Patents

Literature

539results about How to "Satisfy the use effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

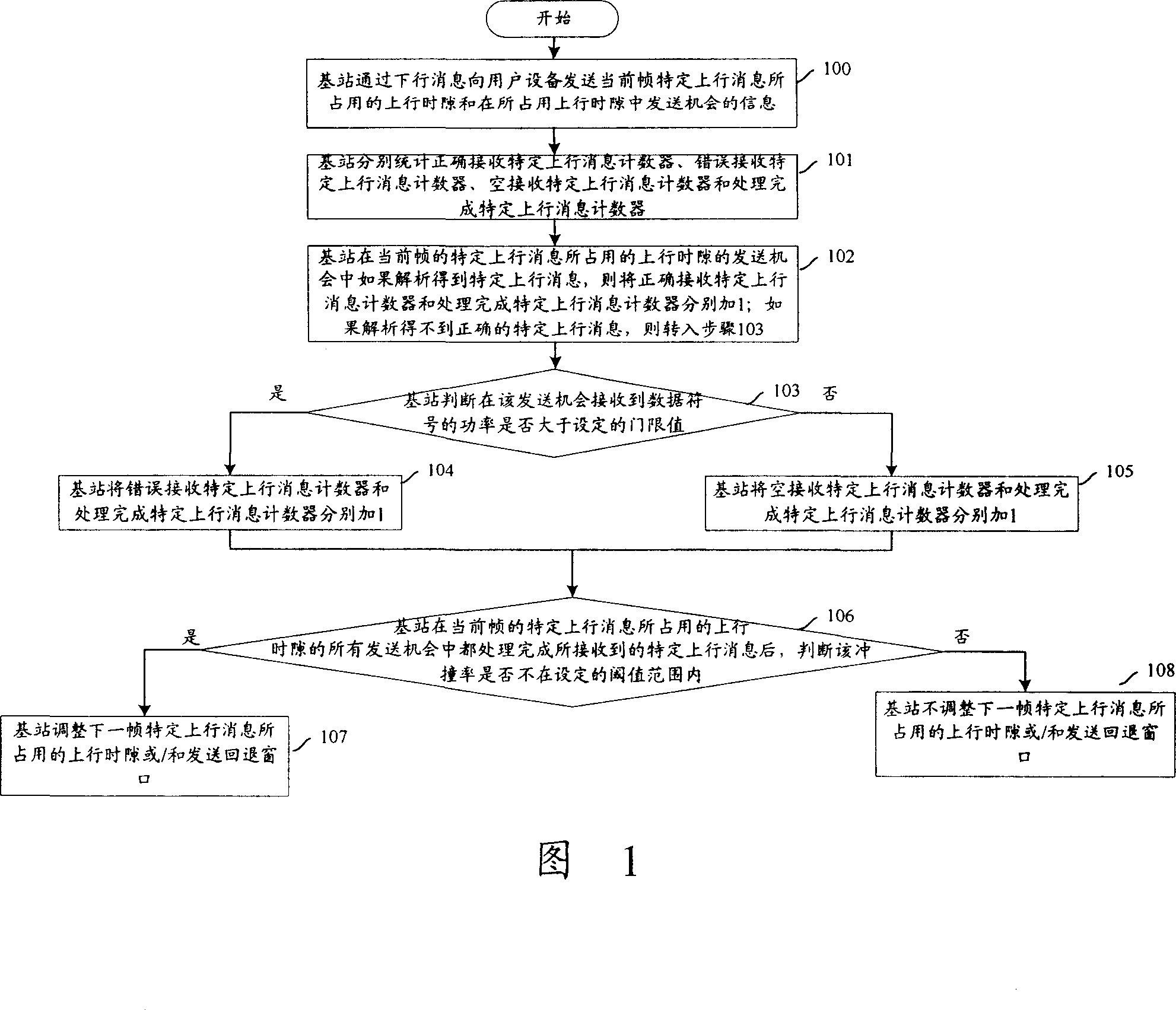

Method for distributing uplink resource

InactiveCN101047432ABest performanceSatisfy the use effectRadio/inductive link selection arrangementsRadio transmission for post communicationCollision rateReal-time computing

A method for distributing uplink resource includes calculating collision rate of specific uplink message current frame sent from multiple user device by base station, judging whether calculated out collision rate is in scope of set threshold or not, regulating uplink time slot and sending-backspace window occupied by next frame specific uplink information and sending information of regulated time slot and sending-backspace window to user device through downlink message at next frame as well as sending out specific uplink message by user device in next frame through regulated time slot and sending-backspace if it is not.

Owner:HUAWEI TECH CO LTD

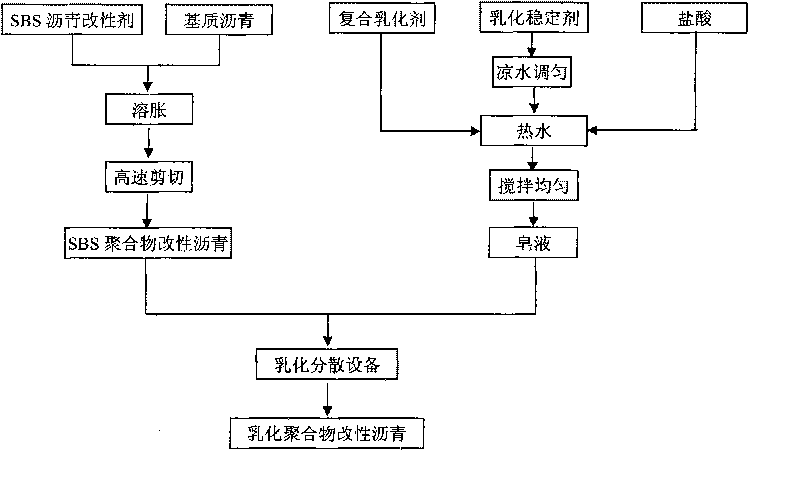

Emulsified SBS polymer modified asphalt and preparation method thereof

InactiveCN101717585AImprove performanceReduce the difficulty of productionClimate change adaptationBuilding insulationsPolymer scienceHigh-speed grinding

The invention relates to an emulsified SBS polymer modified asphalt and preparation method thereof. At present, emulsification and emulsified modified asphalt applied to surfacing is hard to produce and not stable in quality, high temperature performance improvement is not obvious. The raw materials of the invention are matrix asphalt, water, SBS asphalt modifier, compound asphalt emulsifier, emulsification stabilizer and hydrochloric acid; firstly the matrix asphalt is heated, added with SBS asphalt modifier and then stirred to be swelled, high speed grinding by colloid grinder and full dispersion are carried out, and heat preservation growth is carried out to obtain SBS modified asphalt; compound asphalt emulsifier is added into water, emulsification stabilizer smoothened by water in advance is added, and appropriate hydrochloric acid is added to adjust pH value, so as to obtain liquid soap; and finally the SBS modified asphalt is subject to temperature reduction and then mixed with the liquid soap and emulsification dispersion is carried out, thus obtaining emulsified SBS polymer modified asphalt. The invention is applicable to coat tacking, coat sealing, surface treatment, slurry sealing and asphalt pavement recycling, asphalt wet-mixing of road construction and cerement asphalt mortar layer of passenger special line plate type unballasted track.

Owner:深圳路安特沥青高新技术有限公司

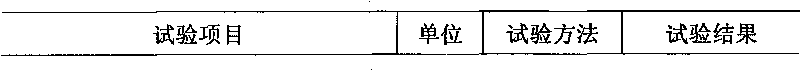

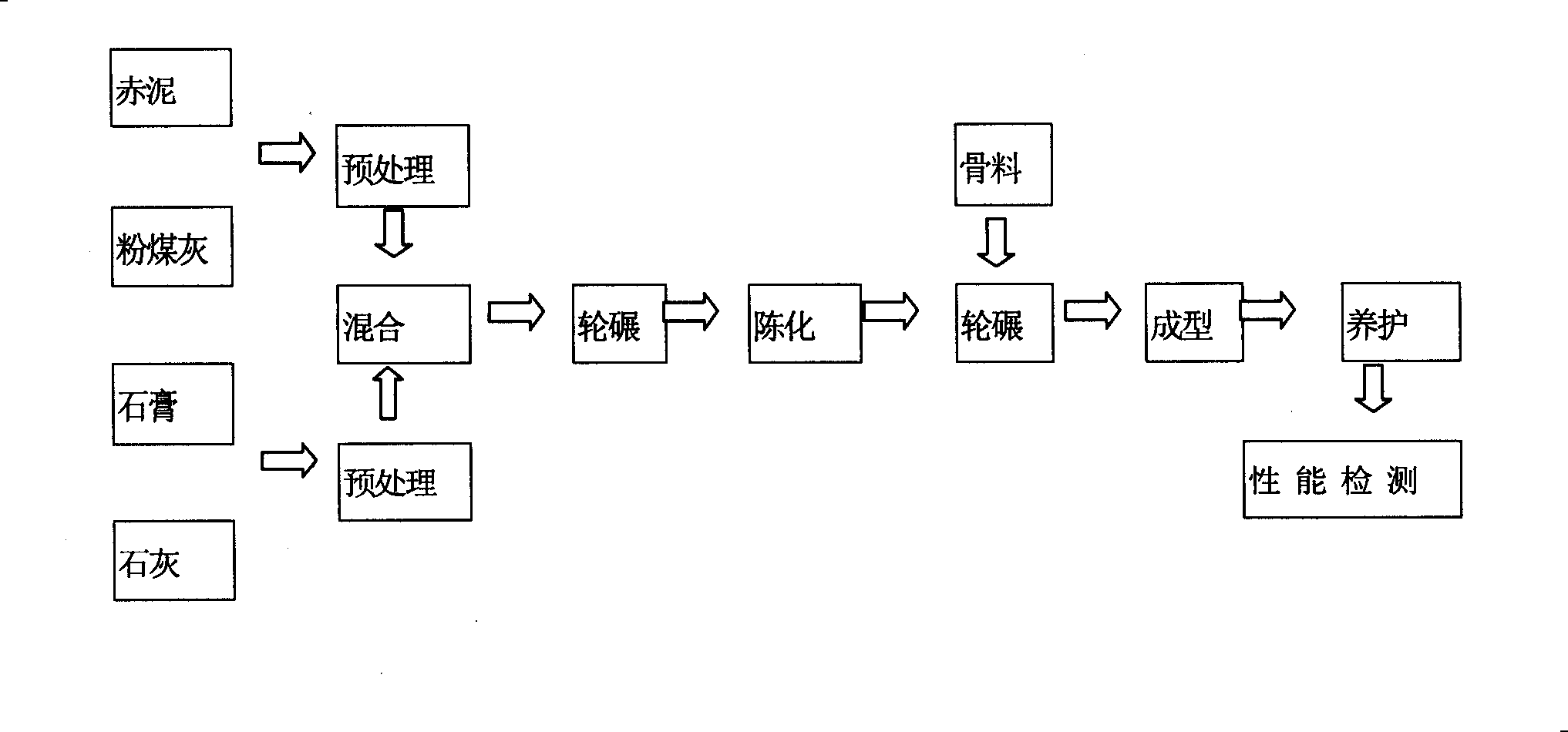

Braking-free brick mainly prepared from polyaluminum chloride waste residues and red mud and preparation method thereof

The invention relates to a braking-free brick mainly prepared from polyaluminum chloride waste residues and red mud and a preparation method thereof. Raw materials for preparing the braking-free brick comprise the red mud, the polyaluminum chloride waste residues, an active mineral material, lime and gypsum. The preparation method comprises the following steps: uniformly mixing the raw materials in proportion, adding 8-12 parts of water, stirring, mixing, carrying out compression molding, sprinkling water and curing. The preparation method has the advantages that the red mud and the PAC (polyaluminum chloride) waste residue are used as the main raw materials, pulverized fuel ash, cement, the lime and the gypsum are added, so that the using amount of an excitant is reduced, the strength of the brick is improved, the usability of the braking-free brick can be improved, meanwhile the national standard requirements are completely satisfied, a gel material does not need to be added in a production process, the heat energy does not need to be consumed, the accumulation of the red mud and the PAC is reduced in a larger sense, and the pollution to environments due to the emission of the red mud and the PAC waste residues is solved.

Owner:SHANDONG UNIV

Hot stamping forming method of lightweight aluminum alloy vehicle body component

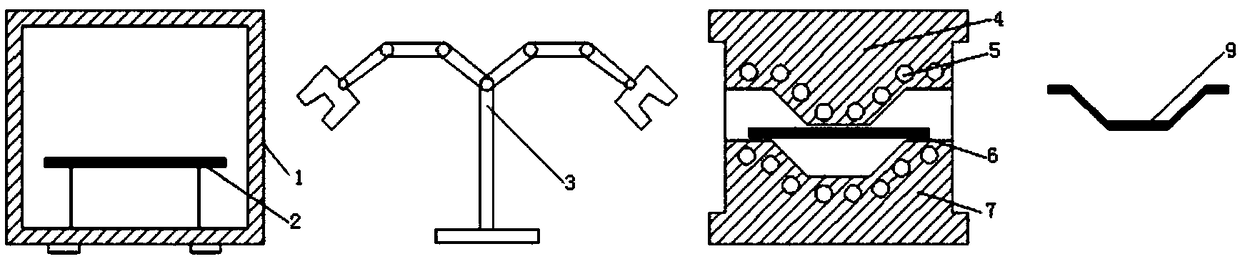

PendingCN108380722AImprove plasticityReduce processing timeShaping toolsInternal pressureHot stamping

The invention provides a hot stamping forming method of a lightweight aluminum alloy vehicle body component. An original T6-state aluminum alloy board blank is placed in a heating device, the temperature rises to be within the temperature range of 50 to 300 DEG C below the solid solution temperature, heating heat preservation is carried out for 1 to 5 minutes, then, the blank is rapidly transferred to a stamping mold to be subject to hot stamping forming and mold inner pressure maintaining quenching, and a formed part is obtained. The adopted blank is T6-state aluminum alloy, the subsequent solution aging heat treatment strengthening adopted in the traditional stamping process is not needed, the hot forming production period is shortened, production efficiency is greatly improved, and product use performance can be ensured.

Owner:WUHAN UNIV OF TECH

Multi-laser polishing and reinforcing method for surfaces of additive manufacturing metal parts

InactiveCN104109860AAchieving Surface Quality Polishing IssuesQuick polishSurface stressLaser scanning

The invention discloses a multi-laser polishing and reinforcing method for surfaces of additive manufacturing metal parts, and the polishing on the surfaces of the additive manufacturing metal parts can be realized by repeatedly scanning and processing the surfaces of the additive manufacturing metal parts through utilizing millisecond pulse laser and nanosecond pulse laser; during the multi-laser scanning polishing process, the additive manufacturing metal parts are subjected to thermal preservation treatment, so that the stress on the surfaces of the additive manufacturing metal parts can be evenly distributed; laser scanning reinforcement is carried out on the surfaces of the laser-polished additive manufacturing metal parts, so that the stress state on the surfaces of the additive manufacturing metal parts can be changed into pressure stress from tensile stress, the anti-fatigue property of the additive manufacturing metal parts can be enhanced, and the usage performance of the metal parts can be met; compared with a manual polishing method, the multi-laser polishing and reinforcement efficiency of the additive manufacturing metal parts is high and is as 20 times as that of the manual polishing, the non-contact rapid polishing of the additive manufacturing metal parts can be realized, the tensile stress, caused by the laser polishing, of the additive manufacturing metal parts can be eliminated, and the anti-fatigue property of the additive manufacturing metal parts can be enhanced.

