Acrylate rubber sizing material for high performance requirements

A technology of acrylate and rubber compound, applied in the field of rubber compound, can solve the problem that the comprehensive performance is not very good, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

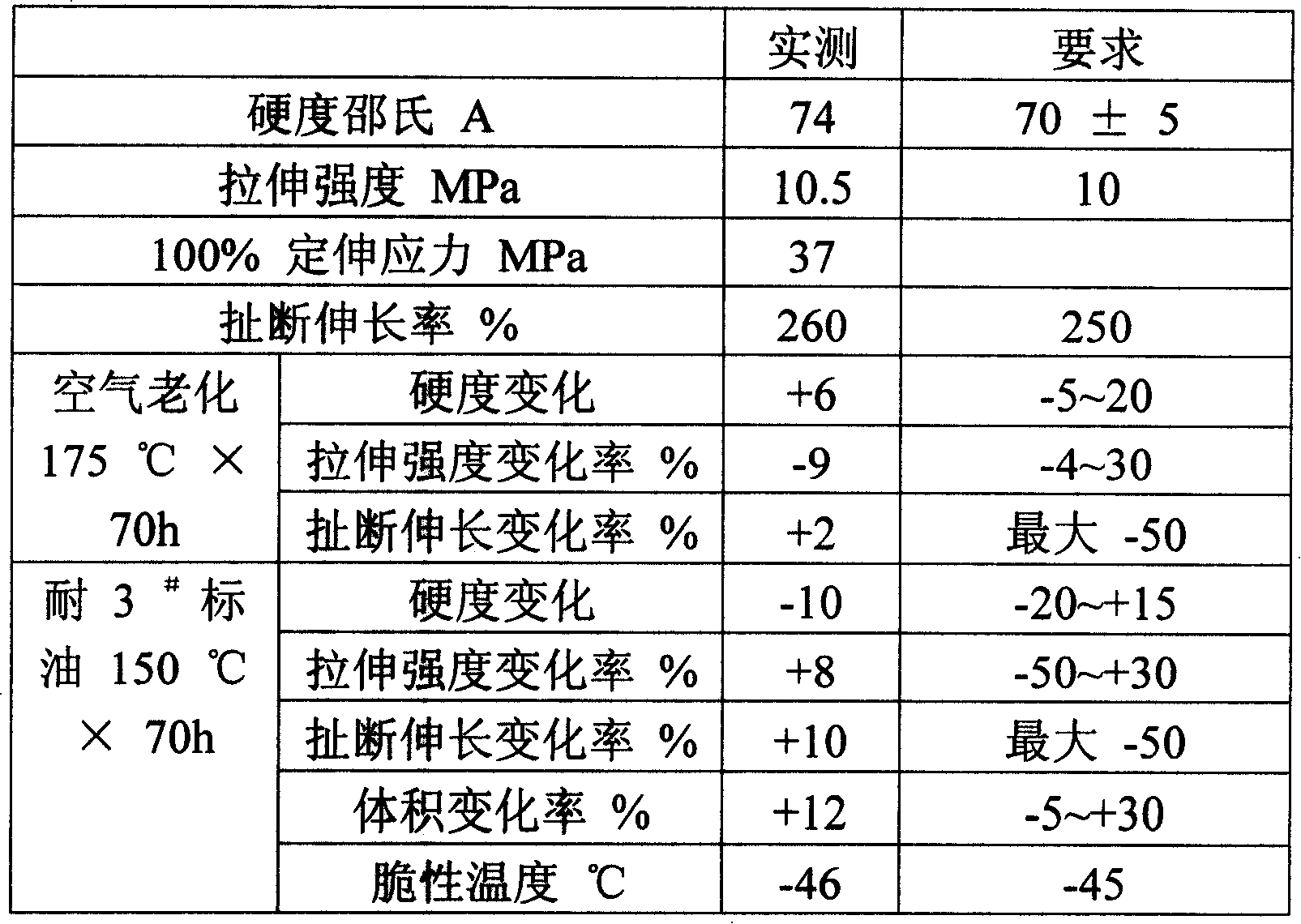

Image

Examples

Embodiment Construction

[0023] Acrylate rubber with active chlorine that introduces epoxy genes is selected, and thiocyanate (TCY) is used as the vulcanization system. Appropriately add ether fat plasticizer and other materials to obtain a compound with good comprehensive performance and low temperature resistance.

[0024] Specific ingredients one:

[0025] Acrylate rubber AR5160 100 parts

[0026] Carbon black N330 60 parts

[0027] Stearic acid 1.0 parts

[0028] Ether adipate TP-95 8 parts

[0029] Fatty acid ester WB-212 2.0 parts

[0030] N-trichloromethylthio-N-phenylsulfamide E / C 0.1 parts

[0031] Dialkylated diphenylamine 445 2.0 parts

[0032] Tripolythiocyanate TYC 1.0 parts

[0033] 1.5 parts of zinc dibutyldithiocarbamate BZ;

[0034] Specific ingredients two:

[0035] Acrylate rubber AR5160 100 parts

[0036] Carbon black N330 90 parts

[0037] Stearic acid 2.0 parts

[0038] Adipate ether ester TP-95 14 parts

[0039] Fatty acid ester WB-212 2.5 parts

[0040] N-trichlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com