Pneumatic feeding device

A feeding device and feeding technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of short service life, troublesome spring replacement, and easy damage of springs, so as to improve work efficiency and facilitate processing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

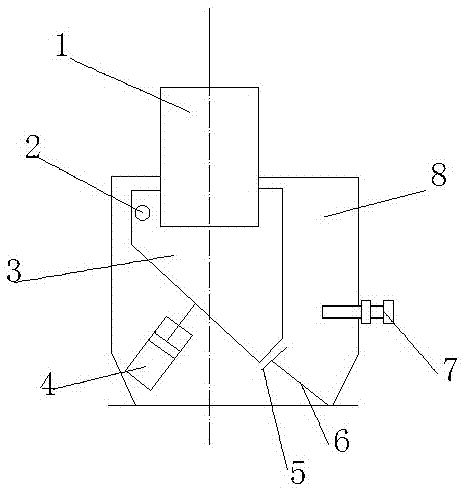

[0012] The reference signs in the drawings of the description include: observation tube 1, hinge shaft 2, rotary hopper 3, cylinder 4, baffle plate 5, support shaft 6, limit bolt 7, and feed box 8.

[0013] Such as figure 1 As shown, the pneumatic feeding device of this embodiment includes a feeding box body 8, an observation tube 1 is provided at the upper end of the feeding box body 8, and a rotating hopper 3 is provided at a position parallel to the observation tube 1, and the rotating hopper 3 includes a feed inlet and an outlet. The diameter of the feed port is greater than the diameter of the discharge port, and a slope is provided between the feed port and the discharge port. The rotary hopper 3 is located inside the feed box body 8, and the rotary hopper 3 is connected to the feed box through the hinge shaft 2. The body 8 is hinged and the rotating hopper 3 can r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com