Owner:XI AN JIAOTONG UNIV

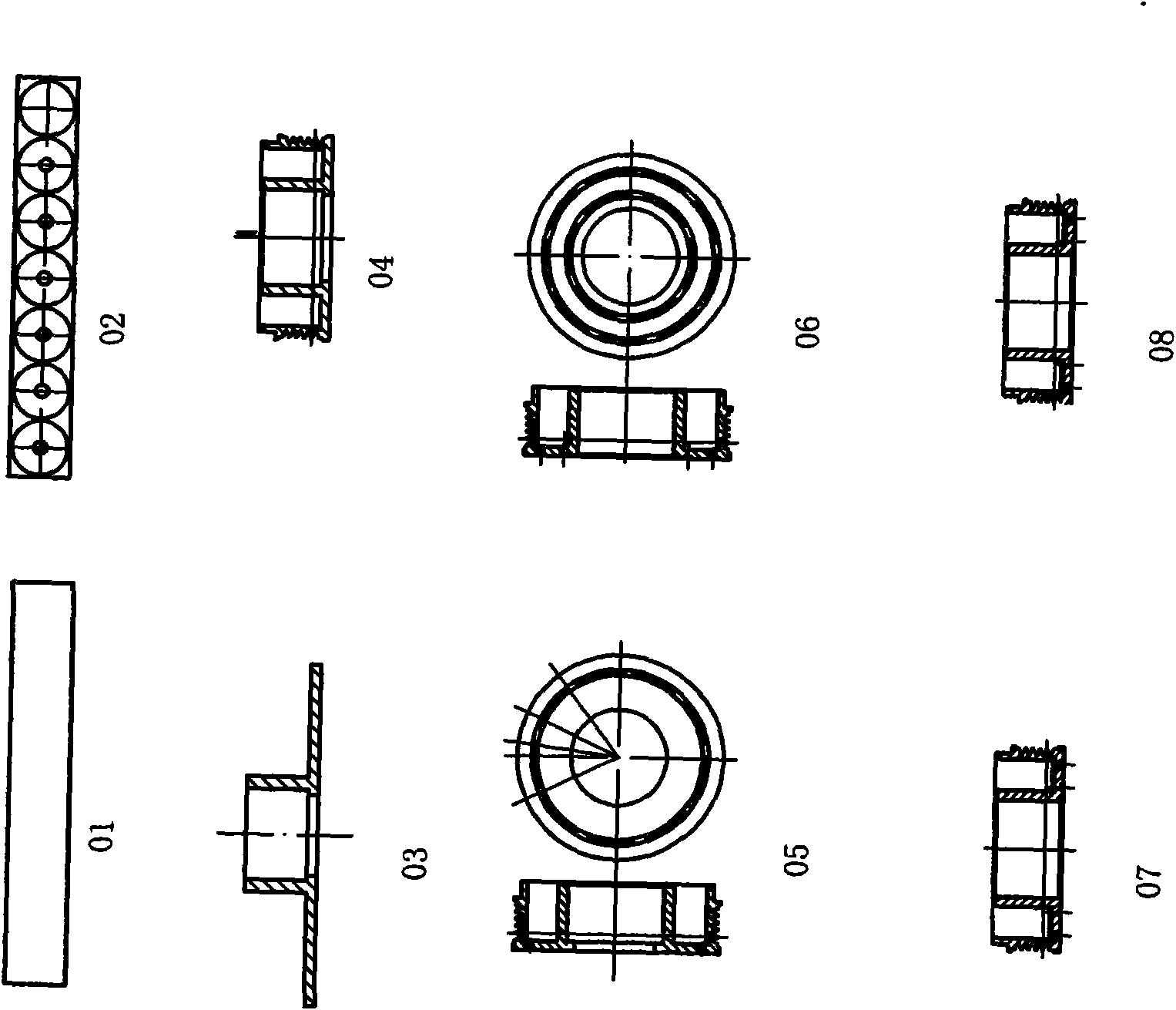

Cold spinning belt pulley and fabricating method and fabricating equipment thereof

InactiveCN101619762AHigh transmission powerGood flexibilityPortable liftingGearing elementsGear driveAgricultural engineering

The invention relates to a cold spinning one-step coaxial multi-wedge type belt pulley which comprises a rim, a spoke and a hub, wherein the rim is provided with a plurality of multi-wedge type V-shaped grooves, effective diameter center of each V-shaped groove is concentric with axle hole center of the hub, each V-shaped groove is in bilateral symmetry, and the centre line of each V-shaped groove is vertical to the centre axle line of the hub, annular grooves are arranged among the rim, the spoke and the hub, the spoke is provided with a plurality of arc grooves, and the rim, the spoke and the hub are integrally formed on a spinning machine by using a steel plate in a cold spinning way. The cold spinning one-step coaxial multi-wedge type belt pulley has good softness of a flat belt pulley and large drive power of a V-shaped belt pulley, can absorb impaction and vibration, and is quieter than that of chain and gear drive with little noise. The invention also provides a fabricating method and fabricating equipment of the product.

Owner:温州市南亚机械配件有限公司

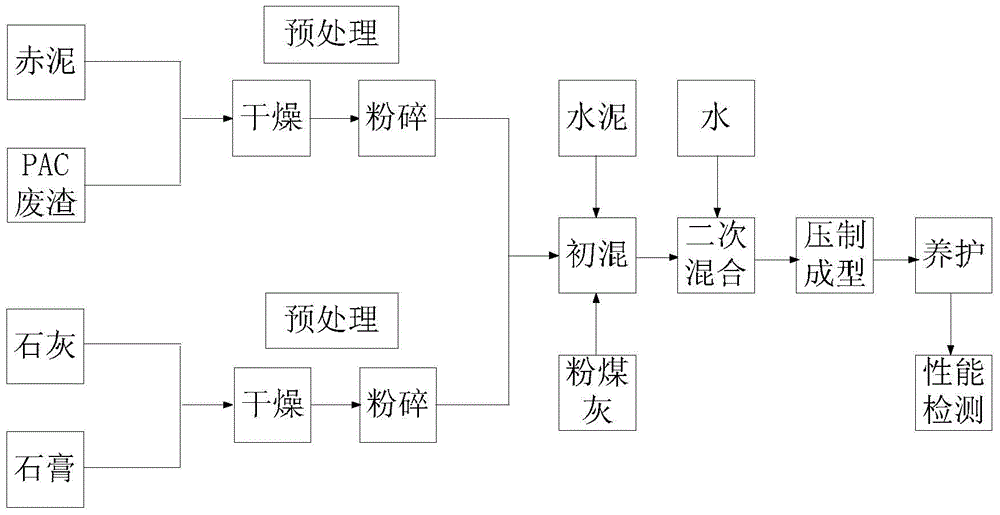

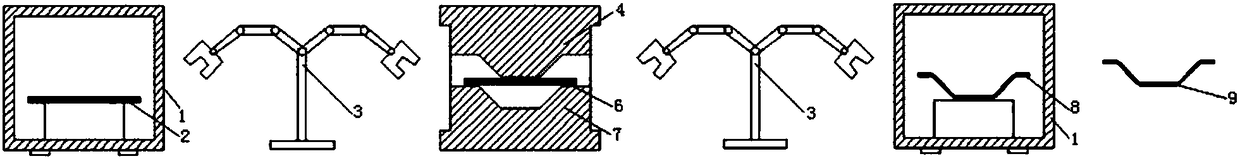

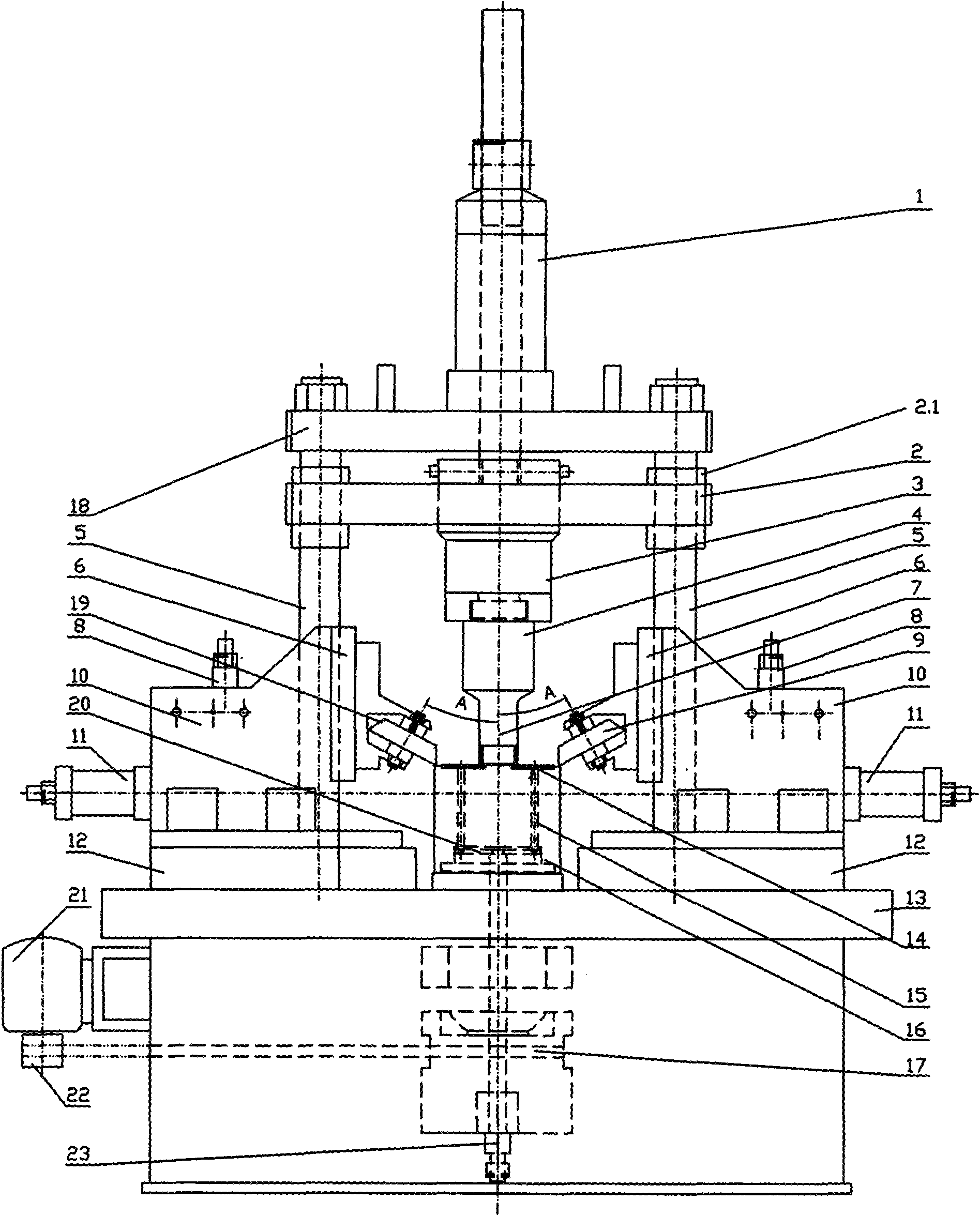

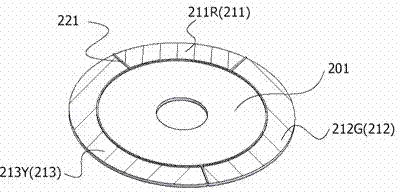

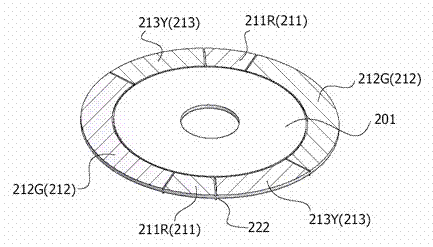

Fluorescent powder color wheel base plate with demarcation structures and manufacturing method thereof

InactiveCN103900035APrecisely control relative positionControl relative positionProjectorsSpectral modifiersCrystallographyAdhesive

The invention relates to a fluorescent powder color wheel base plate with demarcation structures and a manufacturing method of the fluorescent powder color wheel base plate. The manufacturing method comprises the steps that firstly, the base plate is machined, the base plate generates certain deformation, demarcation is conducted, and the demarcation structures which are convex or concave relative to a datum plane are formed at the demarcation positions; meanwhile, protrusion layers which are in a required shape and have a certain height and width are formed in advance in required color section areas on the base plate through adhesives, and accurate demarcation and accurate control are conducted in the process of follow-up manufacturing of fluorescent powder color sections; then, multiple fluorescent powder color sections are manufactured through printing, adhesive dispensing, spaying and the like, and finally a needed multi-color-section fluorescent powder color wheel is manufactured. The fluorescent powder color wheel base plate with the demarcation structures has the advantages that the important parameters such as the relative positions, the required shape (the width, the thickness, the flatness, the angle, the gap and the like), and evenness of fluorescent powder sheet layers on the fluorescence powder color wheel base plate can be more accurately controlled, control over the demarcation of the fluorescent powder sheet layers is guaranteed, the requirement for the performance of the fluorescent powder sheet layers is met, and therefore the accuracy, the efficiency and the quality of the fluorescence powder sheet layers in the forming process are greatly improved.

Owner:YANGZHOU G-NOVA OPTOELECTRONIC CO LTD

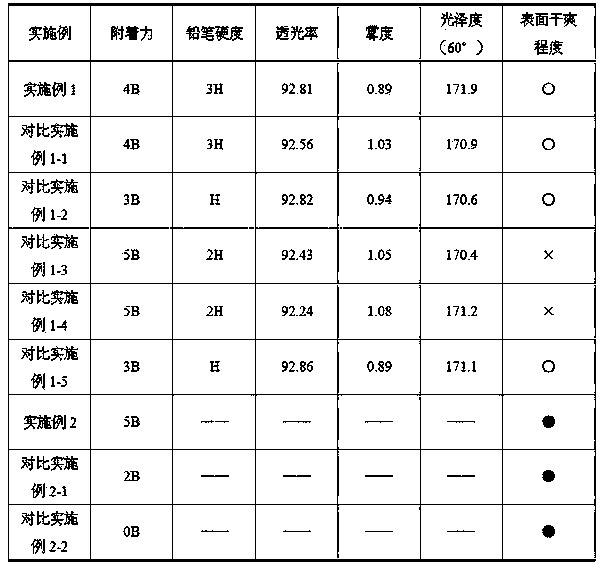

UV-heat dual-curing polyurethane coating, and preparation method and application thereof

ActiveCN104098999ARich varietyImprove performancePretreated surfacesPolyurea/polyurethane coatingsPolymer scienceUV curing

The invention provides an UV-heat dual-curing polyurethane coating, and a preparation method and application thereof. The UV-heat dual-curing polyurethane coating is composed of an UV curing system and a heat curing system. The UV curing system comprises, by weight, 40%-70% of a prepolymer, 10%-30% of an active monomer and 1%-10% of a photoinitiator. The heat curing system comprises, by weight, 50%-80% of an adhesive and 20%-50% of a cross-linking agent. The coating disclosed by the invention solves the problem that the adhesive property of the functional coating with a PET membrane is bad. Compared with the prior art, the used UV curing system and the heat curing system are both a polyurethane system, the kinds of the polyurethane system are various, the comprehensive performances are relatively good than those of other systems and the various polyurethane systems are capable of satisfying many performances of an optical film, and also the UV curing system and the heat curing system are relatively good in compatibility and can form an interpenetrating network structure. The coating has good adhesive force on the PET membrane and is high in hardness and transparency.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

