Color-change resistant latch-locked valve cock rubber formula and method for making same

A valve and rubber technology, applied in tire inflation valves, tire parts, transportation and packaging, etc., can solve the problems of paint color changes, affecting the appearance quality of rims, and not considering the discoloration of rubber to paint, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

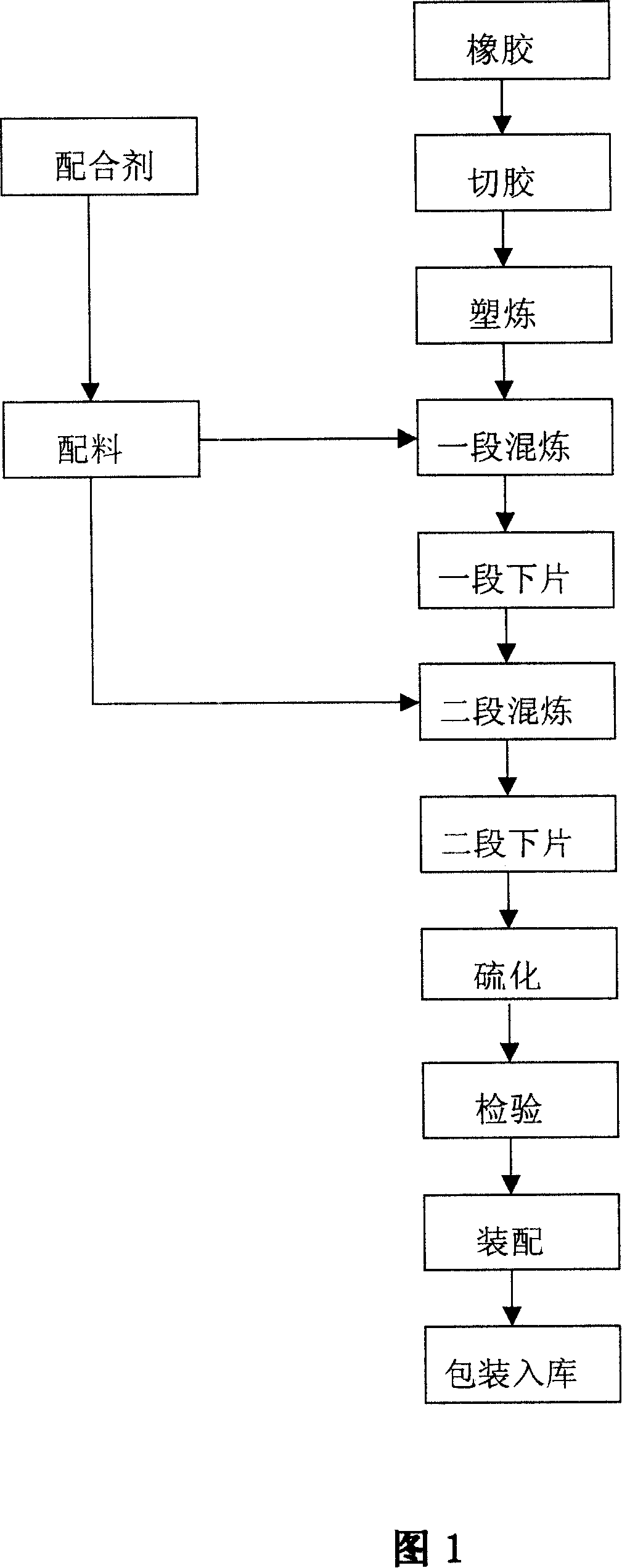

[0078] In one embodiment of the present invention, the preparation method step of anti-color change rubber is provided as follows:

[0079] 1. Processing technology:

[0080] 1) Mastication: In order to improve the plasticity of raw rubber, use a closed rubber mixer for plastication, and it is required to park for 8-72 hours after cooling;

[0081] 2), batching: batching according to the mass parts specified in the rubber formula, that is, other raw material components except rubber;

[0082] 3), one-stage mixing: using a closed rubber mixer for mixing

[0083] In the first step, drop into the masticated rubber of step 1), and knead for 3 minutes;

[0084] In the second step, put in compounding agent (active agent, stearic acid, anti-aging agent, protective paraffin), 30-40 parts of reinforcing agent, and knead for 2 minutes;

[0085] In the third step, put in 20-30 parts of reinforcing agent and plasticizer, and mix for 3 minutes;

[0086] The fourth step is to discharge ...

Embodiment 1

[0157] The composition of the rubber formula composition is shown in Table 1 below:

[0158] Table 1 Composition of Anti-color Change Rubber Formula Composition

[0159] material name

parts by mass

parts by mass

rubber

100. 0

Plasticizer naphthenic oil

6.0

5.0

accelerator DM

(dibenzothiadisulfide

0.6

2.0

Accelerator CZ

(N-cyclohexyl-2-benzene

and thiazole sulfenamide)

0.7

Antiaging agent CPL

1.0

Accelerator TT

0.2

[0160] (GREATLAKES public

produced by the company)

(Tetramethyl sulfide

Lamb)

protective paraffin

1.5

vulcanizing agent sulfur

1.2

Reinforcing agent carbon black

50

Vulcanizing agent DTDM

(Dimorphine disulfide ...

Embodiment 2

[0188] The composition of the rubber formulation composition is shown in Table 2 below:

[0189] Table 2 Discoloration-resistant rubber formula composition composition

[0190] material name

[0191] The same preparation method as in Example 1 was used to prepare the snap-on air valve, and the method of Comparative Example 1 was used to measure the resistance to discoloration, and it remained unchanged for 12 months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com