Valve sealing gasket for new energy automobile cooling system

A technology for new energy vehicles and cooling systems, which is applied in the field of valve gaskets for cooling systems of new energy vehicles, can solve the problems of complicated design of cooling and sealing valve plates, overloading of automobile engines or batteries, and not very ideal, and achieves good sealing performance. , the effect of reducing the contact area and reducing the stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

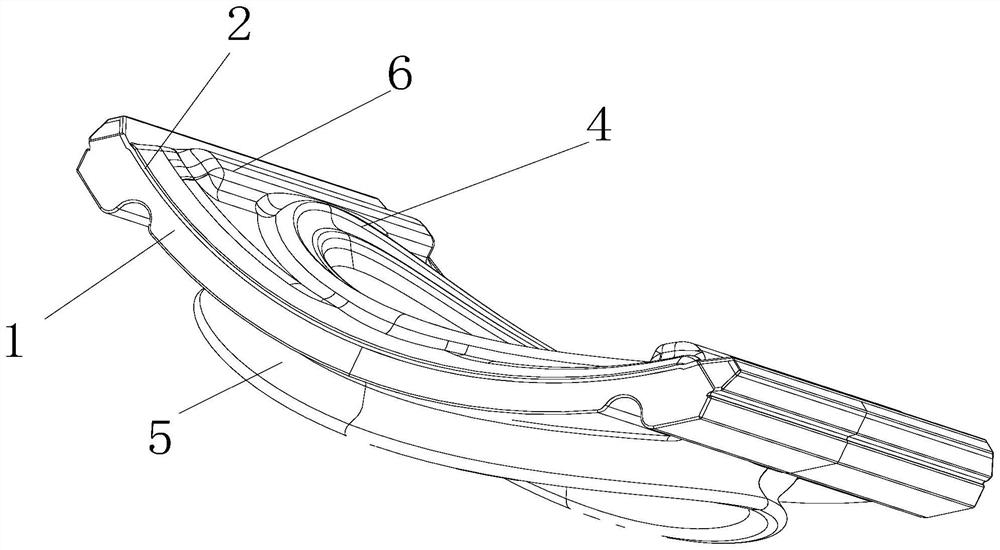

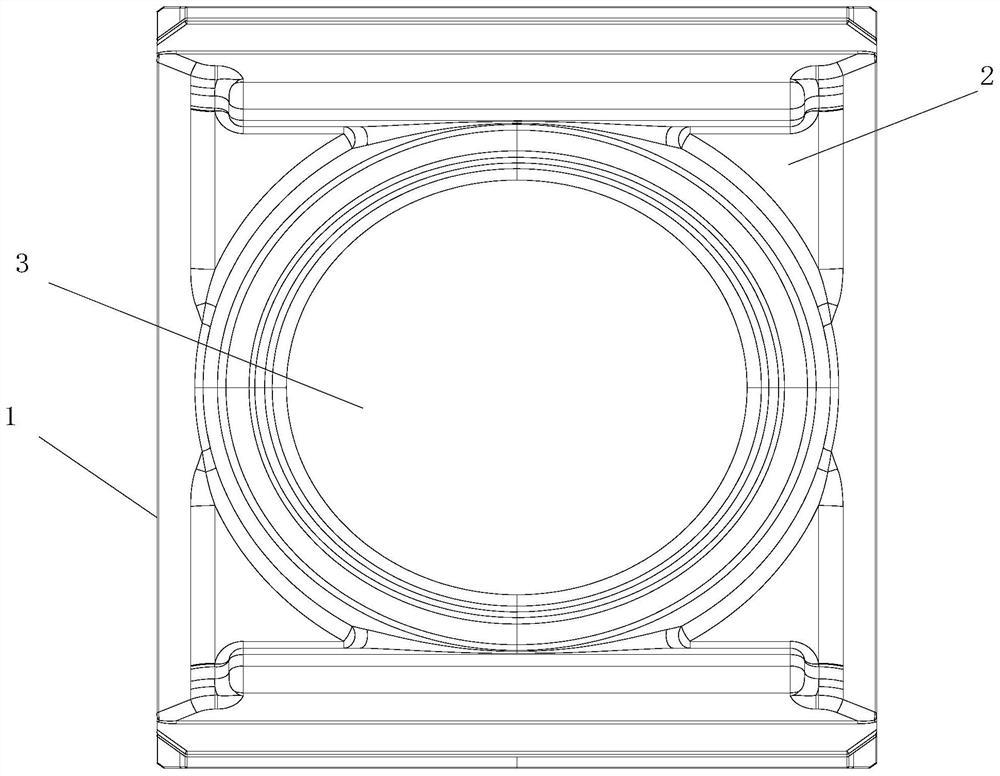

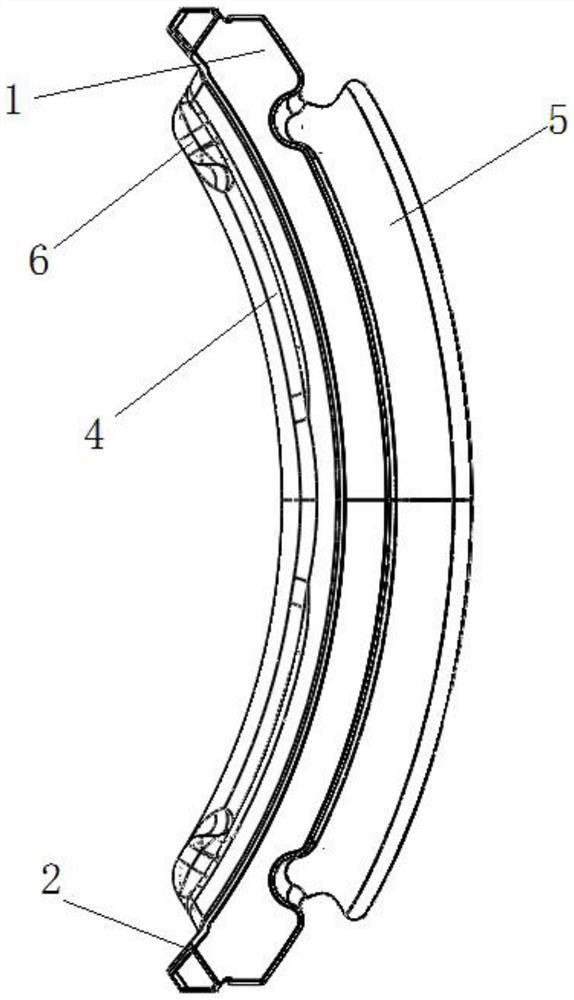

[0017] refer to Figure 1-Figure 3 , The present invention proposes a valve gasket for a cooling system of a new energy vehicle, comprising a gasket base 1 and a PTEF diaphragm skeleton 2; wherein:

[0018] A through hole 3 is formed through the middle of the gasket base 1 , and an inner sealing rib 4 annularly arranged around the through hole 3 is formed on the first side of the gasket base 1 . The first side of the gasket base 1 is located in the inner sealing rib. 4. Bosses 6 are formed to protrude outwards at the positions on both sides, and the two bosses 6 are arranged in parallel and opposite to each other. An outer sealing lip 5 annularly arranged around the through hole 3 is formed on the second side surface of the gasket base body 1 , and the outer sealing lip 5 has a 7-shaped cross section.

[0019] The PTFE diaphragm frame 2 is connected to the first side surface of the gasket base body 1 and wraps the inner sealing rib 4 . The PTFE diaphragm frame 2 extends to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com