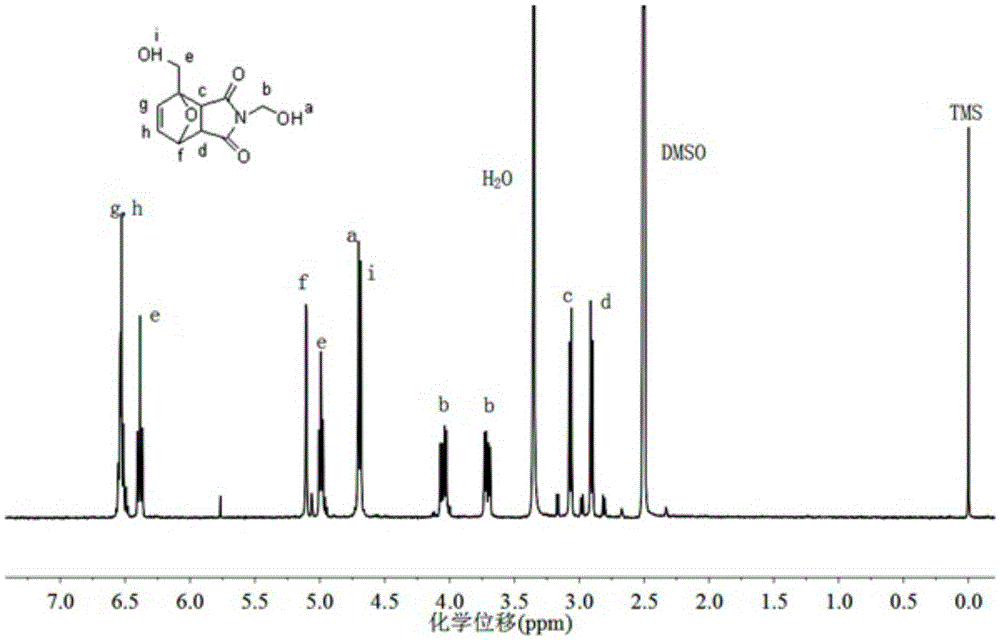

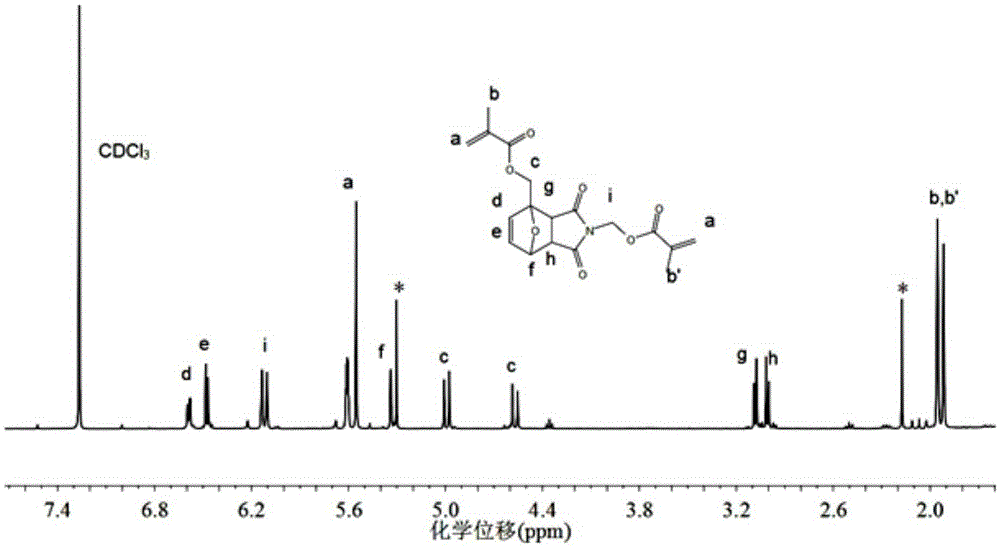

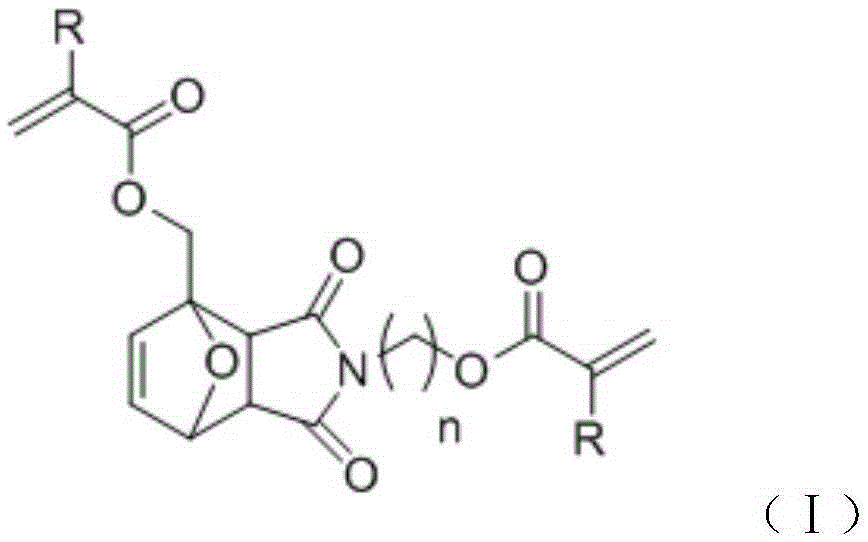

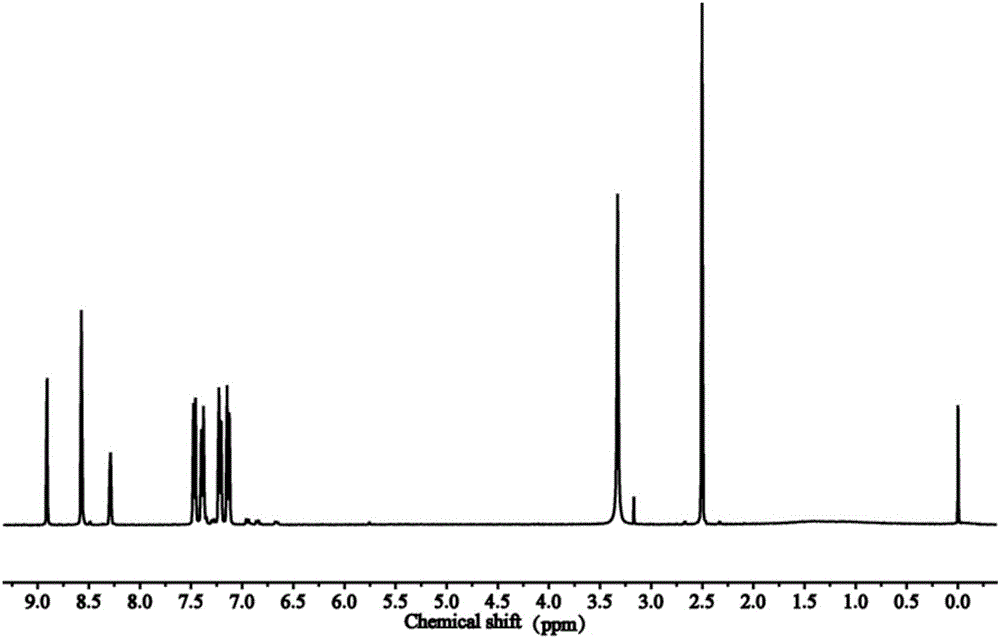

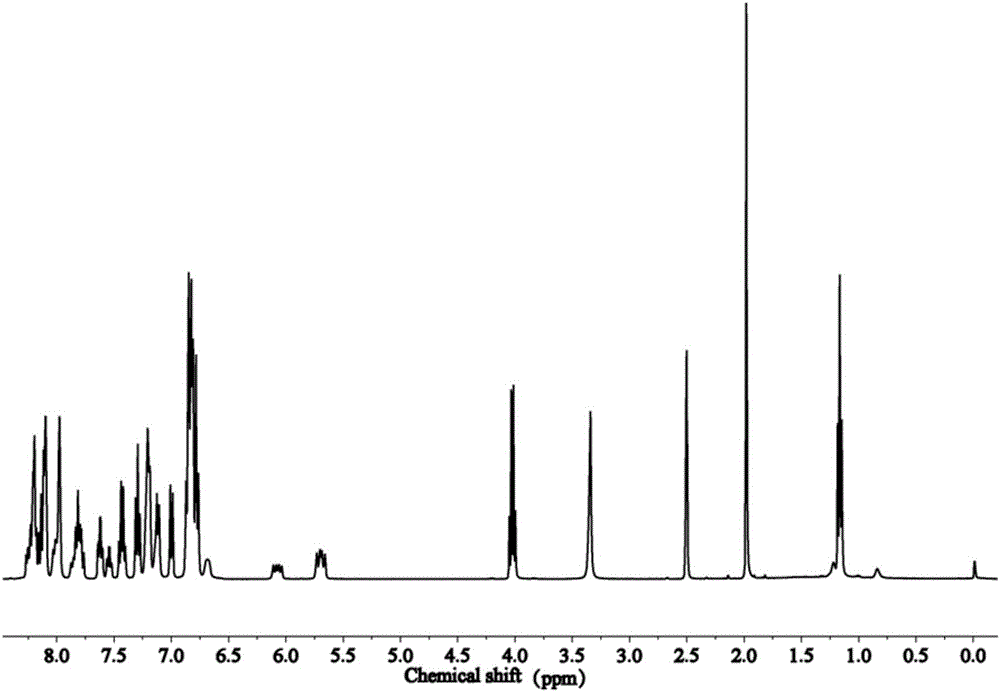

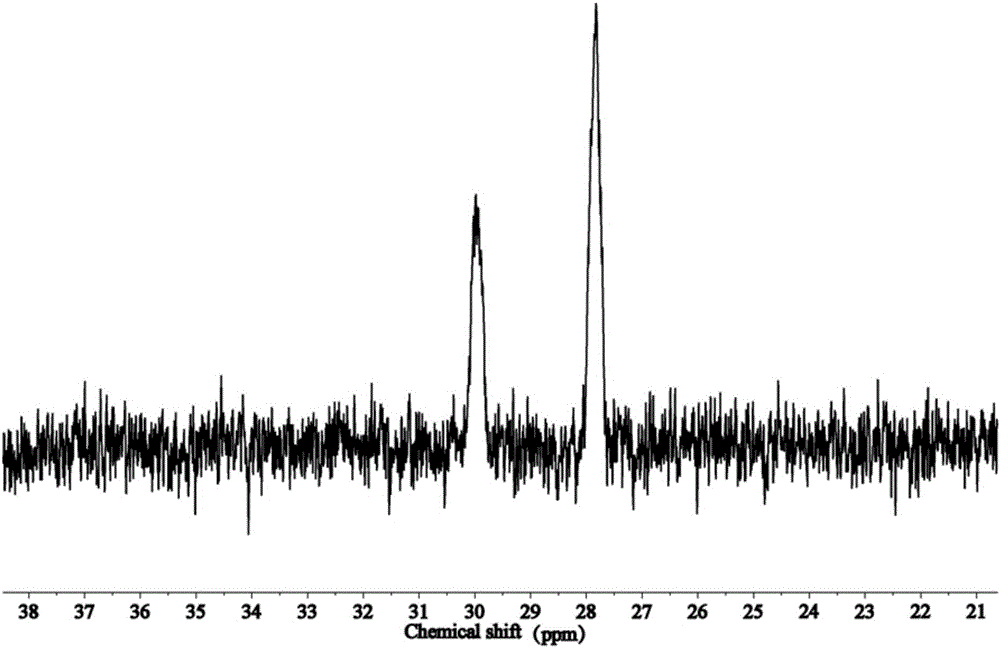

Bi-functionality-degree acrylic ester cross-linking agent and application thereof to 3D printing

The invention relates to the field of high molecular materials for photocuring 3D printing fast forming equipment and aims to provide a bi-functionality-degree acrylic ester cross-linking agent and application thereof to 3D printing. According to the preparation steps, under protection of nitrogen, furfuryl alcohol, N-hydroxyalkyl maleimide and solvent react, and suction filtration, washing and vacuum drying are carried out on the reaction product to obtain a dihydroxy-terminated Diels-Alder addition product; the addition product is dissolved into the solvent, a pyridine catalyst and acid anhydride are added, the mixture reacts, methyl alcohol is added, the mixture continues to react, methylene chloride is used for dissolving the product, and organic phases are collected to obtain a final product. The initial raw materials are wide in source, the preparation process and purification are simple, and the cross-linking agent is suitable for industrial production process; the product has universality, and the prepared vinyl polymer has excellent mechanical performance and solvent resistant performance of a thermosetting material at normal temperature, and has a recovery processing characteristic of thermoplastic at high temperature; use performance of the product is met, and the application is important breakthrough of the 3D printing material equipment technology.

Owner:殷若瑜

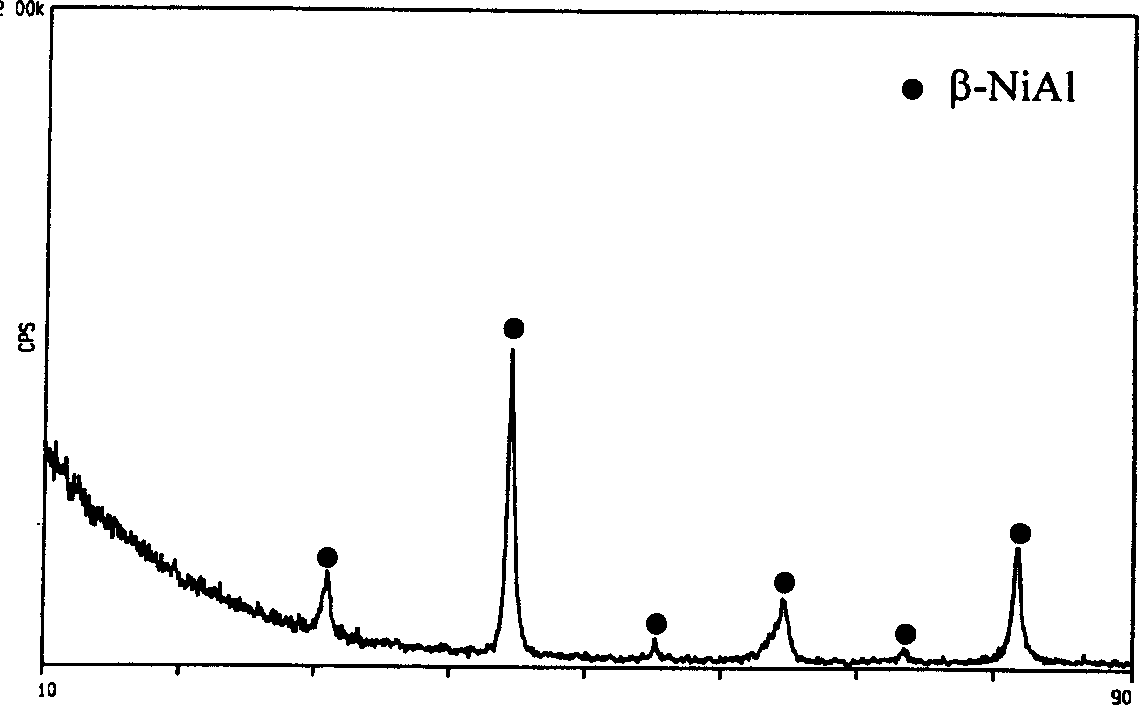

Laser synthesis preparation method of intermetallic compound and granule reinforced composite material

InactiveCN1546694AThe ingredients are designed to be simpleReduce manufacturing costHigh power lasersChemical compound

The invention relates to a laser synthesis preparation method of intermetallic compound and granule reinforced composite material which includes, using the powder stock containing the same elements with the intermetallic compound to be prepared, adding additionally elements during the process of sedimentation and mixing, forming local molten pool on the base material surface through high power laser irradiation, feeding the mixed powder into molten pool, stacking up to obtain large area coating, block material or formed parts, adjusting powder components or laser technique to obtain intermetallic compound or particle reinforcement intermetallic composite material with dissimilar compositions, structure and property.

Owner:TSINGHUA UNIV

Machining method of high-abrasion resistance valve core

The invention discloses a machining method of a high-abrasion resistance valve core. The method comprises a material preparing step, a turning step, a heat treatment step, a clinching step, a grinding step, a clinching step, a surface treatment step, a grinding step, a clinching step and the like. The valve core machined by the method is abrasion resistant, light in weight and stable in quality, and can meet the using performance of a precise control valve.

Owner:贵州凯星液力传动机械有限公司

Method for preparing modified asphalt

The invention discloses a preparation method of modified asphalt. The modified asphalt is produced by asphalt and an undersaturation double bond compound which are reacted under the action of an evocating agent; the method comprises the following steps: firstly, the asphalt is put into a reaction kettle; the evocating agent is added into the reaction kettle; the weight of the evocating agent is 0.05-1 percent of the weight of the asphalt; the undersaturation double bond compound with the weight of 1-10 percent of that of the asphalt and 0.1-1 percent of N-phenyl maleimide are added into the reaction kettle at the temperature of 80-160 DEG C; and the pressure remains 0.1-0.4 MPa. The reaction is carried out for 3-6 hours; the reaction product is deaerated and filtered, and then the modified asphalt is obtained. The chemically modified asphalt provided by the method has good performance, which greatly improves the shortcomings that the common asphalt has strong temperature sensibility, low viscosity, poor flexility and the like. The modified asphalt can meet the use performance of roads and prolong the service life of roads; when the modified asphalt is used in road maintaining, maintenance, the time of traffic closing is shortened, the construction condition is improved and the construction efficiency is increased.

