Baking-free brick mainly prepared from river/lake dredging sediment and natural-curing manufacturing method thereof

A technology for dredging sediment and natural conservation, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve low cost, obvious economic benefits, and improved compression resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

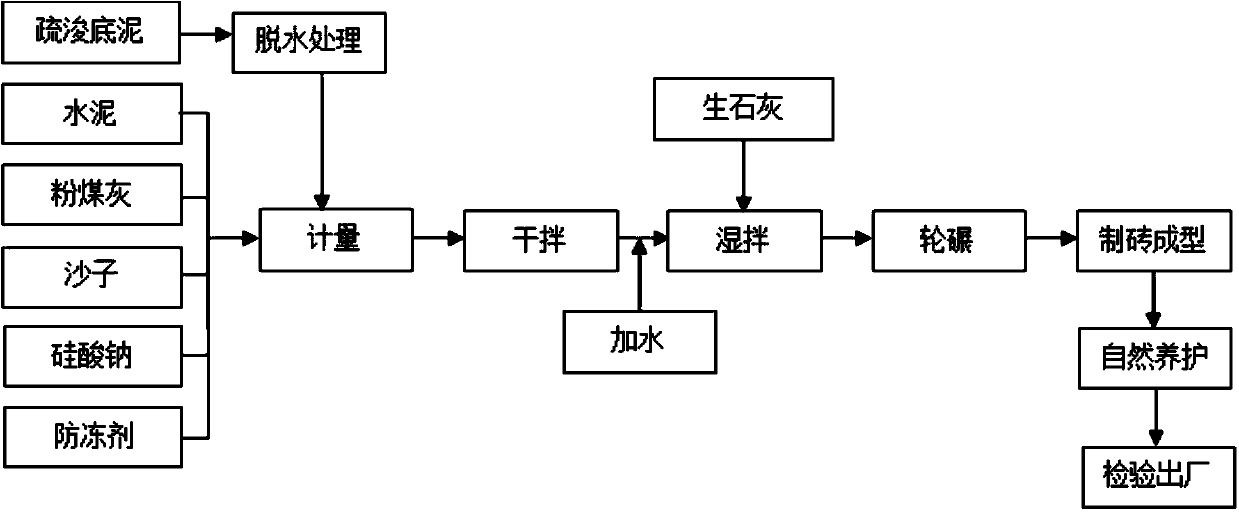

Method used

Image

Examples

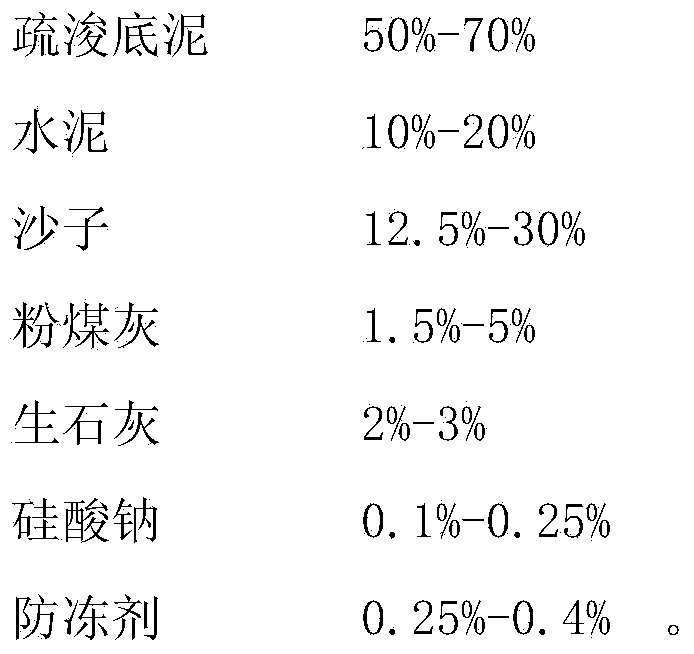

Embodiment 1

[0036] A non-burning brick with river and lake dredging sediment as the main material, the composition of the raw material weight percentage is as follows: dredged sediment: 50%; cement: 15%; sand: 30%; fly ash: 2%; quicklime: 2.5%; Sodium silicate: 0.2%; antifreeze calcium chloride: 0.3%. The process of making unburned bricks is as described above. The test indicators are: compressive strength 12.8Mpa, flexural strength 3.4Mpa, frost resistance 18%.

Embodiment 2

[0038] A non-burning brick with river and lake dredging sediment as the main material, the raw materials and proportions are as follows: dredged sediment: 60%; cement: 20%; sand 12.5%; fly ash: 5%; quicklime: 2%; Sodium Silicate: 0.1%; Antifreeze Magnesium Chloride: 0.4%. The process of making unburned bricks is as described above. The test indicators are: compressive strength 11.1Mpa, flexural strength 2.9Mpa, frost resistance 15%.

Embodiment 3

[0040] Disclosed is a non-burning brick with river and lake dredging sediment as the main material. The raw materials and proportions are as follows: dredged sediment: 70%; cement: 10%; sand: 15%; fly ash: 1.5%; quicklime: 3%; Sodium silicate: 0.25%; antifreeze calcium chloride: 0.25%. The process of making unburned bricks is as described above. The test indicators are: compressive strength 10.7Mpa, flexural strength 2.5Mpa, frost resistance 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com