UV-heat dual-curing polyurethane coating, and preparation method and application thereof

A polyurethane coating and dual-curing technology, which is applied in polyurea/polyurethane coatings, coatings, and devices for coating liquid on the surface, etc., can solve the problem of high coating stress, lack of substrate penetration of UV-cured coatings, and stable surface tension of materials Poor resistance and other problems, to achieve the effect of improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

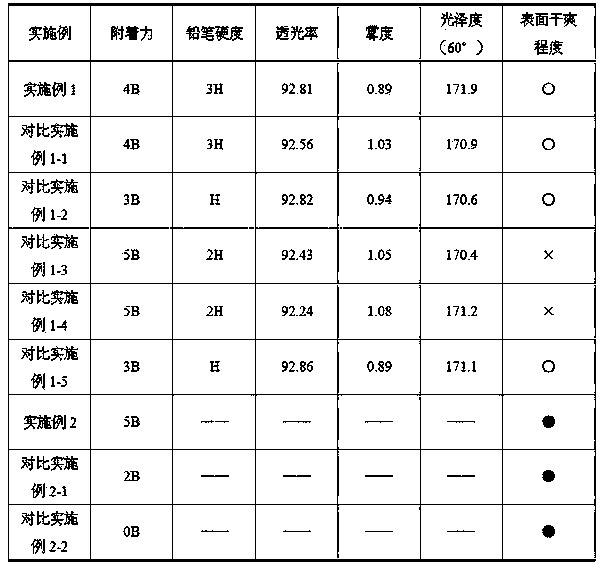

Examples

Embodiment 1

[0050] This example illustrates the raw material and mass percent of UV-heat dual-curing coating of the present invention:

[0051] Hexafunctional polyurethane acrylate (product of Sartomer, USA, brand name CN9010NS) 7.8%

[0052] Difunctional polyurethane acrylate (product of Sartomer, USA, brand name CN983NS) 4.1%

[0053] Pentaerythritol tetraacrylate (product of Sartomer, USA, brand SR295) 2.6%

[0054] Polyacrylate polyol (product of DIC, brand WDU-938) 27.7%

[0055] Polyester polyol (product of Bayer, brand RD181X) 3.2%

[0056] HDI trimer (product of Bayer, brand N3600) 4.0%

[0057] Irgacure 184 (produced by Huatai, Changzhou, Jiangsu) 0.6%

[0058] Auxiliary (mixture of organic solvent and leveling agent) 50%

[0059] Among them, organic solvent 40%, methyl ethyl ketone: toluene = 1:1; leveling agent 10%, BYK company, brand BYK-361N.

[0060] Divide the additive into two parts, and the ratio is not limited. Add hexafunctional urethane acrylate, difunctional ur...

Embodiment 2

[0120] This example illustrates the advantages of using the UV-heat dual-cure coating of the present invention as a base coat and using the coating process mentioned in the present invention.

[0121] Coat the UV-heat dual-curing coating of the present invention on a 100 μm corona-treated polyethylene terephthalate (PET) film, and dry the wet coating film with hot air. The temperature of the hot air is designed in a gradient form, that is, to coat The cloth base material passes through three temperature zones of medium temperature (60-90°C), high temperature (90-150°C) and medium temperature (60-90°C) in sequence. The hot air drying time is about 1min, and it is wound up, and then coated on the surface of the coating. Coat a layer of functional UV-curable coating (self-made urethane acrylate system), dry the coated substrate through high temperature (90-150°C) heat separation for about 1min, and then pass through 250mJ / cm 2 The curing time is about 11 s under the ultraviolet l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com