Owner:JURONG NINGWU SCI & TECH DEV

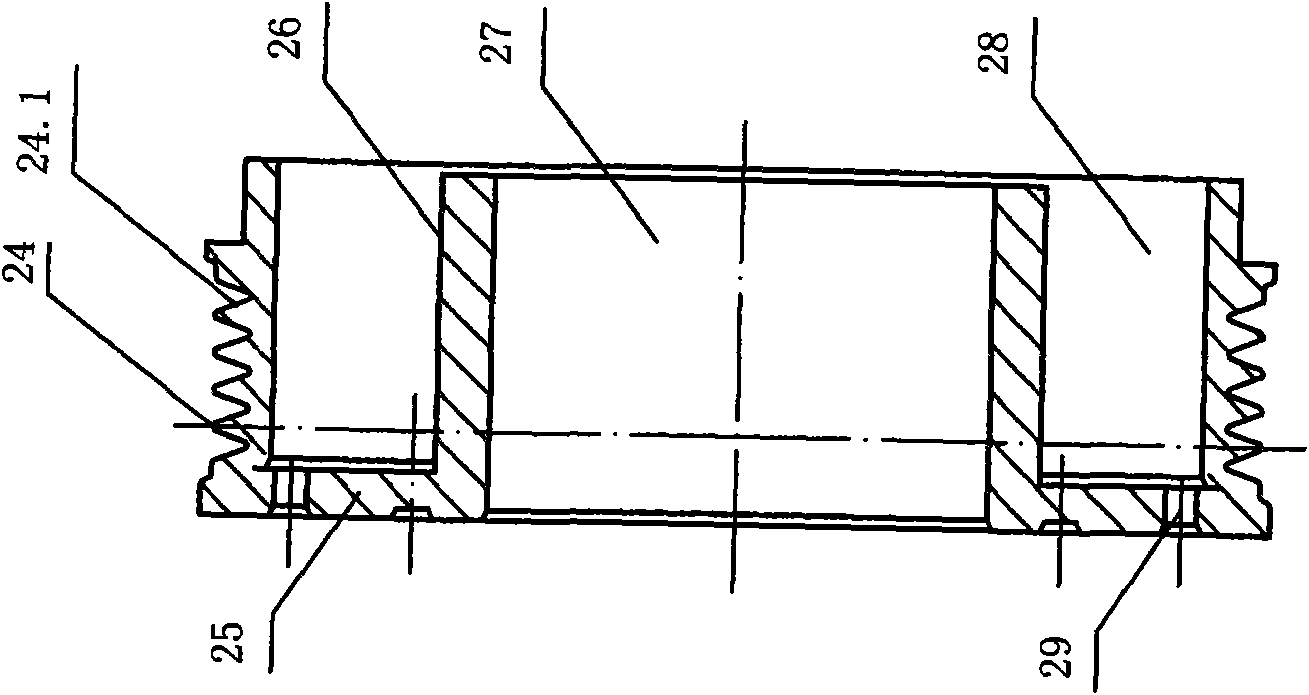

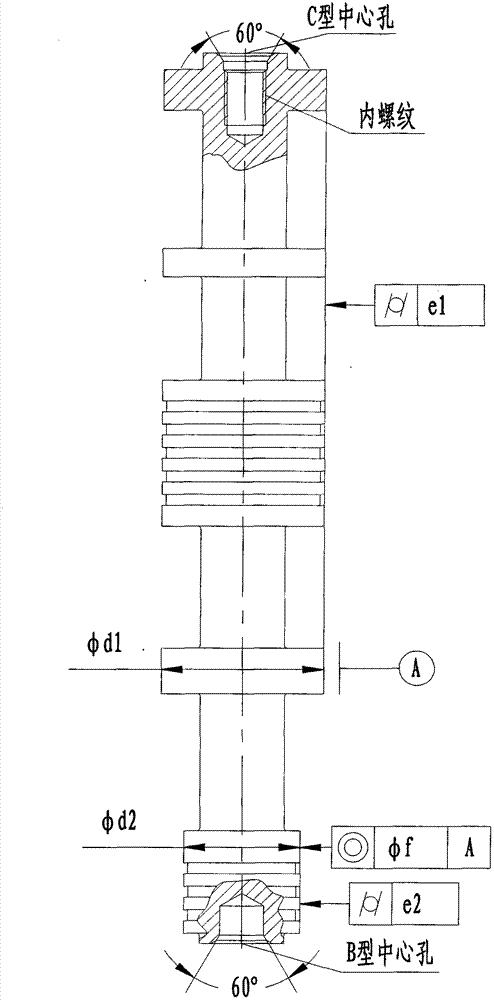

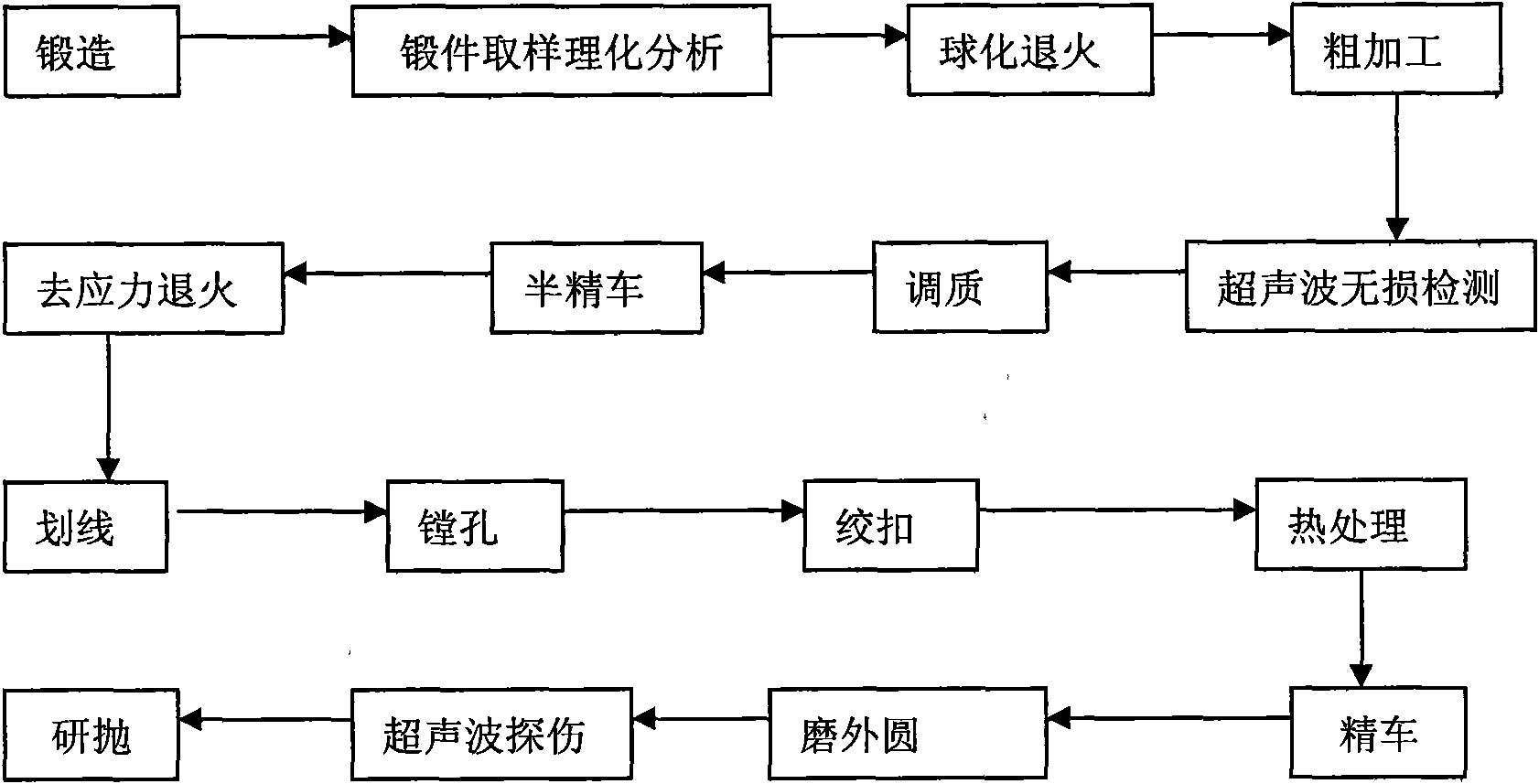

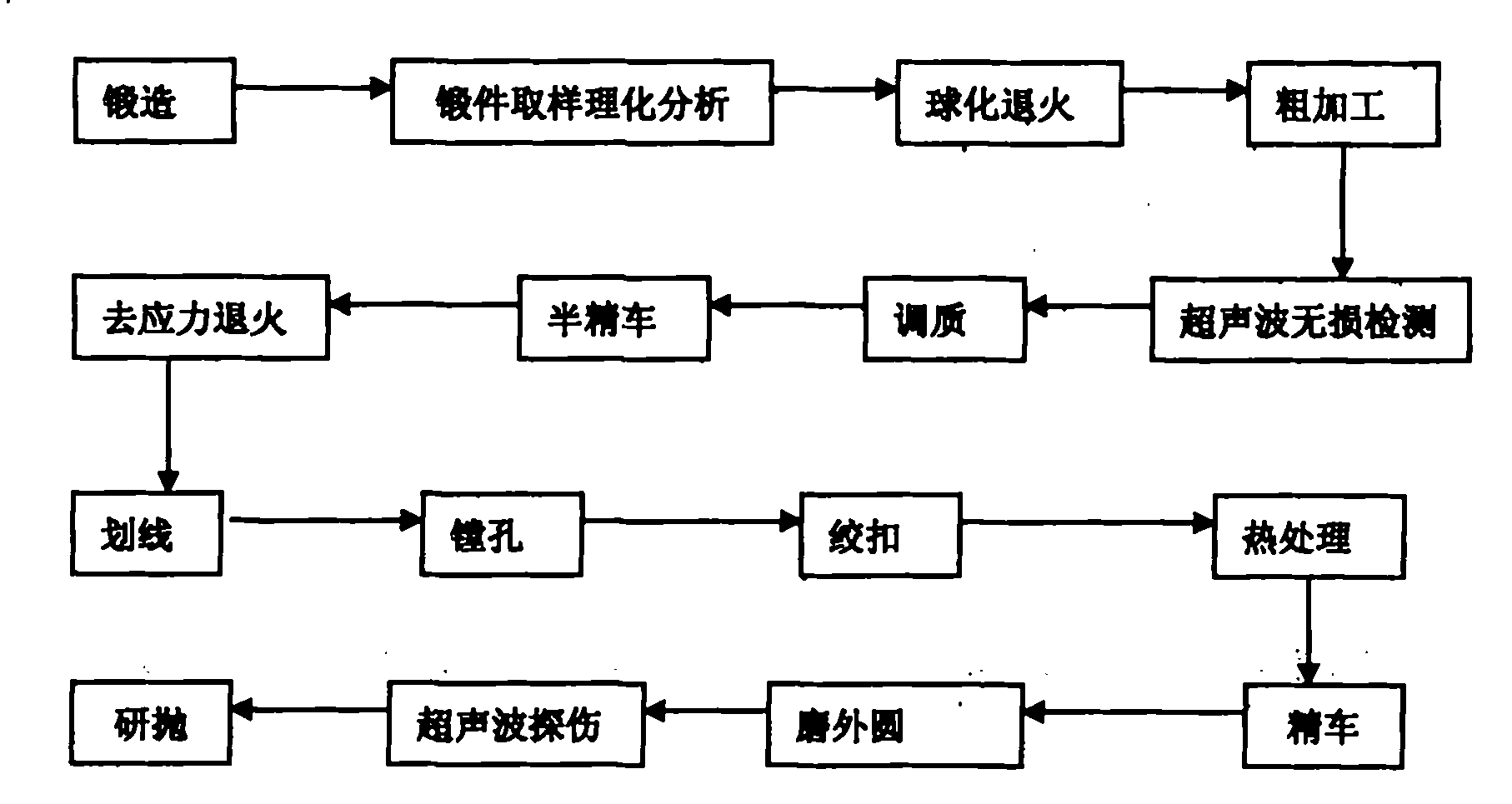

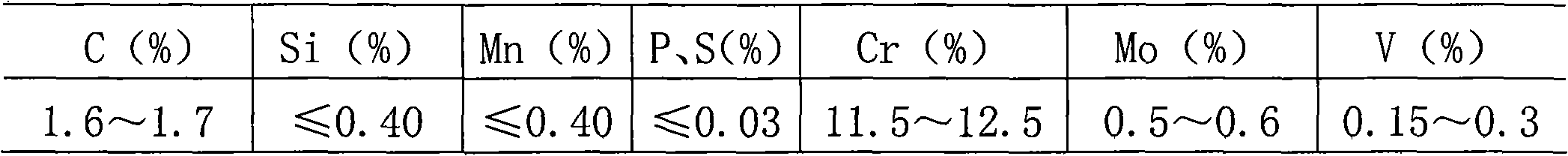

Machining method of cylindrical spinning mandrel

InactiveCN102114511ASatisfy the use effectExtended service lifeShaping toolsThermal treatmentMachining

The invention relates to a machining method of a cylindrical spinning mandrel, belonging to the technical field of machining. The process comprises the following steps of: sampling and physically and chemically analyzing a forgeable piece; forging; spheroidizing; rough machining; carrying out ultrasonic nondestructive detecting; conditioning; half finely turning; distressing and annealing; scribing; boring a hole; hinging a buckle; carrying out thermal treatment; finely turning; grinding the excircle; ultrasonically detecting defects; lapping and polishing. The machining allowance of the forgeable piece before spheroidizing and thermal treatment is confirmed to lay the favorable foundation for ensuring sequential geometric allowance. In the machining method provided by the invention, the processing production of a common lathe is fully utilized, and the machining allowance can meet use performance through reliable processing flows; and the mandrel manufactured by using the process has long service life and can be widely applied to the manufacture and the production of the cylindrical mandrel as a key part in spinning machining.

