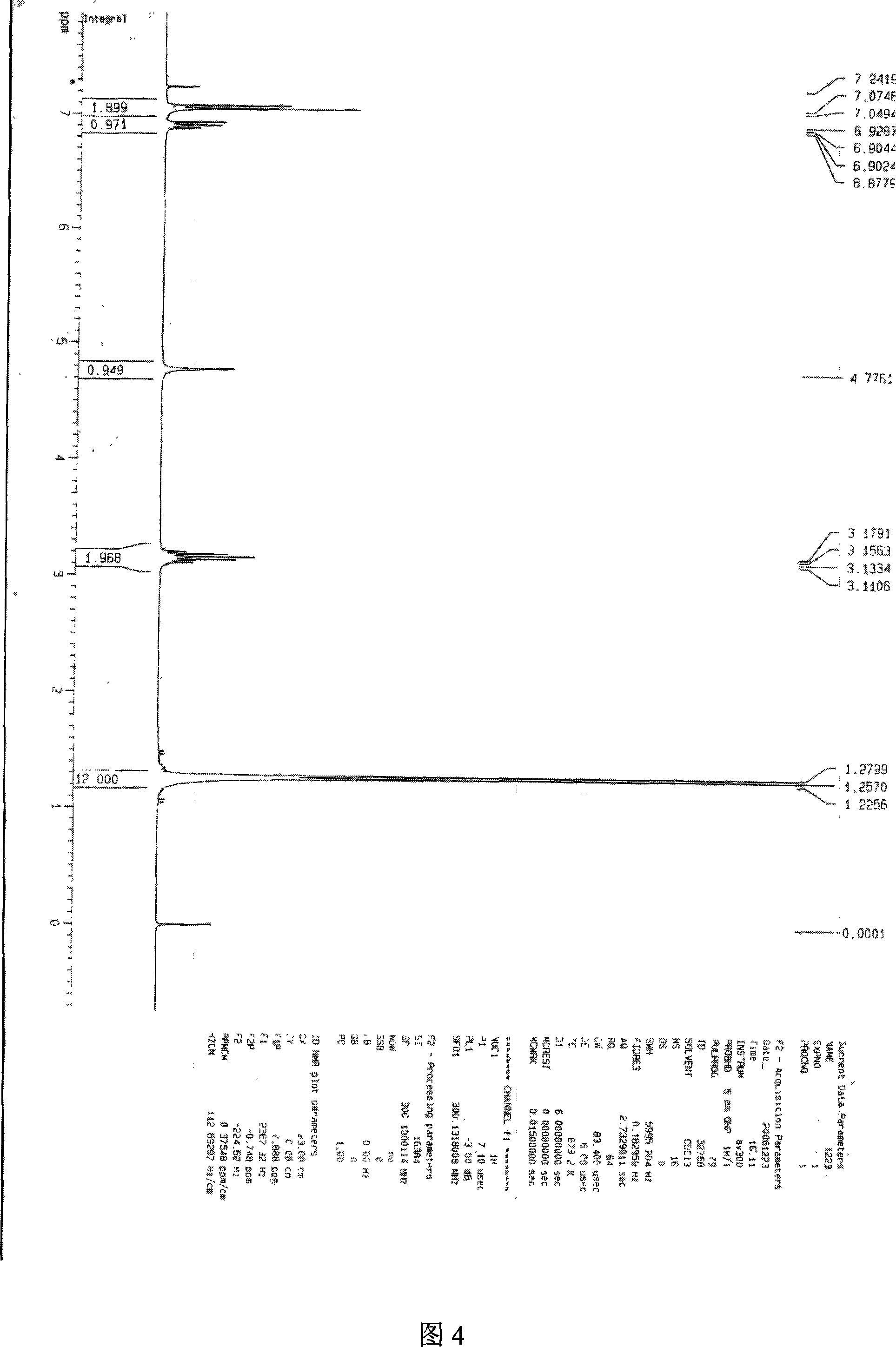

[0028] Draw 1.0 g of crude dipropofol with a purity of 98.33% with a straw, and slowly flow the sample down along the inner wall of the chromatographic column near the sand layer in a circle. Slowly add the eluent petroleum ether (or n-hexane) along the inner wall of the column, open the cock of the chromatography column, start elution and add eluent successively (pressurization can be used to speed up the elution speed). The elution process was monitored by thin-layer chromatography, the main fraction (about 1.0-1.5 L) was collected, concentrated with a rotary thin film evaporator, and the solvent was evaporated to dryness to obtain 0.9 g of the product, with a yield of 91.5%. Testing (including bacterial testing and product quality analysis) fully m...

Embodiment 2

[0059] Put 500g~800g, 200mesh~300mesh silica gel into a Φ65mm×800mm chromatography column, put a little clean sand on the upper layer of silica gel, and install it. Slowly and evenly add 100.0 g of crude dipropofol with a purity of 91.7% along the inner wall of the chromatography column. Slowly add the eluent petroleum ether along the inner wall of the column, open the cock of the chromatography column, start elution and add eluent successively (pressurization can be used to speed up the elution speed). Use TLC to monitor the elution process, collect the main fraction (about 8-15 L), concentrate with a rotary thin film evaporator, evaporate the solvent to dryness, and obtain 82.6 g of the finished product, with a yield of 90.0%. Testing (including bacterial testing and product quality analysis) fully meets the requirements of the USP28 standard, and the purity is 99.93%. Then packed with nitrogen and stored at low temperature. The purity analysis method and structure determi...

Embodiment 3

[0061] Put 5kg~8kg, 200mesh~300mesh silica gel into a Φ160mm×1600mm chromatography column, and install it. Slowly and evenly add 1.0 kg of crude dipropofol with a purity of 83.4% along the inner wall of the chromatography column. Slowly add the eluent n-hexane along the inner wall of the column, open the cock of the chromatography column, start elution and add eluent successively (pressurization can be used to speed up the elution speed). The elution process was monitored by TLC, the main fraction (about 60-100 kg) was collected, concentrated by a rotary thin film evaporator, and the solvent was evaporated to dryness to obtain 743 g of the finished product with a yield of 89.1%. Testing (including bacterial testing and quality analysis of finished products) fully meets the requirements of the USP28 standard, and the purity is 99.94%. The purity analysis method and structure determination are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com