Device and method for the continuous treatment of masses and milling material

A material and abrasive technology, which is applied in the field of chocolate material equipment, can solve problems such as difficult adjustment of grinding speed and energy input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Use in Figure A , The consecutive pictures in A1 to A8 illustrate the principle of the swash plate. A simple gyroscope (which rolls around the top of the cone on the side surface) can explain how the swing swash plate swings according to the invention.

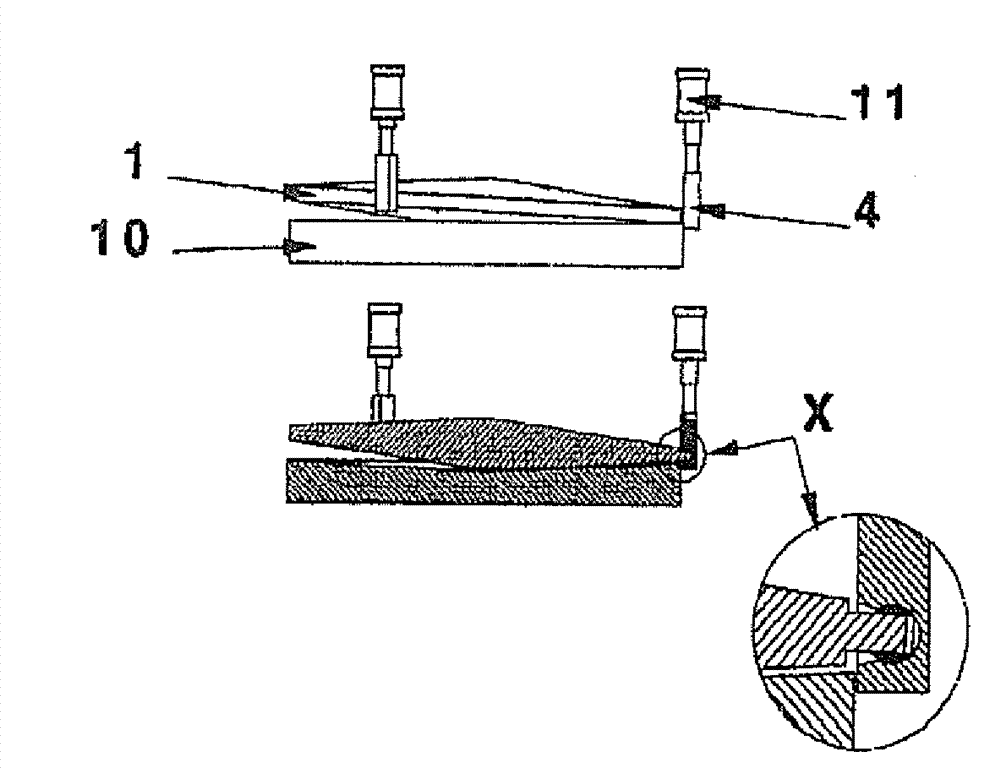

[0028] Picture B Two oscillating swash plates 1 are shown, which are connected to an oscillating feed shaft 4, which in its respect runs on the right cam 3 and on the left cam 2. The cams are arranged symmetrically.

[0029] Figure C , C1 to C3 show in cross-section and in 3D how the swash plate swings relative to each other via cam control.

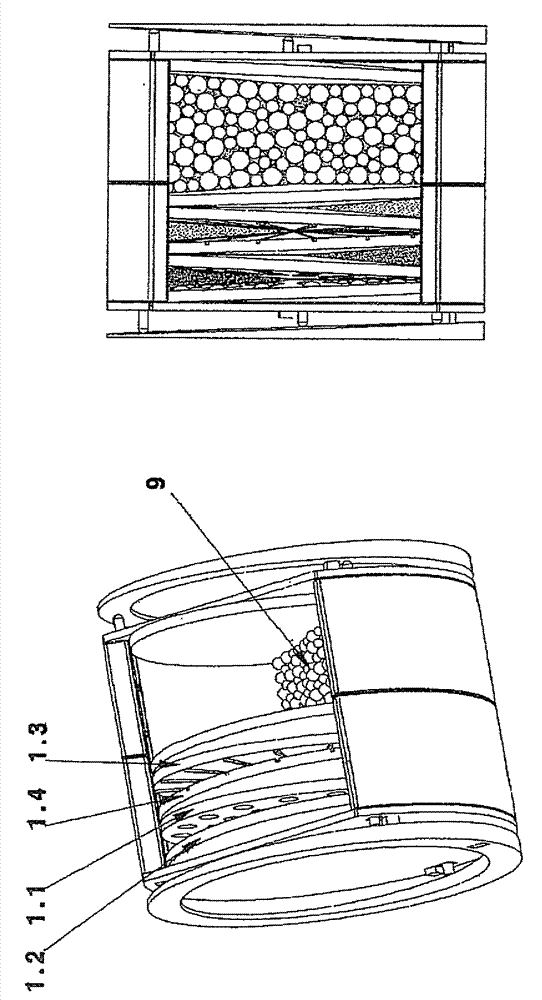

[0030] Figure D1 Shows the structure for a refiner with a swing swash plate 1, a swing swash plate 1.1 with a negative texture profile, and a swing swash plate 1.2 with a positive texture profile, with a positive shear profile The swing swash plate 1.3, the swing swash plate 1.4 with a negative shear profile. They are housed in a housing composed of a housing cover 7 and a housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com