Owner:山西晋西精密机械有限责任公司

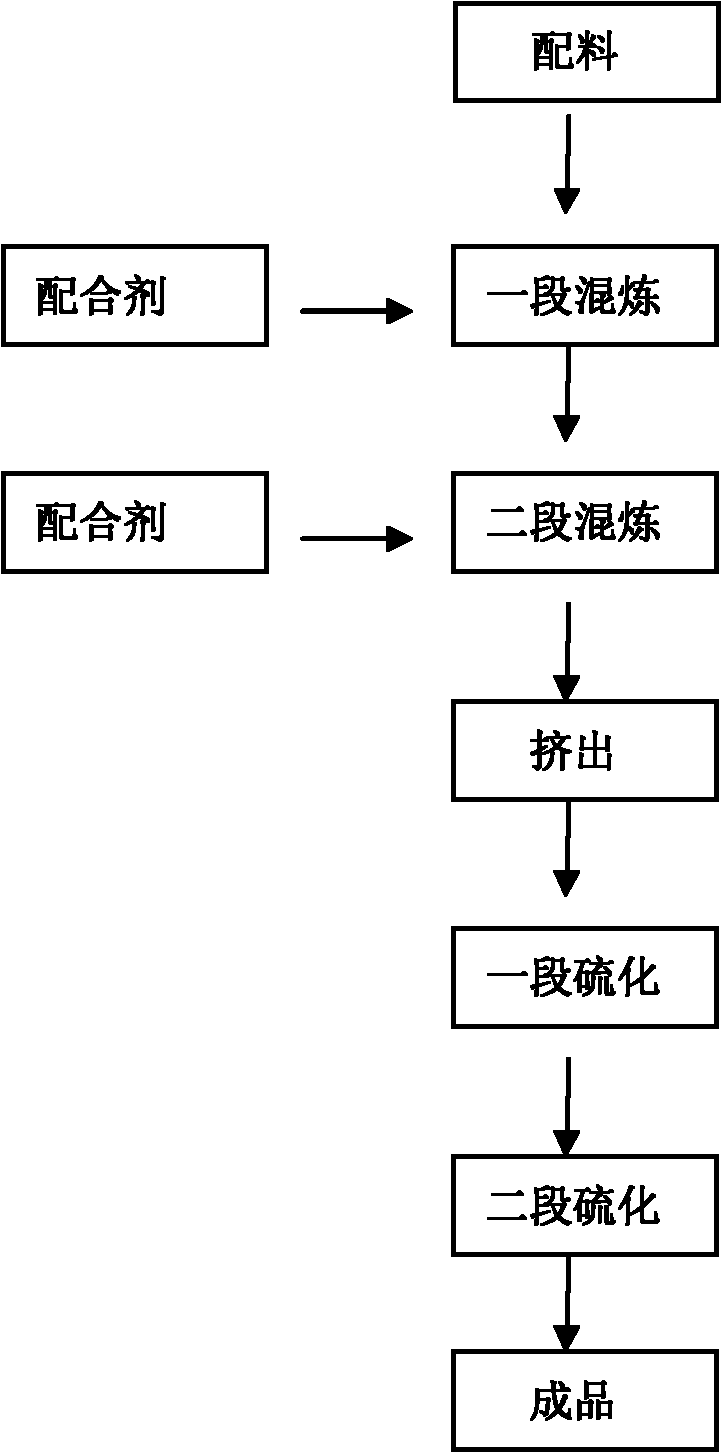

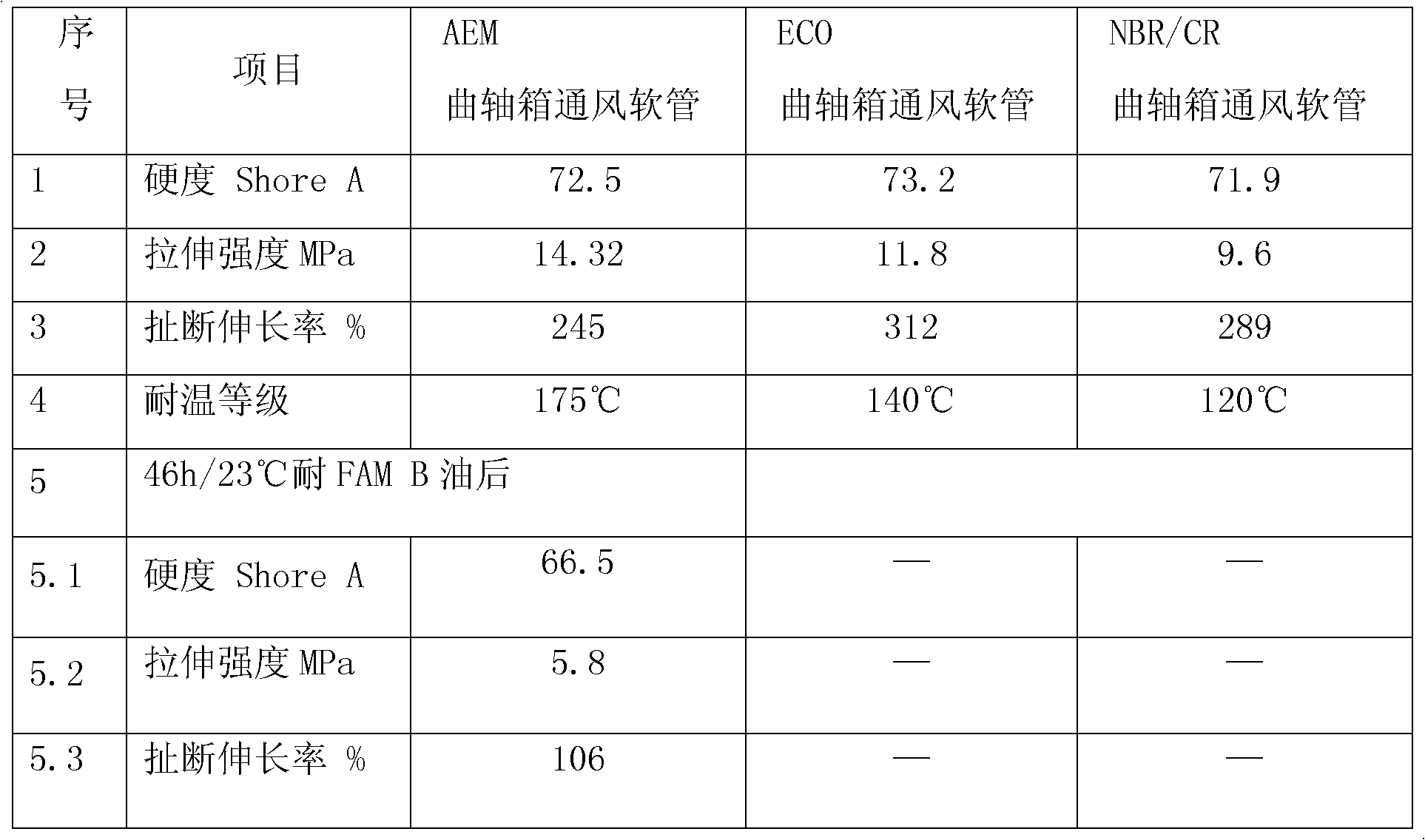

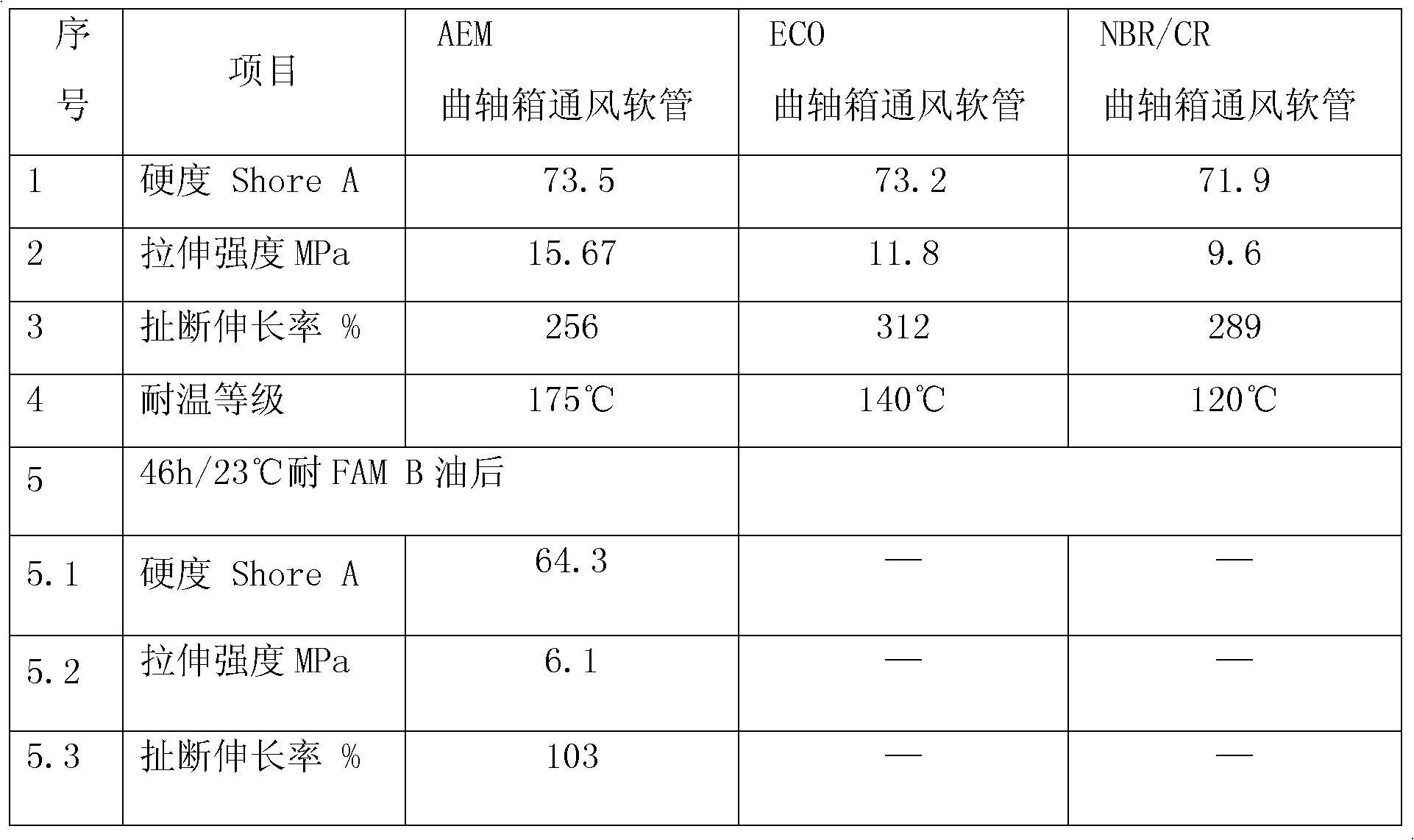

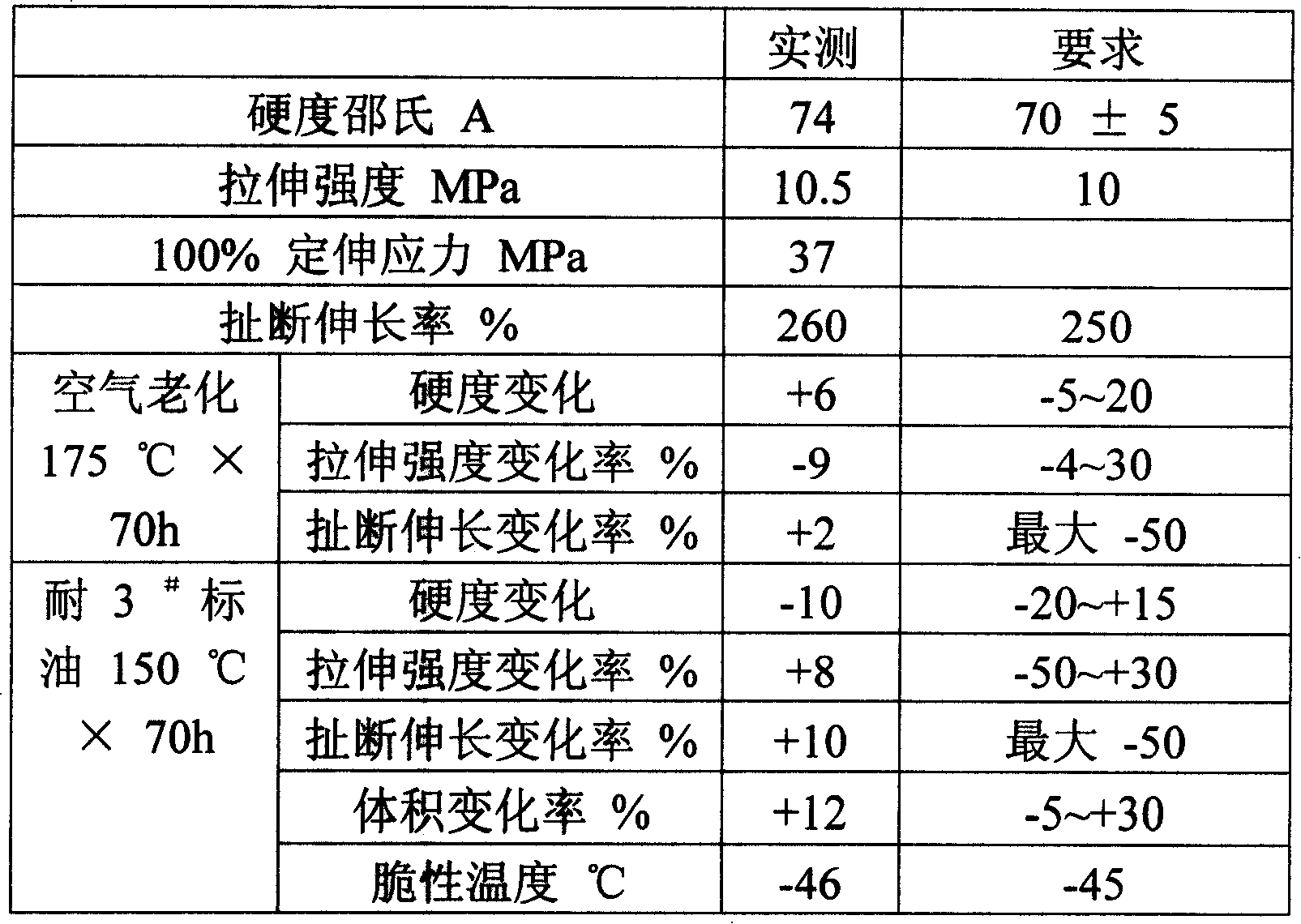

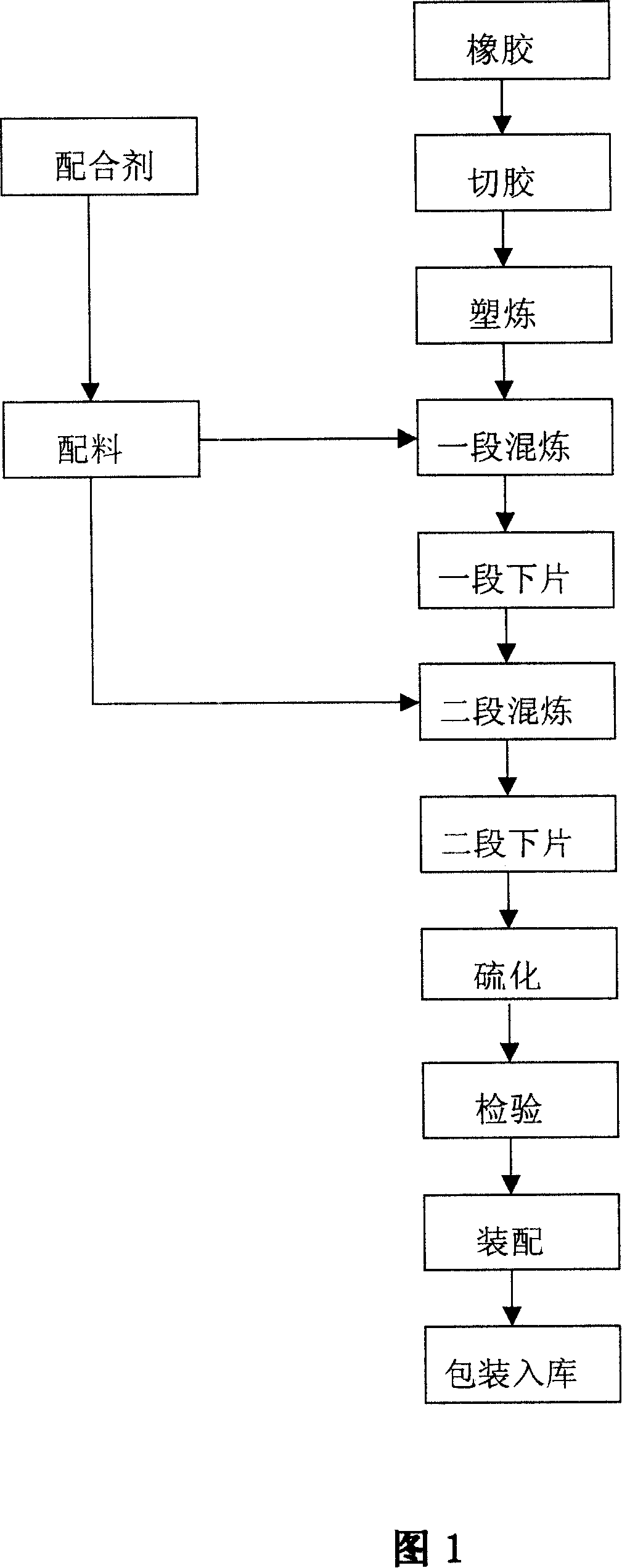

Crankcase ventilation rubber hose and machining method thereof

InactiveCN102093623AHighlight the characteristics of resistance to FAM B oilBest performance combinationEthyleneDelivery system

The invention relates to a crankcase ventilation rubber hose and a machining method thereof. Raw materials include ethylene acrylate rubber, acrylic ester rubber, nitrile rubber, a reinforcing agent, a plasticizing agent, an interior parting agent, an age inhibitor, a vulcanizing agent and an accelerator; all the rubber and corresponding auxiliary materials are blended according to mass parts specified in a rubber formula; and the reinforcing agent and the plasticizing agent are automatically fed by an automatic pipeline conveying system. The rubber hose is produced by using a Banbury mixer through a two-stage rubber mixing process, so that a sizing material has a bright exterior after being mixed, and is mixed uniformly. A cold feed extruder is used for extruding finished hose blanks. A hose is required to be molded by first-stage and second-stage vulcanization. By using the machining method, an optimal material performance combination is obtained, comprehensive requirements on the using performance, the production cost and the like of a product are met, the FAM B oil resistance of the crankcase ventilation hose is prominent, the resistance to oil temperature is increased from 140 DEG C to 175 DEG C, the oil resistance is enhanced from 135 DEG C to 160 DEG C, and higher using requirements are met.

Owner:TIANJIN PENGYI GRP CO LTD

Phosphorus-containing fluorine-containing synergic flame-retardant compound and preparation method thereof

InactiveCN105732715AHas synergistic flame retardant effectImprove flame retardant performanceGroup 5/15 element organic compoundsBenzaldehydeEvaporation

The invention provides a phosphorus-containing fluorine-containing synergic flame-retardant compound and a preparation method thereof, relating to flame-retardant compounds. The preparation method comprises the following steps: carrying out reaction on a diamido compound and 5-bis(trifluoromethyl)benzaldehyde in a first solvent, carrying out rotary evaporation, and drying to obtain an intermediate containing carbon-nitrogen double bond; and carrying out reaction on the intermediate containing carbon-nitrogen double bond and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide in a second solvent, precipitating the product with a precipitant, washing with the precipitant, and drying to obtain the phosphorus-containing fluorine-containing synergic flame-retardant compound. The compound simultaneously comprises the flame-retardant elements phosphorus and fluorine, and the phosphorus and fluorine have the synergic flame-retardant actions; and thus, the compound can be used as a flame retardant and has favorable flame-retardant effect. The introduced fluorine element can enhance the heat stability and chemical stability, lower the surface energy of the material and lower the dielectric constant and hydroscopic property of the material, thereby satisfying the required properties of the electronic packaging material. The compound contains two active groups, thereby being beneficial to enhancing the compatibility with the high-polymer material, improving the loss of the flame retardant and enhancing the flame retardancy.

Owner:XIAMEN UNIV

Cement flakeboard and production process thereof

InactiveCN101117005AEasy to useLow costSolid waste managementCeramic shaping apparatusWood shavingsChloride

The present invention provides a cement particle board and the manufacturing method thereof; the cement particle board comprises the weight percentage compositions of raw materials: 15 to 35 percent of wood wool (absolute dry wood wool), 15 to 45 percent of high-calcium fly ash, 30 to 55 percent of cement, 1 to 3 percent of sodium silicate, 0.3 to 1.8 percent of calcium chloride and 0.1 to 2 percent of addition agent. The method of the present invention uses high-calcium fly ash of industrial wastes, frutex or lops wood shavings for manufacture of hard board, thereby reaching the 'Cement Xylolite Slab (JC / T411-1991)' standard and saving production cost, reducing environmental pollution, expanding, at the same time, the range of wood raw materials for particle board production and creating higher economic value.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Red-mud coal ash baking-free brick

The invention belongs to construction material,Which provides material components and weight percentage rate of a baking-free brick with red mud and flyash are: 22-40 of the red mud, 20-35 of the flyash, 20-40 of aggregate, 8-12 of lime and 1-3 of plaster.With the aim of realizing the largest utilization quantity of the red mud and economizing the cost, through the researches and experiments, the invention uses the red mud and the flyash as main material and uses grit and friable rubbles as the aggregate so as to facilitate compressive strength of the products; the lime and the plaster is added to improve plasticity of the blank material, strength of a semi-finished blank brick and the compressive strength of the products. The invention can satisfy the utilization performance of the products and at the same time completely can meet the national standard requirement, thus solving the problem of the environmental pollution caused by the discharge of the red mud in larger sense.

Owner:LUOYANG ZHONGCHAO NEW MATERIAL SHARES CO LTD

Acrylate rubber sizing material for high performance requirements

The invention relates to sizing material used for the acrylic acid ester rubber with high performance requirement. The acrylic acid ester rubber of active chlorine introduced from epoxy gene is chosen, and trimerization thiocyanic acid TCY is adopted as a vulcanizing system; the invention comprises concrete ingredients as follows: 100 parts of AR5160, 60-90 parts of carbon black N330, 1.0-2.0 parts of stearic acid, 8-14 parts of plasticizer, 2.0-2.5 parts of WB-212, 0.1-0.3 part of anti-scorching agent E / C, 2.0-3.0 parts of antioxidant, 1.0-1.5 parts of curing agent TYC, and 1.5-2.5 parts of accelerator BZ; glass with Mooney viscosity of ML1+4 50 is adopted to be vulcanized and transformed into -25 DEG C acrylic acid ester rubber for matching, so as to ensure that the brittleness intensity reaches above -45 DEG C. The sizing material of the acrylic acid ester rubber with high performance requirement is obtained. The sizing material has the advantages that the comprehensive physical property is good, and simultaneously the brittleness temperature is lower. The invention meets the requirement of the vehicle industry to the sealing material, and the technical level achieves the domestic advanced level. The invention is suitable for the ranges of vehicle engine, crank oil seal, gear shifting box oil seal, and heat resistant, oil proof and cold resistant rubber hose, and protecting sleeve, etc.

Owner:天津海程工贸有限公司

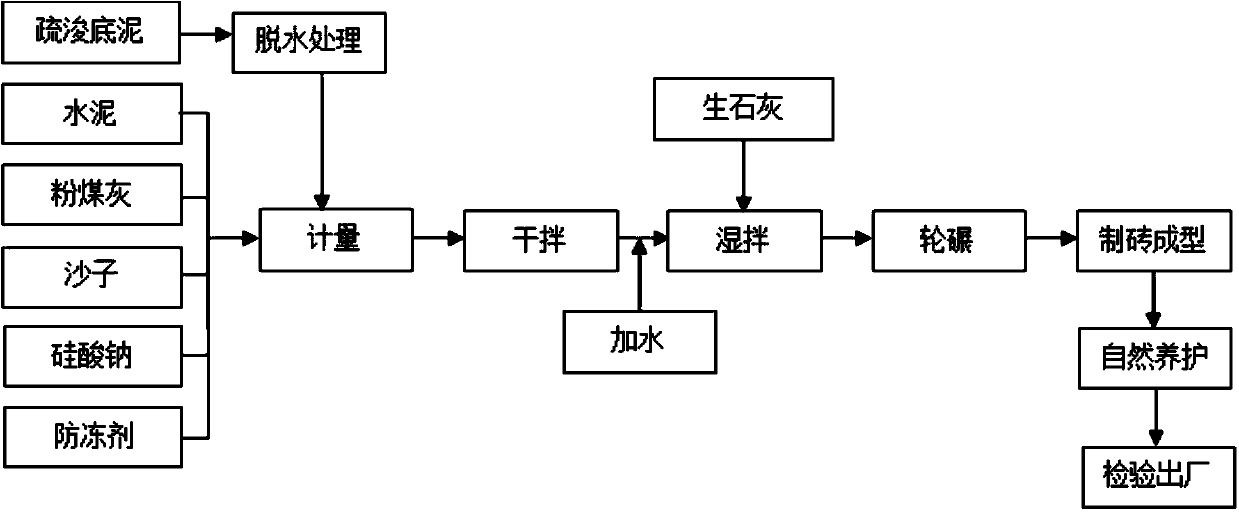

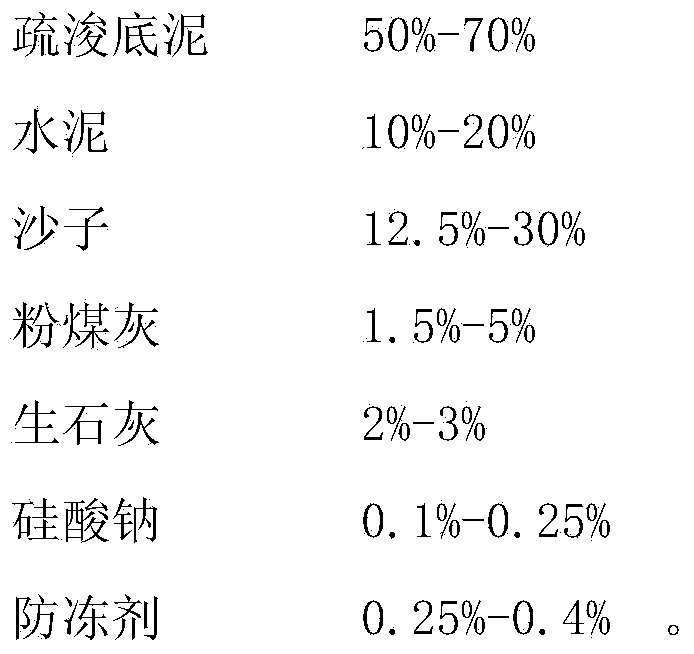

Baking-free brick mainly prepared from river/lake dredging sediment and natural-curing manufacturing method thereof

ActiveCN104177015ASolve the problem of low contentSolve the problem of resource utilizationSolid waste managementBrickSodium silicate

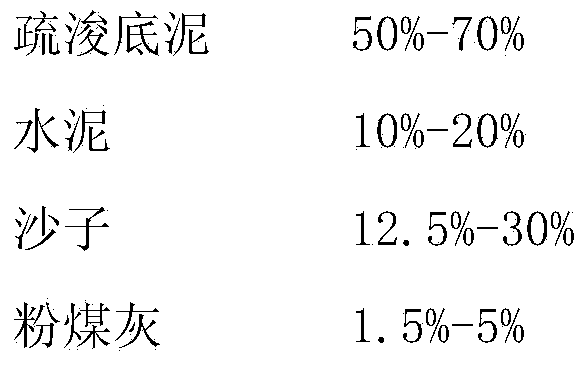

The invention relates to a baking-free brick mainly prepared from river / lake dredging sediment and a natural-curing manufacturing method thereof, belonging to the technical fields of environmental engineering and construction materials. The baking-free brick is composed of the following raw materials in percentage by weight: 50-70% of dredging sediment, 10-20% of cement, 12.5-30% of sand, 1.5-5% of fly ash, 2-3% of quicklime, 0.1-0.25% of sodium silicate and 0.25-0.4% of antifreezing agent. The manufacturing method comprises the following steps: (1) dredging sediment dehydration: dehydrating the dredging sediment until the water content is less than 30%; (2) mixing: carrying out dry mixing on the dredging sediment, cement, sand, fly ash, sodium silicate and antifreezing agent; adding water, carrying out wet mixing, adding quicklime and stirring; (3) rolling; (4) brick making: making the brick with a brick making machine through vibration and pressurization; and (5) natural curing: piling the bricks, and naturally curing to obtain the baking-free bricks. The method is simple in technique and convenient to operate, changes wastes into valuable substances, and has the advantages of high brick quality, low cost, obvious benefit, environment friendliness and the like.

