Electrolytic method of high-antimony lead

A lead electrolysis and electrolyte technology, applied in the field of high antimony lead electrolysis, can solve the problems of long fire refining time, increased production cost, low current density, etc., to resist market risks, increase product rate, and reduce refining energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

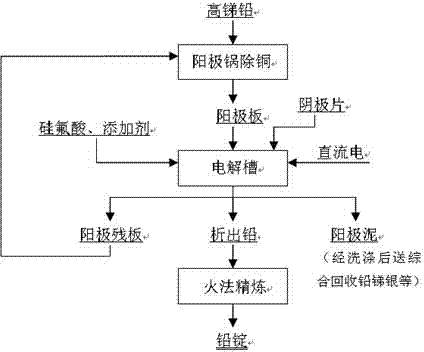

[0017] Embodiment 1: as figure 1 Shown, the method concrete operation of this high antimony lead electrolysis is as follows:

[0018] (1) Two kinds of crude lead (Pb83.8%, Sb11.5%, Cu2.5%, Ag0.2152% and Pb92.8%, Sb<3.55%, Cu2.3%, Ag0.2318%) is matched according to the ratio of mass ratio 3:5, put into the anode pot and keep the temperature at 580-600°C for melting, 90% of the material has been melted after 4.5 hours of melting, at this time, stir and remove the slag; after removing the slag, put The temperature of the lead liquid in the pot is lowered to about 340°C for copper removal by smelting. After copper removal, the temperature is raised and the temperature of the lead liquid is kept at 450-470°C. The anode plate is cast with a disc casting machine, and the cast high antimony anode plate ( Pb90.09%, Sb6.5%, Cu0.056%);

[0019] (2) Put the prepared high-antimony anode plate (Sb6.5%, Cu0.056%) and cathode plate into the electrolytic cell according to the same pole dista...

Embodiment 2

[0022] Embodiment 2: the method specific operation of this high antimony lead electrolysis is as follows:

[0023](1) Two kinds of crude lead (Pb86.1%, Sb9.62%, Cu1.96%, Ag0.2328% and Pb92.5%, Sb<4.1%, Cu2.22%, Ag0.2658%) is matched according to the ratio of mass ratio 1:1.7, put into the anode pot and keep the temperature at 560-580°C for melting, 85% of the material has melted after 4.5 hours of melting, at this time, stir and remove the slag; after removing the slag, put it into The remaining anode plate lowers the temperature of the lead liquid in the pot to about 340°C to remove copper by melting. After removing copper, raise the temperature and keep the temperature of the lead liquid at 450-470°C. Cast the anode plate with a disc casting machine. Antimony anode plate (Pb91.1%, Sb6.12%, Cu0.058%);

[0024] (2) Put the prepared high-antimony anode plate (Sb6.12%, Cu0.058%) and cathode plate into the electrolytic cell according to the same pole distance of 87mm, use the fl...

Embodiment 3

[0027] Embodiment 3: the specific operation of the method for this high antimony lead electrolysis is as follows:

[0028] (1) Two kinds of crude lead (Pb85.6%, Sb10.34%, Cu2.32%, Ag0.2361% and Pb92.8%, Sb<4.56%, Cu2.28%, Ag0.2668%) is matched according to the mass ratio of 2:3, put into the anode pot and keep the temperature at 550-580°C for melting, 80% of the material has been melted after 4 hours of melting, at this time, stir and remove the slag; after removing the slag, put it into The remaining anode plate lowers the temperature of the lead liquid in the pot to about 340°C to remove copper by melting. After removing copper, raise the temperature and keep the temperature of the lead liquid at 450-470°C. Cast the anode plate with a disc casting machine. Antimony anode plate (Pb89.89%, Sb6.9%, Cu0.048%);

[0029] (2) Put the prepared high-antimony anode plate (Sb6.9%, Cu0.048%) and cathode plate into the electrolytic cell according to the same pole distance of 87mm, use t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com