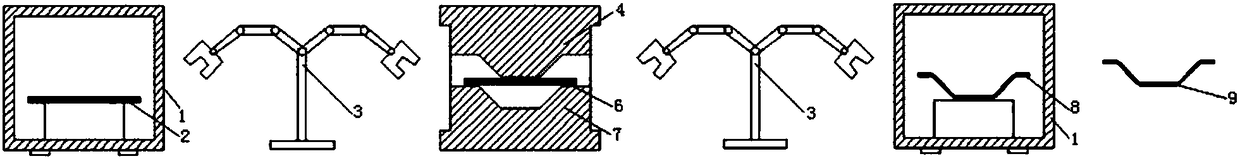

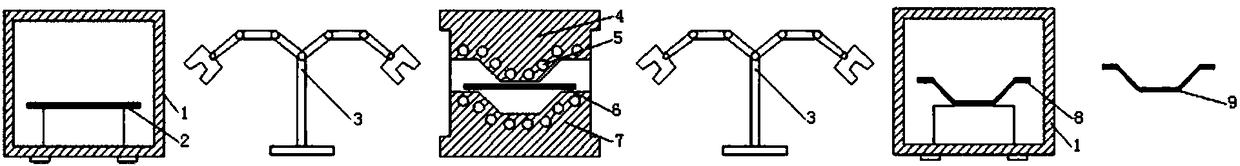

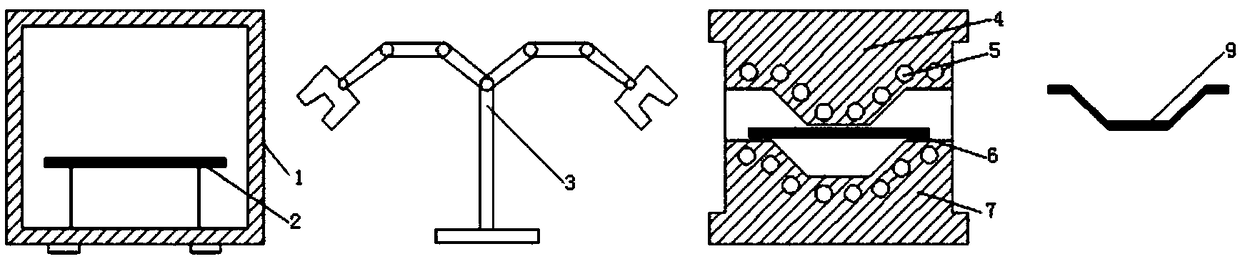

Hot stamping forming method of lightweight aluminum alloy vehicle body component

A hot stamping and aluminum alloy technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of no simplified forming process, limited improvement of production efficiency, long holding time, etc., and achieve labor costs and production equipment. The effect of cost reduction, saving processing time, and short holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Now, a 7075 aluminum alloy plate is taken as an example to describe the embodiment of the present invention in detail. According to the national standard GB / T228.1-2010 "Metallic Materials Tensile Test Part One: Room Temperature Test Method", the aluminum alloy sheet blank was subjected to a tensile test, and its tensile strength was measured to be 565MPa.

[0029] According to the traditional hot stamping method, it is generally heated to the required forming temperature for thermoforming. After the thermoforming is completed, solid solution + artificial aging treatment is carried out, that is, heating to 460-499°C for 30-40 minutes, and heating to 115°C after quenching. ~125°C for 24 hours to obtain parts whose strength meets the requirements of use; according to the integrated thermoforming-quenching process, the billet needs to be solid solution treated first, that is, heated to 460-499°C for 30-40 minutes, and then the temperature Reduce to the required forming tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com