Owner:CCCC TDC ENVIRONMENTAL ENG

Method for repairing wear of inner wall of intermediate casing of engine

InactiveCN102953058AAchieve metallurgical bondingSatisfy the use effectMetallic material coating processesTitaniumTitanium alloy

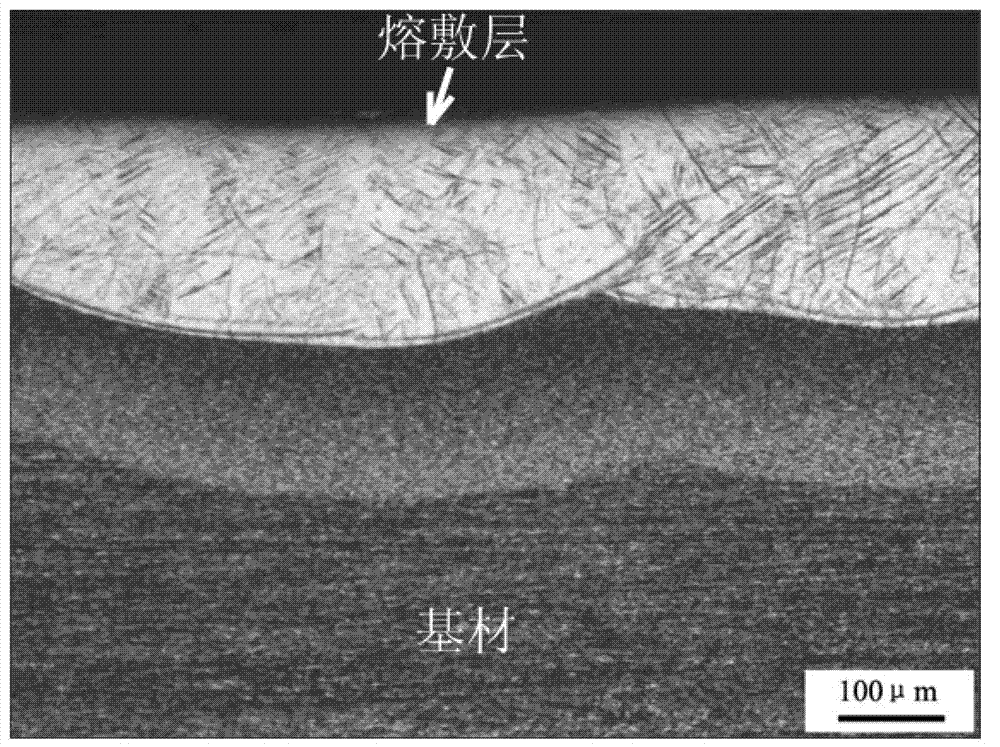

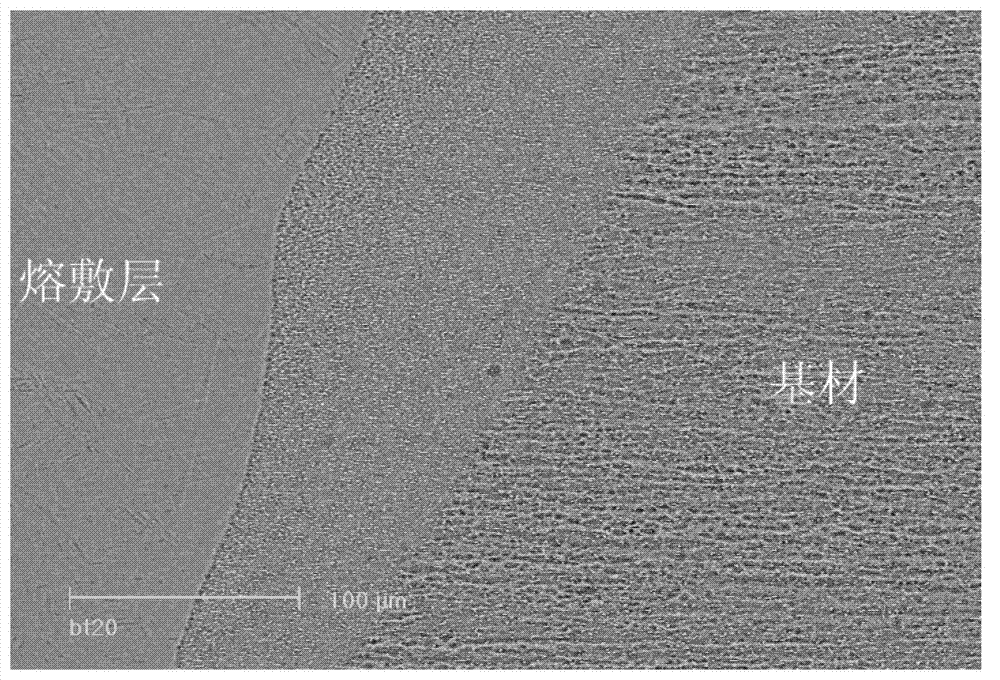

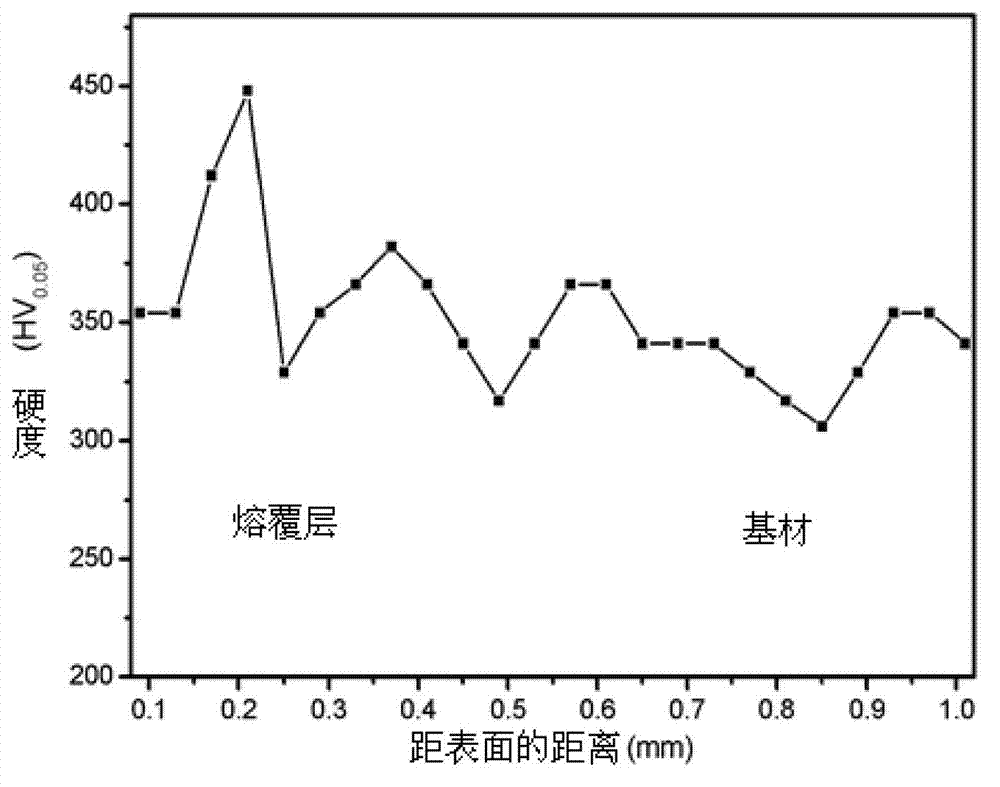

The invention aims to provide a method for repairing the wear of the inner wall of an intermediate casing of an engine, and the method is characterized in that a laser cladding method is adopted to repair the worn part on the inner wall of the intermediate casing of the engine; the repair process is as follows: a cladding material is a BT20 titanium alloy; the weight percentage of the components of the titanium alloy is as follows: 5.5 percent to 7.5 percent of aluminum (Al), 1.5 percent to 2.5 percent of zirconium (Zr), 0.5 percent to 2.0 percent of molybdenum (Mo), 0.8 percent to 1.8 percent of vanadium (V), and the rest titanium (Ti); the single-pulse energy is 50J, the frequency is 4Hz, the pulse width is 5ms, the focus is 150mm, the diameter of light spots is 1.2mm, the scanning speed is 1.2mm / s and argon is adopted for protection. Due to the adoption of the method, the service life of the intermediate casing in the aero-engine can be prolonged, so that the intermediate casing can work in a complete technical state, and the use performance is met.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

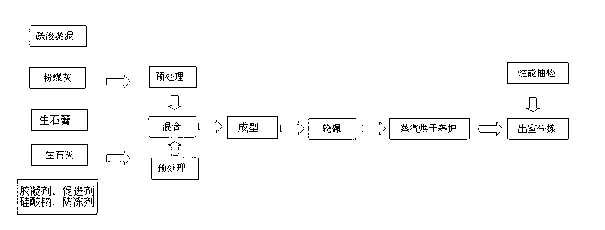

Sludge baking-free brick and preparation method thereof

The invention relates to a sludge baking-free brick. The brick comprises the following components in percentage by mass: 25-40% of dredged sludge (moisture is removed), 30-45% of coal ash, 16-26% of quicklime, 4-8% of raw gypsum, 0.3-0.5% of gelatinizing agent, 0.2-0.4% of accelerant, 0.1-0.15% of sodium silicate and 0-0.25% of anti-freezing agent. Meanwhile, the invention further discloses a preparation method of the sludge baking-free brick. According to the sludge baking-free brick and the preparation method of the sludge baking-free brick, the industrial production can be completely realized, and the produced products can be used for replacing clay sintered bricks, so that not only is the environment protected, but also a mass of earth-rock resources are saved.

Owner:JIANGSU PROVINCIAL COMM PLANNING & DESIGN INST

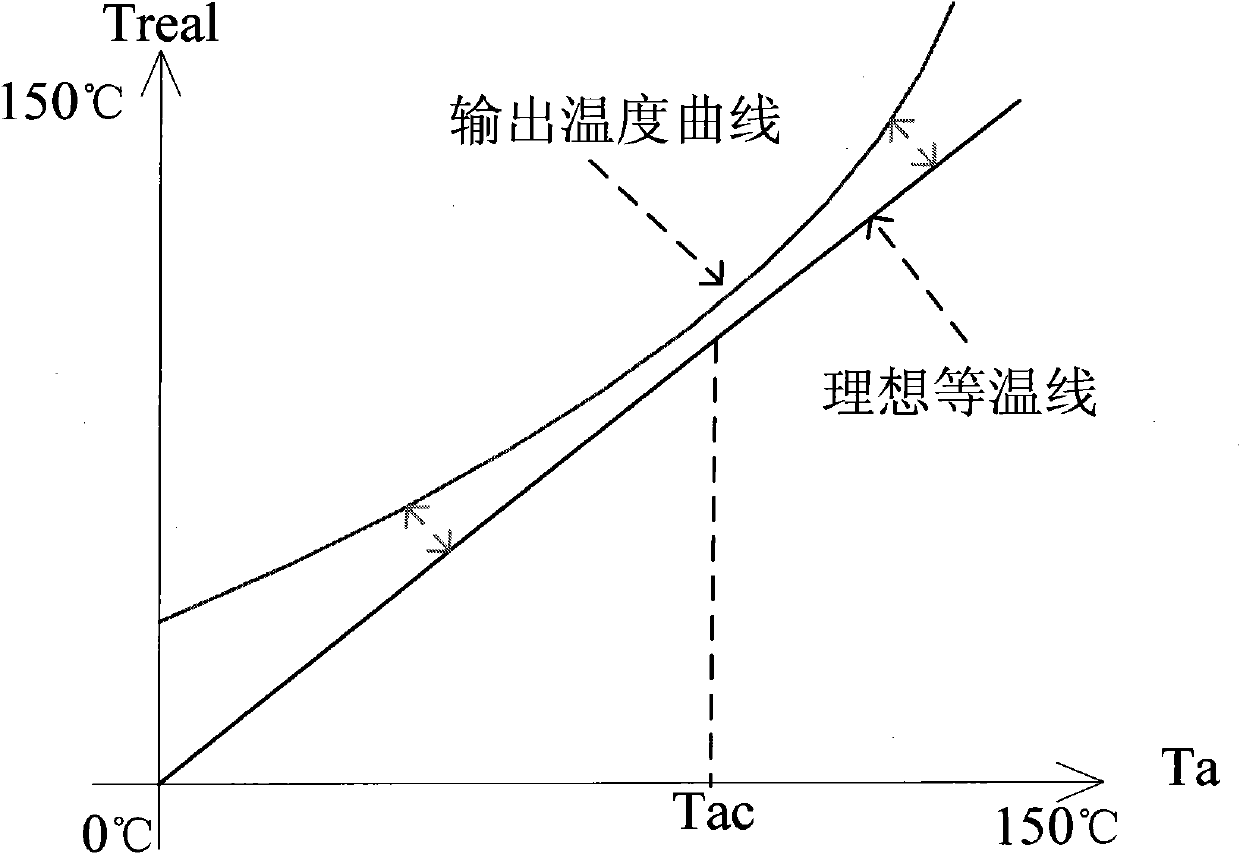

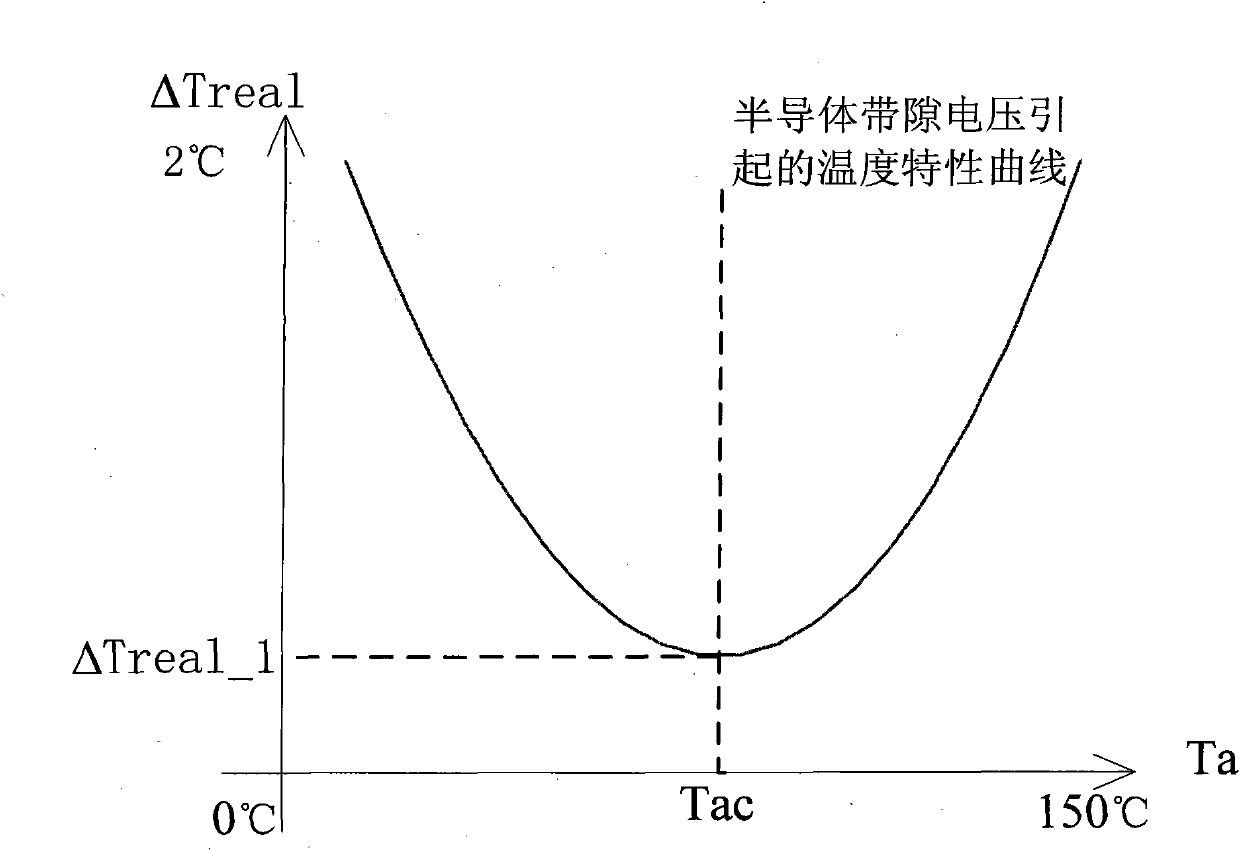

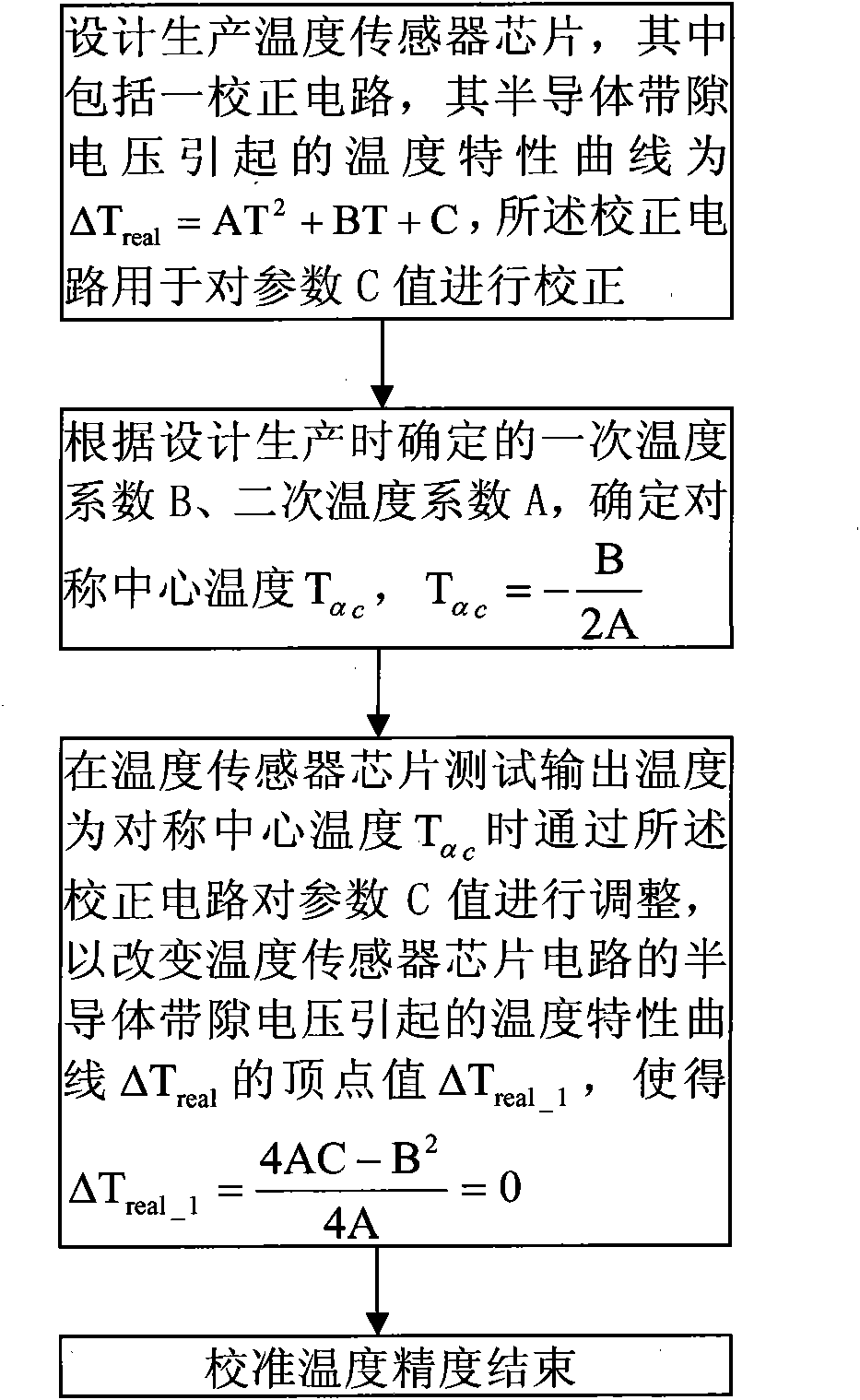

Method for calibrating temperature precision of temperature sensor chip

ActiveCN102116687AReduce test steps and test timeLow costThermometer testing/calibrationTemperature testingBand gap

The invention discloses a method for calibrating temperature precision of a temperature sensor chip. The method comprises the following steps of: designing and producing the temperature sensor chip, wherein the temperature sensor chip comprises a correction circuit, and a temperature characteristic curve caused by band gap voltage of a semiconductor is shown in the specification: deltaTreal=AT<2>+BT+C; determining symmetric center temperature Talphac; when the temperature sensor chip determines that output temperature is the symmetric center temperature Talphac through a test, adjusting a parameter value C by the correction circuit so as to change a vertex value deltaTreal_1 of the temperature characteristic curve deltaTreal caused by the band gap voltage of the semiconductor in the circuit of the temperature sensor chip; and finally completing calibration of the temperature precision of the temperature sensor chip. By utilizing the invention, the final output temperature precision of the temperature sensor chip can be calibrated only by one temperature test.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

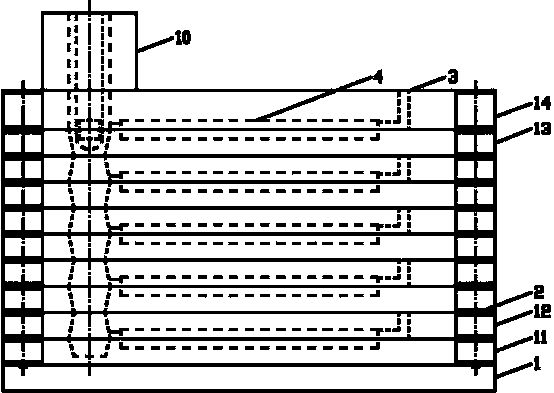

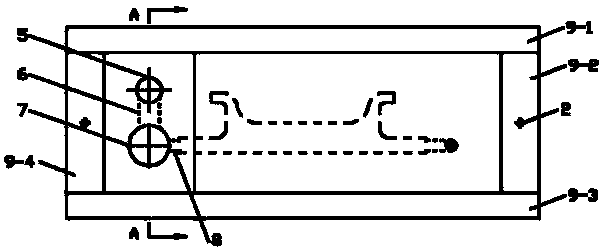

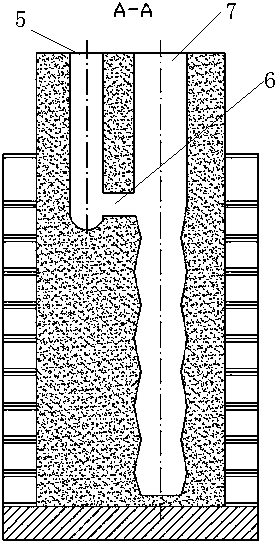

Grate bar material and production method thereof as well as combined pouring unit of sintering machine

ActiveCN103849819AReduce contentHigh hardnessFoundry mouldsFurnace typesChemical compositionBar product

The invention relates to a production method of a grate bar material of a sintering machine. The production method mainly solves the problems that a high-alloy grate bar is complex in production process, relatively high in production cost, difficult in casting flaw control, non-uniform in performance and the like in the prior art. The technical scheme of the invention is as follows: the grate bar material of the sintering machine comprises the following chemical components in percentage by mass: 1-1.5% of C, 1.5-2.5% of Si, 1.2-2.2% of Al, 2.5-3% of Mn, 11-15% of Cr, 0.3-0.8% of Mo, 0.01-0.03% of Nb, 0.01-0.03% of Ti, 0.03-0.1% of Re, less than or equal to 0.06% of P, less than or equal to 0.06% of S, and the balance of Fe and inevitable impurity elements. A sand casting process of 'one pouring with more molds' is applied, so that the aluminum content and the casting flaws of a silicon grate bar are reduced, and the production cost is reduced. A heat treatment furnace provided with a flow guide circulating fan is applied to low-temperature uniform heat treatment on a cast so as to improve the performance uniformity of casts of the same batch. By adopting the production method disclosed by the invention, a grate bar product of the sintering machine, which is good in process stability, good in performance and relatively low in production cost, can be obtained.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

High temperature nickel-hydrogen battery

InactiveCN1702902AImprove charging efficiencyHigh yieldElectrode carriers/collectorsAlkaline accumulator electrodesZincYttrium

This invention relates to high temperature nickel and hydrogen battery in battery field, which comprises base board and positive electrode components, wherein the positive substance has sphere nickel hydroxide activity subject, conductor agent, adhesive agent and addictive agent, wherein the addictive agent is of calcium fluoride, zinc oxide, barium hydrate, erbium oxide, yttrium oxide. The invention improves the positive electrode reaction level and adds the NiOOH quantity through adding zirconium element into the positive subjects.

Owner:宜兴新兴锆业有限公司

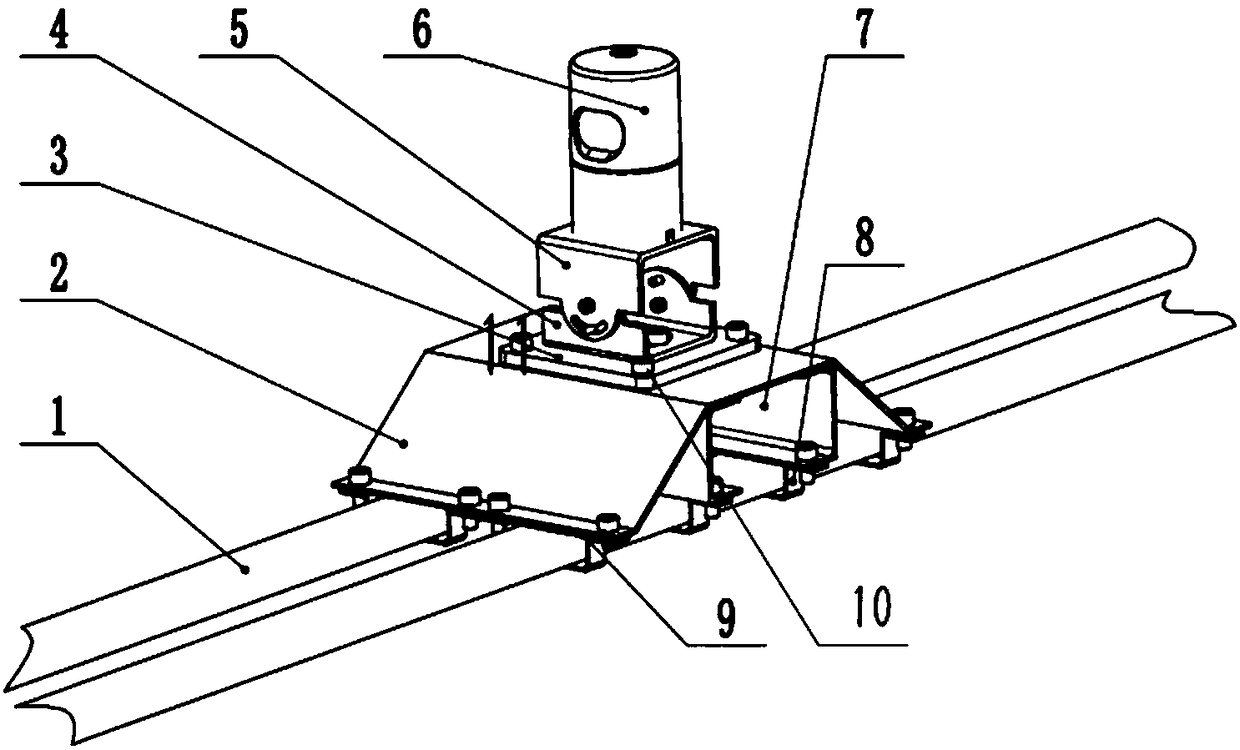

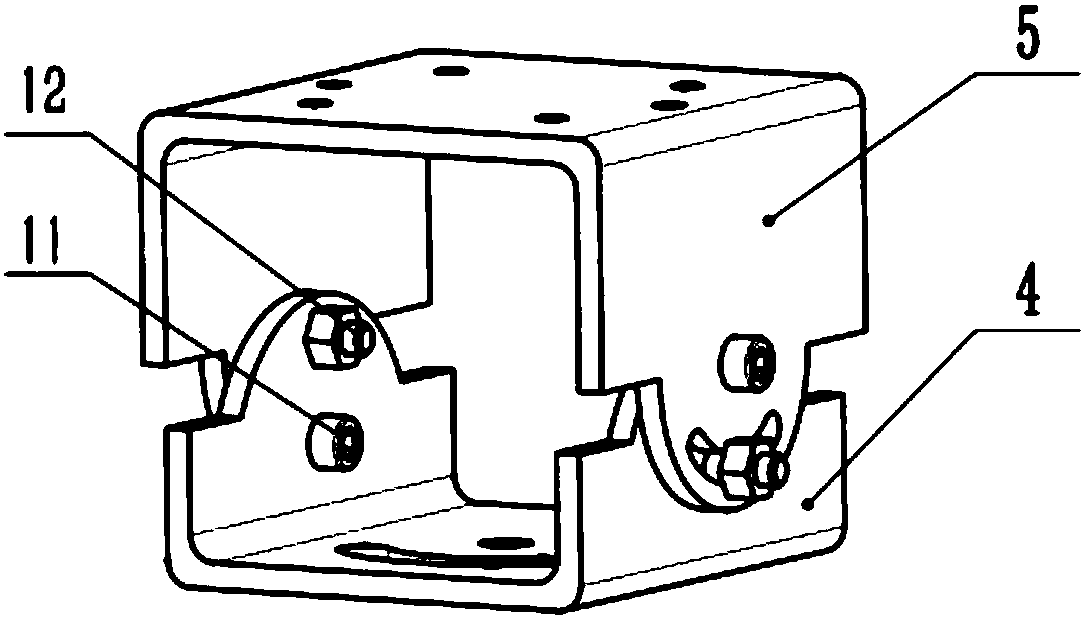

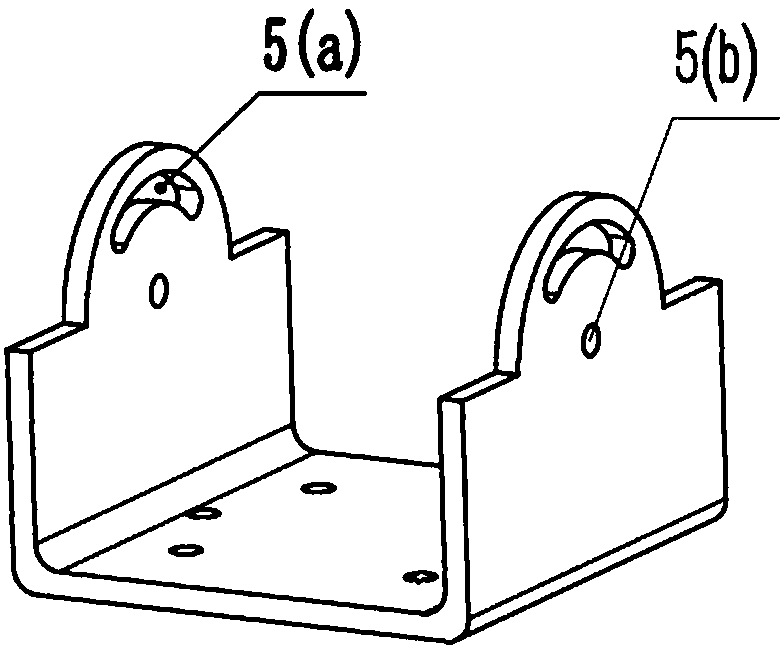

Laser radar mounting bracket and sensing system

InactiveCN108107418AEasy to adjust left and right rotation angleSatisfy the use effectElectromagnetic wave reradiationRadarHorizontal axis

The invention provides a laser radar mounting bracket and a sensing system, which relate to the technical field of unmanned vehicle sensing. The laser radar mounting bracket is suitable for being mounted on a carrier, and comprises a general support frame, a lower adjustment support, an upper adjustment support and a laser radar, wherein the general support frame can be mounted on the carrier; thelower adjustment support is mounted on the top part of the general support frame; the lower adjustment support can rotate around a vertical axis relative to the general support frame; the upper adjustment support is mounted at the upper part of the lower adjustment support, and the two can rotate relatively around a horizontal axis; and the laser radar is mounted at the top part of the upper adjustment support. A sensing system comprises the laser radar mounting bracket. The invention aims at providing a laser radar mounting bracket and a sensing system, so as to alleviate the problems of large volume, large mass, complex structure and inconvenient mounting of the laser radar mounting bracket in the prior art.

Owner:TIANJIN TRINOVA AUTOMOTIVE TECH CO LTD

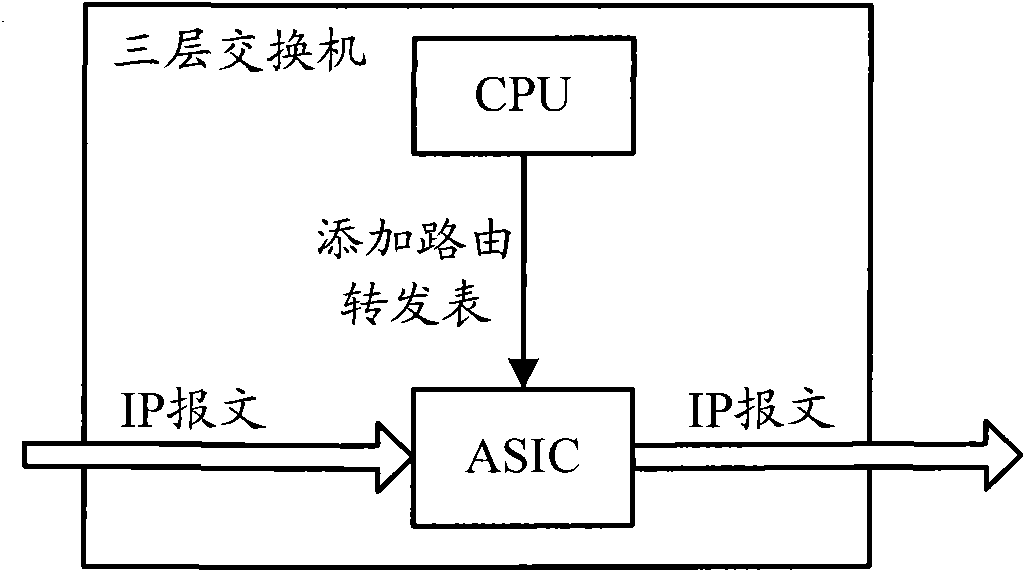

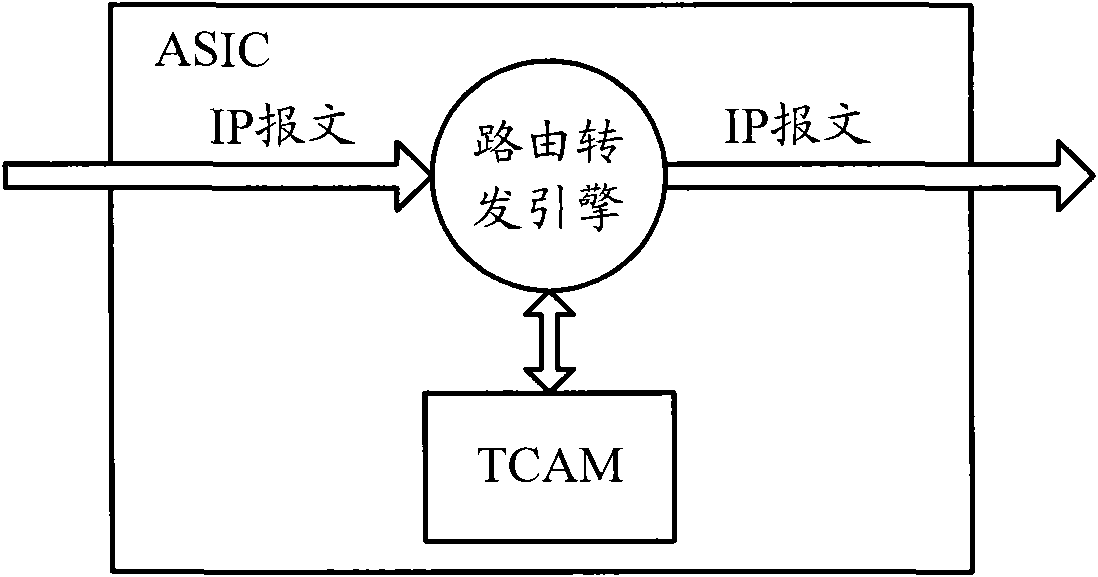

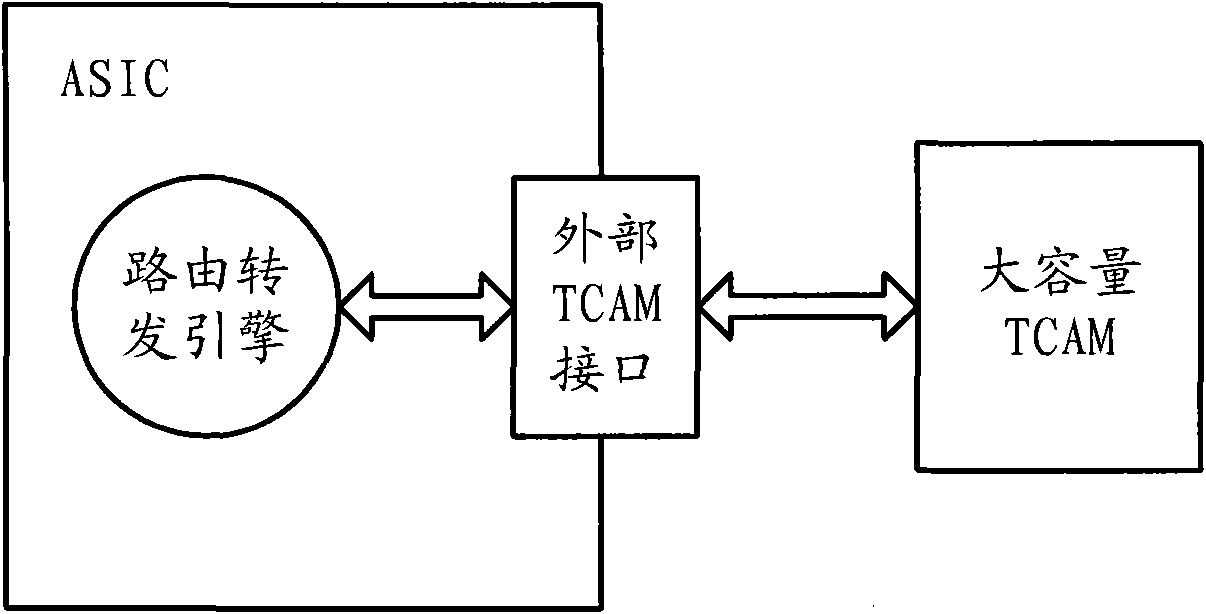

Capacity expansion realization method and device of routing forwarding table and switching device

ActiveCN101883055AMeet the needs of useIncrease frequency of useData switching networksMass storageRouting table

The invention discloses a capacity expansion realization method and device of a routing forwarding table and a switching device. The method comprises the following steps: the intradomain routing forwarding table entry generated by interior gateway protocol is stored in a ternary content addressable memory (TCAM), the interdomain routing forwarding table entry generated by exterior gateway protocol is stored in a mass memory; when a message is received, a routing forward unit is used to search the intradomain routing forwarding table in the TCAM, when the matched intradomain routing forwarding table entry is searched, the corresponding output interface is determined through the searched intradomain routing forwarding table entry to send the message; and when the matched intradomain routing forwarding table entry is not searched, the message is forwarded to a coprocessing unit, and the output interface corresponding to the interdomain routing forwarding table entry which is searched by the coprocessing unit from the memory, is used to send the message. By separately storing the intradomain routing table entry and the interdomain routing table entry, the comprehensive performance of routing forward can be ensured, the capacity of the routing forwarding table can be expanded, the cost can be reduced, and power consumption and other system resources can be saved.

Owner:RUIJIE NETWORKS CO LTD

Color-change resistant latch-locked valve cock rubber formula and method for making same

InactiveCN101134825AImprove performanceSatisfy the use effectTyre-inflating valvesPolymer sciencePlasticizer

The present invention provides one kind of color distortion resistant rubber composition for tyre valve. The rubber composition consists of rubber 100.0 weight portions, phenolic antiager 1.0-2.5 weight portions, plasticizer 5.0-12.0 weight portions, and vulcanizer 2.0-4.3 weight portions, and contains rubber in 30-90 wt%. The color distortion resistant rubber and its product have color distortion resisting performance.

Owner:SHANGHAI BAOLONG AUTOMOTIVE CORP

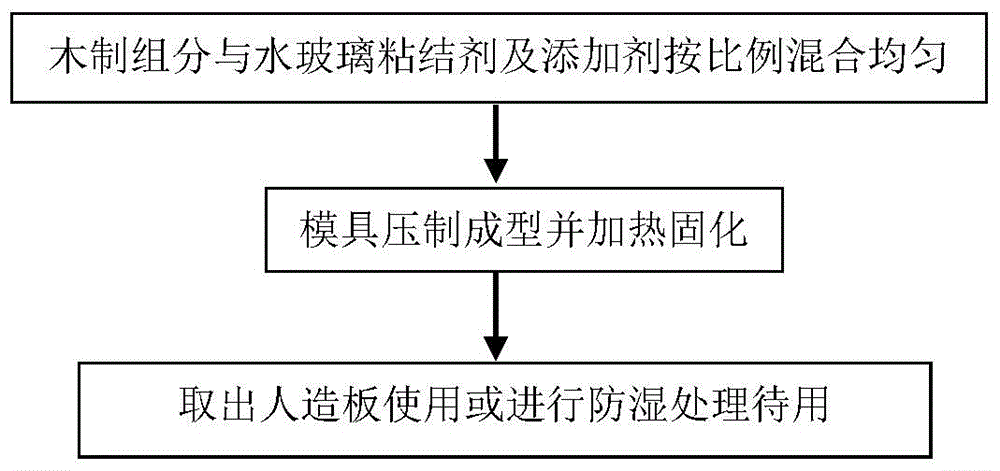

Inorganic binder refractory artificial board material and preparation method thereof

InactiveCN104962099AMeet the requirements of green environmental protectionSatisfy the use effectRefractoryHeat stability

The invention discloses an inorganic binder refractory artificial board material and a preparation method thereof. The inorganic binder refractory artificial board material comprises a wood component and an environment-pollution-free sodium silicate binder, wherein the modulus of the sodium silicate binder is 1.5-3.0. The preparation method comprises the following steps: uniformly mixing the wood component and sodium silicate binder, putting the mixture into a mold, compacting, heating for thermosetting, and demolding to obtain the inorganic binder refractory artificial board. The method can be used for preparing the inorganic binder refractory artificial board which has the advantages of no formaldehyde release, favorable static bending strength, favorable elastic modulus, favorable hydroscopic property, favorable heat stability and favorable fire resistance. The method has the advantages of wide raw material sources and low price.

Owner:HUAZHONG UNIV OF SCI & TECH

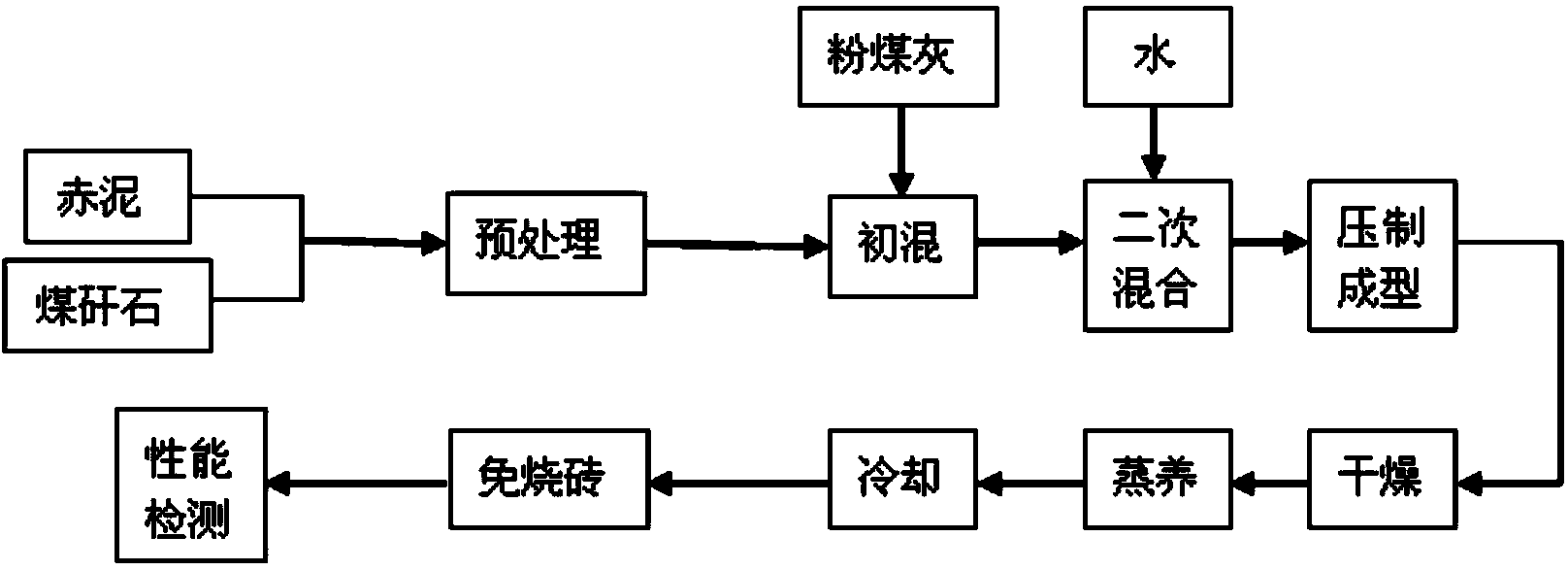

Baking-free brick using coal gangue and red mud as main materials, and preparation method for baking-free brick

ActiveCN104072069AReduce manufacturing costLow costSolid waste managementCoal ganguePulverised fuel ash

The invention relates to a baking-free brick using coal gangue and red mud as main materials, and a preparation method for the baking-free brick. The preparation method comprises the following steps: selecting red mud, coal gangue and fly ash as raw materials, adding water to make a green body, and then steaming and nourishing in water vapor of which the temperature is 60-140 DEG C and the pressure is 0.12-0.35 MPa for 2-10 h. Through steaming and nourishing at the specific pressure and the specific temperature, the structure of the prepared baking-free brick is relatively compact, the average compressive strength is further improved, the dose of an exciting agent is reduced, the strength of the brick is improved, the plasticity of the green body and the compressive strength of the product are improved, the baking-free brick not only satisfies the usability of the product, but also completely achieves the requirements of national standard, no cementing material is needed to be added in the production process, no firing is needed, accumulation of red mud and coal gangue is reduced in a larger sense, and the problem of red mud and coal gangue discharge on environment is solved.

Owner:SHANDONG UNIV

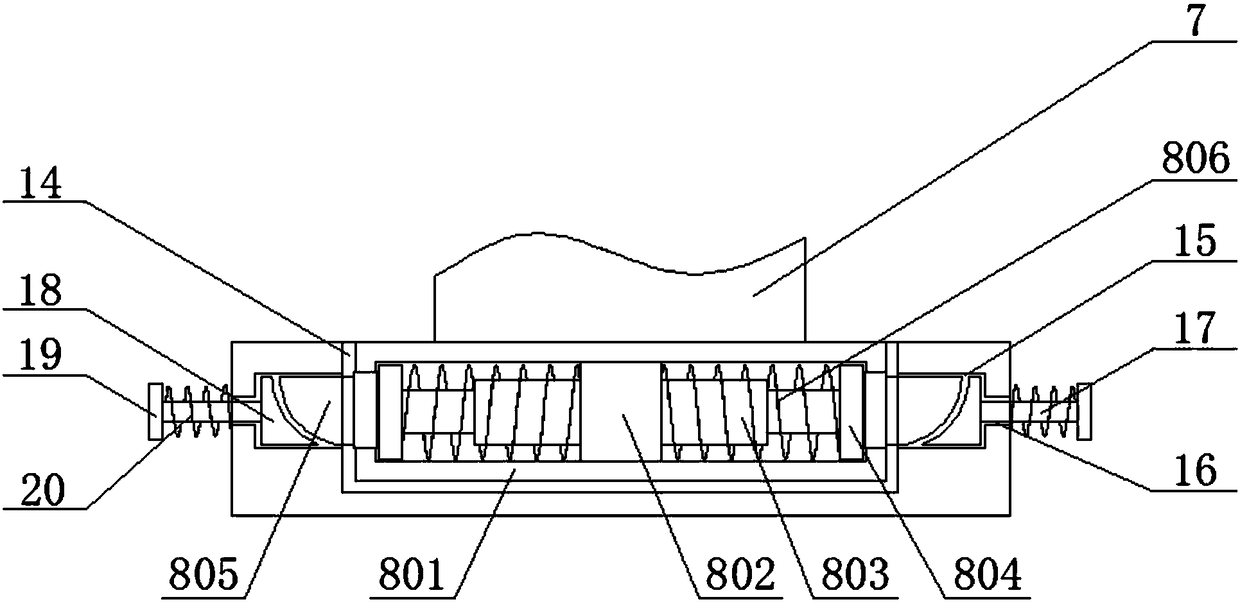

Shock absorbing type electronic capacitor fixed containing box

InactiveCN108100476APlay a protective effectHas the function of classificationContainers to prevent mechanical damageInternal fittingsMaterial resourcesEngineering

The invention discloses a shock absorbing type electronic capacitor fixed containing box. The shock absorbing type electronic capacitor fixed containing box comprises a box body and a box cover, the inside of the box body is provided with a support plate, the top of the support plate is provided with a containing frame, the bottom of the support plate is provided with a buffering device, and the bottom of the buffering device is fixedly connected with the bottom of the inner cavity of the box body; one side of the box cover is rotatably connected with one side of the box body, one side of thebox body is provided with a fixing block, the other side of the box cover is provided with a connecting plate, and the bottom of the connecting plate is provided with a fixing device. The shock absorbing type electronic capacitor fixed containing box relates to the technical field of capacitors. By means of the buffering device, first buffering springs, a stopper and a rubber cushion, the shock absorbing type electronic capacitor fixed containing box achieves the aim of absorbing shock and avoids the problem of damage caused by shock as well as economic loss; by means of the fixing device, thefixing block, a fixing groove, a limiting groove and a sliding groove, the box cover is convenient to open and close, so that labor and material resources can be saved, and the use demands of users can be met.

Owner:浙江万工电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com